Trans. Nonferrous Met. Soc. China 23(2013) 916-922

Influence of strain rate on microstructure and formability of AZ31B magnesium alloy sheets

Li-fei WANG1,2, Guang-sheng Huang1,2,3, Hong-cheng LI3, Hua ZHANG1,2

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400045, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China;

3. Chongqing Research Center for Advanced Materials, Chongqing Academy of Science & Technology, Chongqing 401123, China

Received 3 November 2011; accepted 15 April 2012

Abstract: The effects of strain rate on microstructure and formability of AZ31B magnesium alloy sheets were investigated through uniaxial tensile tests and hemispherical punch tests with strain rates of 10-4, 10-3, 10-2, 10-1 s-1 at 200 °C. The results show that the volume fraction of dynamic recrystallization grains increases and the original grains are gradually replaced by recrystallization grains with the strain rate decreasing. A larger elongation and a smaller r-value are obtained at a lower strain rate, moreover the erichsen values become larger with the strain rate reducing, so the formability improves. This problem arises in part from the enhanced softening and the coordination of recrystallization grains during deformation.

Key words: AZ31B magnesium alloy; strain rate; dynamic recrystallization; formability

1 Introduction

In recent years, due to the advantages of high specific strength, shocking absorption, high electromagnetic shielding and so on, magnesium alloys have been widely used in automotive and electronic industries [1,2]. However, because magnesium alloys are of the hexagonal closed-packed crystal structure, the forming processes cannot conduct smoothly at room temperature [3]. So, in order to improve the press formability, forming at different temperatures and strain rates is widely investigated. MAKSOUD et al [4] indicated that the peak stress and work-hardening diminished, dynamic recrystallization started and the recrystallization grains grew up with the strain rate reducing in a range of 10-4-10-2 s-1. TUCKER et al [5] presented that the twin density and fractured particle density increased as the strain rate increased during compression tests. NAKA et al [6] reported that the effect of strain rate on the mechanical properties became visibly at a higher temperature in the strain rate range of 10-4-10-2 s-1. In addition, some researches characterized that the forming limit increased as the strain rate decreased, which related to the dynamic recrystallization and the diversification of microstructure [7,8]. LEE et al [9] considered that the warm formability of magnesium alloy sheets was related to the grain size at strain rates between 10-3 s-1 and 10-1 s-1.

In previous studies, the effects of strain rate on the microstructure and the mechanical properties of AZ31B magnesium alloy had been detected in an extensive survey. However, the examinations about strain rate on the stamping formability were rarely reported, especially the Erichsen value. So, in order to obtain the effects of strain rate on press formability, this work focuses on the IE-values at different strain rates. Previous studies show that the formability of AZ31B magnesium alloy sheets increases with the temperature raising but decreases after 250 °C. So, in this experiment, the strain rate range of 10-4-10-1 s-1 and the temperature of 200 °C are chosen. The uniaxial tensile tests and hemispherical punch tests are the main research methods.

2 Experimental

In tensile tests, the supplied AZ31B magnesium alloy (Mg-3% Al-1% Zn, mass fraction) sheets with the thickness of 0.6 mm were machined into specimens. The tensile specimens with 28 mm gauge length and 10 mm gauge width along the directions of 0° (RD) and 45° and 90° (TD) were wire-cut. Firstly, before the uniaxial tensile tests, the specimens were heated to 200 °C by a resistance furnace, then carried out on a CMT6305-300KN electronic universal testing machine with the strain rates of 10-1, 10-2, 10-3 and 10-4 s-1 to determinate the flow stress, yield strength, tensile strength and fracture elongation. The strain-hardening exponent (n-value) was resolved from the uniform plastic deformation region of the tensile stress—strain curves, and the Lankford value (r-value) was measured from the additional tensile tests with the specimens deformed to a true tensile-direction strain of 15%.

The square specimens of Erichsen tests were cut into 90 mm×90 mm along the RD orientation. The temperature was set at 200 °C and the respective initial strain rates were 10-1, 10-2, 10-3, 10-4 s-1. The tests were carried out using a hemispherical punch with the diameter of 20 mm. The blank-holder force was set to be 10 kN and a graphite grease as a lubricant was pasted on the center part of the specimens.

After testing, the samples were cooled down in the air. And the microstructure was inquired by a metallographic microscope and optical micrographs were taken.

3 Results and discussion

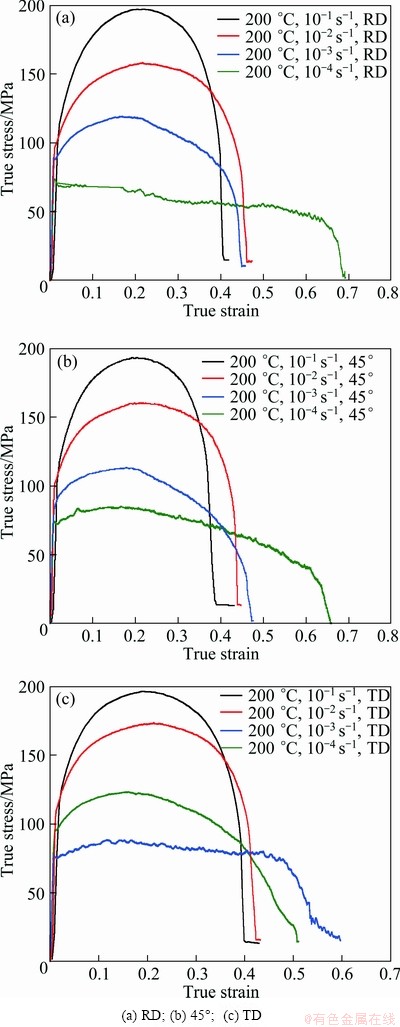

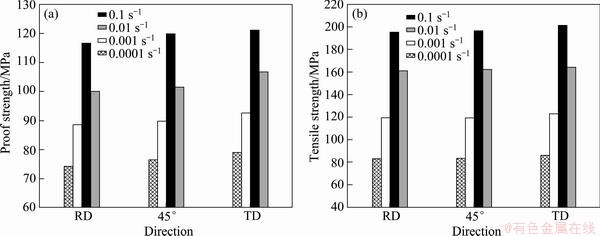

The true stress—strain curves of AZ31B magnesium alloy sheets at different strain rates in the tensile directions of RD, 45° and TD are shown in Fig. 1. The deformation temperature is 200 °C. The yield strength and tensile strength are shown in Fig. 2. According to curves, the flow stress decreased and the fracture elongation increased with the strain rate lowering. Especially at 10-4 s-1, the fracture elongation reached 123%, which represented superplasticity. The yield strength and tensile strength enhanced with the strain rate raising. In addition, the strength along the direction of RD is lower than 45° or TD. This is consistent with the results of previous studies, which mainly relied heavily on the crystallographic texture [8].

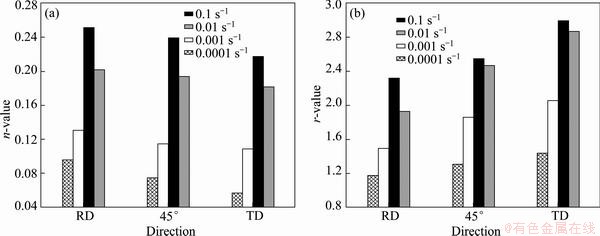

The strain-hardening exponent (n-value) and Lankford value (r-value) are shown in Fig. 3. Figure 3(a) shows n-value and Fig. 3(b) shows the r-value.

Fig. 1 True stress—strain curves of AZ31B alloy sheets at different strain rates along different directions

Irrespective of directions of tensile axis, the n-value decreased with the strain rate lowering. While the r-value decreased in a dropping of strain rate along three directions, but the anisotropy of r-value became weaker at the lower strain rate.

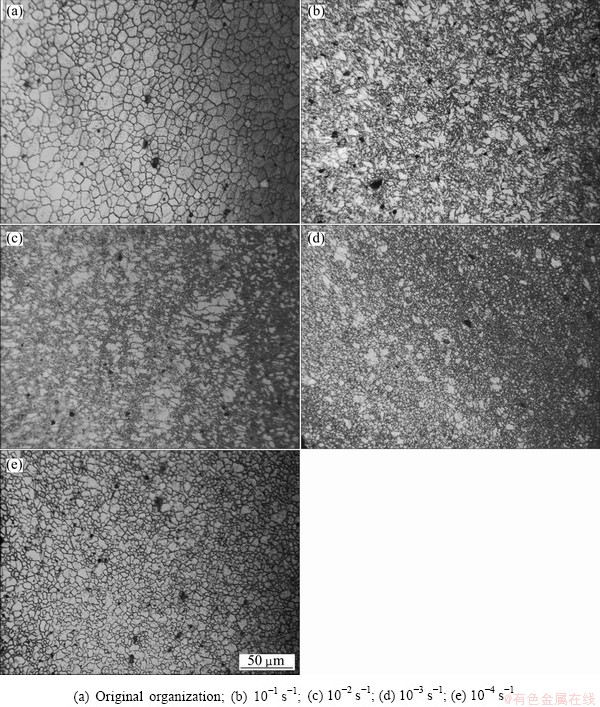

The optical micrographs of the AZ31B alloy specimens stretch-formed to failure at different strain rates and as-received AZ31B alloy sheet in the direction RD are shown in Fig. 4. It can be seen that many fine equiaxial grains distributed apparently near the original grain boundaries, which confirmed the occurrence of dynamic recrystallization during the tensile deformation. Moreover, the volume fraction of dynamic recrystallization grains increased with the strain rate lowering, and when it reduced to 10-3 s-1, the recrystallization behaviors became more severely and original grains were surrounded by dense and fine recrystallization grains, as shown in Figs. 4(b)-(d). Lastly, due to the slowness of deformation speed, the grains even grew up to uniform equiaxed grains at the strain rate of 10-4 s-1, as shown in Fig. 4(e).

Fig. 2 Curves of 0.2% proof strength (a) and ultimate tensile strength (b) at different strain rates

Fig. 3 n-value (a) and r-value (b) at different strain rates

Fig. 4 Optical micrographs of AZ31B alloy specimens stretch-formed to failure along direction RD at 200 °C and different strain rates

Through an analysis of the microstructure, it is helpful to understand the mechanism for the effects of strain rate on stretch properties at 200 °C. While it is well known that the dynamic recrystallization is the main softening mechanism in magnesium alloys. As shown in Fig. 1, the flow stress and strength reduced with the strain rate lowering. This consequence related to the softening occurring and the dynamic recrystallization during deformation. At a higher strain rate, the deformation completed in a short time and the dislocation motion was blocked at the same time. However, at a smaller strain rate, it had enough time to release the stress concentration through dynamic recrystallization. In addition, the volume fraction of recrystallization grains increased and the softening effects enhanced with the strain rate reducing, so the stress and strength reduced. Moreover, the enhanced softening effects were also the main factors of elongation increasing in a dropping of strain rate [10].

The n-value cut down with the strain rate lowering, as shown in Fig. 3(a). In previous studies, it indicated that the dislocation motion promoted with temperature rising, which led to the n-value down during tensile tests [11]. While due to the volume fraction of recrystallization grains increasing, the effects of softening enhanced and the stress concentration released, which resulted in the promotion of dislocation motion. So, the n-value cut down, also the recrystallization resulted in the CRSS reducing and the non-basal slip starting [4,12,13], which further reduced the n-value.

The r-value reduced with the strain rate dropping. As the optical micrographs shown in Fig. 4, the volume fraction of recrystallization grains increased as strain rate reduced, so the softening effects enhanced. Compared with room temperature, the r-value was smaller at 200 °C [11]. Furthermore, the refined recrystallization grains played a role in coordination during deformation [14], which enhanced the ability of thinning. With the strain rate reducing, the volume fraction of recrystallization grains increased and the coordination ability reinforced, so it was easier to hreasingen . ocessese ())sses4; E-mail: ljy158@163.comthin and the r-value dropped as well. According to Fig. 3(b), the anisotropy of r-value became weaker with the strain rate lowering. In other words, the differences of r-value in three directions (RD, 45°, TD) transformed smaller. The results might be due to the fact that the more severe dynamic recrystallization reduced the effect of texture on anisotropy as the strain rate lowered [15].

Generally, a larger r-value did benefit to the press formability of sheet for the common materials, such as aluminum alloys. However, the previous study confirmed that it was easier to deform at the thickness-direction with a smaller r-value, so the formability improved [16]. YI et al [17] claimed that the mechanical anisotropy was bigger with a larger r-value and the formability became worse. So, the smaller the r-value, the better the thinning ability, which coordinated deformation more, and the formability improved as well.

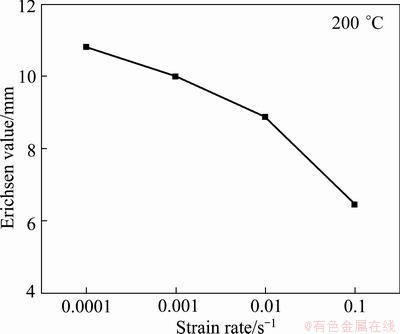

The IE-values at different strain rates are shown in Fig. 5. It reflects the drawing ability of sheets during plastic deformation. As the strain rate dropped, the IE-value increased and the formability improved as well. In particular, the IE-value reached 8.88 mm at the strain rate of 10-2 s-1, and compared with 10-1 s-1, it was increased by 37.5%.

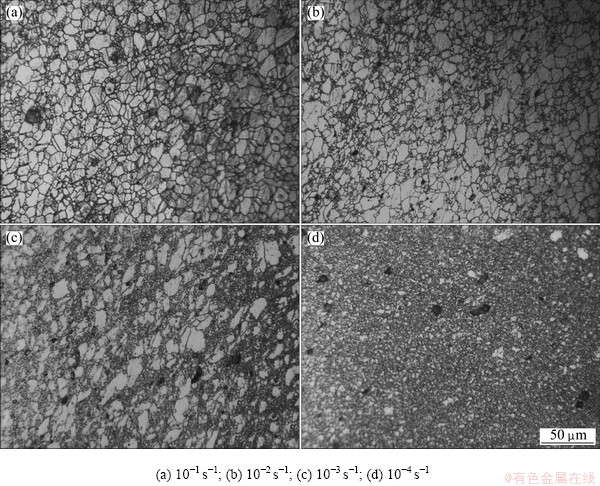

Figures 6(a)-(d) respectively show the optical micrographs of Erichsen tests at the strain rates of 10-1, 10-2, 10-3 and 10-4 s-1, from which the evolution of organization could be seen. Firstly, at the strain rate of 10-1s-1, the twinning occurred and the dynamic recrystallization started, while some fine grains distributed near the original grains boundaries, as shown in Fig. 6(a). With the strain rate lowering, the twinning disappeared and the range of the dynamic recrystallization expanded. Then the recrystallization became more marked, and new grains emerged around most of the original grain boundaries. When the strain rate reduced to 10-4 s-1, the dynamic recrystallization grains were distributed uniformly and densely in the region of deformation, most of the original grains were replaced by the smaller recrystallization grains.

Fig. 5 Erichsen values of sheets at 200 °C with different strain rates

The IE-value improved with the strain rate reducing mainly because that at a higher strain rate, the dislocation

motion exacerbated and stress concentration emerged during deformation. So the slipping could not carry on smoothly. In order to coordinate the deformation, the mechanism of twinning started and the twins came into being. However, the forming of twin boundaries hindered the dislocation motion which did harm to the plastic deformation of magnesium alloy [18]. Then due to the more conspicuous of dynamic recrystallization with the strain rate lowering, the stress concentration released and the dislocation motion promoted, so the twins vanished, as shown in Figs. 6(b)-(d). Previous researches showed that when the grain size was less than 10 μm at the strain rate of 10-3 s-1, the grain boundary sliding (GBS) happened [19,20,21]. BRUNI et al [8] reported that the grain boundary sliding (GBS) operated in the early stage of deformation before the grain coarsening progresses, dislocation motion and dynamic recrystallisation on the same magnesium alloy under similar process conditions. In Fig. 6(d), the average size of grains was 4.5 μm, so the grain boundary sliding started. As a consequence, the GBS delayed the onset of DRX, and the very fine grain size was obtained at the strain of 10-4 s-1. In addition, the grain boundary sliding (GBS) did help to the following deformation [22]. IWANAGA et al [23] showed that the effects of texture on the IE-value were much significant at room temperature. However, at a higher temperature, the effects of elongation and evolution of microstructure were more important than the texture [8,19]. As shown in Fig. 5, the initial grains were replaced by the smaller recrystallization grains, which aroused the increased softening effects and the enhanced function of coordination by dynamic recrystallization grains, so the IE-value improved with strain rate dropping.

Compared the optical micrographs in Fig. 4 with Fig. 6, it could be seen that the microstructures were conspicuously different between Erichsen and tensile tests. This result might be related to the difference of the time and the mode of deformation. The tensile tests were axial deformation, while the Erichsen tests were plane deformation. In the plane deformation, it needed the thinning of thickness to coordinate the deformation.

Fig. 6 Optical micrographs of Erichsen tests with different strain rates at 200 °C

4 Conclusions

The microstructure and stamping formability of AZ31B magnesium alloy sheet at different strain rates and a temperature of 200 °C were investigated. At the strain rates of 10-1, 10-2, 10-3 and 10-4 s-1, the IE-values respectively increase from 6.46 mm, 8.88 mm and 9.98 mm to 10.8 mm, so the formability improves as strain rate decreases. The improvement of press formability is mainly attributed to the raising volume fraction of dynamic recrystallisation grains, which results in the coordination and the softening effects enhancing during deformation with the strain rate decreasing.

References

[1] SONG Bo, HUANG Guang-sheng, LI Hong-cheng, ZHANG Lei, HUANG Guang-jie, PAN Fu-sheng. Texture evolution and mechanical properties of AZ31B magnesium alloy sheets processed by repeated unidirectional bending [J]. Journal of Alloys and Compounds, 2010, 489: 475-481.

[2] Aghion E, BronFIN B. Magnesium alloys development towards the 21st century [J]. Materials Science Forum, 2000, 350-351: 19-30.

[3] YANG P, YU Y, CHEN L, MAO W. Experimental determination and theoretical prediction of twin orientations in magnesium alloy AZ31 [J]. Scripta Materialia, 2004, 50: 1163-1168.

[4] MAKSOUD I A, AHMED H, RODEL J. Investigation of the effect of strain rate and temperature on the deformability and microstructure evolution of AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2009, 504: 40-48.

[5] TUCKER M T, HORSTEMEYER M F, GULLETT P M, KADIRI H, WHITTINGTON W R. Anisotropic effects on the strain rate dependence of a wrought magnesium alloy [J]. Scripta Materialia, 2009, 60: 182-185.

[6] NAKA T, UEMORI T, HINO R, KOHZU M, HIGASHI K, YOSHIDA F. Effects of strain rate, temperature and sheet thickness on yield locus of AZ31 magnesium alloy sheet [J]. Journal of Materials Processing Technology, 2008, 201: 395-400.

[7] XIN Ren-long, WANG Bing-shu, ZHOU Zheng, HUANG Guang-jie, LIU Qing. Effects of strain rate and temperature on microstructure and texture for AZ31 during uniaxial compression [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 594-598.

[8] BRUNI C, FORCELLESE A, GABRIELLI F, SIMONCINI M. Effect of temperature, strain rate and fibre orientation on the plastic flow behaviour and formability of AZ31 magnesium alloy [J]. Journal of Materials Processing Technology, 2010, 210: 1354-1363.

[9] LEE Y S, KWON Y N, KANG S H, KIM S W, LEE J H. Forming limit of AZ31 alloy sheet and strain rate on warm sheet metal forming [J]. Journal of Materials Processing Technology, 2008, 201: 431-435.

[10] YIN D L, ZHANG K F, WANG G F, HAN W B. Warm deformation behavior of hot-rolled AZ31 Mg alloy [J]. Materials Science and Engineering A, 2005, 392: 320-325.

[11] ZHANG Hua, HUANG Guang-sheng, KONG De-qiang, SANG Gao-feng, SONG Bo. Influence of initial texture on formability of AZ31B magnesium alloy sheets at different temperatures [J]. Journal of Materials Processing Technology, 2011, 10: 1575-1580.

[12] BEER A G, BARNETT M R. Microstructural development during hot working of Mg-3Al-1Zn [J]. Metallurgical and Materials Transactions A, 2007, 38: 1857-1867.

[13] YI S B, ZAEFFERER S, BROKMEIER H G. Mechanical behaviour and microstructural evolution of magnesium alloy AZ31 in tension at different temperatures [J]. Materials Science and Engineering A, 2006, 424: 275-281.

[14] WANG Cheng, ZHAO Xi-cheng, YANG Xi-rong, WANG Xing-yun, DING Ru. ECAP plastic deformation mechanism of commercial pure titanium at room temperature [J]. Materials for Mechanical Engineering, 2010, 34: 23-25.

[15] HUANG Guang-sheng, LI Hong-cheng, SONG Bo, ZHANG Lei. Tensile properties and microstructure of AZ31B magnesium alloy sheet processed by repeated unidirectional bending [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 28-33.

[16] ZHANG Hua, HUANG Guang-sheng, SONG Bo, ZHANG Lei, KONG De-qiang. Influence of microstructure and texture on formability of AZ31 magnesium alloy sheets [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 844-850.

[17] YI Sang-bo, BOHLEN J, HEINEMANN F, LETZIG D. Mechanical anisotropy and deep drawing behaviour of AZ31 and ZE10 magnesium alloy sheets [J]. Acta Materialia, 2010, 58: 592-605.

[18] KALIDINDI S R, SALEM A A, DOHERTY R D. Role of deformation twinning on strain hardening in cubic and hexagonal polycrystalline metals [J]. Advanced Engineering Materials, 2003, 5: 229-232.

[19] CHINO Y, IWASAKI H, MABUCHI M. Stretch formability of AZ31 Mg alloy sheets at different testing temperatures [J]. Materials Science and Engineering A, 2007, 466: 90-95.

[20] WATANABE H, TAKARA A, SOMEKAWA H, MUKAI T, HIGASHI K. Effect of texture on tensile properties at elevated temperatures in an AZ31 magnesium alloy [J]. Scripta Materialia, 2005, 52: 449-454.

[21] BUSSIBA A, BEN ARTZY A, SHTECHMAN A, IFERGAN S, KUPIEC M. Grain refinement of AZ31 and ZK60 Mg alloys-towards superplasticity studies [J]. Materials Science and Engineering A, 2001, 302: 56-62.

[22] PANICKER A R, CHOKSHI A A H, MISHRA B R K, VERMA B R, KRAJEWSKI B P E. Microstructural evolution and grain boundary sliding in a superplastic magnesium AZ31 alloy [J]. Acta Materialia, 2009, 57: 3683-3693.

[23] IWANAGA K, TASHIRO H, OKAMOTO H, SHIMIZU K. Improvement of formability from room temperature to warm temperature in AZ31 magnesium alloy [J]. Journal of Materials Processing Technology, 2004, 155-156: 1313-1316.

应变速率对AZ31B镁合金板材组织和成型性能的影响

王利飞1,2,黄光胜1,2,3,李红成3,张 华1,2

1. 重庆大学 材料科学与工程学院,重庆 400045;

2. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044;

3. 重庆科学技术研究院 重庆新材料研究中心,重庆 401123

摘 要:在200 °C下通过不同应变速率(10-1,10-2,10-3,10-4 s-1)进行单轴拉伸试验和半球形冲压成型试验,研究应变速率对AZ31B镁合金板材组织和成形性能的影响。结果表明,随着应变速率的降低,动态再结晶体积分数变大,原始晶粒逐渐被动态再结晶晶粒取代;在低的应变速率下,伸长率较大,r值较小;并且随着应变速率的降低,Erichsen突值变大,成型性能提高。这主要是由于随着变形速率的降低,变形过程中动态再结晶软化作用和动态再结晶晶粒协调变形作用而逐渐增强的结果。

关键词:AZ31B镁合金;应变速率;动态再结晶;成型性能

(Edited by Hua YANG)

Foundation item: Project (CSTC2010AA4035) supported by Scientific and Technological Project of Chongqing Science and Technology Commission, China; Project (CDJZR11130008) supported by the Fundamental Research Funds for the Central Universities, China; Project (2008DFR50040) supported by the Ministry of Science and Technology of China

Corresponding author: Guang-sheng HUANG; Tel: +86-23-65112239; E-mail: gshuang@cqu.edu.cn

DOI: 10.1016/S1003-6326(13)62548-0