氯化铵法处理氟碳铈矿原矿提取稀土

来源期刊:中国有色金属学报2000年第5期

论文作者:朱国才 田君 池汝安 徐盛明 张志庚

文章页码:701 - 704

关键词:氯化铵; 氟碳铈原矿; 稀土

Key words:bastnasite crude ore; ammonium chloride; rare earth

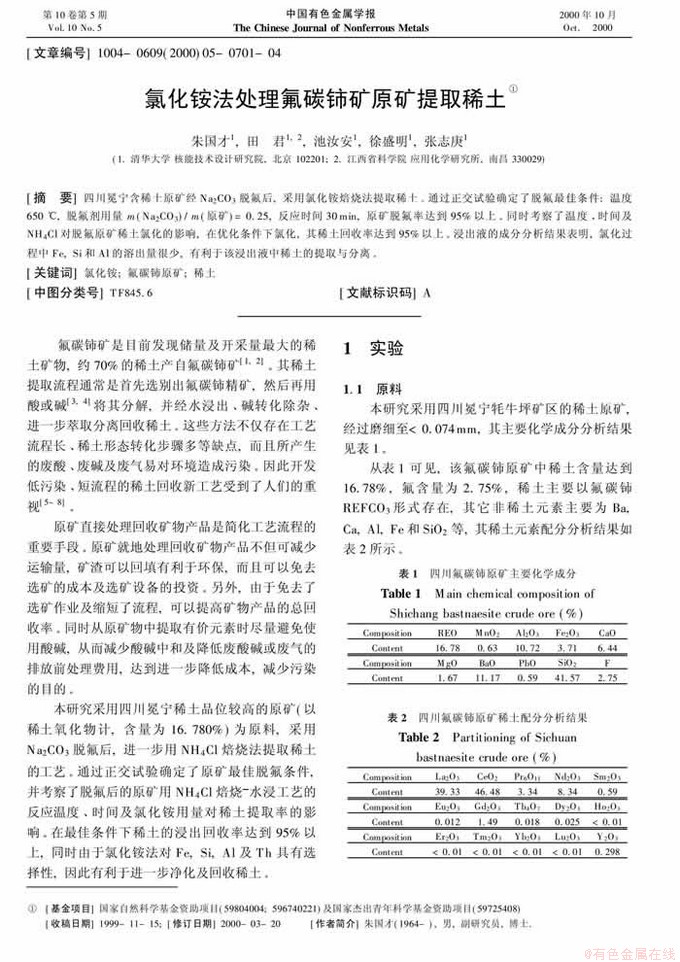

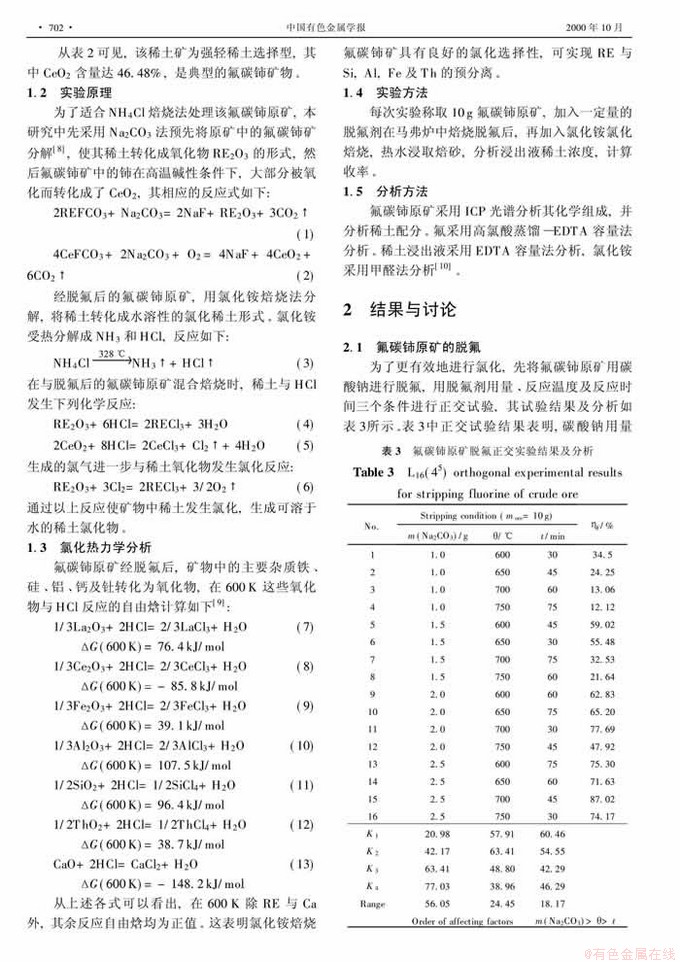

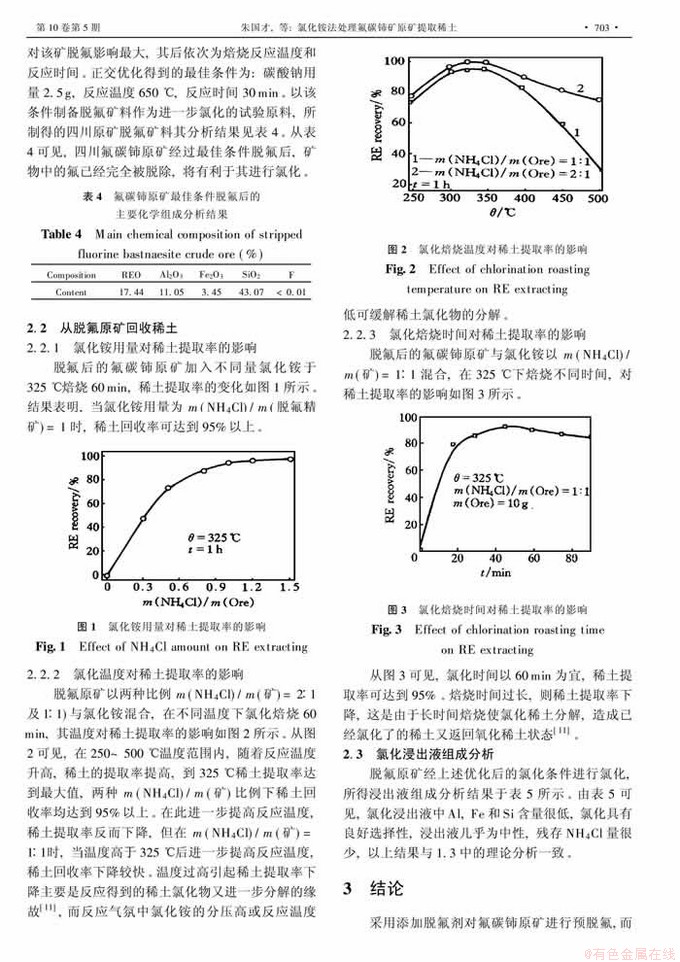

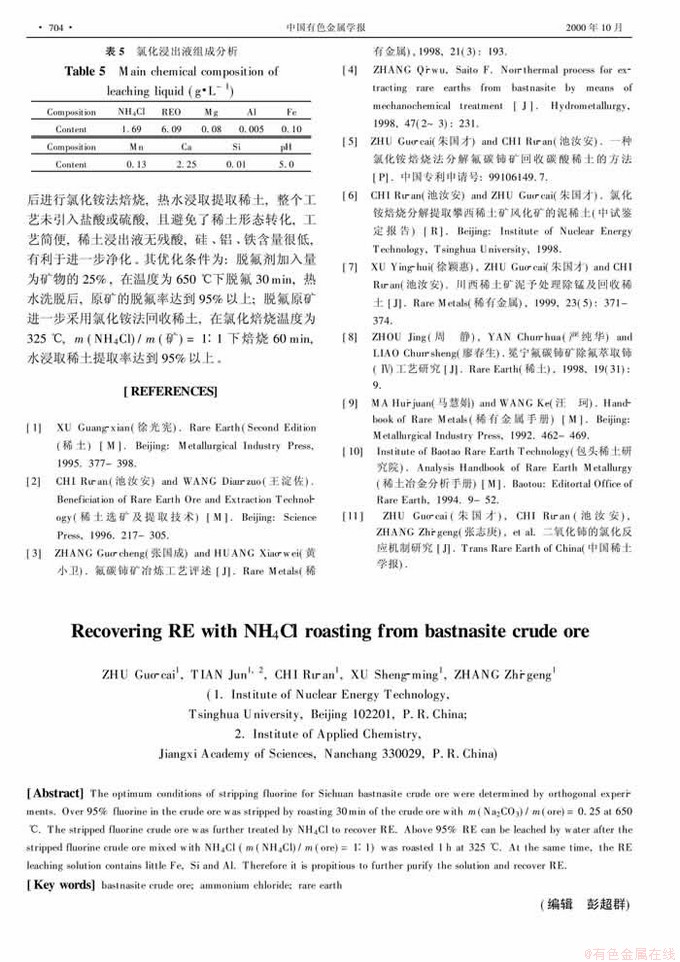

摘 要:四川冕宁含稀土原矿经Na2CO3脱氟后, 采用氯化铵焙烧法提取稀土。 通过正交试验确定了脱氟最佳条件:温度650 ℃, 脱氟剂用量m (Na2CO3)/m (原矿)=0.25, 反应时间30 min,原矿脱氟率达到95%以上。 同时考察了温度、 时间及NH4Cl对脱氟原矿稀土氯化的影响, 在优化条件下氯化, 其稀土回收率达到95%以上。 浸出液的成分分析结果表明, 氯化过程中Fe, Si和Al的溶出量很少, 有利于该浸出液中稀土的提取与分离。

Abstract: The optimum conditions of stripping fluorine for Sichuan bastnasite crude ore were determined by orthogonal experiments. Over 95% fluorine in the crude ore was stripped by roasting 30 min of the crude ore with m (Na2CO3)/m (ore)=0.25 at 650 ℃. The stripped fluorine crude ore was further treatedby NH4Cl to recover RE. Above 95% RE can be leached by water after the stripped fluorine crude ore mixed with NH4Cl (m (NH4Cl)/ m (ore)=1∶1) was roasted 1 h at 325 ℃. At the same time, the RE leaching solution contains little Fe, Si and Al. Therefore it is propitious to further purify the solution and recover RE.