工艺参数对Ni/Cu复合中间层下的铝/钢激光焊接接头显微组织与性能的影响

来源期刊:中国有色金属学报(英文版)2021年第8期

论文作者:曹雪龙 王刚 邢昌 檀财旺 蒋俊俊

文章页码:2277 - 2286

关键词:激光焊接;铝/钢异种金属;中间层;显微组织;力学性能

Key words:laser welding; aluminum/steel dissimilar metals; interlayer; microstructure; mechanical properties

摘 要:研究激光参数和中间层材料对6061铝合金与不锈钢焊接接头显微组织和性能的影响。结果表明,以0.05 mm铜箔和0.1 mm镍箔为中间层,改变激光功率可以优化焊接接头的致密度和组织;在铝合金附近发现大量新的Cu-Al二元相,有效地抑制Fe-Al二元脆性相的形成。当激光功率为2200 W时,最大剪切力为1350.96 N;当铜箔厚度为0.02 mm时,焊接接头剪切力增大到1754.73 N。

Abstract: The effects of laser parameters and interlayer material on the microstructure and properties of the welded joint between 6061 aluminum alloy and stainless steel were studied. The results show that the density and microstructure of the welded joint can be optimized by changing the laser power with 0.05 mm Cu foil and 0.1 mm Ni foil as interlayer. A large number of new Cu-Al binary phases were found near the aluminum alloy, which effectively inhibited the formation of the binary brittle phase of Fe-Al. The maximum shear force of 1350.96 N was obtained with laser power of 2200 W. The shear force of the welded joint increased to 1754.73 N when the thickness of the Cu foil thickness changed to 0.02 mm.

Trans. Nonferrous Met. Soc. China 31(2021) 2277-2286

Xue-long CAO1, Gang WANG1, Chang XING1, Cai-wang TAN2, Jun-jun JIANG2

1. Anhui Key Laboratory of High-performance Non-ferrous Metals, Anhui Polytechnic University, Wuhu 241000, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology (Weihai), Weihai 264209, China

Received 23 August 2020; accepted 11 January 2021

Abstract: The effects of laser parameters and interlayer material on the microstructure and properties of the welded joint between 6061 aluminum alloy and stainless steel were studied. The results show that the density and microstructure of the welded joint can be optimized by changing the laser power with 0.05 mm Cu foil and 0.1 mm Ni foil as interlayer. A large number of new Cu-Al binary phases were found near the aluminum alloy, which effectively inhibited the formation of the binary brittle phase of Fe-Al. The maximum shear force of 1350.96 N was obtained with laser power of 2200 W. The shear force of the welded joint increased to 1754.73 N when the thickness of the Cu foil thickness changed to 0.02 mm.

Key words: laser welding; aluminum/steel dissimilar metals; interlayer; microstructure; mechanical properties

1 Introduction

In recent years, with the improvement of human living standard, the demand for the transportation is also increased. This requires us to reduce pollution to the environment as much as possible while ensuring travel. Reducing the mass of the transport tool is an effective way to reduce energy consumption and emission. Aluminum/steel heterogeneous metal composite structure has high strength and light mass, which can effectively reduce the mass of the transport tool while promise the safety.

Among various aluminum/steel dissimilar metal connection processes, explosive welding [1], friction stir welding [2] and other processes show great advantages on the shape of welding parts. Laser thermal conductivity welding has become a popular research method for aluminum/steel heterogeneous metal connection due to its low thermal input, easy operation and low limitation of workpiece shape [3]. However, aluminum/steel has a great difference in physical and chemical properties, and easy to form Fe-Al binary brittle phase during the welding process [4], which significantly reduces the mechanical properties of the welded joint.

It has been reported that the addition of Ni, Co, Cu and other intermediate materials can effectively inhibit the formation of Fe-Al binary brittle intermetallic compounds, improving the metallurgical reaction of the weld pool during laser welding and thus optimizing the structure and mechanical properties of the welded joint [5-8]. WANG et al [9] reported that the interface layer of the welded joint becomes smoother after adding a certain amount of Fe-B-Si to the aluminum/steel interface during laser welding. The island- like region and the needle-like FeAl3 structure are significantly reduced, and the mechanical properties are improved. HE et al [10] found that the addition of Al-Cu dual-hot welding wire in the process of pulse arc welding of aluminum/steel can reduce the thickness of the intermetallic compound layer at the bottom of the molten pool. It inhibited the formation of the Fe-Al binary brittle phase and the formation of Cu-Al binary new phase by replacing some Fe atoms with Cu atoms, thus improving the mechanical properties of the welded joints. ESMAILY et al [11] reported that in the process of pulse laser welding of aluminum/steel, the use of Ni-based BNi-2 interlayer material can effectively inhibit the generation of the binary brittle phase of Fe-Al, and the number of cracks in the weld zone is reduced. The hardness of the interface layer is reduced while the shear strength of the welded joint is improved. CHEN et al [12] used Ni and Cu foils as interlayers to weld aluminum and steel. The results showed that the addition of Ni and Cu foils could effectively inhibit the generation of Fe-Al binary intermetallic compounds and improve the mechanical properties of the welded joints.

It is reported that Cu and Ni can be infinitely miscible. When the Ni content in the metal Cu reaches a certain value, the formation of Cu-Ni alloy has many characteristics, such as high strength, high hardness, and good toughness [13]. Moreover, the addition of Cu and Ni as interlayer materials can effectively improve the metallurgical reaction of the aluminum/steel interfaces during the welding process, thereby improving the mechanical properties of the welded joint [14]. Therefore, in this work the weldability of aluminum/steel dissimilar metals was investigated by laser welding with various laser process parameters and thickness values of Ni/Cu composite interlayer. The microstructure and mechanical properties of the welded joint were studied in detail.

2 Experimental

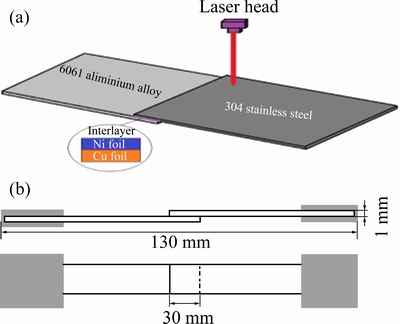

In this study, 6061 aluminum alloy plate and 304 stainless steel plate were used. The sizes of the samples were both 80 mm × 50 mm × 1 mm. Their chemical compositions are shown in Table 1 and Table 2, respectively. The thickness of the interlayer was 0.1 mm Ni foil and 0.02 mm and 0.05 mm Cu foils. Before the welding, the oxide layer was removed by sandpaper and the oil layer on the surface was cleaned by acetone. Laser equipment is the YLS-6000 type yttrium-doped fiber laser. Due to the high reflectivity of the aluminum alloy to the laser beam, the stainless steel plate was placed above the aluminum alloy plate. Considering the relatively high melting point of the Ni foil, which plays a good physical barrier to the diffusion of the Al and Fe elements during the welding process, the Ni foil was placed above the Cu foil. Figure 1(a) shows the schematic diagram of welding. The optimized process parameters as well as the middle layer material selection are shown in Table 3.

The metallographic samples were obtained by grinding and polishing the weld cross-section after linear cutting. The solution with volume fractions of 2% HF, 2% H2O2, 10% HNO3 and 86% H2O was used to corrode the metallographic samples for 10 s. Scanning electron microscope (Hitachi SU8010) with EDAX OCTANE PLUS was used to observe the microstructure of the weld cross-section and analyze the element composition of the weld zone. X-ray diffractometer (SHIMADZU 6000X) was used to determine the main phase of the welded joint. The size of sample for shear force test is shown in Fig. 1(b). The shear strength was measured with a WDS digital explicit electronic universal testing machine at the rate of 1 mm/min. Three samples were tested in each group during the experiment and the average value was taken.

Table 1 Chemical composition of 6061 aluminum alloy (wt.%)

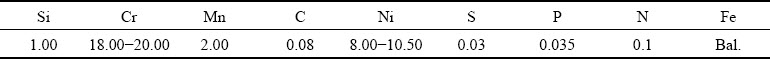

Table 2 Chemical composition of 304 stainless steel (wt.%)

Fig. 1 Schematic diagrams of aluminum/steel laser welding (a) and shear specimen (b)

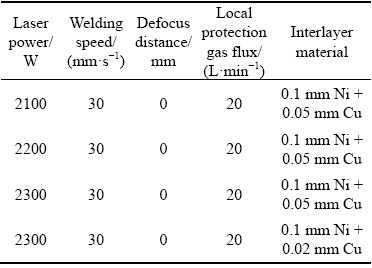

Table 3 Laser process parameters and interlayer selection

3 Results and discussion

3.1 Effect of laser power on joint microstructure

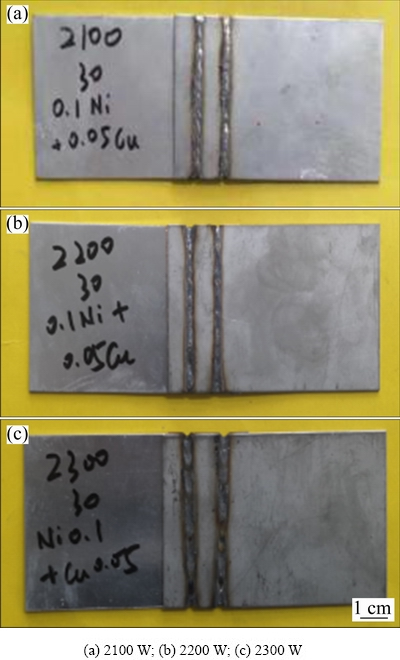

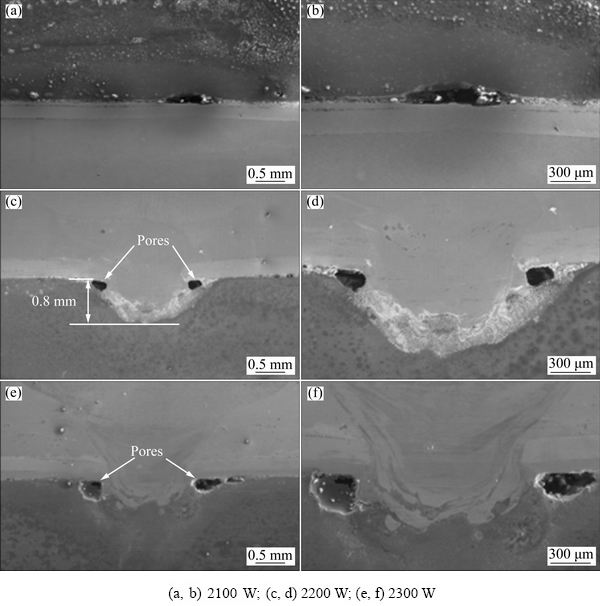

Figure 2 shows the original surface morphologies of the welded samples prepared under different laser powers with 0.05 mm Cu and 0.1 mm Ni as the composite interlayer. It can be seen that the weld height obtained under three laser powers is obvious when using the same interlayer material. When the laser power is 2100 and 2200 W, the weld surface is uniform and smooth, without spatter. However, when the laser power is 2300 W, the weld surface is not uniform. None of the three groups of welded samples showed any visible deformation.

Fig. 2 Welded samples obtained under different laser powers using 0.05 mm Cu/0.1 mm Ni as composite interlayer

Figure 3 shows the macroscopic morphology of the surface along the vertical laser welding direction. When the laser power is 2100 W, the sample does not form an effective welding pool and there is no obvious finger-like keyhole. When the laser power is 2200 and 2300 W, the sample forms finger-like keyhole during the laser welding process. The width and depth of the molten pool expand with the increase of the laser power. From Figs. 3(c) and (e), there are pores in the weld zone, which may be caused in the process of welding metal. The metal vapor is generated under laser irradiation, and the protective gas is drawn into the molten pool under the violent movement of the metal vapor. Due to the fast cooling rate of laser welding, the protective gas that is drawn into the molten pool cannot escape, thus forming pore defects. At the same time, when the laser power is 2300 W, some obvious cracks are found in the weld zone. In addition, it can be observed from the images that when the laser power is 2200 and 2300 W, although an obvious welding pool is formed, the depth of the pool is relatively small. The maximum depth of the welding pool is 0.8 mm at the laser power of 2200 W. With the increase of laser power, the plasma on the keyhole surface increases, and the refraction and absorption of the laser are enhanced. The absorption of laser energy by the workpiece is reduced, so when the laser power is increased to 2300 W, the depth and width of the weld pool are reduced.

Fig. 3 Macroscopic morphologies of weld cross-section using 0.05 mm Cu/0.1 mm Ni as interlayer

Fig. 4 Microstructures of weld cross-section using 0.05 mm Cu/0.1 mm Ni as interlayer

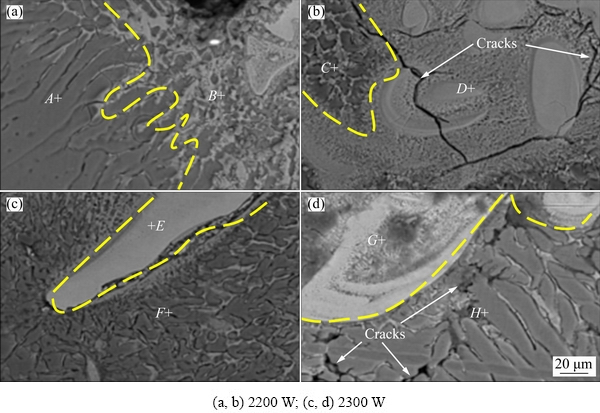

Figure 4 shows the microstructure of welded joints at laser powers of 2200 and 2300 W. Unfortunately, when the laser power is 2100 W, the joint fails to form an effective welding joint, so it is impossible to study and analyze the microstructure of the joint. From Figs. 4(b) and (d), obvious crack defects can be observed in the joints at laser powers of 2200 and 2300 W, respectively. However, no needle-like structure mainly composed of FeAl2 [15] binary brittle phase is observed in the weld zone of the two groups of samples. In Fig. 4(a), a large number of flocculent tissues can be observed in Region B, which are connected into pieces, while a small number of network structures appear in Region C in Fig. 4(b). As can be seen from Figs. 4(c) and (d), many network structures are formed in the welded area, which are interlaced and closely linked. Such structures may improve the mechanical properties of the welded joints.

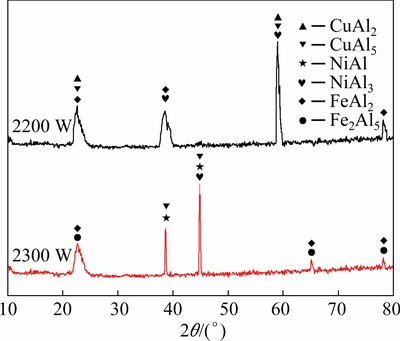

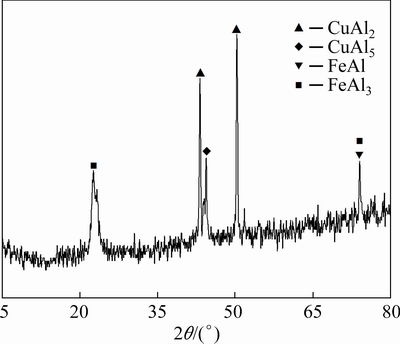

Fig. 5 XRD pattens of welded joint cross-section at different laser powers

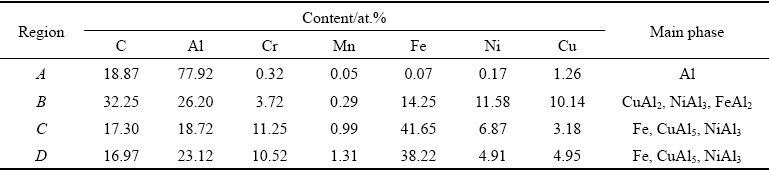

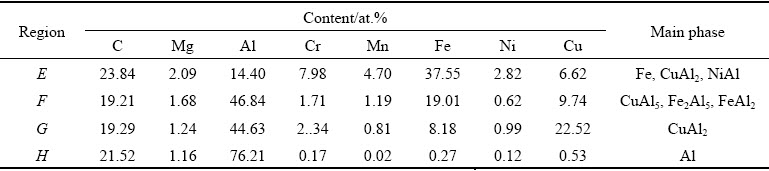

Figure 5 shows the XRD analysis results of the weld cross-section at the laser powers of 2200 and 2300 W. Table 4 shows the EDS analysis results of Regions A-D in Figs. 4(a) and (b). Table 5 shows the EDS analysis results of Regions E-H in Figs. 4(c) and (d). Combined with EDS and XRD analysis results, it can be seen that the composition of Region A is close to that of the base metal of aluminum alloy. The proportion of elements in Area B is relatively uniform. Although no obvious needle-like structure is observed in Figs. 4(a) and (b), a part of FeAl2 [15] binary brittle phase may be produced in Region B, and a small amount of CuAl2 [16] and NiAl3 [17] ductile phases are also formed in Region B. The components of Regions C

and D are close to those of the stainless steel base material, which may form CuAl5 [16] and NiAl3 binary ductile phases. The component in Region E is close to that of stainless steel base material, and CuAl2 and NiAl binary ductile phases may be formed. According to the EDS and XRD analysis results, a large number of grid-like structures are found in Area F, which may be a mixture composed of CuAl5 [18], Fe2Al5 [19] and FeAl2 [20,21] binary phases. A large number of CuAl2 binary ductile phases may be formed in Region G. The component in Region H is close to that of the base metal of aluminum alloy.

Table 4 EDS analysis results of Regions A-D in Figs. 4(a) and (b)

Table 5 EDS analysis results of Regions E-H in Figs. 4(c) and (d)

In the welding process, the molten metal Cu has good fluidity. When the temperature at the aluminum/steel interface rises to 232-548 °C [18],the fluidity of the molten metal becomes better under the action of a small amount of Al-Cu molten alloy. Combined with EDS analysis, it can be seen that Fe-Al binary intermetallic compounds are reduced, indicating that the liquid of Al-Cu alloy with a low melting point has good wettability, which effectively reduces the reaction of Fe and Al elements at the interface and optimizes the microstructure of the joints. Besides, it is reported that there are no intermetallic compounds formed between Fe and Cu elements, only Fe-rich or Cu-rich solid solutions [22]. When the interlayer is added, considering the fact that the higher melting point of Ni foils can produce good physical barriers to the mutual diffusion of Fe and Al elements during the welding process, Ni foils are placed above the Cu foils. On the basis of adding Ni foil, Cu foil is further added for laser welding. Combined with the EDS and XRD results, the interface between intermetallic compounds is mainly composed of Fe-Al and Al-Cu binary phases. It can effectively improve the metallurgical reaction at the aluminum/steel interface. The microstructure has been optimized, which may improve the mechanical properties of the welded joint.

By comparing the weld microstructure obtained at laser powers of 2200 and 2300 W, it can be seen that when the laser power increases to 2300 W, the type of Fe-Al binary phase in the weld zone increases, and the proportion of Fe-Al binary phase also increases. According to the analysis, during the welding heating process, the low-melting metal liquid formed first spreads at the aluminum/ steel interface, thereby hindering the interdiffusion of Fe and Al elements. However, with the increase of laser power, the liquid metal is stirred under the violent movement of metal vapor. Good fluidity of molten Cu promotes the mutual diffusion of Fe and Al elements, resulting in a lot of Fe-Al binary brittle phases.

3.2 Effect of interlayer thickness on joint micro- structure

According to the above experimental results, when 0.05 mm Cu and 0.1 mm Ni foils were added as the composite interlayer, the macroscopic morphology and microstructure of the weld were optimized and improved. Considering the fact that good fluidity of metal Cu in the molten state may lead to a large number of pore defects, the amount of molten Cu at aluminum/steel interfaces in the welding process should be controlled. Now, a thinner 0.02 mm Cu foil is selected for the experiment, and the microstructure of the obtained welded joint is analyzed.

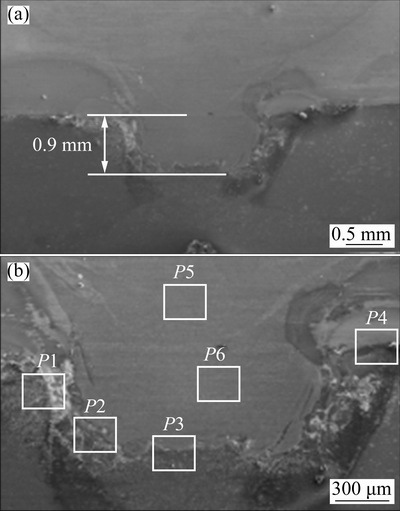

Figure 6 shows the macroscopic morphology of the surface along the vertical laser welding direction. By comparing the joint obtained when adding 0.05 mm Cu foil as shown in Figs. 3(e) and (f), it can be seen that when the thickness of the added Cu foil is 0.02 mm, the overall appearance of the joint is better. No defects such as pores, shrinkage and cracks are found in the joint. Also, the melting depth of the molten pool has increased to about 0.9 mm.

Fig. 6 Macroscopic morphologies of weld cross-section using 0.02 mm Cu/0.1 mm Ni as interlayer

Figure 7 shows the microstructures of marked areas in Fig. 6(b). It can be observed that the morphology of welded joint is good, and no obvious defects are seen. It can be seen from Fig. 7(a) that Areas J and K form a gear-like morphology, two phases meshing together tightly, which may improve the mechanical properties of the welded joint. From Fig. 7(b), it is found that during the welding process, the metals in each phase are mixed more uniformly due to good flowability of molten Cu. Considering good physical barrier effect of Ni foil interlayer on the elements diffusion of the aluminum/steel interface, more Cu-Al binary ductile phases will be produced, so as to better inhibit the formation of Fe-Al binary brittle phase, and optimize the microstructure of the weld zone. As can be seen in Fig. 7(c), even at the bottom of the molten pool, the metals remain mixed well and embed themselves into each other. In Region S of Fig. 7(d), some small cracks are observed, which may be caused by the rapid heating and cooling at the interface between the pool edge and the base metal during the welding process. However, no cracks are found in other areas.

Fig. 7 Microstructures of weld cross-section of different regions in Fig. 6(b) using 0.02 mm Cu/0.1 mm Ni as interlayer

Fig. 8 XRD pattern of cross-section of welded joint using composite interlayer made of 0.02 mm Cu/0.1 mm Ni

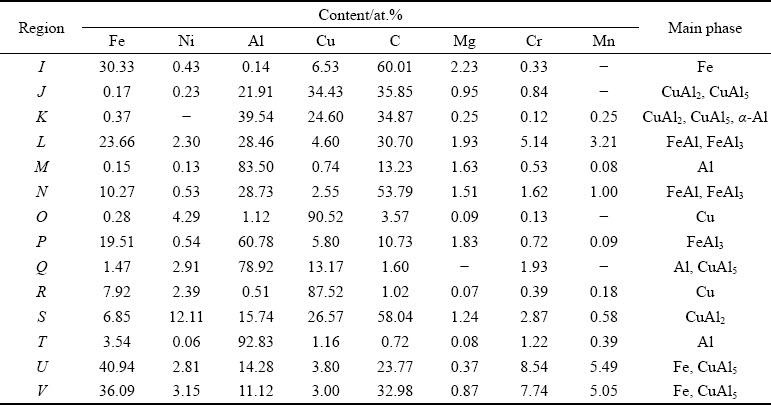

Figure 8 shows the XRD analysis results of the welded joint when 0.02 mm Cu and 0.1 mm Ni foils were added as the interlayer. Table 6 shows the EDS analysis results of the Region I-V from Fig. 7. The element compositions in Region I in Fig. 7(a) is very close to those of the base stainless steel. A large number of CuAl2 and CuAl5 ductile phases may coexist in Region J. Only trace amount of Fe is present in Region K. The element compositions in Region M are close to those of the base material of aluminum alloy, and most of them are composed of Al and Cu elements. Combined with XRD results, it can be seen that most of them are binary ductile phases of CuAl2 and CuAl5. FeAl and FeAl3 [23] binary brittle intermetallic compounds are produced in Regions L and N, and most of them are composed of CuAl5 binary ductile phase, but there was no needle structure dominated by FeAl2 binary brittle intermetallic compounds. Combined with EDS and XRD analysis results, it can be seen that Region O in Fig. 7(c) is mainly Cu, and a large number of FeAl3 brittle phases are formed in Region P. The element compositions of Region Q are close to those of the base material of aluminum alloy, and a small amount of CuAl5 binary ductile phase may be produced in Region Q. The element compositions of Area R are close to those of the base stainless steel. CuAl2 binary ductile phase is dominant in Region S. This region is located at the place where the weld edge is combined with the base material. Based on EDS analysis results, a small amount of FeAl3 is also produced in Region S, which may be another reason for the cracks in Area S. The element compositions of Region T are close to those of the aluminum alloy base material. Regions U and V are dominated by stainless steel base, and some Cu-Al binary ductile phases are produced.

Table 6 EDS analysis results of Regions I-V from Fig. 7

Because the Cu-Al interface is far from the laser keyhole, with increasing the interface temperature, the ability of atomic inter-diffusion at the Cu-Al contact interface is enhanced, and the mutual diffusion rate reaches the peak at about 65 °C. The concentrated energy and short action time of laser welding make the rise and fall of the interface temperature during the welding process very short. Cu atoms are diffused into Al matrix, forming a small amount of aluminum-based solid solution and causing lattice distortion. Lattice distortion increases the resistance of dislocation motion and makes slip difficult to be carried out, thus playing the role of solid solution strengthening. The toughness and strength of the welded joint are improved to different degrees.

Moreover, when the temperature reaches the Cu-Al eutectic point (548.2 °C) [18], due to the relatively high temperature and uneven composition of the liquid phase, the diffusion rate of atoms in the liquid phase is relatively high. When the Cu composition reaches eutectic composition, the Al matrix near the liquid phase is dissolved, which makes the thickness of the liquid phase increase, and hinder the Fe element diffusion to aluminum side. When the laser moves forward, the interface temperature decreases with the reduction of the conductive heat. Once the temperature is lower than the melting point of the liquid phase, crystallization begins. At last, eutectic products CuAl2 and α-Cu [21] are precipitated in the interfacial layer, further improving the weldability of laser welded joints of aluminum/steel dissimilar metals.

3.3 Mechanical properties

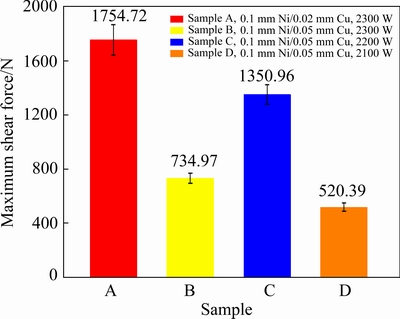

Figure 9 shows the tensile shear test results of the aluminum/steel welded joints. The results show that the shear force of the welded joint is 520.39 N (Sample D) at laser power of 2100 W and 734.97 N (Sample B) at 2300 W. The maximum shear force is 1350.96 N (Sample C) obtained at 2200 W. With the increase of laser power, the interlayer between the material and the parent metal is more “stirred”. Cu and Ni atoms in the welding process generate more Ni-Al and Cu-Al binary phases, respectively, which suppresses the formation of Fe-Al binary brittle phase. However, as the laser power continues to rise, the molten Cu with good fluidity is further amplified under the intense movement of metal vapor. The diffusion of Fe and Al is improved. At 2300 W, EDS and XRD results show that a large number of Fe2Al5 and FeAl2 binary phases appear in the weld zone, which reduces the mechanical properties of the welded joint. After that, when 0.02 mm Cu and 0.1 mm Ni foils are used as the composite interlayer, the shear force is obtained to be 1754.72 N (Sample A).

Fig. 9 Histograms of tensile shear test results with different process parameters

When the thickness of Cu foil decreases to 0.02 mm, the temperature at the Cu-Al interface increases relatively, the diffusion efficiency of Cu element into the base material of aluminum alloy increases, and the grain symbiosis becomes more obvious. At the same time, as the temperature increases, the homogenization process of liquid compounds is simpler, the element diffusion is uniform, and more strengthened phases are precipitated. Compared with 0.05 mm Cu foil addition, the shear force is dramatically increased.

4 Conclusions

(1) The addition of Cu/Ni as composite interlayer effectively inhibits the generation of the binary brittle phase of Fe-Al. The formation of the new binary phases of Cu-Al and Ni-Al in the weld zone improves the weldability of aluminum/steel dissimilar metals.

(2) When the thickness of Cu foil is 0.05 mm, the mechanical properties of the welded joint first increases and then decreases with the increase of laser power. The maximum shear force of 1350.96 N can be achieved when laser power is 2200 W.

(3) With the same laser power, the mechanical properties of the welded joint decrease with the increase of the thickness of the Cu foil. The addition of the 0.02 mm Cu foil makes the maximum shear force of the welded joint reach 1754.72 N. The welding reaction zone forms a gear-like shape and is combined closely.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51704001), the Natural Science Foundation of Anhui Province, China (No. 2008085J23), and the Talent Project of Anhui Province, China (Z175050020001).

References

[1] ELANGO E, SARAVANAN S, RAGHUKANDAN K. Experimental and numerical studies on aluminum-stainless steel explosive cladding [J]. Journal of Central South University, 2020, 27(6): 1742-1753.

[2] SHAFFER D, GRIMM T, RAGAI I, ROTH J. Utilization of XSYTIN-1 tool in electrically-assisted friction stir welding of dissimilar metals Al 6061-T651 to mild steel [J]. Advanced Materials Research, 2019, 4604(2304): 31-41.

[3] CUI Li, LU Dong-qi, WANG Guo-hong, HE Ding-yong. Research progress of steel/aluminum dissimilar alloys joining using laser keyhole welding-brazing and keyhole welding processes [J]. Aeronautical Manufacturing Technology, 2018, 61(3): 66-73. (in Chinese)

[4] YAN Fei, WANG Xian-wei, CHAI Fang, MA Hui-juan, TIAN Lin-li, DU Xiao-zhong, WANG Chun-ming, WANG Wei. Improvement of microstructure and performance for steel/Al welds produced by magnetic field assisted laser welding [J]. Optics & Laser Technology, 2019, 113: 164-170.

[5] MEAN N J, JACQUES P J, DING L P, GAUQUELIN N, SCHRYYERS D, IDRISSI H, DELANNAY F, SIMAR A. Enhancement of toughness of Al-to-steel friction melt bonded welds via metallic interlayers [J]. Materials Science and Engineering A, 2019, 740/741: 274-284.

[6] WANG Hong-yang, FENG Bao-qiang, SONG Gang, LIU Li-ming. Laser-arc hybrid welding of high-strength steel and aluminum alloy joints with brass filler [J]. Materials and Manufacturing Processes, 2018, 33(7): 735-742.

[7] WANG Nan-nan, QIU Ran-feng, SHI Hong-xin. Resistance spot welding of aluminum alloy/steel via an insert [J]. Transactions of Materials and Heat Treatment, 2019, 40(1): 155-160. (in Chinese)

[8] XIA Hong-bo, ZHAO Xiao-ye, TAN Cai-wang, CHEN Bo, SONG Xiao-guo, LI Li-qun. Effect of Si content on the interfacial reactions in laser welded-brazed Al/steel dissimilar butted joint [J]. Journal of Materials Processing Technology, 2018, 258: 9-21.

[9] WANG Xiao-hong, GU Xiao-yan, SUN Da-qian. Research on interface characteristic of laser welding joints of steel/aluminum dissimilar materials [J]. Journal of Mechanical Engineering, 2017, 53(4): 26-33. (in Chinese)

[10] HE Huan, WU Chuan-song, LIN San-bao, YAN Chun-li. Pulsed TIG welding-brazing of aluminum-stainless steel with an Al-Cu twin hot wire [J]. Journal of Materials Engineering and Performance, 2019, 28(2): 1180-1189.

[11] ESMAILY H, HABIBOLAHZADEH A, TAJALLY M. Improving pulsed laser weldability of duplex stainless steel to 5456 aluminum alloy via friction stir process reinforcing of aluminum by BNi-2 brazing alloy [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(7): 1401-1412.

[12] CHEN Shu-hai, HUANG Ji-hua, MA Ke, ZHAO Xing-ke, VIVEk A. Microstructures and mechanical properties of laser penetration welding joint with/without Ni-foil in an overlap steel-on-aluminum configuration [J]. Metallurgical and Materials Transactions A, 2014, 45(7): 3064-3073.

[13] CHEN Shu-hai, ZHAI Zhi-liang, HUANG Ji-hua, ZHAO Xing-ke, XIONG Ji-guang. Interface microstructure and fracture behavior of single/dual-beam laser welded steel-Al dissimilar joint produced with copper interlayer [J]. The International Journal of Advanced Manufacturing Technology, 2016, 82(1-4): 631-643.

[14] WADA K, YAMABE J, OGAWA Y, TAKAKUWA O, IIJIMA T, MATSUNAGA H. Comparative study of hydrogen-induced intergranular fracture behavior in Ni and Cu-Ni alloy at ambient and cryogenic temperatures [J]. Materials Science and Engineering A, 2019, 766: 138349.

[15] YANG Jin, LI Yu-long, ZHANG Hua. Microstructure and mechanical properties of pulsed laser welded Al/steel dissimilar joint [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(4): 994-1002.

[16] ZUO Di, HU Sheng-sun, SHEN Jun-qi, XUE Zhi-qing. Intermediate layer characterization and fracture behavior of laser-welded copper/aluminum metal joints [J]. Materials and Design, 2014, 58(6): 357-362.

[17] AWOTUNDE M, ADEGBENJO A, AYODELE O, OKORO M, SHONGWE M, OLUBAMBI P. Effects of carbon nanotube weight fraction on the fracture toughness of spark plasma sintered nickel aluminide-NiAl3 [J]. Materials Today, 2020, 28(2): 625-629.

[18] CHEN C Y,HWANG W S. Effect of annealing on the interfacial structure of aluminum-copper joints [J]. Materials Transactions, 2007, 48(7): 1939-1947.

[19] CHEN Nan-nan, WANG Min, WANG Hui-ping, WAN Zi-xuan, CARLSON B E. Microstructural and mechanical evolution of Al/steel interface with Fe2Al5 growth in resistance spot welding of aluminum to steel [J]. Journal of Manufacturing Processes, 2018, 34: 424-434.

[20] SHEN Zhong-bao, QIU Ran-feng, SHI Hong-xin, MA Heng-bo. Growth mechanism of intermetallic compounds at the solid-state joining interface of aluminum/steel [J]. Transactions of the China Welding Institution, 2019, 40(6): 58-63, 163-164. (in Chinese)

[21] DUDINA D V, BOKHONOV B B, LEGAN M A, NOVOSELOV A N, SKOVORODIN I N, BULINA N V, ESIKOV M A, MALI V I. Analysis of the formation of FeAl with a high open porosity during electric current-assisted sintering of loosely packed Fe-Al powder mixtures [J]. Vacuum, 2017, 146(12): 74-78.

[22] REN Da-xin, LIU Li-ming. Interface microstructure and mechanical properties of arc spot welding Mg-steel dissimilar joint with Cu interlayer [J]. Materials and Design, 2017, 59(4): 369-376.

[23] ZHOU Dian-wu, JIANG De-fu, LIU Jin-shui, ZHOU Lai-qin, PAN Jing-chun. Microstructure and mechanical properties of laser welding joint with aluminum/steel surface preset filler powder addition [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(5): 942-953.

曹雪龙1,王 刚1,邢 昌1,檀财旺2,蒋俊俊2

1. 安徽工程大学 安徽省高性能有色金属材料重点实验室,芜湖 241000;

2. 哈尔滨工业大学(威海) 材料科学与工程学院,威海 264209

摘 要:研究激光参数和中间层材料对6061铝合金与不锈钢焊接接头显微组织和性能的影响。结果表明,以0.05 mm铜箔和0.1 mm镍箔为中间层,改变激光功率可以优化焊接接头的致密度和组织;在铝合金附近发现大量新的Cu-Al二元相,有效地抑制Fe-Al二元脆性相的形成。当激光功率为2200 W时,最大剪切力为1350.96 N;当铜箔厚度为0.02 mm时,焊接接头剪切力增大到1754.73 N。

关键词:激光焊接;铝/钢异种金属;中间层;显微组织;力学性能

(Edited by Wei-ping CHEN)

Corresponding author: Gang WANG, Tel: +86-13721218343, E-mail: gangwang@ahpu.edu.cn

DOI: 10.1016/S1003-6326(21)65654-6

1003-6326/  2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press