基于UG的高精度棱体成形车刀CAD/CAM系统

刘吉兆1, 2, 何将三1, 邓朝晖3

(1.中南大学 机电工程学院, 湖南 长沙, 410083;

2.湖南工学院 机械工程系, 湖南 衡阳, 421008;

3.湖南大学 机械与汽车工程学院, 湖南 长沙, 410082)

摘要: 根据成形车刀的设计理论, 综合运用UG/OpenMenuScript, UG/Open UIStyler, UG/Open API和Visual C++6.0等UG二次开发工具, 开发出基于Windows XP和UG二次开发平台、 以VC为编程工具的成形车刀CAD/CAM系统。 该系统利用自动截形法获得成形车刀“零误差”刀刃廓形; 采用导入燕尾槽模型的方法, 利用最小半径控制点技术实现了棱体成形车刀的基于特征参数化设计; 使用数据库技术实现成形车刀的切削角度、 结构尺寸的参数化设计; 通过编程实现工程图的尺寸标注功能; 解决原来成形车刀设计的设计精度和效率低等问题, 消除了双曲线误差。 该系统实现了与UG系统的无缝集成, 具有良好的人机交互性、 可扩充性和可移植性。 借助该系统可直接快速、 准确地生成高精度棱体成形车刀工程图以及廓形的数控线切割加工程序。

关键词: 棱体成形车刀; UG; CAD/CAM系统; 参数化设计; “零误差”截形; 最小半径控制点

中图分类号:TG712; TP391.7 文献标识码:A 文章编号: 1672-7207(2005)06-1031-06

CAD/CAM system of high precision prismatic-formed turning tools based on UG

LIU Ji-zhao1, 2, HE Jiang-san1, DENG Zhao-hui3

(1.School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. Department of Mechanical Engineering, Hunan Institute of Technology, Hengyang 421008, China;

3. College of Mechanical and Automotive Engineering, Hunan University, Changsha 410082, China)

Abstract: A CAD/CAM system of forming turning tools is developed by useing UG/Open MenuScript, UG/Open UIStyler, UG/Open API and Visual C ++6.0, which regards Windows system and UG as a platform according to forming turning tools design theory. This system utilizes the method of intersecting work-piece automatically to obtain zero error intersection of the tools edge. Importing swallowtail trough model method and utilizing the technique of minimum radius control point, parametric design is realized based on feature on prismatic-formed turning tools. Cutting angle, parameters of structure dimension are designed by useing database technique, and the dimension-driven function is realized by means of system programming. This method solves the former problem of the tools design, such as low design precision and efficiency, etc, and eliminates the hyperbolic errors. This system realizes the integration of UG system, good man-machine interaction, expandability and portability, and can quickly, directly and accurately make not only the detail drawing of high precision prismatic-formed turning tools, but also the numerical control(NC) program of wire electric discharge machine(WEDM) of the tool profiles.

Key words: prismatic-formed turning tools; UG; CAD/CAM system; parameterized design; “zero error” intersection; minimum radius control point

成形车刀是广泛应用于各种车床及自动线加工的专用刀具, 可用于加工各种回转的成形表面, 主要用于大批量生产。 采用成形车刀加工精度稳定, 刀具使用寿命长, 刃磨简便, 加工精度高, 表面粗糙度可达到2.5~10 μm, 生产效率较高[1, 2]。 但是, 采用传统的图解法和计算法, 设计精度和效率低。 随着计算机技术的发展, 近年来出现的一些采取交互设计的成形车刀CAD系统[3-7], 也是以直线或圆弧近似地代替曲线设计廓形, 存在一定的廓形误差, 且没有实现参数化。 为此, 作者把Unigraphics(简称UG)的三维造型技术、 参数化设计技术及CAD/CAM技术结合使用, 开发出基于Windows XP和UG二次开发平台、 以Microsoft Visual Studio.NET为开发环境的成形车刀CAD系统。 该系统解决设计中的双曲线误差问题, 实现成形车刀的廓形“零误差”及参数化设计, 而且大大提高设计效率。 用户的工作只是选择工件材料、 工件模型和刀具材料, 输入工件材料的机械性能, 点击按钮便可自动实现成形车刀的设计。 在此, 在系统模块结构的基础上, 介绍棱体成形车刀设计系统的设计理论及关键技术、 系统程序编制及应用等。 设计生成的棱体成形车刀二维工程图文件能被数控线切割软件调用, 可以自动生成刀刃廓形的加工程序代码供线切割机床加工[8]。

1 系统开发工具及模块化设计结构

1.1 系统的开发平台及编程工具

成形车刀CAD/CAM系统以Windows XP操作系统和Unigraphics NX2.0[9]为支持平台, 利用UG/OPEN[10]中的API, UIStyler, MenuScript和Microsoft Visual Studio.NET联合进行二次开发。 UG/Open API编写的成形车刀应用程序编译后生成动态链接库文件(*.dll), 在UG软件启动时自动加载到UG运行环境中, 由Unigraphics自动分配内存, 成为UG的一部分, 直接控制UG的操作行为。 应用程序的执行代码小, 连接速度快, 运行结果可以在UG界面的图形窗口中显示。 由MenuScript编制的用户对话框形成与UG融合统一的界面, 采用中文交互式操作, 简捷直观, 操作方便, 具有良好的人机交互性、 可扩充性和可移植性。

1.2 系统的模块化设计结构

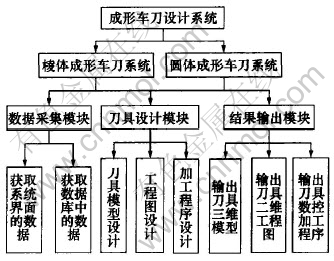

模块化设计有利于系统的设计与维护。 由于各个模块之间是相互独立的, 所以要更改某一模块的功能比较容易实现, 同时, 也不会影响其他的模块。 成形车刀设计系统分为棱体成形车刀设计系统和圆体成形车刀设计系统, 每一系统又各自分为3个模块: 数据采集、 刀具设计和结果输出模块。 各个主模块又包括很多分模块, 其模块化设计结构如图1所示。

图 1 成形车刀设计系统模块图

Fig. 1 Blocks of formed turning tool design system

2 棱体成形车刀设计系统的设计理论及关键技术

2.1 “零误差”截形理论

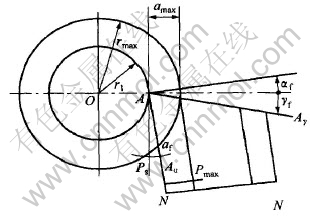

通过对成形车刀设计理论的研究, 可以得出零误差截形理论图, 如图2所示。 前刀面Aγ截取工件回转面, 其截交线为刀刃廓形, 刀刃廓形沿后刀面方向拉伸的曲面为刀具成形柱面, 在刀具成形柱面后刀面Aα的法剖面N—N内的截面曲线就是所求的刀具廓形。 由于成形车刀设计采用的是前刀面Aγ与工件实体相截交的方法, 图2中工件回转面(其中, r1为工件最小半径, rmax为工件最大半径, amax为工件最大切深)、 刀具成形柱面(其中, γf为刀具前角, αf为刀具后角, Pmax为刀具最大廓深)以及各个截面(Ps(切削平面), Aγ和Aα)可以用三维建模方法方便实现, 工件、 刀刃廓形和刀具廓形曲线上每一点数据均可以获得, 其误差由三维软件的造型误差决定, 而UG三维建模误差在小数点后11位, 几乎不存在设计误差[11], 可以说实现了设计上的“零误差”, 这就是棱体成形车刀廓形精确设计的基础。

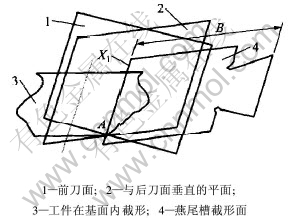

2.2 最小半径控制点技术

棱体成形车刀实体创建过程中利用最小半径控制点技术。 最小半径控制点即工件廓形最小半径圆与过工件轴线的刀具基面的交点, 如图3所示。 图中A为工件的最小半径控制点, 最小半径控制点把工件模型、 成形车刀形成的基准面、 燕尾槽截面紧密联系成有机体; B为刀体厚度。 利用数据库中的前角和后角值, 过最小半径点A创建基准面1和2。 为了简化应用程序编写, 系统采用导入燕尾槽的方法, 导入前燕尾槽截形面4的工作坐标X1必须约束在最小半径点, 这样, 才可以保证燕尾槽的结构尺寸标准化。

图 2 零误差截形理论图

Fig. 2 Theory diagram of zero error intersection

图 3 最小半径控制点技术图

Fig. 3 Technique diagram of minimum radius control point

2.3 燕尾槽结构设计关键技术

棱体成形车刀的装夹部分采用燕尾槽结构。 由于燕尾槽的结构比较复杂, 对于燕尾槽的设计方法是提前做好燕尾槽, 然后, 用import命令导入做好的燕尾槽, 调用数据库中的数据, 修改表达式的命令UF_MODL_edit_exp来修改相应的尺寸。 由于采用最小半径控制点技术, 使得燕尾槽的处理更加简便, 精简应用程序。

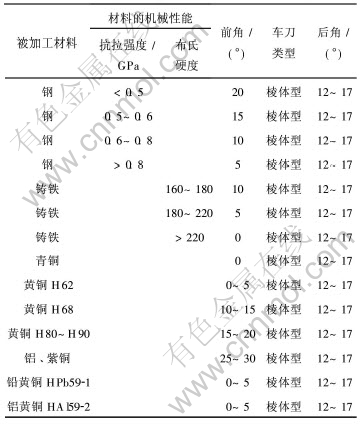

2.4 数据库技术

在系统的数据采集模块中, 成形车刀的切削角度、 燕尾槽结构尺寸的参数化设计主要用到数据库技术。 成形车刀的前角、 后角的大小根据用户选择的工件材料及其机械性能便可以在数据库中定位, 取出前角、 后角值。 这些数据表格采用VC++.NET的ADO(Active Data Object, 活动数据对象)直接操作Microsoft Office Access创建的数据库, 如表1所示。 ADO是一种基于组件对象模型的自动化接口技术[12, 13], 利用它可以简化数据库访问, 采用数据库访问技术明显缩短了开发时间, 并提供了更好的性能保证。

表 1 棱体成形车刀的前角和后角[1]

Table 1 Angles of prismatic-formed turning tool

3 系统编程流程图及应用程序设计

3.1 系统程序流程图

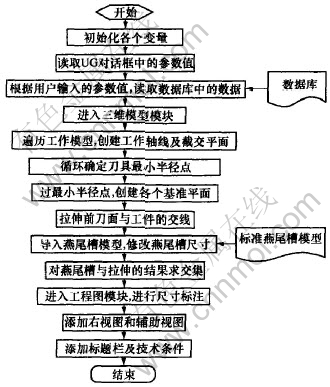

在棱体成形车刀CAD/CAM系统的开发过程中, 由于采用了前述的设计理论及关键技术, 才使得程序简洁, 结构紧凑, 输出结果具有更强的指导意义。 其系统程序流程图如图4所示。

3.2 应用程序设计

应用程序是基于特征的参数化形式编制的程序集合。 UG/Open API是基于UG的以Visual C++为编程环境的面向对象开发工具[14], 它几乎提供了UG中所有特征的函数类库和操作命令。 UG/Open API应用程序是用C/C++语言编写的, 它除了能够在UG环境下对UG进行功能调用外, 还能在程序中实现软件的文件管理、 流程控制、 数据传输、 窗口调用、 数值计算等C/C++语言支持的全部功能, 所以, 使用非常灵活。 棱体成形车刀CAD设计系统中的创建、 信息提示、 警告信息输出、 逻辑判断、 相关建模参数计算、 表达式编辑更新、 尺寸标注, 以及工程图创建与修改等功能都是通过Visual C++编写的UG/Open API应用程序来实现的[15]。

图 4 系统程序流程图

Fig. 4 Flow chart of system program

UG/Open API应用程序通过编译构建生成动态链接库(*.dll)文件。 生成的*.dll文件放在用户目录下的\startup目录内, UG启动时会自动加载动态链接库文件, 供用户菜单调用。

在棱体成形车刀CAD系统的开发过程中, 首先必须在用户对话框和用户菜单之间建立相应的联系, 其中用到的用户应用程序接口如下:

extern void ufsta (char *param, int *retcode, int rlen)

{ int error_code;

if ( (UF_initialize()) != 0)

return;

if ( (error_code = UF_MB_add_styler_actions ( actions ) ) != 0 )

{ char fail_message[133];

UF_get_fail_message(error_code, fail_message);

printf ("%s\n", fail_message );

}

UF_terminate();

return;

}

4 设计实例及设计结果

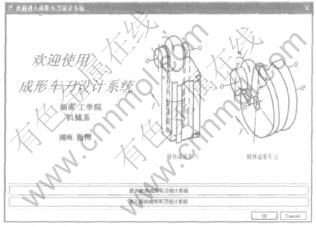

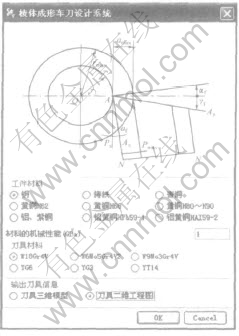

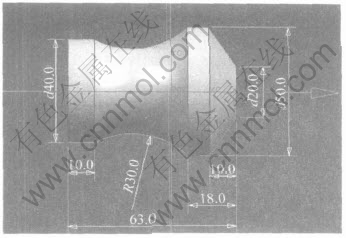

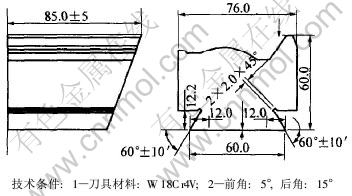

首先进入系统总界面(如图5所示), 选择棱体成形车刀设计系统出现图6所示的对话框中, 选择工件材料: 钢; 输入工件材料的机械性能——抗拉强度σb, 1 GPa; 选择刀具材料: W18Cr4V; 选择输出信息。 点击OK按钮, 再根据后面的提示即可完成加工工件(见图7)的棱体成形车刀的设计。 得出的棱体成形车刀三维模型、 二维工程图分别如图8和图9所示。

图 5 系统界面

Fig. 5 System interface

图 6 子系统对话框

Fig. 6 Dialog box of subsystem

利用安装在线切割机床上的CAXA线切割软件, 调用UG生成的二维工程图文件, 点击需加工的刀具廓形, 进行有关的后置处理, 即可生成刀具廓形的线切割加工数控程序代码。

图 7 工件三维模型

Fig. 7 3D model of work-piece

图 8 刀具三维模型

Fig. 8 3D model of tool

图 9 刀具二维工程图

Fig. 9 Detail drawing of tool

5 结 论

a. 通过分析棱体成形车刀及与工件模型的几何关系, 利用UG强大的三维造型功能, 棱体成形车刀CAD系统采用截形法获得刀刃廓形, 取代了原来设计的作图法、 计算法及增加组成点计算工件廓形来提高设计精度等方法, 实现了“零误差”设计。 同时, 用户可以为系统提供精确的工件模型, 这与草图相比, 更能保证刀具的设计质量, 从而大大提高了设计精度。

b. 使用数据库技术实现成形车刀的切削角度、 结构尺寸等的参数化设计; 采用导入燕尾槽模型的方法, 通过读取刀具结构数据库的数据, 采用最小半径控制点技术, 实现了棱体成形车刀基于特征的参数法造型设计, 从而大大简化了应用程序。

c. 由于棱体成形车刀的结构特征相似, 计算方法统一, 设计过程一致, 把不同的成形车刀看作同一系列产品。 通过建立的工件廓形最小半径控制点, 使设计过程不再依赖于具体的工件廓形, 每次只需用新的工件廓形替代原有的工件廓形就可以自动实现成形车刀的三维参数化自动设计。 采用这种设计方法有效地减少了修改设计的时间及成本, 提高了成形车刀的设计效率。

d. 开发的CAD/CAM系统的用户菜单直接挂在UG系统的主菜单上, 利用UG/Open UIStyler制作了UG风格的对话框, 简捷直观, 操作方便, 实现了与UG系统的无缝集成, 具有良好的人机交互性、 可扩充性和可移植性。 通过编程实现了工程图的尺寸标注, 使成形车刀的工程图对实际生产更具有指导性。

e. 该系统开发成功, 用户的工作只是选择工件材料、 刀具材料和工件模型, 输入工件材料的机械性能, 点击按钮便可自动实现棱体成形车刀的精确设计。 利用线切割机床上安装的CAXA线切割软件调用UG生成的棱体成形车刀二维工程图文件, 进行相关的处理, 生成车刀廓形线切割加工程序, 启动机床就可将刀具廓形加工出来。 本系统的设计思想和方法不仅适合于棱体成形车刀CAD/CAM系统的二次开发, 还可为其他专用CAD/CAM系统的二次开发提供参考。

参考文献:

[1]张维纪. 金属切削原理及刀具[M]. 杭州: 浙江大学出版社, 2002.

ZHANG Wei-ji. Principle and Tools of Metal Cutting[M]. Hangzhou: Zhejiang University Press, 2002.

[2]陆剑中, 孙家宁. 金属切削原理与刀具[M]. 北京: 机械工业出版社, 1998.

LU Jian-zhong, SUN Jia-ning. Principle and Tools of Metal Cutting[M]. Beijing: Mechanical Industry Press, 1998.

[3]郑友益, 徐云龙. 成形车刀的计算机辅助设计[J]. 精密制造与自动化, 2002 (4): 35-37.

ZHENG You-yi, XU Yun-long. Computer aided design of formed turning-cutter[J]. Precise Manufacturing & Automation , 2002 (4): 35-37.

[4]叶伟昌, 郑良红, 汪通悦. 棱体成形车刀廓形的简化设计与制造[J]. 机械设计与制造工程, 1999, 28(1): 22-25.

YE Wei-chang, ZHENG Liang-hong, WANG Tong-yue. The simplified design and manufacture of prism formed turning tool profile[J]. Machine Design and Manufacture Engineering, 1999, 28 (1): 22-25.

[5]陈为国. 基于AUTOCAD的成形车刀廓形设计方法[J]. 工具技术, 2001, 35(3): 21-23.

CHEN Wei-guo. AutoCAD based graphing design method for profiles of forming turning tools[J]. Tool Engineering, 2001, 35(3): 21-23.

[6]陈辽军. 基于Solid Works特征造型的成形车刀参数化设计[J]. 工具技术, 2003, 37(7): 43-46.

CHEN Liao-jun. Parameter design of formed turning tools based on characteristic moulding of solid works[J]. Tool Engineering, 2003, 37(7): 43-46.

[7]王有远. 棱体成形车刀的计算机辅助设计[J]. 工具技术, 2001, 35(12): 22-24.

Wang You-yuan. CAD of flat forming turning tools[J]. Tool Engineering, 2001, 35(12): 22-24.

[8]陈辽军, 程伟. 用于成形车刀CAD/CAM的三维实体造型法[J]. 工具技术, 2000, 34(11): 18-21.

CHEN Liao-jun, CHENG Wei. 3D solid sculpting method for CAD/CAM of forming turning tools [J]. Tool Engineering, 2000, 34(11): 18-21.

[9]洪如瑾. UG CAD快速入门指导[M]. 北京: 清华大学出版社, 2002.

HONG Ru-jin. Celerity Introduction Guidance of UG CAD[M]. Beijing: Tsinghua University Press, 2002.

[10]董正卫, 田立中, 付宜利. UG/OPEN API编程基础[M]. 北京: 清华大学出版社, 2002.

DONG Zheng-wei, TIAN Li-zhang, FU Yi-li. Programming Foundation of UG/OPEN API[M]. Beijing: Tsinghua University Press, 2002.

[11]张鹏. 棱体成形车刀的三维参数化设计[J]. 工具技术, 2003, 37(6) : 25-29.

ZHANG Peng. 3D parametric design for prismatic form turning tool [J]. Tool Engineering, 2003, 37(6) : 25-29.

[12]东方人华, 张红中, 郇春艳. Visual C++. NET范例入门与提高[M]. 北京: 清华大学出版社, 2003.

DONGFANG Ren-hua, ZHANG Hong-zhang, XUN Chun-yan. Visual C++. NET Example Introduction and Elevation[M]. Beijing: Tsinghua University Press, 2003.

[13]Kruglinski D J, Wingo S, Shepherd G. Programming Microsoft Visual C++ 6. 0技术内幕[M]. 希望图书创作室, 译. 北京: 北京希望电子出版社, 1999. 509-524.

Kruglinski D J, Wingo S, Shepherd G. Technique Low-down of Programming Microsoft Visual C++ 6. 0[M]. Hope Books Produce Room, translates. Beijing: Beijing Hope Electron Press, 1999. 509-524.

[14]王庆林. UG/OPEN GRIP 实用编程基础[M]. 北京: 清华大学出版社, 2002.

WANG Qing-lin. Practical Programming Foundation of UG/OPEN GRIP [M]. Beijing: Tsinghua University Press, 2002.

[15]陈青, 陈军. 基于UGII的二次开发中特征的分类和描述[J]. 机械设计, 2003, 20(1): 64-66.

CHEN Qing, CHEN Jun. Characteristic classifying and describing based on UGII re-development[J]. Journal of Machine Design, 2003, 20(1): 64-66.

收稿日期:2005-04-26

基金项目: 湖南省教育厅科研基金资助项目(02C014)

作者简介: 刘吉兆(1964-), 男, 湖南常宁人, 博士研究生, 副教授, 从事机械CAD/CAM技术、 数控及高速切削加工技术研究

论文联系人: 刘吉兆, 男, 博士研究生; 电话: 0734-8432321(O); E-mail: liujz080@163.com