DOI: 10.11817/j.ysxb.1004.0609.2020-37629

轧制与时效处理对Cu-Cr-Zr合金组织和性能的影响

刘海斌1, 2,郑月红1, 3,喇培清1, 2,盛 捷1, 2,丁彦龙1, 2

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 材料科学与工程学院,兰州 730050;

3. 大连理工大学 三束材料改性教育部重点实验室,大连 116024)

摘 要:采用光学显微镜(OM)、扫描电子显微镜(SEM)、万能材料试验机、涡流金属电导仪等分析技术研究了30%、60%、90%变形量轧制与(450 ℃, 1 h)时效处理对Cu-1.0Cr-0.1Zr合金组织和性能的影响。结果表明:Cu-1.0Cr-0.1Zr合金经适当的冷变形和时效处理,其力学性能和导电性能都显著提高,在90%冷变形+(450 ℃, 1 h)时效后的综合性能最好,其抗拉强度、屈服强度、硬度、伸长率和导电率分别达到411.7 MPa、364.69 MPa、127.6 HV、25.72%和63.7%IACS。通过显微组织分析和理论计算可知,时效处理后,第二相的弥散析出是该合金获得高强度的重要原因,同时合金元素大量析出,使导电主体(Cu基体)中固溶原子减少,进而获得了较高的导电率。

关键词:Cu-Cr-Zr合金;轧制;时效;微观组织;力学性能;导电性能

文章编号:1004-0609(2020)-09-2075-09 中图分类号:TG146.1+1 文献标志码:A

铜合金以其优异的导电、导热性能和良好的延展性、耐磨损性能,被广泛用于电力、电子信息、机械制造、交通运输等各个领域[1-5]。其中,Cu-Cr-Zr系合金兼具较高的强度和良好的导电性能,应用极为广泛。作为一种典型的析出强化型铜基合金,热处理与冷塑性变形对Cu-Cr-Zr系合金性能影响较大[6-10]。因此,研究人员对冷变形与时效处理对Cu-Cr-Zr系合金组织和性能的影响规律和作用机制进行了系统的研究,并取得了一定的成果[11-16]。

HUANG等[12]采用旋锻结合二级时效工艺制备了抗拉强度为612 MPa、伸长率为5%、导电率达84.7% IACS的Cu-Cr-Zr合金,该合金优异的性能主要源于超细晶结构和纳米沉淀相的存在。白宁等[14]研究发现:Cu-0.33Cr-0.06Zr合金固溶后经冷拉拔(80%变形量)再加上不同温度和时间时效处理可以显著提高合金的导电率和显微硬度,晶粒细化和第二相沉淀是性能提高的主要原因。FU等[15]研究了轧制温度、轧制变形量(60%~95%)和(450 ℃, 1 h)时效处理对Cu- 0.98Cr-0.057Zr合金组织和性能的影响,结果表明:相比于室温轧制,该合金在液氮温度轧制条件具有更高的强度,而在300 ℃轧制条件下具有更优的导电性能,经(450 ℃, 1 h)时效工后形成了大量细小的Cr和Cu4Zr析出相,明显改善了合金的综合性能。

虽然研究人员通过适当的冷变形和时效处理使Cu-Cr-Zr系合金具有较高的强度和导电率,但也面临着许多问题,例如制备工艺复杂、加工费用昂贵、产品尺寸较小等,难以实现工业化生产。因此,本文采用铝热反应制备了较大尺寸Cu-1.0Cr-0.1Zr合金,着重研究了不同变形量轧制和(450 ℃, 1 h)时效处理对该合金组织和性能的影响,并对性能强化机制进行了探究,以期为此类合金的量化生产和性能优化提供理论指导。

1 实验

本文采用铝热反应法在5 MPa氩气环境下制备了铸态Cu-1.0Cr-0.1Zr合金,然后用电火花线切割机切割出如图1所示的铸态金相试样和用于轧制的多组板材试样。室温下将板材试样在二辊轧机上进行多道次轧制,每道次压下量为0.02 mm,轧制变形量分别为30%、60%、90%,最后将轧制变形后的试样放入箱式电阻炉中进行(450 ℃, 1 h)时效处理。

图1 铸态Cu-1.0Cr-0.1Zr合金金相试样宏观形貌

Fig. 1 Macrophoto of casted Cu-1.0Cr-0.1Zr alloy metallographic sample

将各组试样经不同规格水砂纸逐级打磨并进行抛光后,用5 g FeCl3+50 mL HCl+100 mL H2O溶液进行腐蚀,在MeF3光学显微镜(OM)下观察试样的金相组织。利用WDW-100D电子万能材料试验机对各组试样进行单轴拉伸测试,试样按照GB/T 6397—1986的相关规定将板坯加工成标准矩形拉伸样,标距为20 mm,拉伸速率为0.2 mm/min,每一处理条件下试样,取3个试样拉伸结果的平均值作为最终的测定结果,并在扫描电子显微镜(SEM)下观察了各组试样的断口形貌。硬度测试是在HBRVU-187.5型布洛维氏光学硬度计上进行,载荷1 N,加载时间10 s,每个样品测5个点,取平均值。使用Sigma2008B/C型数字涡流金属电导仪测量各组试样的导电率,每个试样在测量时选取5个点,避开试样边缘取点,实验结果取5次测量的平均值,导电率的大小用国际退火纯铜标准(%IACS)表示。

2 结果与分析

2.1 微观组织分析

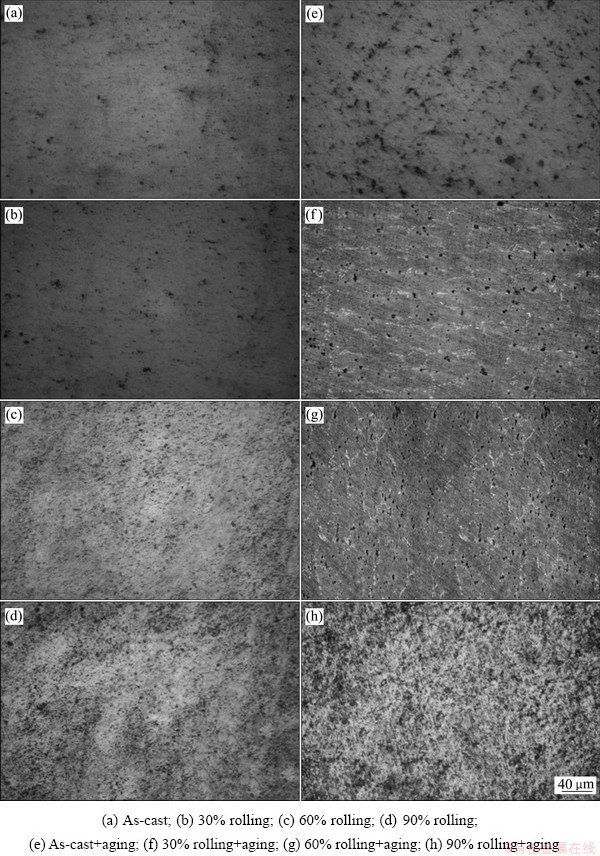

图2所示为铸态Cu-1.0Cr-0.1Zr合金经不同变形量轧制及(450 ℃, 1 h)时效处理后的OM像。由图2(a)可知,铸态试样由Cu基体和黑色颗粒状的富Cr析出相组成,析出相均匀地分布于Cu基体上;时效处理之后,析出相的数量和尺寸都有所增加(见图2(e))。经30%变形量轧制后,析出相的尺寸和体积分数没有明显变化,但随着变形量的进一步增加,析出相明显细化,且弥散分布于Cu基体上,其体积分数也显著增加(见图2(b)~(d))。不同变形量条件轧制试样经时效处理之后,析出相尺寸明显增大,体积分数变化较小,但经90%变形量轧制和时效处理后的合金试样,其析出相的尺寸仍然比较细小,且均匀弥散分布在Cu基体上(见图2(f)~(h))。

2.2 材料性能分析

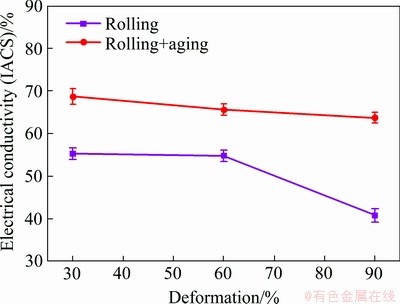

图3所示为Cu-1.0Cr-0.1Zr合金经不同变形量轧制及(450 ℃, 1 h)时效处理后的导电性能变化曲线。由图3可知,随着轧制变形量由30%增加到60%时,导电率下降幅度不大,但当变形量增加到90%时,其电导率急剧下降。然而,在三种变形条件下时效处理明显提高了合金的导电性能,特别是将90%变形量轧制后时效时,导电率提升幅度最大,从轧制态的40.8% IACS上升为63.7%IACS。

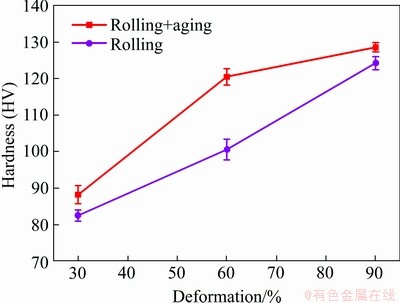

Cu-1.0Cr-0.1Zr合金经不同变形量轧制和(450 ℃, 1 h)时效处理后的硬度变化曲线如图4所示。轧制之后,合金的硬度随变形量的增加显著增大,90%变形后的合金硬度为124.3 HV。轧制态试样经(450 ℃, 1 h)时效后,30%和90%变形条件下合金的硬度略微有所改善,而60%变形条件下合金的硬度增幅较大,为20 HV。

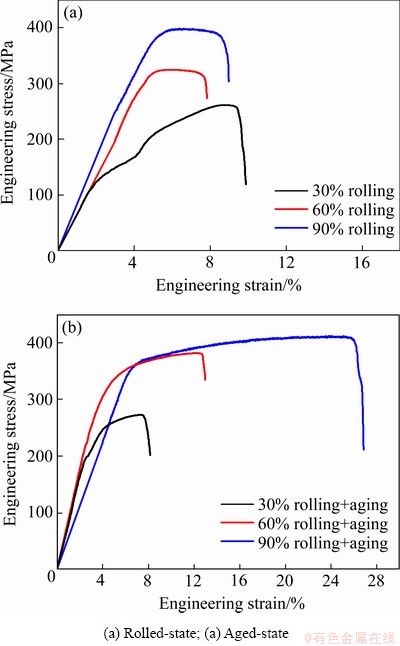

图5所示为Cu-1.0Cr-0.1Zr合金在轧制态和时效态下的工程应力-应变曲线。由图5确定出合金在不同状态下的各项力学性能参数,如表1所示。随着轧制变形量的增加,合金的屈服强度(σ0.2)和抗拉强度(σb)逐渐增大,而伸长率(δ)先下降后增加,呈V型变化趋势(见图5(a))。合金在不同冷变形条件下经(450 ℃, 1 h)时效后,其强度和塑性都有所改善,其中60%变形条件下合金的抗拉强度明显增加,增幅为78.5 MPa,而30%和90%变形条件下合金的强度变化不明显,但是90%变形量轧制后时效时,合金的伸长率有了很大的改善,相比于轧制态,伸长率提高了199.4%(见图5(b))。通过对不同状态下合金的导电性能和力学性能的分析发现,90%变形量轧制+(450 ℃, 1 h)时效处理后,合金具有最佳的综合性能,其抗拉强度为411.7 MPa,屈服强度为364.7 MPa,伸长率为25.72%,硬度为127 HV,导电率达63.7%IACS。

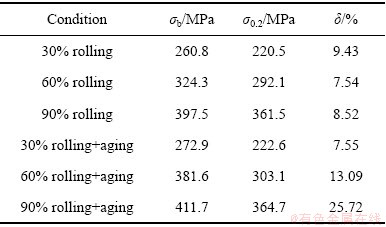

轧制态试样断口形貌(见图6(a)~(c))表明,30%轧制后的试样断口有较多的浅而小的韧窝,表现出较好的塑性,而且大多数韧窝中存在着析出相。随轧制变形量的增大,韧窝的数量减少,韧窝尺寸变大,解理断裂出现,塑性损失较小。60%变形量轧制后试样的断口出现撕裂棱和河流状花样,为韧脆混合断裂断口形貌。90%变形量轧制后试样的断口处观察不到韧窝的存在,基本为解离面,为典型的脆断断口形貌。图6(d)~(f)所示为不同变形量轧制态试样经时效处理后的断口形貌,相比于轧制态,每个变形量条件下的合金经过时效后的断口的韧窝数量都有所增加,韧窝尺寸也有一定程度的减小。尤其是90%变形量轧制后试样的断口为解离断裂的断口形貌,但在时效以后断口出现大量韧窝,使得其从脆断转变为韧性断裂。

图2 Cu-1.0Cr-0.1Zr合金不同处理条件下的OM像

Fig. 2 OM images of Cu-1.0Cr-0.1Zr alloys under different treatment conditions

图3 轧制和时效处理对Cu-1.0Cr-0.1Zr合金导电性能的影响

Fig. 3 Effect of cold rolling and aging treatment on electrical conductivity of Cu-1.0Cr-0.1Zr alloy

图4 轧制和时效处理对Cu-1.0Cr-0.1Zr合金硬度的影响

Fig. 4 Effect of cold rolling and aging treatment on hardness of Cu-1.0Cr-0.1Zr alloy

图5 不同处理状态下合金的工程应力-应变曲线

Fig. 5 Engineering stress-strain curve of alloy under different treatment conditions

表1 Cu-1.0Cr-0.1Zr合金在不同状态下的力学性能参数

Table 1 Mechanical properties of Cu-1.0Cr-0.1Zr alloy under different treatment conditions

3 讨论

3.1 轧制对Cu-Cr-Zr合金导电性能和力学性能的影响机制

Cu-Cr-Zr合金在轧制时,由于严重的冷塑性变形导致晶体内部产生大量位错并且在轧制变形程度增大时位错不断增殖,这些位错会在晶界处塞积阻碍滑移的进行。一般地,金属塑性变形抗力的增量△σ与位错密度ρ存在如下关系[17]:

(1)

(1)

式中: 为与材料有关的常数;G为切变模量;b为柏氏矢量。在30%、60%和90%三个变形量下对制备的Cu-1.0Cr-0.1Zr合金轧制时,合金的抗拉强度和硬度显著增加,这是由于轧制过程中晶体内部的位错密度不断增加。而且位错运动时的相互交割导致了位错塞积群、割阶、缠结的形成,阻碍位错的进一步运动,使材料的变形抗力增加,从而提高了其强度和硬度。在室温轧制过程中产生的缺陷也有利于析出相的形核和长大,这些析出相也阻碍了位错的运动。Cu-1.0Cr-0.1Zr合金轧制的组织中析出相的体积分数随着轧制变形量的增加而增加,并且析出相尺寸在90%变形量时明显细化。这是由于Cu-1.0Cr-0.1Zr合金在较大的变形量中形成大量位错,为合金提供形核中心,形核率增加,所以析出相更弥散、细小[18]。而且,随着变形量的增加,晶粒不断被细化,使得合金的强度和塑性同时得到改善,因此相比于60%变形量,经90%变形后的合金试样的塑性有所提高。

为与材料有关的常数;G为切变模量;b为柏氏矢量。在30%、60%和90%三个变形量下对制备的Cu-1.0Cr-0.1Zr合金轧制时,合金的抗拉强度和硬度显著增加,这是由于轧制过程中晶体内部的位错密度不断增加。而且位错运动时的相互交割导致了位错塞积群、割阶、缠结的形成,阻碍位错的进一步运动,使材料的变形抗力增加,从而提高了其强度和硬度。在室温轧制过程中产生的缺陷也有利于析出相的形核和长大,这些析出相也阻碍了位错的运动。Cu-1.0Cr-0.1Zr合金轧制的组织中析出相的体积分数随着轧制变形量的增加而增加,并且析出相尺寸在90%变形量时明显细化。这是由于Cu-1.0Cr-0.1Zr合金在较大的变形量中形成大量位错,为合金提供形核中心,形核率增加,所以析出相更弥散、细小[18]。而且,随着变形量的增加,晶粒不断被细化,使得合金的强度和塑性同时得到改善,因此相比于60%变形量,经90%变形后的合金试样的塑性有所提高。

同时,正是由于这些大量位错和空位等缺陷的存在,导致晶格畸变,对电子的散射作用增强,从而降低了合金的电导率[12, 15, 19-22]。因此,Cu-1.0Cr-0.1Zr合金在轧制后导电率明显下降,并且变形量越大,导电率下降越明显。但是,缺陷有利于溶质原子从过饱和固溶体中析出,尤其缺陷处往往是优先形核的区域。在时效过程中,大变形铜合金的时效处理的强化效果更加明显,导电率上升幅度也较大[12, 15, 21]。因此可以通过时效工艺对制备的Cu-1.0Cr-0.1Zr合金的导电性能进行改善。

图6 不同处理状态下合金的断口形貌

Fig. 6 Fracture morphologies of alloy under different conditions

3.2 时效对Cu-Cr-Zr合金导电性能和力学性能的影响机制

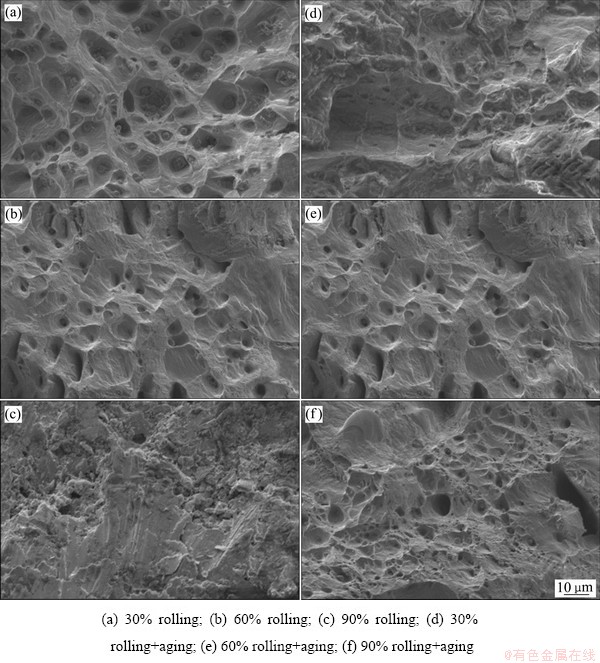

基体中析出相与位错间的相互作用关系决定了合金的时效强化的效果。按照位错通过析出相的方式不同,时效强化机制可分为切过机制与绕过机制[23-24]。

图7 位错运动机制示意图[23]

Fig.7 Schematic diagram of dislocation motion mechanism[23]

若析出相颗粒位于位错线的滑移面上,且不太硬时,位错线可以切过析出相颗粒运动,如图7(a)所示[23]。位错线切过析出相颗粒时,不仅需要克服析出相颗粒造成的应力场,而且还要克服析出相颗粒被切成两部分而增加的有序界面,从而引起合金强度的升高。随析出相的聚集长大,析出相颗粒的间距不断增大。当析出相颗粒间距足够大,且析出相颗粒又很硬,位错不能切过时,在外力作用下,位错线将绕过第二相颗粒,即Orowan绕过机制,如图7(b)所示[23]。切过机制和绕过机制对临界分切应力的影响用公式表示[23-24]:

(2)

(2)

(3)

(3)

(4)

(4)

式中:τG为切过机制下材料的强度;Δσs为绕过机制下的屈服强度的增量;kl为常数;γA为反向畴界能;f为质点体积分数;b为柏氏矢量;τ0是基体强度;G为剪切模量;r为质点半径; 是泊松比;λ为有效质点间距。由式(2)和(3)可知,切过机制的强化效应随质点体积分数和尺寸的增大而增大;而绕过机制的强化效果则随质点体积分数的增大而增大,随质点尺寸的增大而减小。

是泊松比;λ为有效质点间距。由式(2)和(3)可知,切过机制的强化效应随质点体积分数和尺寸的增大而增大;而绕过机制的强化效果则随质点体积分数的增大而增大,随质点尺寸的增大而减小。

Cu-Cr-Zr合金的析出相主要以Cr的原子团簇为主,其尺寸和间距较小,位错容易切过。在90%变形量轧制及轧制后时效时,析出相的体积分数明显多于其他变形量的体积分数,并且轧制后析出相的尺寸较为细小,此时可能绕过析出相。时效后富Cr析出相的尺寸变大,体积分数变大,位错可能切过析出相,两种方式都使得合金的强度增大。此外,通过断口形貌(见图6)发现,90%变形量的Cu-1.0Cr-0.1Zr合金时效以后,断口形貌由解离断口转变为韧性断口。这可能是因为轧制过程中产生的缺陷为析出相提供了形核和长大的条件,在时效过程中Cu基体上弥散析出了第二相,在提高强度的同时也使塑性改善,并且在时效时合金中的缺陷发生部分恢复,降低了缺陷密度,增加了塑性。

根据文献报道[12, 25],材料在形变和时效处理过程中,屈服强度的增加(Δσ0.2)主要由晶界(ΔσGB)、位错(ΔσD)和第二相(ΔσP)所贡献:

(5)

(5)

而ΔσP可以通过式(6)计算[26]:

(6)

(6)

式中:M是泰勒因子;G为剪切模量;b是伯氏矢量; 是泊松比,

是泊松比, ,r是第二相的平均半径;λ与第二相粒子的体积分数f有关,可用式(7)计算[25]:

,r是第二相的平均半径;λ与第二相粒子的体积分数f有关,可用式(7)计算[25]:

(7)

(7)

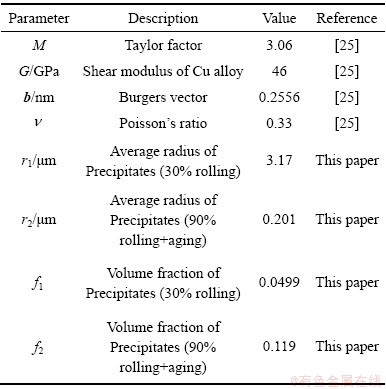

根据表2中列出的参数计算可得,Cu-1.0Cr-0.1Zr合金经30%轧制处理后,ΔσP为3.6 MPa;而合金经90%轧制+(450 ℃, 1 h)时效处理后,ΔσP为77.8 MPa。由表1可知,相比于30%轧制态,经90%轧制+(450 ℃, 1 h)时效处理后,合金的屈服强度增加了144.2 MPa,而这两种工艺处理后,第二相所贡献的合金屈服强度差为74.2 MPa,即占屈服强度总增量的1/2以上。由此可见,Cu-1.0Cr-0.1Zr经90%轧制+(450 ℃, 1 h)时效处理后,第二相强化是合金强化的重要原因。

表2 屈服强度计算中使用的参数

Table 2 Parameters used in yield strength calculations.

Cu-Cr-Zr合金中的晶界、缺陷、固溶原子、析出相等对电子散射作用影响着合金的导电率[12, 25-26]。Cu-Cr-Zr合金导电性能主要与Cu基体中固溶原子的浓度有关,在时效处理之后固溶在Cu基体中的溶质原子大量析出形成第二相降低了由异类原子引起的Cu基体的晶格畸变对自由电子的散射作用,从而使合金的电导率升高。同时,时效过程中晶粒长大和缺陷恢复降低了晶界和缺陷密度,当基体中溶质原子浓度基本达到时效温度下的平衡值时,合金导电率保持平稳,因此时效后的Cu-1.0Cr-0.1Zr合金导电率随轧制变形量的变化不明显。

4 结论

1) 随轧制变形量的增加,Cu-1.0Cr-0.1Zr合金的硬度、屈服强度和抗拉强度明显增加,而电导率变化趋势正好相反。

2) 轧制后时效处理合金的力学性能和导电性能都得到了明显改善。Cu-1.0Cr-0.1Zr合金90%冷变形+ (450 ℃, 1 h)时效后的综合性能最佳,其抗拉强度、屈服强度、硬度、伸长率分别达到411.7 MP、364.69 MPa、127.6 HV、25.72%,导电率为63.7%IACS。

3) Cu-1.0Cr-0.1Zr合金经90%冷变形+(450 ℃, 1 h)时效处理后,第二相的弥散析出是该合金获得高强度的重要原因,同时合金元素的大量析出,使导电主体(Cu基体)中固溶原子减少,进而获得了较高的导电率。

REFERENCES

[1] ZHANG Shao-jian, LI Ren-geng, KANG Hui-jun, CHEN Zong-ming, WANG Weu, ZOU Cun-lei, LI Ting-ju, WANG Tong- min. A high strength and high electrical conductivity Cu-Cr-Zr alloy fabricated by cryorolling and intermediate aging treatment[J]. Materials Science and Engineering A, 2017, 680(5): 108-114.

[2] GAO Yuan, JIE Jin -chuan, ZHANG Peng- chao, ZHANG Jian, WANG Tong- min, LI Ting -ju. Wear behavior of high strength and high conductivity Cu alloys under dry sliding[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2293-2300.

[3] LARBI F H, AZZEDDINE H, BAUDIN T, MATHON M H, BRISSET F, HELBERT A L, KAWASAKI M, BRADAI D, LANGDON T G. Microstructure and texture evolution in a Cu-Ni-Si alloy processed by equal-channel angular pressing[J]. Journal of Alloys and Compounds, 2015, 638(25): 88-94.

[4] 文靖瑜. 高强高导铜合金制备方法的研究现状及应用[J].金属材料与冶金工程, 2017, 45(3): 3-9.

WEN Jing-yu. Study status and applications of preparation methods of high strength and high conductivity copper alloy[J]. Metal Materials and Metallurgical Engineering, 2017, 45(3): 3-9.

[5] 曹光明, 王志国, 李成刚, 贾 飞, 张元祥. 基于热轧流程下Cu-Ni-Si合金组织和性能演变规律[J]. 中国有色金属学报, 2018, 28(10): 2024-2032.

CAO Guang-ming, WANG Zhi-guo, LI Cheng-gang, JIA Fei, ZHANG Yuan-xiang. Evolution of structure and property for Cu-Ni-Si alloy based on hot-rolling process[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(10): 2024-2032.

[6] MISHNEV R, SHAKHOVA I, BELYAKOV A, KAIBYSHEV R. Deformation microstructures, strengthening mechanisms, and electrical conductivity in a Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2015, 629(1): 29-40.

[7] PURCEK G, YANAR H, SHANGINA D V, DEMIRTAS M, BOCHVAR N R, DOBATKIN S V. Influence of high pressure torsion-induced grain refinement and subsequent aging on tribological properties of Cu-Cr-Zr alloy[J]. Journal of Alloys and Compounds, 2018, 742(25): 325-333.

[8] 胡号旗, 许 赪, 杨丽景, 张恒华, 宋振纶. 高强高导铜铬锆合金的最新研究进展[J]. 材料导报, 2018, 32(3): 453-460.

HU Hao-qi, XU Cheng, YANG Li-jing, ZHANG Heng-hua, SONG Zhen-lun. Recent advances in the research of high strength and high conductivity Cu-Cr-Zr alloy[J]. Materials Review, 2018, 32(3): 453-460.

[9] PANG Yong, XIA Cheng-dong, WANG Ming-pu, LI Zhou, XIAO Zhu, WEI Hai-gen, SHENG Xiao-fei, JIA Yan-lin, CHEN Chang. Effects of Zr and (Ni, Si) additions on properties and microstructure of Cu-Cr alloy[J]. Journal of Alloys and Compounds, 2014, 582(5): 786-792.

[10] 丁宗业, 贾淑果, 宁向梅, 宋克兴, 刘 平. 高强高导Cu-Cr-Zr合金时效性能[J]. 中国有色金属学报, 2017, 27(12): 2420-2425.

DING Zong-ye, JIA Shu-guo, NING Xiang-mei, SONG Ke-xing, LIU Ping. Aging properties of high-strength and high-conductivity Cu-Cr-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2420-2425.

[11] 梁 博, 王庆娟, 周 晓, 周 滢, 苗承鹏. 时效对ECAP变形Cu-Cr-Zr合金组织与性能的影响[J]. 金属热处理, 2017, 42(7): 43-45.

LIANG Bo, WANG Qing-juan, ZHOU Xiao, ZHOU Yin, MIAO Cheng-peng. Effect of aging on microstructure and properties of ECAPed Cu-Cr-Zr alloy[J]. Heat Treatment of Metals, 2017, 42(7): 43-45.

[12] HUANG A H, WANG Y F, WANG M S, SONG L Y, LI Y S, GAO L, HUANG G X, ZHU Y T. Optimizing the strength, ductility and electrical conductivity of a Cu-Cr-Zr alloy by rotary swaging and aging treatment[J]. Materials Science and Engineering A, 2019, 746(11): 211-216.

[13] KULCZYK M, PACHLA W, GODEK J, SMALC- KOZIOROWSKA J, SKIBA J, PRZYBYSZ S, WROBLEWSKA M, PRZYBYSZ M. Improved compromise between the electrical conductivity and hardness of the thermo-mechanically treated Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2018, 724: 45-52.

[14] 白 宁, 张彦敏, 宋克兴, 李宁宁, 何 霞. 时效对Cu-0.33Cr -0.06Zr合金导电率与硬度的影响[J]. 金属热处理, 2015, 40(1): 103-106.

BAI Ning, ZHANG Yan-min, SONG Ke-xing, LI Ning-ning, HE Xia. Influence of aging on conductivity and hardness of Cu-0.33Cr-0.06Zr alloy[J]. Heat Treatment of Metals, 2015, 40(1): 103-106.

[15] FU Hua-dong, XU Sheng, LI Wei, XIE Jian-xin, ZHAO Hong-bin, PAN Zhi-jun. Effect of rolling and aging processes on microstructure and properties of Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2017, 700(17): 107-115.

[16] PURCEK G, YANAR H, DEMIRTAS M, ALEMDAG Y, SHANGINA D V, DOBATKIN S V. Optimization of strength, ductility and electrical conductivity of Cu-Cr-Zr alloy by combining multi-route ECAP and aging[J]. Materials Science and Engineering A, 2016, 649(1): 114-122.

[17] 胡庚祥, 蔡 珣, 戎咏华. 材料科学基础[M]. 上海: 上海交通大学出版社, 2010: 192-195.

HU Geng-xiang, CAI Xun, RONG Yong-hua. Fundamentals of materials science[M]. Shanghai: Shanghai Jiao Tong University Press, 2010: 192-195.

[18] LIU Yong, WANG De-jun, TIAN Bao-hong. Aging behavior of Cu-Cr-Zr-Y alloy[J]. Advanced Materials Research, 2011, 311/313: 2005-2008.

[19] CHENNA KRISHNA S, KARTHICK N K, SUDARSHAN RAO S, JHA A K, PANT B, CHERIAN R M. High strength, utilizable ductility and electrical conductivity in cold rolled sheets of Cu-Cr-Zr-Ti alloy[J]. Journal of Materials Engineering & Performance, 2018, 27(2): 787-793.

[20] GHOLAMI M, VESELY J, ALTENBERGER I, KUHN H A, JANECEK M, WOLLMANN M, WAGNER L. Effects of microstructure on mechanical properties of Cu-Ni-Si alloys[J]. Journal of Alloys and Compounds, 2017, 696(5): 201-212.

[21] LIU Jia, WANG Xian-hui, CHEN Jian, LIU Ji-tuo. The effect of cold rolling on age hardening of Cu-3Ti-3Ni-0.5Si alloy[J]. Journal of Alloys and Compounds, 2019, 797: 370-379.

[22] 石德珂,米维斗. 材料物理[M]. 北京: 机械工业出版社, 2006.

SHI De-ke, MI Wei-dou. Material physics[M]. Beijing: China Machine Press, 2006.

[23] FICKETT F R. Aluminum-1. A review of resistive mechanisms in aluminum[J]. Cryogenics, 1971, 11(5): 349-367.

[24] 王 松, 谢 明, 陈敬超, 陈永泰, 王塞北. 高强高导电Cu-Cr-Zr合金时效过程中组织和性能的演化[J]. 电工材料, 2015(1): 15-18.

WANG Song, XIE Ming, CHEN Jing-chao, CHEN Yong-tai, WANG Sai-bei. Microstructure and properties evolution of Cu-Cr-Zr Alloy with high strength and high conductivity during aging[J]. Electrical Materials, 2015(1): 15-18.

[25] SUN Xing-long, JIE Jin-chuan, WANG Peng-fei, QIN Bai-liang, MA Xiao-dong, WANG Tong-min, LI Ting-ju. Effects of Co and Si additions and cryogenic rolling on structure and properties of Cu-Cr alloys[J]. Materials Science and Engineering A, 2019, 740/741(7): 165-173.

[26] LUO Bao-min, LI Dao-xi, ZHAO Chao, WANG Zhi, LUO Zong-qiang, ZHANG Wei-wen. A low Sn content Cu-Ni-Sn alloy with high strength and good ductility[J]. Materials Science and Engineering A, 2019, 746(11): 154-161.

Effect of rolling and aging treatment on microstructure and properties for Cu-Cr-Zr alloy

LIU Hai-bin1, 2, ZHENG Yue-hong1, 3, LA Pei-qing1, 2, SHEN Jie1, 2, DING Yan-long1, 2

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. School of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China;

3. Key Laboratory of Materials Modification by Laser, Ion and Electron Beam, Ministry of Education, Dalian University of Technology, Dalian 116024, China)

Abstract: The effects of rolling with 30%, 60% and 90% deformation and aging treatment at 450 ℃ for 1 h on the microstructure and properties of Cu-1.0Cr-0.1Zr alloy were investigated by optical microscope (OM), scanning electron microscope (SEM), universal material testing machine, and eddy current metal conductivity instrument. The results show that the mechanical properties and electrical conductivity of Cu-1.0Cr-0.1Zr alloy are significantly improved after proper cold deformation and aging treatment. The comprehensive performance are the best after 90% cold deformation+(450 ℃, 1 h) aging, and the tensile strength, yield strength, hardness, elongation and electrical conductivity are 411.7 MPa, 364.69 MPa, 127.6 HV, 25.72% and 63.7%IACS, respectively. From the microstructure analysis and theoretical calculation, it is known that the dispersion precipitation of the second phase is an important reason for the high strength of the aged alloy, simultaneously, the large amount of precipitation reduces the number of solutes in the conductive main body (Cu matrix), and then higher conductivity is obtained.

Key words: Cu-Cr-Zr alloy; rolling; aging; microstructure; mechanical property; electrical conductivity

Foundation item: Project(51561020) supported by the National Natural Science Foundation of China; Project(KF1803) supported by the Open Project of Key Laboratory of Materials Modification by Laser, Ion and Electron Beams (Dalian University of Technology), Ministry of Education, China

Received date: 2019-11-07; Accepted date: 2020-04-28

Corresponding author: LA Pei-qing; Tel: +86-1389316 6172; E-mail: pqla@lut.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51561020);大连理工大学三束材料改性教育部重点实验室开放基金资助项目(KF1803)

收稿日期:2019-11-07;修订日期:2020-04-28

通信作者:喇培清,教授,博士;电话:1389316 6172;E-mail:pqla@lut.cn