文章编号:1004-0609(2014)05-1118-09

正向电压对ZK60镁合金微弧氧化过程及膜层的影响

杜翠玲1,陈 静1, 2,汤 莉1,芦 笙1,卢向雨1,许 蕾1

(1. 江苏科技大学 材料科学与工程学院,镇江 212003;

2. 江苏科技大学 档案馆,镇江 212003)

摘 要:在自主研制的铝酸钠-磷酸钠复合电解液体系中,采用不同的正向电压(220~340 V)对ZK60变形镁合金进行微弧氧化,在镁合金表面制备陶瓷膜层。利用扫描电镜、超景深光学显微镜及能谱仪观察分析膜层组织,通过电流变化及放电现象分析微弧氧化过程,并用全浸实验和电化学阻抗法测试膜层在3.5% NaCl(质量分数)介质中的耐腐蚀性能。结果表明:电流平稳阶段是膜层的主要生长阶段,正向电压是微弧氧化过程的重要驱动力,电压过高或过低都不利于获得优质膜层。280 V正向电压下制备的膜层组织较为均匀致密,其腐蚀速率较低,为0.2054 g/(m2·h),此时膜层电化学阻抗模值为正向电压340 V下膜层的3倍。

关键词:ZK60镁合金;微弧氧化;正向电压;耐腐蚀性

中图分类号:TG174.2 文献标志码:A

Effect of positive voltage on micro-arc oxidation process and coating of ZK60 Mg alloy

DU Cui-ling1, CHEN Jing1, 2, TANG Li1, LU Sheng1, LU Xiang-yu1, XU Lei1

(1. School of Materials Science and Engineering, Jiangsu University of Science and Technology, Zhenjiang 212003, China;

2. Archives, Jiangsu University of Science and Technology, Zhenjiang 212003, China)

Abstract: Micro-arc oxidation (MAO) process was conducted on ZK60 Mg alloy in a self-made aluminate-phosphate dual electrolyte system containing aluminate and phosphate with positive voltage from 220 to 340 V. A MAO coating was prepared on the surface of ZK60 Mg alloy. The microstructure characteristics of coatings were investigated by scanning electron microscope (SEM), super depth of field microscope and energy dispersive spectrometer (DSC). The process evolution was evaluated through current change and electric discharge phenomena. The corrosion resistance of coatings was measured in 3.5% NaCl (mass fraction) solution by immersion test and electrochemical impedance spectroscope (EIS). The results show that the main growth of coating takes place in stable current stage and positive voltage is an important driving force for better MAO coating. A uniform and compact MAO coating can be obtained under certain suitable positive voltage. The MAO coating prepared at 280 V exhibits good corrosion resistance with corrosion rate of 0.2054 g/(m2·h), and its impedance value is as 3 times as that of coating made at 340 V.

Key words: ZK60 Mg alloy; micro-arc oxidation; positive voltage; corrosion resistance

微弧氧化(Micro-arc oxidation,MAO)是一种工艺简单、高效、环保的表面处理技术,可在铝、镁、钛等金属制品表面原位生长陶瓷氧化膜,膜层与基体结合力强,并具有良好的耐磨、耐腐蚀、耐高温冲击和电绝缘等特性[1-3]。电源是微弧氧化工艺的关键设备,可通过调节电源模式、控制方式及参数来控制反应过程中的能量输入,从而影响成膜过程及膜层质量[4]。通常采用恒流或恒压两种电源控制方式进行微弧氧化,即在氧化过程中维持电流(或电压)幅值不变,而电压(或电流)随时间变化[5]。一般认为,恒压法便于控制膜层厚度,但后期击穿不够[6]。为此,研究人员试图探索正向电压、负向电压、频率、占空比、氧化时间等电参数对成膜过程的影响规律,从而提高膜层质量。其中,正向电压对成膜过程和膜层特性有重要影响。研究表明,较低正向电压下形成的AZ31镁合金的氧化膜层较薄,晶粒尺寸则随电压增加而变粗[7];电压增幅对AZ91D镁合金的放电火花形态、膜层厚度、表面形貌和耐蚀性均有影响[8]。ABBASI等[9]采用恒压模式在钛合金表面制备了HAp-TiO2微弧氧化膜,发现只有在合适的电压下才能制备出Ca、P质量比接近1.67的膜层。可见,在不同基体和电解液中,正向电压对膜层表现出不同的影响规律。

本文作者在前期研制的新型复合电解液的基础 上[10],采用双极性脉冲微弧氧化电源,在恒压模式下对ZK60变形镁合金进行微弧氧化处理,研究不同正向电压对微弧氧化成膜过程及膜层微观组织和耐腐蚀性的影响。

1 实验

基体材料为20 mm×20 mm×5 mm 的ZK60变形镁合金,其化学成分(质量分数)如下:Zn 4.8%~6.2%,Zr>0.45%,杂质含量≤0.30,余量为Mg。试样经砂纸逐级打磨至1200号,用酒精浸泡并超声清洗,冷风吹干后备用。采用WHD-20双极性交流脉冲微弧氧化装置,以不锈钢槽为阴极,镁合金试样为阳极,以铝酸钠、磷酸钠为主成膜剂配制复合电解液[10],微弧氧过程中,通过循环水冷却控制电解液温度不超过40 ℃。在恒压控制模式下,固定其他电参数不变(见表1),研究不同正向电压对微弧氧化成膜过程及膜层性能的影响。微弧氧化过程中,自动采集电流-时间变化曲线。

表1 微弧氧化电参数

Table 1 Electrical parameters of micro-arc oxidation

采用JSM-6480扫描电镜及所附INCA能谱仪观察分析膜层形貌及微区成分,通过VHX-900超景深光学显微镜测量膜层厚度。采用全浸实验评价试样耐腐蚀性:将试样全浸到浓度为3.5%NaCl介质中,浸泡168 h后取出,放入蒸馏水中超声清洗10 min去除表面腐蚀产物,冷风吹干后用精度为±0.1 mg的电子天平称量,计算试样的平均腐蚀速率v。采用M283恒电位仪和M1025锁相放大器,测试膜层在3.5%NaCl溶液中的电化学阻抗谱。测量体系为三电极系统,试样为工作电极,参比电极为饱和甘汞电极,辅助电极为铂片,盐桥为介质/饱和KCl溶液,采用ZSimWin软件对阻抗数据进行分析。同时,为研究膜层的生长动力学,将不同阶段获得的微弧氧化膜层进行分析,测量其膜厚,各阶段膜层生长速率v的计算公式如下:

v=Δh/Δt (1)

式中:Δh为各阶段膜层增厚值(μm);Δt为各阶段时间(min)。

2 结果与分析

2.1 正向电压的选择

对于一定条件下的微弧氧化过程都存在两个特征电压:起弧电压和大弧电压。电源电压小于起弧电压时,阳极表面只发生阳极氧化;大于起弧电压时,开始发生微弧氧化;超过大弧电压时,阳极表面出现固定位置的持续放电电弧,即大弧放电[8]。实际施加电压与起弧电压的差值即为过电压,起弧电压越低、大弧电压越高,则微弧氧化过程越稳定。由本文作者所在课题组前期恒流模式的研究结果可知[10],ZK60镁合金在复合电解液中的起弧电压约为210 V,最高工作电压约为340 V。因此,本文作者将正向电压研究范围确定为220~340 V,选定实验电压值为220、240、260、280、300、320和340 V。根据实验现象和膜层特征,将其分2组进行研究:一组为低电压,电压范围为220~260 V;另一组为高电压,电压范围为280~340 V。

2.2 低电压下的微弧氧化过程及膜层特征

2.2.1 低电压制备的膜层特征

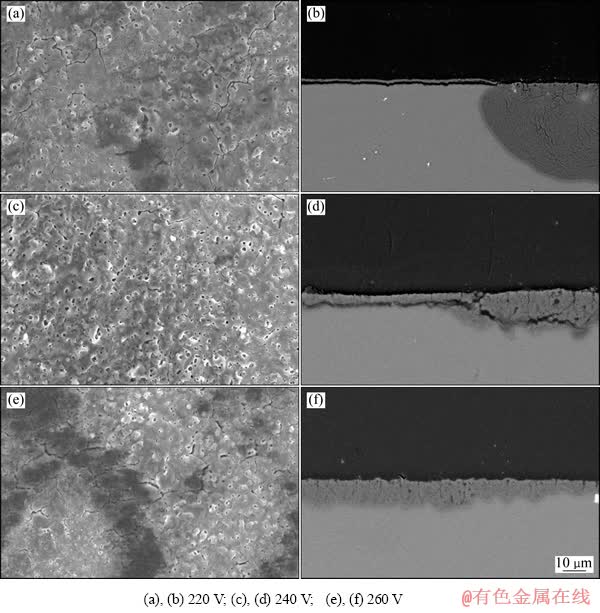

研究发现,当正向电压在低值范围时(220~260 V),即过电压较小时,膜层表面存在大量裂纹,低电压220 V下尤其显著(见图1(a));随电压升高,表面裂纹有所减少(见图1(c)和(d))。低电压下获得的膜层极不均匀,整体较薄而局部很厚(见图1(b)和(d))。电压增至260 V,膜厚不均匀现象有所改善。显然,表面裂纹及膜厚不均匀都易导致膜层薄弱区受腐蚀介质侵蚀,从而影响整个MAO膜层的质量。

图1 低电压下制备的膜层表面及截面形貌

Fig. 1 Surface ((a), (c), (e)) and cross-section ((b), (d), (f)) morphologies of coatings at low voltages

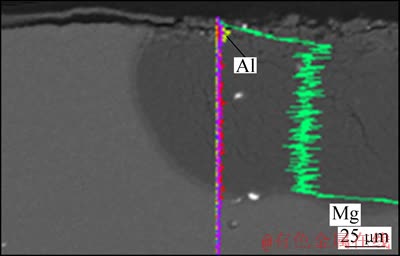

图2所示为正向电压为220 V下制备的膜层的截面形貌及元素分布。表面化所列为膜层不同位置处的能谱分析结果。从成分看无论厚薄,该陶瓷膜的组成物主要是MgO和MgAl2O4[11],但薄膜层处Al、P元素含量较高,这主要是因为所使用的复合电解液以铝酸钠、磷酸钠为主成膜剂,微弧氧化过程中电解液中的Al、P元素易通过扩散、电迁移等形式沉积于膜层表面,这也被图2中Al、P在厚膜处的能谱线扫描结果所证实。同时可见,厚膜层处Mg含量高,而Al含量较低,并含有1.31%Zr(摩尔分数)。可以认为,因受电解液扩散和电迁移的影响较小,远离表面的陶瓷膜更接近于镁合金基材的成分,以MgO为主,而其中MgAl2O4含量大幅减少。

图2 220 V电压下制备的膜层SEM像及元素分布曲线

Fig. 2 SEM image and element distribution of coating fabricated at voltage of 220 V

表2 220 V电压下制备的膜层的EDS能谱分析结果

Table 2 EDS results of coating fabricated at voltage of 220 V

2.2.2 低电压下微弧氧化过程分析

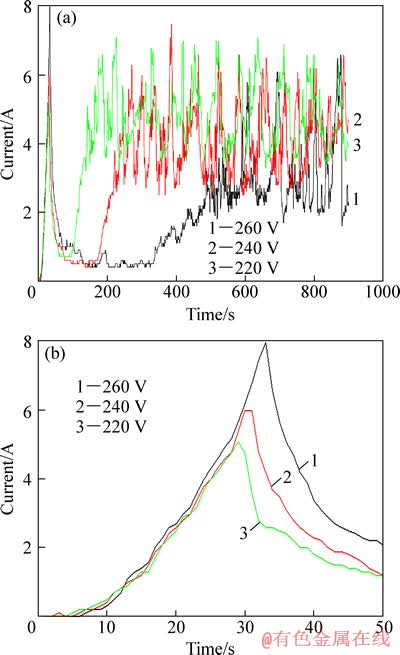

图3 正向电压220~260 V下ZK60镁合金微弧氧化过程的电流—时间曲线

Fig. 3 Current-time curves of ZK60 Mg alloy during MAO at voltages from 220 to 260 V

图3所示为低电压下的电流—时间变化曲线。其峰值电流较小(5~8 A),膜层生长的不均匀过程也得到体现。3组曲线都经历了电流快速上升、快速下降、平稳变化以及剧烈波动的4个阶段。随正向电压的升高,峰值电流增加,电流平稳阶段延长、平稳电流值减小,电流波动阶段缩短、波动程度减小。结合图1(e),(f)可知,当电压为260 V时,其膜层质量较220和240 V的好,所对应的平稳电流阶段持续时间最长,平稳电流值也最小。由此可见,过电压大小对微弧氧化过程有重要影响,过电压太小不利于膜层均匀生长并获得致密膜层。这可从以下两方面加以说明。

一方面,如图3(b)(氧化初期电流变化的放大图)所示,过电压对微弧氧化的起始时间影响不大,基本都在30 s左右结束阳极氧化并开始火花放电。但正向电压较大时(260 V,过电压50 V),第一阶段持续时间更长,电流峰值较大,因此,获得的阳极氧化膜较厚 [12],后续微弧氧化放电形成的陶瓷膜也较厚,因陶瓷的绝缘性导致电流迅速下降,进入第二阶段;由于膜层较厚且较均匀致密,进入电流稳定的第三阶段后,放电火花数量多且分布均匀,并维持了较长时间进行微弧氧化增厚(200 s左右);后期因局部击穿导致大弧放电,进入电流剧烈波动的第四阶段。反之,正向电压较小时(220和240 V,过电压10和30 V),可较快地达到峰值电流,且电流峰值较小,生成的阳极氧化膜也较薄,电阻值相对较小,因此经第二阶段过渡后,第三阶段的平稳电流值也相对较高,但仅维持很短的时间(40~110 s);较薄的氧化膜层即使在较低的过电压下也可轻易击穿,使第四阶段大弧放电维持较长时间。

另一方面,对于第一阶段形成的微弧氧化膜,当正向电压较低时,其过电压太小,难以击穿试样表面大部分区域的膜层,而微弧氧化电击穿总是发生在膜层的薄弱区[13],因此,前期成膜缺陷处容易被再次击穿,并诱导该局部区域发生集中放电反应,且由于存在正反馈效应[7],放电越剧烈,弧点与周边温度越高,高温使气体电离度增加进而更易放电,导致大弧放电反应持续集中于某局部区域,因而呈现典型的不均匀膜层,即大部分区域非常薄,但局部很厚。反之,随正向电压升高,过电压增大,能够满足膜层再生击穿的区域增多,电压分散在更多的击穿点,因而前期细小、均匀放电的时间延长,后期局部微弧放电反应相对减弱,膜层厚薄差异减小,更为均匀。

综上所述,正向电压主要通过对大弧放电的控制来影响微弧氧化成膜过程和膜层特点。为提高成膜质量,必须提供足够大的正向电压,即充分的过电压,才能增加微弧氧化膜层的再击穿区域,使均匀放电成膜过程占主导地位,从而获得表面均匀、截面均厚、致密的膜层。结合上述试验结果,确定正向电压应大于260 V。因此,选定电压分别为280、300、320和340 V,进一步研究正向电压对微弧氧化过程、不同阶段的生长速率、膜层组织和耐腐蚀性能的影响。

2.3 高电压下的微弧氧化过程及膜层特征

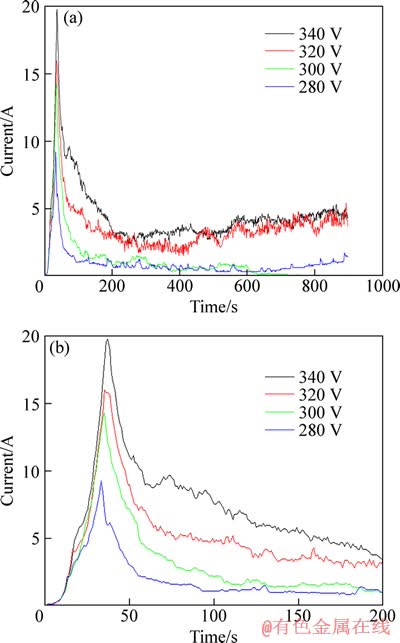

2.3.1 高电压下微弧氧化过程分析

图4所示为280~340 V对应的电流-时间关系曲线,与图2类似,也经历了电流的快速上升(第一阶段)、快速下降(第二阶段)、电流平稳变化(第三阶段)及电流后期无规律波动(第四阶段),且随正向电压的升高,峰值电流增加,但其值(9~20 A)明显高于低电压时的(5~8 A)。与低电压组相比最明显的差异是,电流平稳的第三阶段大幅延长,而第四阶段缩短;且随正向电压由340和320 V分别降到300和280 V,第三阶段的电流稳定值由5 A左右减小到低于1 A,第四阶段也几乎消失。而340和320 V对应的第四阶段在后期出现了曲线翘曲现象,这与实验过程中试样底部局部区域强烈弧光放电相对应,检查发现试样出现了局部烧蚀。

图4 正向电压280~340V下ZK60镁合金微弧氧化过程的电流-时间曲线

Fig. 4 Current-time curves of ZK60 Mg alloy during MAO at voltages from 280 to 340 V

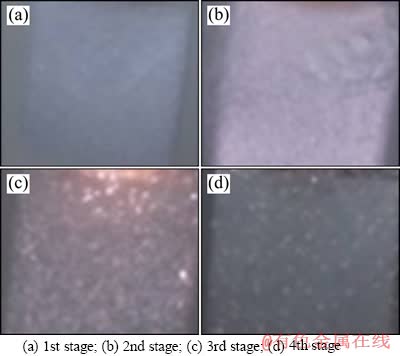

以280 V为例,根据微弧氧化过程中电流变化情况,并结合实验过程中的火花放电现象,对恒压模式下的微弧氧化过程进行分析。图5所示为280 V电压下各阶段的膜层厚度。图6所示为280 V电压下不同阶段的火花放电照片。第一阶段(0~30 s),即阳极氧化阶段,电流快速上升,合金表面析出气体并失去金属光泽,见图6(a)。当电压达到210 V击穿电压时,开始火花放电并发出微弱轰鸣声,36 s时电流达到峰值,试样表面可见细密、均匀的银白色火花(见图6(b))。随后,电流值开始迅速下降,试样表面银白色火花逐渐变成橘黄色,进入电流平稳的第三阶段(见图6(c))。因电流迅速下降的第二阶段已进入微弧氧化过程,且放电现象与第三阶段相似,故将两者合并,称为均匀火花放电阶段。从放电特征看,第四阶段(360~900 s)为微小火花放电阶段,火花数量减少,火花强度有所减弱(见图6(d))。如前所述,当电压更高时(320和340 V),其过程有所不同,第四阶段的后期电流呈现翘升,以局部固定区域的大弧放电为主。

图5 280 V电压下各阶段的膜层厚度

Fig. 5 Thickness of MAO coating at different stages under voltage of 280 V

图6 280 V电压下各阶段的火花放电照片

Fig. 6 Spark discharge photos at different stages under voltage of 280 V

按照以上微弧氧化各阶段的划分,进一步分析膜层厚度变化及生长速率。因阳极氧化阶段时间很短,生成非常薄的钝化膜,其生长速率忽略不计,将其与后续的均匀火花放电阶段综合考虑,即将第一、二、三阶段(0~360 s)并称为均匀微弧氧化阶段(Uniform MAO),而第四阶段称为局部微弧氧化阶段(Local MAO)。由图5可知,均匀微弧氧化阶段膜层生长速率高达1.35 μm/min(增厚8.126 μm),远大于局部微弧氧化阶段的0.34 μm/min(仅增厚3.094 μm),因此,膜层的主要生长都发生在均匀微弧氧化阶段,尤其是在电流平稳区。微弧氧化第四阶段膜层生长速率较低,这是因为随着陶瓷膜层的增厚,膜层的击穿电压升高[14],施加的电压与所形成的陶瓷层的击穿电压逐渐相近,后期击穿力不足,因此,该阶段微小的火花放电反应已经满足不了膜层再生长的动力需要。可见,为获得较大厚度的均匀膜层,就必须提供足够高的过电压,但正向电压过高也容易出现大弧放电,使局部区域出现烧蚀或溶解,也可能局部增厚。由此可见,只有采用适当的过电压,才能维持微弧氧化陶瓷层不断产生均匀的局部微区击穿现象,这是一个关键因素。

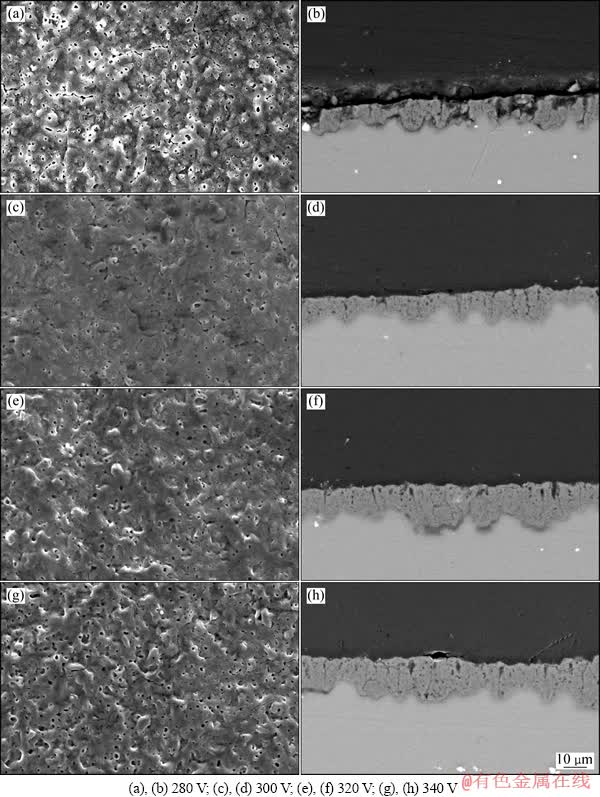

2.3.2 高电压制备的膜层特征

正向电压280~340 V下所获得微弧氧化膜层表面及截面形貌如图7所示。与低电压220~260 V相比,高电压下制备的膜层表面质量较好,孔洞及裂纹较少,截面也较均匀、致密;随电压增大,膜厚增加,但空洞、裂纹等疏松缺陷也有所增加。

以280、320 V为例,280 V的膜层表面较为致密、平坦,孔径较小(平均约为1 μm),而340 V的膜层表面凸起堆积物增多,微孔数量和孔径也增大,很多孔径都超过2 μm,且膜层截面贯穿性孔洞或微裂纹增多,同时因高电压导致大弧现象,在局部出现类似图1(d)所示的膜厚不均匀现象。

这是由于微弧氧化过程是一个“成膜-击穿-熔融-凝固-烧结”的循环过程,氧化膜层通过膜层的不断击穿、再生成、烧结、排泄、堆垛等非平衡物质传输过程形成[15]。如前分析,膜层的主要生长发生在均匀微弧氧化阶段,尤其是电流平稳的第三阶段,当电压较低时,输入能量和电流平稳值也小,在击穿过程中对陶瓷膜层的破坏程度较小,从而陶瓷膜比较致密,孔隙率较低;而电压增大后,平稳电流值也变大,反应过程中的放电能量越大,瞬间产生的热量越多,氧气和熔融态的生成物越多,凝结越困难,因而放电气孔孔径加大,表面堆积的熔融覆盖物也越明显,膜层的致密性也越差,也容易因大弧放电导致膜层的局部烧蚀或过厚。因此,在制备微弧氧化膜时也并非过电压越高越好,为保证成膜质量,应选择适当的正向电压。在本实验条件下,280 V制备的膜层总体质量更好。

图7 高电压下制备的膜层表面及截面形貌

Fig. 7 Surface and cross-section morphologies of coatings at high voltages

2.3.3 膜层耐蚀性

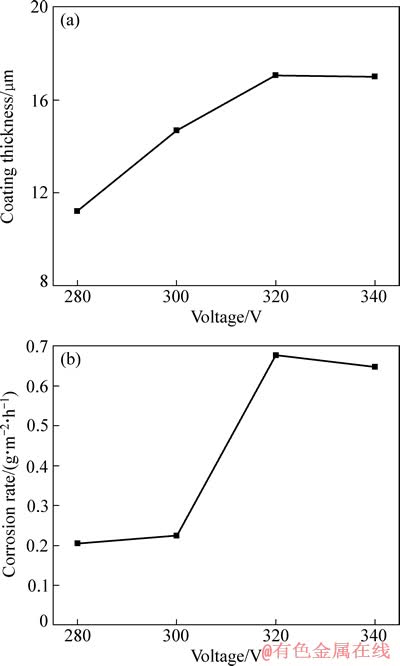

图8 不同正向电压下微弧氧化膜层厚度和腐蚀速率变化曲线

Fig. 8 Changing curves of thickness (a) and corrosion rate (b) of MAO coatings at different positive voltages

图8(a)和(b)所示分别为膜层厚度、腐蚀速率随电压的变化趋势。随正向电压的增加,膜层厚度逐渐增加,在3.5% NaCl溶液中的腐蚀速率总体上也呈增大趋势,亦即膜层耐蚀性逐渐降低。这说明微弧氧化膜的厚度不是决定其耐蚀性的首要因素,在膜层达到一定厚度的前提下,耐蚀性还取决于膜层的致密性和均匀性。当正向电压为280 V时,微弧氧化膜层虽然最薄,但其致密度最高,也较均匀;如图6所示,其膜层中的孔洞、裂纹数量远少于高电压320和340 V下制得的膜层,因此,腐蚀速率最低,仅为0.2054 g/(m2·h)。此外,显然可见,大于320 V时,膜层厚度及腐蚀速率的变化较小,这从另一个角度说明提高正向电压并不能有效改善膜层质量。

图9 ZK60镁合金微弧氧化膜试样在3.5%NaCl溶液中的电化学阻抗图

Fig. 9 Electrochemical impedance spectroscopy of MAO coated ZK60 Mg alloy specimens in 3.5% NaCl solution

不同正向电压下制备的微弧氧化膜在3.5%NaCl溶液中的阻抗谱如图9所示。由图9(a)可以看出,各正向电压下制备的微弧氧化膜的阻抗都有两个容抗弧,随着正向电压的升高,低频段容抗弧的圆弧半径逐渐变小,表明微弧氧化膜的致密层电阻随着电压的增加而逐渐降低,其中,280 V正向电压下制备的微弧氧化膜致密层电阻值明显高于其他膜层的;同时,随正向电压的增加,高频段容抗弧的圆心逐渐向第四象限偏移,其“弥散效应”更加明显,表明微弧氧化膜层的外层结构越来越疏松[16], 这同图 7中各正向电压下制备的微弧氧化膜的截面形貌相吻合。

图9(b)所示为各正向电压下制备的微弧氧化膜的Bode图。与图9(a)结果相一致,随正向电压的上升,微弧氧化膜的阻抗模值逐渐降低,表明其耐蚀性逐渐降低。其中,340 V下制备的微弧氧化膜阻抗模值最低,而280 V的最高,0.1 Hz下其阻抗膜值达2.4911×104 Ω·cm2,约为前者的3倍。虽然交流阻抗和全浸实验的结果并不完全相同,但相互印证了正向电压280 V制备的膜层耐蚀性最好这一事实。

3 结论

1) 恒压模式下,ZK60镁合金微弧氧化过程中的电流平稳区是膜层的主要生长阶段,该阶段持续时间越长,膜层的质量越好。

2) 正向电压是微弧氧化的重要驱动力,过电压太小不利于膜层均匀生长并获得致密膜层,过电压太大则易导致膜层后期局部烧蚀或过厚,适当的过电压可维持微弧氧化陶瓷层不断产生均匀的局部微区击穿,从而获得均匀致密的微弧氧化膜。

3) 在自主研制的复合电解液中,在280 V正向电压下制备出ZK60镁合金微弧氧化陶瓷膜,其耐腐蚀性能优异,在3.5%NaCl溶液中的腐蚀速率仅为0.2054 g/(m2·h),电化学阻抗模值为340 V下的3倍。

REFERENCES

[1] 薛文斌, 邓志威, 来永春, 陈如意, 张通和. 有色金属表面微弧氧化技术评述[J]. 金属热处理, 2000(1): 1-3.

XUE Wen-bin, DENG Zhi-wei, LAI Yong-chun, CHEN Ru-yi, ZHANG Tong-he. Review of microarc oxidation technique on surface of non-ferrous metals[J]. Heat Treatment of Metals, 2000(1): 1-3.

[2] DELPHINE V R, EMMANUEL R,  H. Micro-arc oxidation of AZ91 Mg alloy: An in-situ electrochemical study[J]. Electrochemistry Communications, 2013, 31: 42-45.

H. Micro-arc oxidation of AZ91 Mg alloy: An in-situ electrochemical study[J]. Electrochemistry Communications, 2013, 31: 42-45.

[3] TSUTSUMI Y, NIINOMI M, NAKAI M, TSUTSUMIB H, DOI H, NOMURA N, HANAWA T. Micro-arc oxidation treatment to improve the hard-tissue compatibility of Ti-29Nb-13Ta-4.6Zr alloy[J]. Applied Surface Science, 2012, 262: 34-38.

[4] ZHANG R F, SHAN D Y, CHEN R S, HAN E H. Effects of electric parameters on properties of anodic coatings formed on magnesium alloys[J]. Materials Chemistry and Physics, 2008, 107: 356-363.

[5] 冯欣荣, 吴汉华, 龙北玉. 多功能微弧氧化电源的研制[J]. 仪表技术与传感器, 2004(9): 32-33.

FENG Xin-rong, WU Han-hua, LONG Bei-yu. Research of multifunction microarc-oxidation power supply[J]. Instrument Technique and Sensor, 2004(9): 32-33.

[6] ZOZULIN A J, BARTAK D E. Anodized coatings for magnesium alloys[J]. Metal Finishing, 1994, 92(3): 39-44.

[7] 熊文名, 宁成云, 顾艳红, 张 京. 正向电压对镁合金微弧氧化膜层相结构的影响[J]. 稀有金属材料与工程, 2011, 40(12): 2236-2240.

XIONG Wen-ming, NING Cheng-yun, GU Yan-hong, ZHANG jing. Effect of positive voltage on phase structure of microarc oxidation films of magnesium alloy[J]. Rare Metal Materials and Engineering, 2011, 40(12): 2236-2240.

[8] 陈 明, 马跃洲, 马 颖, 郝 远. 电压增幅对镁合金微弧氧化膜层性能的影响[J]. 稀有金属材料与工程, 2010, 39(11): 1943-1947.

CHEN Ming, MA Yue-zhou, MA Ying, HAO Yuan. Effects of voltage increment on performances of micro-arc oxidation coatings of magnesium alloys[J]. Rare Metal Materials and Engineering, 2010, 39(11): 1943-1947.

[9] ABBASI S, BAYATI M R, GOLESTANI-FARD F, REZAEI H R, ZARGAR H R,SAMANIPOUR F, SHOAEI-RAD V. Microarc oxidized hap-TiO2 nanostructured hybrid layers—part I: Effect of voltage and growth time[J]. Applied Surface Science, 2011, 257: 5944-5949.

[10] LU S, WANG Z X, CHEN J, ZHOU X S. Optimization of dual electrolyte and characteristic of micro-arc oxidation coating fabricated on ZK60 Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(4): 929-935.

[11] 张永君, 严川伟, 楼翰一, 王福会, 曹楚南. Mg及其合金的阳极氧化技术进展[J]. 腐蚀科学与防护技术, 2001, 13(4): 214-217.

ZHANG Yong-jun, YAN Chuan-wei, LOU Han-yi, WANG Fu-hui, CAO Chu-nan. Progress on anodizing technology for magnesium and its alloys[J]. Corrosion Science and Protection Technology, 2001, 13(4): 214-217.

[12] 张荣发, 李明升, 龙小丽, 何向明, 单大勇, 韩恩厚. 电参数对镁合金阳极氧化膜性能影响的研究进展[J]. 中国有色金属学报, 2006, 16(11): 1829-1837.

ZHANG Rong-fa, LI Ming-shen, LONG Xiao-li, HE Xiang-min, SHAN Da-yon, HAN En-hou. Research progress in effects of electric parameters on properties of anodic coatings on magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(11): 1829-1837.

[13] YEROKHIN A L, LYUBIMOV V V, ASHITKOV R V. Phase formation in ceramic coatings during plasma electrolytic oxidation of aluminium alloys[J]. Ceramics International, 1998, 24(1): 1-6.

[14] 王玉林, 沈德久. 铝材微弧氧化陶瓷膜的电绝缘性[J]. 轻合金加工技术, 2001, 29(10): 34-35.

WANG Yu-lin, SHEN De-jiu. Electric insulation of micro-arc oxidation ceramic coating on aluminium[J]. Light Alloy Fabrication Technology, 2001, 29(10): 34-35.

[15] 陈显明, 罗承萍, 刘江文, 李文芳. 镁合金微弧氧化热力学和动力学分析[J]. 兵器材料科学与工程, 2006, 29(3): 17-20.

CHEN Xian-ming, LUO Cheng-ping, LIU Jiang-wen, LI Wen-fang. Thermodynamic and kinetic analysis of micro-arc oxidation on magnesium alloy[J]. Ordnance Material Science and Engineering, 2006, 29(3): 17-20.

[16] 张鉴清. 电化学测试技术[M]. 北京: 化学工业出版社, 2010: 264-268.

ZHANG Jiang-qing. Electrochemical measurement technology[M]. Beijing: Chemical Industry Press, 2010: 264-268.

(编辑 龙怀中)

基金项目:江苏省优势学科建设项目(SZB20011-6);江苏省先进焊接技术重点实验室基金资助项目(JSAWT-11);江苏省研究生创新计划资助项目(CXZZ12-0716)

收稿日期:2013-04-15;修订日期:2013-12-20

通信作者:芦 笙,教授,博士;电话:0511-84407569;E-mail:lusheng88168@qq.com