Trans. Nonferrous Met. Soc. China 23(2013) 904-908

Effects of Sn on microstructure of as-cast and as-extruded Mg-9Li alloys

Bin JIANG1,2,3, Ying ZENG1,2, Ming-xing ZHANG4, Heng-mei YIN1,2, Qing-shan YANG1,2, Fu-sheng PAN1,2,3

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China;

3. New Materials Center, Chongqing Academy of Science and Technology, Chongqing 401123, China;

4. School of Mechanical and Mining Engineering, University of Queensland, St Lucia 4072, Australia

Received 6 January 2012; accepted 25 June 2012

Abstract: The effects of Sn addition on the microstructure of as-cast and as-extruded Mg-9Li alloys were investigated. The results show that α-Mg, β-Li, Li2MgSn, and Mg2Sn are primary phases in the microstructures of the as-cast and as-extruded Mg-9Li-xSn (x=0, 5; in mass fraction, %) alloys. Li2MgSn phase evolves from continuously net-like structure in the as-cast state to fine granular in the as-extruded state. After the extrusion, Mg-9Li-5Sn alloy has finer microstructures. Li2MgSn or Mg2Sn compound can act as the heterogeneous nucleation sites for dynamic recrystallization during the extrusion due to the crystallography matching relationship. Extrusion deformation leads to dynamic recrystallization, which results in the grain refinement and uniform distribution. The as-extruded Mg-9Li-5Sn alloy possesses the lowest grain size of 45.9 μm.

Key words: Mg-9Li alloys; Sn; microstructure; heterogeneous nucleation

1 Introduction

Magnesium-lithium (Mg-Li) alloys, which are among the lightest metallic alloys, have some attractive properties including low density, high specific strength and good damping ability. Therefore, they have been widely used in aerospace structural applications [1,2]. According to Mg-Li phase diagram [3], Mg-Li alloy with 5%-11% Li exhibits a dual phase structure, which is comprised of Mg-based α-phase (HCP) and Li-based β-phase (BCC).

The Mg-Li dual phase alloys show better ductility [4] and lower strength. For example, yield strength and elongation of the as-cast Mg-9Li alloy are 85 MPa and 46%, respectively [5]. In order to improve their strength, many approaches have been used. Rapid solidification [6,7], directional solidification [8] and equal channel angular pressing (ECAP) [9] have been reported in recent years. However, the complicated process, high cost and strict technical requests limit their further applications. Rolling and extrusion can improve microstructure and mechanical properties mainly due to the reduction of grain size caused by dynamic recrystallization, but the improvement is limited [10,11].

Matrix composite reinforcement [5] and multi-element alloying [12] can increase the strength, but sacrifice lightness and ductility. Furthermore, Al and Zn are the most widely used elements in multi-element alloying. However, MgLi2Al and MgLiZn intermetallic compounds will be formed and transformed to the compounds with no strengthening effect on Mg-Li alloy. The over-aging appears in Mg-5Li-3Al-2Zn alloy due to the existence of Li2MgAl or LiMgZn [13]. Previous works have shown that Sn has a good refinement effect on Mg-7Zn-5Al based alloy [14] and Mg-5Li-3Al- 2Zn alloy [13]. But the matrix of these two alloys is α-Mg, and as for the second alloy, over aging exists due to the existence of Li2MgAl or LiMgZn.

In the present work, in order to develop new Mg-Li alloy containing Sn, Mg-9Li-5Sn alloy is selected as the experimental alloy. Based on the Mg-Li-Sn ternary phase diagram [15], Li2MgSn will be formed in Mg-9Li-5Sn alloys and is chemically steady. Through the examination of crystallography data based on the edge-to-edge matching model [16], Li2MgSn has good crystallography matching with α-Mg and β-Li and thus has large potential to refine the microstructure consisting of α-Mg and β-Li. So far, few literatures have reported the effect of Sn addition on microstructure and the mechanism of the grain refinement of Li2MgSn.

2 Experimental

The materials used in the experiment were commercially pure Mg (99.9%), pure Li (99.9%), and pure Sn (99.9%). Before melting, all the materials were polished to remove surface oxide. The charging was made according to the nominal chemical compositions, Mg-9Li and Mg-9Li-5Sn. Then, they were put into a steel crucible (90 mm in diameter and 250 mm in height) and a vacuum induction furnace was used to melt the charging under the protection of argon atmosphere. All the chargings were heated to 730 °C until complete melting, then held for 10 min and cooled down in the furnace until complete solidification. Consequently, cast ingots of 85 mm in diameter and 150 mm in height were gained. The chemical compositions of the as-cast alloys were measured by inductively coupled plasma atomic emission spectroscopy (ICP-AES) and the results are listed in Table 1.

Table 1 Chemical composition of as-cast alloys (mass fraction, %)

The ingots were milled to 75 mm in diameter and 100 mm in height, and then were extruded with the extrusion ratio of 27 at 250 °C. The microstructure analysis and phase analysis were conducted with an optical microscope (OM), scanning electron microscope (SEM) with energy dispersive spectroscope (EDS), and X-ray diffractometer (XRD). The grain size was measured by the linear interception method at the centre of the transverse sections.

3 Results and discussion

3.1 Microstructure of as-cast Mg-9Li-xSn alloys

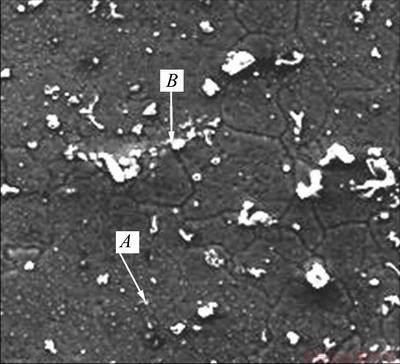

Optical microstructures of the as-cast alloys, shown in Fig. 1, are observed as typical dual-phase structure Mg-9Li alloy, with the white blocky part for Mg-rich α phase and the grey area for Li-rich β matrix. In addition, as for Mg-9Li-5Sn alloy, some unknown compounds (dark area) exist and distribute in the as-cast alloy as coarse net-like structure which means that these compounds were formed at higher temperatures. From the SEM image and EDS result of the as-cast Mg-9Li-5Sn alloy (Fig. 2), the majority of the compounds (point A) are characterized as a large quantity of coarse plate-like features. As for the chemical composition, the Sn content is high and the mole ratio of Mg to Sn is very close to 1, consistent with the mole ratio of Mg to Sn in Li2MgSn. There are some other compounds which are fine granular and locate in the matrix such as point B, so it is possible that these compounds were precipitated at lower temperatures. The mole ratio of Mg to Sn in these compounds is found to be more than 2, so the compound (point B) could be Mg2Sn. According to Mg-Li-Sn phase diagram [15], Li2MgSn is formed over 609 °C at which the alloy is at a molten state and Mg2Sn is precipitated from the solid β-Li phase below 550 °C. Therefore, the coarse plate-like compound and the fine granular compound should be Li2MgSn and Mg2Sn, respectively.

Fig. 1 Optical microstructures of as-cast alloys

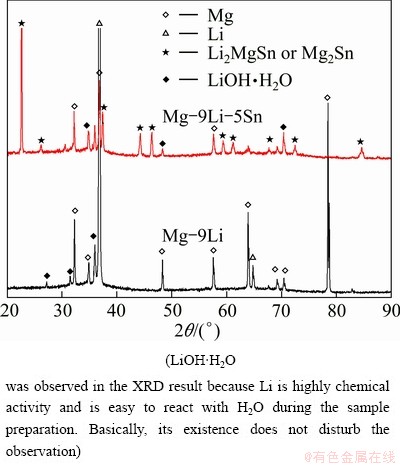

In order to further determine the phase composition, XRD analysis was conducted and shown in Fig. 3. α-Mg and β-Li phases exist in these two alloys, and there are also Li2MgSn and Mg2Sn in Mg-9Li-5Sn alloy. It is difficult to distinguish peaks of the compounds containing Sn because these two compounds have the same lattice structure and possess very close lattice constants,  =0.6764 nm and

=0.6764 nm and  =0.6759 nm.

=0.6759 nm.

Fig. 2 SEM image of as-cast Mg-9Li-5Sn alloy (a) and corresponding EDS spectra of point A (b) and point B (c)

3.2 Microstructure of as-extruded Mg-9Li-xSn alloys

Although the obvious dual-phase structure cannot be observed in optical microstructures of the as-extruded alloys shown in Fig. 4, XRD results of the as-extruded Mg-9Li-xSn alloys (Fig. 5) confirmed the existence of α-Mg and β-Li phases in both two alloys. After the extrusion, the grains of the Mg-9Li-xSn alloys are refined markedly, characterized as homogeneous and equiaxed, compared with the as-cast ones (see Fig. 1). The grain size of the as-extruded Mg-9Li-5Sn alloy is reduced to 45.9 μm, which is much finer than that of the as-extruded Mg-9Li alloy (84.2 μm).

Fig. 3 XRD patterns of as-cast Mg-9Li-xLi alloy

Fig. 4 Microstructure of as-extruded Mg-9Li alloy (a) and Mg-9Li-5Sn alloy (b)

Figure 6 and Table 2 show the SEM images and EDS results of the as-extruded Mg-9Li-5Sn alloys. Li2MgSn and Mg2Sn compounds become granular and distribute depressively due to the dynamic recrystallization and extrusion stress during extrusion.

Fig. 5 XRD patterns of as-extruded Mg-9Li-xLi alloys

Fig. 6 SEM image of as-extruded Mg-9Li-5Sn alloys

Table 2 Corresponding EDS results of points in Fig. 6 for as-extruded Mg-9Li-5Sn alloy

3.3 Mechanism of grain refinement of as-cast and as-extruded Mg-9Li-xSn alloys

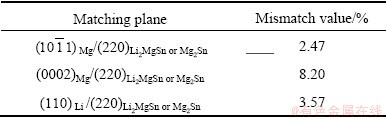

It has been reported that crystallographic matching between the particles and the metal matrix determines the grain refining efficiency of inoculated particles [17]. The edge-to-edge matching (E2EM) model is a simple and effective way to checkout this matching and comprehend the grain refinement mechanism [16]. In general, effective heterogeneous nucleation sites need to achieve the maximum atomic matching between particle and matrix across the interface. To meet the demand, the E2EM model shows that there should be at least a pair of close-packed (CP) atomic rows which are called matching rows, and along which the interatomic spacing misfit (fr) is less than 10% between the particle and the matrix. In addition, there should have one more pair of CP planes containing the CP atomic rows which have interplanar spacing (d-spacing) mismatch (fd) less than 10%. This pair of CP planes are called matching planes. Thus, the values of fr and fd can be used to evaluate the relative grain refining potency of inoculated particles. According to XRD results, three main close packed planes of Li2MgSn or Mg2Sn, β-Li and α-Mg are calculated and shown in Table 3.

Table 3 Three main close packed planes

Based on the calculation method [16], the matching plane pairs to meet the E2EM requirement are listed in Table 4. It shows that there is a preferable crystallography orientation relationship (OR) between α-Mg or β-Li and Li2MgSn or Mg2Sn. Therefore, Li2MgSn or Mg2Sn can serve as the grain refiner for Mg-9Li-xSn alloys during extrusion.

Table 4 Mismatch values of potential matching planes for Li and compounds (%)

As for the as-cast alloy, according to Mg-Li-Sn ternary phase diagram [15], the procedure of solidification of Mg-9Li-5Sn alloy is from Li2MgSn, β-Li, and α-Mg, to Mg2Sn. The growth restriction factor of Sn element in β-Li is almost zero by the calculation method reported by EASTON and STJOHN [18]. Thus as the solute element, Sn element has almost no contribution to the grain refinement of as-cast microstructure of Mg-9Li-5Sn alloy. Due to the confirmed crystallography OR between Li2MgSn or Mg2Sn and β-Li, Li2MgSn should have good grain refinement effects on the as-cast microstructure of Mg-9Li-5Sn alloy, although it is unclear because the β-Li grains could not be shown in the optical microstructure due to the phase boundary of β-Li and α-Mg. Mg2Sn is precipitated from α-Mg at lower temperatures and thus it has no grain refinement effect on the as-cast microstructure of Mg-9Li-5Sn alloy.

4 Conclusions

1) Mg-9Li-xSn (x=0, 5 mass fraction in %) alloys are mainly composed of α-Mg and β-Li, and Li2MgSn and Mg2Sn also exist in the alloy containing Sn. After the extrusion, microstructures of Mg-9Li-xSn alloys are refined markedly, characterized as homogeneous and equiaxed grains due to the dynamic recrystallization during extrusion.

2) After Mg-9Li-5Sn alloy is extruded with the extrusion ratio of 27 at 250 °C, Li2MgSn is changed as fine granular from continuously net-like structure. Li2MgSn or Mg2Sn phase has less than 10% mismatch with both α-Mg and β-Li matrix calculated by edge-to-edge matching model. Therefore, Li2MgSn or Mg2Sn acts as heterogeneous nucleation site for α-Mg and β-Li grains, and serves as a grain refiner for Mg-9Li-5Sn alloy during extrusion.

References

[1] CHIU C H, WU H Y, WANG J Y, LEE S. Microstructure and mechanical behavior of LZ91 Mg alloy processed by rolling and heat treatments [J]. Journal of Alloys and Compounds, 2008, 460 (1-2): 246-252.

[2] MORDIKE B L. Development of highly creep resistant magnesium alloys [J]. Journal of Materials Processing Technology, 2001, 117(3): 391-394.

[3] MOSER Z, ZAKULSKI W, SCHWITZGEBEL G. Thermodynamic studies and the phase diagram of the Li-Mg system [J]. Metallurgical and Materials Transactions A, 1996, 30(9): 1120-1128.

[4] XU D K, LIU L, XU Y B, HAN E H. The strengthening effect of icosahedral phase on as-extruded Mg-Li alloys [J]. Scripta Materialia, 2007, 57(3): 285-288.

[5] SYN C K, LESUER D R, SHERBY O D. Enhancing tensile ductility of a particulate-reinforced aluminum metal matrix composite by lamination with Mg-9%Li alloy [J]. Materials Science and Engineering A, 1996, 206: 201-207.

[6] ZHANG Z M, XU C J, GUO X F. Microstructure of Mg-6.4Zn-1.1Y alloy fabricated by rapid solidification and reciprocating extrusion [J]. Acta Metallurgica Sinica: English Letters, 2008, 21(1): 30-36.

[7] GAO Peng, XUE Zhu, LIU Guang-bo, ZHANG Jin, ZHANG Mi-lin. New MgLi based Mg-Li-Cu-(Y, Gd) BMGs: Preparation, glass forming ability and mechanical properties [J]. Journal of Non-Crystalline Solids, 2011, 357(10): 2182-2186.

[8] PEN De-lin, XING Da-wei, AN Ge-yin. Eutectic structure of binary Mg Li alloy during directional solidification [J]. Journal of Harbin Institute of Technology, 1999, 30(1): 10-12. (in Chinese)

[9] FURUI M, XU C, AIDA T, INOUE M, ANADA H, LANGDON T. Improving the superplastic properties of a two-phase Mg–8% Li alloy through processing by ECAP [J]. Materials Science and Engineering A, 2005, 410-411: 439-442.

[10] YAN Hong, CHEN Rong-shi, HAN En-hou. Microstructures and mechanical properties of cold rolled Mg-8Li and Mg-8Li-2Al-2RE alloys [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 550-554.

[11] CHEN Zhao-yun, LI Zhi-qiang, YU Chun. Hot deformation behavior of an extruded Mg-Li-Zn-RE alloy [J]. Materials Science and Engineering A, 2011, 528(3): 961-966.

[12] LI Rui-hong, PAN Fu-sheng, JIANG Bin, YIN Heng-mei, LIU Ting-ting. Effects of yttrium and strontium additions on as-cast microstructure of Mg-14Li-1Al alloys [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(4): 778-783.

[13] XIANG Q, WU R Z, ZHANG M L. Influence of Sn on microstructure and mechanical properties of Mg-5Li-3Al-2Zn alloys [J]. Journal of Alloys and Compounds, 2009, 477(1-2): 832-835.

[14] XIAO Wen-long, JIA Shu-sheng, WANG Li-dong, WU Yao-ming, WANG Li-min. Effects of Sn content on the microstructure and mechanical properties of Mg-7Zn-5Al based alloys [J]. Materials Science and Engineering A, 2010, 527(26): 7002-7007.

[15] LIU Chu-ming, ZHU Xiu-rong, ZHOU Hai-tao. Magnesium alloy phase gragh set [M]. Changsha: Central South University Press, 2006: 52-274. (in Chinese)

[16] JIANG B, QIU D, ZHANG M X, DING P D, GAO L. A new approach to grain refinement of an Mg-Li-Al cast alloy [J]. Journal of Alloys and Compounds, 2010, 492(1-2): 95-98.

[17] EASTERLING K E , PORTER D A. Phase transformations in metals and alloys [M]. London: Chapman & Hall, 1992: 185-197.

[18] EASTON M A, STJOHN D H. A model of grain refinement incorporating alloy constitution and potency of heterogeneous nucleant particles [J]. Acta Materialia, 2001, 49(10): 1867-1878.

Sn元素对铸态及挤压态Mg-9Li合金显微组织的影响

蒋 斌1,2,3,曾 迎1,2,Ming-xing ZHANG 4,殷恒梅1,2,杨青山1,2,潘复生1,2,3

1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044;

3. 重庆科学技术研究院 新材料中心,重庆 401123;

4. 昆士兰大学 机械与采矿学院,圣卢西亚 4072,澳大利亚

摘 要:研究添加Sn对铸态及挤压态Mg-9Li合金显微组织的影响。结果表明:Mg-9Li-xSn(x = 0,5;质量分数,%)合金的铸态和挤压态的组织为α-Mg,β-Li,Li2MgSn和Mg2Sn;铸态时Li2MgSn为连续的网状结构,挤压后变成均匀分布的颗粒状;由晶体学匹配关系可知,Li2MgSn和Mg2Sn在挤压时可以作为动态再结晶的异质形核点;挤压变形引起的动态再结晶使得晶粒细化且分布均匀。挤压态的Mg-9Li-5Sn合金具有尺寸为45.9 μm的最细晶粒。

关键词:Mg-9Li合金;锡;显微组织;异质形核

(Edited by Xiang-qun LI)

Foundation item: Projects (51171212, 50725413) supported by the National Natural Science Foundation of China; Project (2009AA03Z507) supported by the National High-tech Research Program of China; Projects (2010CSTC-BJLKR, CSTC2010AA4048) supported by Chongqing Science and Technology Commission, China; Project (CDJXS10132203) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: Bin JIANG; Tel: +86-13594190166; Fax: +86-23-65111140; E-mail: jiangbinrong@cqu.edu.cn

DOI: 10.1016/S1003-6326(13)62546-7