DOI:10.19476/j.ysxb.1004.0609.2019.02.07

丝粉同步激光沉积制备WCp/Al复合材料构件工艺

李福泉1,李明伟1,冯鑫友1,孙 靖2,王联凤2

(1. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001;

2. 上海航天设备制造总厂,上海 200245)

摘 要:利用丝粉同步激光沉积技术直接制备成型良好的WCp/Al复合材料单层与叠层沉积件,对工艺参数进行优化,获得了成型良好的单层沉积件。结果表明:可通过改变束流气的大小来改善WC颗粒分布的均匀性;降低激光功率可削弱热积累对叠层沉积件成型造成的有害影响,但激光功率的降低存在一临界值;沉积件冶金质量良好,区域微观结构较为均匀。底层沉积层组织存在由柱状晶向枝晶的转变,WC及Ti的存在会抑制柱状晶的生长,并且可以起到细化晶粒的作用;随着沉积层层数逐渐增加,热积累作用逐渐增强,枝晶的尺寸会逐渐增加。

关键词:激光沉积;WCp/Al复合材料;丝粉同步;微观组织

文章编号:1004-0609(2019)-02-0270-09 中图分类号:TG174.453 文献标志码:A

颗粒增强铝基复合材料具有比强度高、热膨胀系数低、耐磨性优良等特点[1-2]。目前,制备颗粒增强铝基复合材料的方法主要包括粉末冶金、搅拌铸造、原位反应等[3-4]。然而,上述方法制备的颗粒增强铝基复合材料成本高[5],并且在实际应用时需要经过机加工或者焊接工序,而增强相的存在使得机加工及焊接变得困难,这使得上述技术的应用受到了一定程度的限制。利用激光沉积方法制备复合材料可以实现近净成型,减少机加工和焊接量,在颗粒增强铝基复合材料构件直接制备方面具有明显的优势。

激光沉积是利用高能激光束同时熔化送给材料与基材表面薄层以形成冶金结合的沉积层的技术。根据沉积材料形态的不同,材料送给方法主要分为送粉式和送丝式[6-7]。送粉式激光沉积[8]中的粉末具有能量吸收效率高,工艺自动化程度高等优点;但存在粉末利用率低,制备的成品孔隙率大等问题。送丝式激光沉积[9-10]具有成型致密度高、成本低等优点;但存在重复率低、对激光能量吸收效率较低的问题。丝粉同步添加激光沉积技术可综合两种方式的优势,同时避免两者的缺点。XU等[11]利用4 kW的连续光纤激光器和一台电弧焊设备送给316L不锈钢丝,通过优化工艺参数在316L不锈钢基板上成功地制备了沉积层数为十层的样品。张霜银等[12]利用 CO2激光器通过旁轴送粉的方式成功制备TC4合金,研究了激光功率、扫描速度等工艺参数对TC4合金外观成型的影响。WANG等[13]利用同步添加 Ti-25V-15Cr-2Al-0.2C粉末和 Ti-6Al-4V丝的激光沉积方式制备出了复合材料层,说明利用丝粉同步激光沉积方法具备可行性。同样,WANG等[14]利用激光沉积技术,同步添加TiC粉末和Ti-6Al-4V丝,研究了不同TiC粉末送粉速率对复合材料层的影响作用,结果表明,送粉速率会影响熔池的尺寸与温度。

本文采用旁轴送丝同轴送粉的激光沉积技术,通过优化工艺参数制备了外观成型良好的单层与叠层沉积件。在此基础上,对丝粉同步激光沉积制备的WCp/Al复合材料的微观组织及相结构进行了分析,研究了叠层沉积过程中的热积累对成型件宏观形态及组织的影响。

1 实验

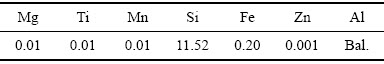

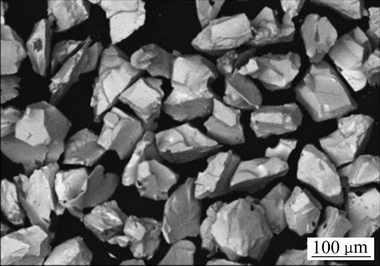

丝粉同步激光沉积实验所用的基板为100 mm× 50 mm×6 mm的6061铝合金板。丝材采用直径为1.2 mm 的4047铝丝,其化学成分如表1所示。粉体选择WC陶瓷颗粒及Ti粉颗粒。其中,WC颗粒大小为45~100 μm,其SEM像如图1所示。图2所示为纯金属Ti粉末的SEM像,宏观呈圆形,表面比较光滑,颗粒大小约为45 μm。Ti粉在本实验中起的作用主要是合金化。实验前进行WC和Ti粉的均匀混合,WC和Ti粉末混合的质量比为4:1。

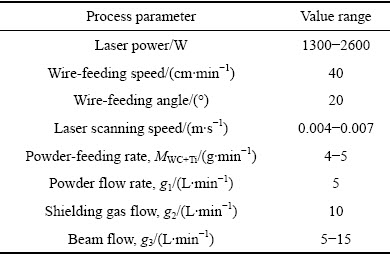

实验采用4 kW半导体激光器作为激光光源,配备1个KUKA六轴联动机器人,可实现在X、Y、Z3个方向上的移动,定位精度为0.1 mm。送粉器采用新松送粉器,送粉精度可以达到0.1 g/min,可以通过调节送粉盘的转速调节粉末的流量,保证送粉的均匀性。熔敷头采用德国PECTIEC公司生产的YC52型同轴熔敷头。经调试,熔敷头距离板材表面15 mm时,形成的激光光斑直径为2 mm,适于激光沉积。本研究采用同轴送粉、旁轴送丝激光沉积技术(粉通过熔敷头进行同轴送粉,同时在旁轴送进4047铝丝)制备 WCp/Al 复合材料沉积件。激光同时作用于粉、丝及基板,在基板上形成沉积层,整个装置如图3所示。

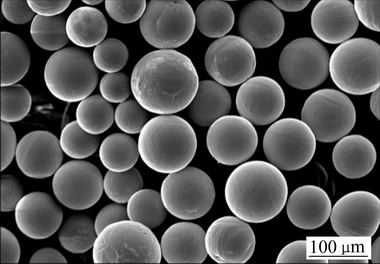

表1 ER4047铝合金成分组成

Table 1 Chemical composition of ER4047 aluminum alloy (mass fraction, %)

图1 WC颗粒的SEM像

Fig. 1 SEM image of WC particles

图2 Ti金属粉末的SEM像

Fig. 2 SEM image of Ti particles

表2 激光沉积工艺参数表

Table 2 Laser deposition process parameters table

图3 丝粉同步激光沉积示意图

Fig. 3 Schematic diagram of simultaneous laser deposition

金相试样抛光后,采用腐蚀液1%HF+1.5%HCl+ 2.5%HNO3+95%H2O(体积分数)进行腐蚀。金相分析采用VHX-1000光学显微镜;沉积层中的物相分析采用 D/MAX-RB 型射线衍射仪进行。

2 结果与分析

2.1 单道沉积工艺成型优化

2.1.1 单道沉积层成型状态分析

表3所示为不同激光功率和激光扫描速度(其余工艺参数均为:送丝速度vf=0.40 m/min,送丝角度θ=20°,送粉载气流量g1=5 L/min,保护气流量g2=10 L/min,束流气流量g3=10 L/min,MWC+Ti=5 g/min)下的单层沉积层宏观成型及横截面。热输入的变化显著影响沉积层外观成型。在热输入为440 J/mm时,沉积层外观成型良好,表面光洁;而当激光能量热输入偏高及偏低时,沉积层外观均存在明显的成型缺欠。

表3 不同工艺参数下单层沉积层的宏观成型及横截面

Table 3 Macro-molding and cross-section of single-layer under different process parameters

由文献[14]可知,进行激光丝粉同步沉积时,送入的丝是通过激光直接辐照熔化形成熔滴的,而送入的粉会在一定程度上屏蔽激光对丝的作用,所以只有在激光能量足够大时,丝的熔化及其熔滴进入熔池的过程才会平稳地进行。在本试验中,当热输入为257 J/mm和333 J/mm时,有相当一部分激光能量被粉末吸收、屏蔽,丝吸收的激光能量较小,熔化量较少,熔滴过渡不平稳,进而导致沉积层外观成型出现严重的缺欠。由于本试验中送粉速率一定,粉吸收的激光能量及其屏蔽作用有限,当热输入增加时,丝吸收的激光能量增加,熔化量增加,熔滴过渡趋向平稳,沉积层外观成型得到改善。热输入为440 J/mm时,外观成型良好,表面光洁;当热输入继续增加,达到600 J/mm时,丝吸收的激光能量过大,这时同样会影响熔滴的正常过渡,外观成型出现一定程度的缺欠。上述现象说明,要想保证良好的外观成型,需要合理控制热输入。

从单层沉积层横截面可以看出,在热输入较低时,存在较为严重的“WC沉底”现象,随着热输入的增加,“WC沉底”现象逐渐得到缓解,当热输入达到600 J/mm时,WC分布较为均匀。在激光沉积过程中,熔池快速形成、快速凝固;当热输入较小时,熔池凝固时间太短,不足以使WC实现均匀化;当热输入增加时,熔池凝固时间增加,WC在熔池内运动时间增加,有足够的时间来实现均匀化。

2.1.2 沉积层WC分布分析

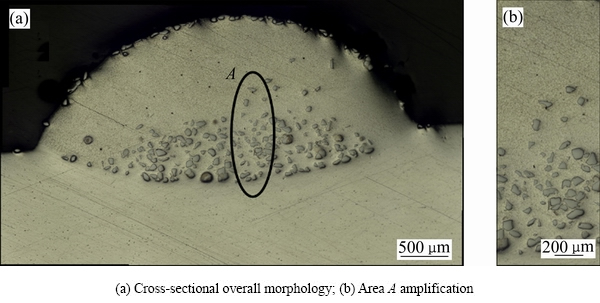

分布均匀的WC在铝基复合材料中既可以起到第二相强化,又能起到弥散强化的作用,所以有必要对WC分布优化进行研究,对于出现“WC沉底”现象的原因进行分析。如图4所示,为激光功率P=2000 W,扫描速度vs=0.005 m/s,送粉速率MWC+Ti=5 g/min时的单层沉积层横截面,沉积层发生“WC沉底”现象,将区域A放大,发现沉底的WC颗粒的尺寸不存在明显的规律,说明在本试验中WC颗粒尺寸对“WC沉底”现象的影响不大。

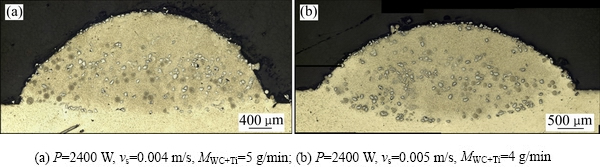

丝粉同步激光沉积试验时,当送粉速率较高时,会造成粉末的不均匀分布。图5(a)所示为激光功率P=2400 W、扫描速度vs=0.004 m/s、送粉速率MWC+Ti= 5 g/min的单层沉积层横截面;图5(b)所示为激光功率P=2400 W、扫描速度vs=0.005 m/s、送粉速率MWC+Ti=4 g/min的单层沉积层横截面。图5(a)中沉积层的热输入大于图5(b)中沉积层的,但可以看出,图5(b)中沉积层中WC分布的均匀性优于图5(a)中沉积层的。出现上述现象的原因在于图5(b)中沉积层的送粉速率小于A沉积层的,这说明降低送粉速率可促进粉末的均匀分布。由于本试验制备的复合材料需要保证WC增强相具有一定比例,故不宜过多地降低送粉速率。

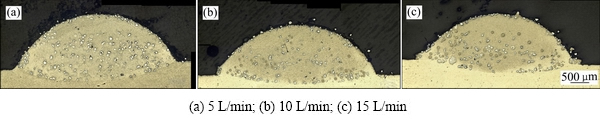

WC颗粒在熔池中的分布受颗粒进入熔池时的初始速度影响。WC进入熔池时的初始速度越大,初始动能就越大,WC就越有向下运动的趋势。而本研究中影响WC速度的可变工艺参数为束流气速度vg。改变束流气速度vg具体到工艺参数的变化为改变束流气g3的大小。图6所示为不同束流气流量下沉积层内WC分布情况。由图6可以看出,随着束流气流量的增加,WC颗粒发生下沉的数目增加。其中,当束流气流量g3为5 L/min和10 L/min时,WC分布较为均匀。其他工艺参数均为如下数值:激光功率P=2400 W,扫描速度vs=0.005 m/s,送丝速度vf=0.40 m/min,送丝角度θ=20°,送粉的气流量g1=5 L/min,保护气流量g2=10 L/min,送粉速率MWC+Ti=5 g/min。

图4 单层沉积层横截面

Fig. 4 Single-layer deposition layer cross-section

图5 单层沉积层横截面

Fig. 5 Cross-sections of single-layer deposition layers

图6 不同束流气大小下WC分布

Fig. 6 WC distributions under different beam flows

实验研究综合考虑实现良好的外观成型及均匀的WC分布,确定单层沉积层的优化工艺参数为:激光功率P=2400 W,扫描速度vs=0.005 m/s,送丝速度vf=0.40 m/min,送丝角度θ=20°,送粉的气流量g1=5 L/min,保护气流量g2=10 L/min,束流气流量g3=10 L/min,送粉速率4 g/min。选择激光功率P=2400 W、扫描速度vs=0.005 m/s是综合考虑热输入对成型及WC分布的影响,既保证成型良好又可在一定程度上实现WC颗粒均匀化。将送粉速率选择为4 g/min,为了使WC分布更均匀。同样,为了使WC分布均匀,选择束流气流量10 L/min。在此工艺参数下的沉积层外观成型如图7所示,横截面成型如图5(b)所示。由图7可以看出,对工艺参数进行优化后,实现了对外观成型及WC分布的综合优化。

图7 优化工艺参数下的单层沉积层的外观成型

Fig. 7 Appearance molding of single-layer deposition under optimized process parameters

2.2 叠层沉积件成型优化

在进行激光叠层沉积时,沉积件易出现的成型问题是沉积件的下塌与变形。沉积件的下塌与变形主要与沉积宽度的不稳定有关,故本试验对叠层沉积件进行成型优化时,选择沉积层宽度为主要的控制指标。不同于单层沉积,进行叠层沉积时需要考虑热积累问题。叠层沉积件在经过多次循环加热后,热积累作用加强,热积累作用使熔池尺寸发生变化,熔池凝固后沉积层宽度发生变化,从而出现叠层沉积件的成型问题。在沉积层数较少时,热积累较少,可以在一定程度上忽略热积累的作用;但当沉积层数较多,其对沉积层成型的影响不可忽略。可以采用逐层降低热输入的方式来降低热积累对成型的有害影响,从而控制各层沉积层宽度均匀一致。本试验中逐层降低热输入是通过逐层降低激光功率来实现的。

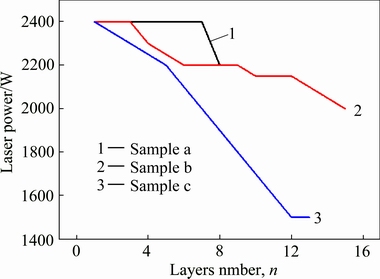

图8 叠层沉积件不同层的激光功率

Fig. 8 Laser power of different layers of multilayer deposit

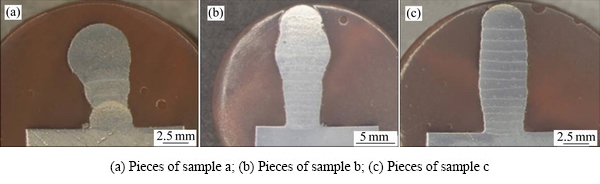

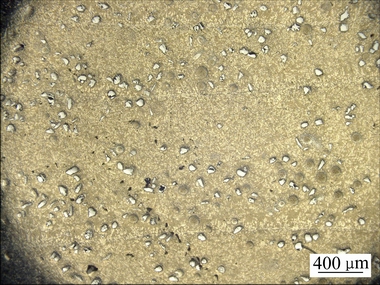

图8所示为叠层沉积件沉积时随层数变化的激光功率值。图9所示为叠层沉积件的宏观成型。从试件a的宏观成型可以看出,从第四层开始,沉积层宽度持续变大,并出现一定程度的倾斜现象,最后叠层沉积件呈“蘑菇”状。造成上述现象的原因是激光功率一直保持在较高水平。随沉积层数的增加,熔池接收的热量越来越高,熔池宽度也会越来越大,凝固后出现沉积层的下塌和整体沉积件的倾斜现象。不同于试件a,试件b从第四层开始随层数增加缓慢降低激光功率,激光功率的降低在一定程度上削弱了热积累的作用,沉积层宽度变化较小。但试件b自第六层开始,保持激光功率为2200 W不变,发现沉积层宽度随层数增加显著增加。试件b自第十层开始,继续降低激光功率,发现沉积层宽度显著减小。上述现象说明,降低激光功率可以削弱热积累作用,使沉积层宽度不致一直增加而发生下塌现象。试件c同样采用逐层降低激光功率的方法来削弱热积累的作用。可以看出,试件c存在两段不同的激光功率降低区域。对比来看,前五层的激光功率降低幅度较小,沉积层宽度存在小幅度的增加;而自第六层以后,激光功率降低幅度增加,沉积层宽度变化较小,宽度趋于一致。如图10所示,为试件c的WC颗粒分布。由图10可以看出,WC颗粒分布较为均匀。图10经Image Pro Plus 分析得出,WC颗粒所占的面积分数约为22.6%。

利用逐层降低激光功率的方法制备了如图11所示的44层沉积件。沉积件的宏观立体成型如图11所示,激光功率变化如图12所示。由图12可以看出,在沉积层数较少时,适当地降低激光功率可以削弱热积累的有害作用,使沉积层宽度保持一致;当沉积层到达区域A时,热积累对沉积层宽度的影响较为明显地显现出来,沉积层宽度增加,此时进一步加大激光功率降低的幅度,发现沉积层宽度迅速趋于一致;在激光功率降低至1300 W时,即沉积层到达区域B时,沉积层宽度呈减小趋势;为了保证沉积层宽度的一致性,将接近顶端沉积层的激光功率提升至1400 W,沉积层宽度趋于一致。上述现象说明,可以增加激光功率降低的幅度来进一步降低热积累对沉积层成型的有害作用。但逐层降低的激光功率存在一临界值,在临界值以下进行激光沉积时,熔池接收的激光能量过小,会导致熔池尺寸减小,凝固后形成的沉积层的宽度减小,这同样会造成成型缺欠。本试验的激光功率临界值在1300~1400 W之间。

图9 沉积层的形貌

Fig. 9 Morphologies of sedimentary layers

图10 叠层沉积件WC颗粒分布

Fig. 10 WC particles distribution of multilayer deposit

图11 44层沉积件立体的成型图

Fig. 11 3D morphology of 44 deposited layers

图12 44层沉积件激光功率变化图

Fig. 12 Variation curve of laser power of 44 layers

2.3 叠层激光沉积件微观组织分析

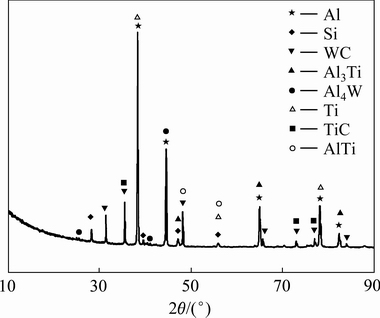

图13 沉积件XRD谱

Fig. 13 XRD pattern of deposition

首先对激光沉积制备的WCp/Al复合材料中的相组成进行了分析,XRD为确认相组成的分析手段。XRD结果如图13所示。从图13中可以看出,沉积层含有的相为Al、Si、WC、Ti、 Al3Ti、Al4W、TiC、AlTi等。在本试验中,不存在Al4C3脆性相,这是由于Ti与C的亲和力大于Al与C的亲和力,生成TiC 从而抑制了Al4C3的形成[17]。Ti在本试验中起到了合金化的作用。

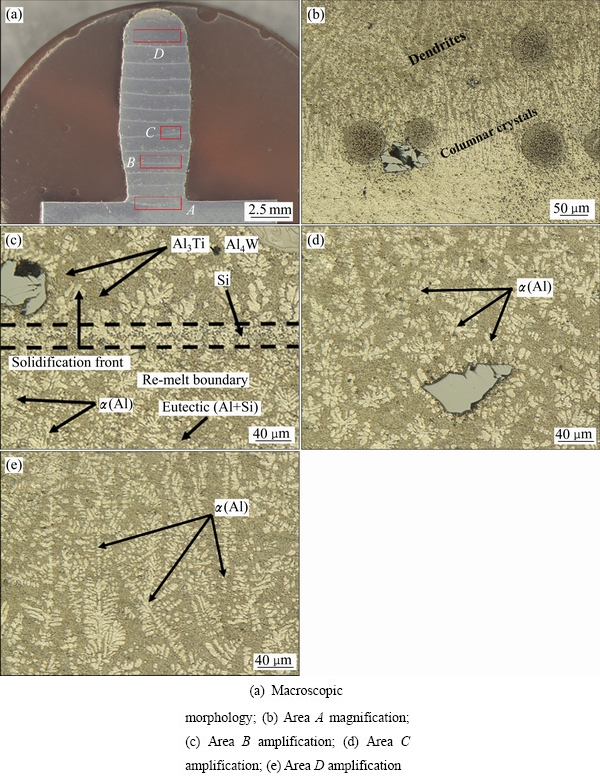

图14所示为13层沉积件的纵截面。图14(a)可以看出,在层与层之间存在明显清晰的边界线。底层的厚度最薄,中间层的厚度比较均匀,顶层的厚度最大。底层与基板接触,热量存在一定程度的散失,故厚度较小;中间层的沉积过程较为稳定,厚度比较均匀;顶层不存在下一层对其的重熔作用,故厚度最大。沉积件没有明显的气孔、裂纹等缺陷,质量较高。冶金结合较好,区域微观结构较均匀。没有明显的外延生长现象。观察底层沉积层微观结构,发现沉积层与基体结合处存在柱状晶。由于基板初始为“冷态”,温度梯度较大,形成柱状晶,而后随着固液界面的移动以及温度梯度G在凝固过程中逐渐减小,底层微观结构由柱状枝晶向树枝晶转变。柱状晶在接近基板的部分生长较充分,可达到1.8 mm。但在有WC及Ti存在的区域,柱状晶的生长受到了明显抑制,晶粒大小明显变小,上述变化如图14(b)所示。

如图14(c)所示,B区域为层与层之间的重熔层,可以发现柱状晶基本消失,只在重熔区存在柱状晶,且尺寸很小。这是热积累作用使得温度梯度降低所造成的。重熔区附近的组织由Al-Si共晶基体、α(Al)树枝晶、细小的Al3Ti和Al4W以及外加的不规则WC和球形Ti组成。细小的Al3Ti和Al4W分布均匀。在重熔区发现一些黑色颗粒物,其为Si颗粒。激光沉积的冷却速度快,在最初凝固时,形成的基体为铝硅亚共晶,当进行下一层沉积时,重熔区附近实现再次加热,而后空冷。在某种程度上可以认为进行了一定程度的固溶处理,使Si颗粒析出。如图14(d)~(e)所示,可以发现,随着沉积层不断长高,枝晶尺寸逐渐增大,尺寸可达到150~200 μm。这是因为当沉积层数逐渐增加时,热积累作用不断加强,枝晶生长会越来越充分。

图14 叠层沉积件的Z向组织

Fig. 14 Z-direction microstructures of multilayer deposition

3 结论

1) 合理的热输入可使单层沉积层具备良好的外观成型,合理的束流气流量可使单层沉积层中WC颗粒分布变得均匀。综合考虑实现良好的外观成型与均匀的WC颗粒分布,确定激光沉积制备WCp/Al复合材料单层沉积层的优化工艺参数为:激光功率P= 2400 W,扫描速度vs=0.005 m/s,送丝速度vf=0.40 m/min,送丝角度θ=20°,送粉的气流量5 L/min,束流气流量10 L/min,保护气流量10 L/min,送粉速率4 g/min。

2) 进行叠层沉积时,可逐层降低激光功率来削弱热积累对沉积层成型的有害作用,保证沉积层宽度一致,进而得到外观成型良好的叠层沉积件。但激光功率的降低存在一个最低临界值,本试验在1300~1400 W之间。

3) 对叠层激光沉积件的微观组织分析结果表明,沉积件冶金质量良好,区域微观结构较为均匀。底层沉积层组织存在由柱状晶向枝晶的转变,WC及Ti的存在会抑制柱状晶的生长,并且可以起到细化晶粒的作用;随着沉积层数逐渐增加,热积累作用逐渐加强,枝晶的尺寸会逐渐增加。

REFERENCES

[1] 王丽雪, 曹丽云, 刘海鸥. 铝基复合材料研究的进展[J]. 轻合金加工技术, 2005, 33(8): 10-12.

WANG Li-xue, CAO Li-yun, LIU Hai-ou. Progress in the research of aluminum matrix composites[J]. Light Alloy Processing Technology, 2005, 33(8): 10-12.

[2] MAO C H, SUN X D, LIANG Q S, YANG J, DU J. Interfacial reaction process of the hot-pressed WC/2024Al composite[J]. Rare Metals, 2013, 32(4): 397-401.

[3] 刘 海. 机械搅拌法制备SiC颗粒增强铝基复合材料技术研究[D]. 重庆: 重庆大学, 2007.

LIU Hai. Study on preparation of SiC particle reinforced aluminum matrix composites by mechanical stirring method[D]. Chongqing: Chongqing University, 2007.

[4] 肖伯律, 马宗义, 王全兆, 倪丁瑞, 毕 敬. 高性能铝基复合材料的设计与加工技术[J]. 中国材料进展, 2010, 29(4): 28-35.

XIAO Bo-lu, MA Zong-yi, WANG Quan-zao, NI Ding-duan, BI Jin. Design and processing technology of high performance aluminum matrix composites[J]. Progress in Chinese Materials, 2010, 29 (4): 28-35.

[5] 李德溥, 姚英学, 袁哲俊. 颗粒增强金属基复合材料加工技术进展[J]. 工具技术, 2006, 40(10): 3-9.

LI De-pu, YAO Ying-xue, YUAN Zhe-jun. Progress in processing technology of granular reinforced metal matrix composites[J]. Tool Technology, 2006,40(10): 3-9.

[6] TOYSERKANI E, KHAJEPOUR A, CORBIN S. Laser cladding[M]. Florida: CRC Press, 2005: 26.

[7] 张魁武. 国外激光沉积材料工艺和组织性能的研究[J]. 金属热处理, 2002, 27(6): 1-8.

ZHANG Kui-wu. Study on the process and microstructure of laser deposition materials in abroad[J]. Metal Heat Treatment, 2002, 27 (6): 1-8.

[8] KARUNAKARAN K P, BERNARD A, SURYAKUMAR S, DEMBINSKI L, TAILLANDIER G. Rapid manufacturing of metallic objects[J]. Rapid Prototyping Journal, 2012, 18(4): 264-280.

[9] BRANDL E, MICHAILOV V, VIEHWEGER B, LEYENS C. Deposition of Ti-6A-4V using laser and wire, Part Ⅰ: Microstructural properties of single beads[J]. Surface and Coatings Technology, 2011, 206(6): 1120-1129.

[10] BRANDL E, MICHAILOV V, VIEHWEGER B, LEYENS C. Deposition of Ti-6Al-4V using laser and wire, Part Ⅱ: Hardness and dimensions of single beads[J]. Surface and Coatings Technology, 2011, 206(6): 1130-1141.

[11] XU Xiang, MI Gao-yang, LUO Yuan-qing. Morphologies, microstructures and mechanical properties of laser metal deposition with 316L stainless wire[J]. Optics and Lasers in Engineering, OLEN-D-16-00736.

[12] 张霜银, 林 鑫, 陈 静. 工艺参数对激光快速成形TC4钛合金组织及成形质量的影响[J]. 稀有金属材料与工程, 2007, 10(36): 1839-1843.

ZHANG Shuang-yin, LIN Xin, CHEN Jing. Effect of process parameters on microstructure and forming quality of TC4 titanium alloy by laser rapid prototyping[J]. Rare Metal Materials and Engineering, 2007, 10(36): 1839-1843.

[13] WANG F, MEI J, WU X. Microstructure study of direct laser fabricated Ti alloys using powder and wire[J]. Applied Surface Science, 2006, 253(3): 1424-1430.

[14] WANG F, MEI J, JIANG H, WU X. Laser fabrication of Ti-6Al-4V/TiC composites using simultaneous powder and wire feed[J]. Materials Science and Engineering A, 2007, 445: 461-466.

[15] VREELING J A, OCELIK V, PEI Y T, van AGTERVELD D, de HOSSON J T M. Laser melt injection in aluminum alloys: On the role of the oxide skin[J]. Acta Materialia, 2000, 48(17): 4225-4233.

[16] FU Y, LOREDO A, MARTIN B, VANNES A B. A theoretical model for laser and powder particles interaction during laser cladding[J]. Journal of Materials Processing Technology, 2002, 128(1/3): 106-112.

[17] LI Fu-quan, GAO Zhen-zeng, ZHANG Yang, CHEN Yan-bin. Alloying effect of titanium on WCp/Al composite fabricated by coincident wire-powder laser deposition[J]. Materials & Design, 2016, 93: 370-378.

Process of WCp/Al matrix compound fabricated by coincident wire-powder laser deposition

LI Fu-quan1, LI Ming-wei1, FENG Xin-you1, SUN Jing2, WANG Lian-feng2

(1. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China

2. Shanghai Aerospace Equipment Manufacturer, Shanghai 200245, China)

Abstract: The well-formed monolayer and laminated WCp/Al composites were fabricated by coincident wire-powder laser deposition. The ideal macroscopic shape of single layer deposition was obtained through parameters optimized. The results show that the uniformity of the WC particles distribution can be improved by changing the size of the beam gas, and reducing the laser power can reduce the detrimental effects of the heat accumulation on the multilayer deposition. However, there is a critical value in the reduction of laser power. The metallurgical quality of the deposit is good and the regional microstructure is uniform. The existence of WC and Ti will inhibit the growth of columnar crystals, and the grain size can be refined. With the increase of the number of sedimentary layers, the heat accumulation effect is gradually strengthened. The size of the dendritic will gradually increase.

Key words: laser deposition; WCp/Al composites; coincident wire-powder feeding; microstructure

Foundation item: Project(SAST2015057) supported by Innovation Fund of Shanghai Academy of Spaceflight Technology, China

Received date: 2017-11-15; Accepted date: 2018-03-23

Corresponding author: LI Fu-quan; Tel: +86-451-86415506; E-mail: lifuquan@hit.edu.cn

(编辑 李艳红)

基金项目:上海航天科技创新研究基金资助项目(SAST2015057)

收稿日期:2017-11-15;修订日期:2018-03-23

通信作者:李福泉,副教授,博士;电话:0451-86415506;E-mail:lifuquan@hit.edu.cn