文章编号:1004-0609(2015)-09-2428-07

搅拌头形状对回填式搅拌摩擦点焊过程中材料流动行为的影响

岳玉梅1,李政玮1,姬书得1,柴 鹏2,马轶男1,王 月1

(1. 沈阳航空航天大学 航空航天工程学部,沈阳 110136;

2. 北京航空航天大学 机械工程与自动化学院,北京 100191)

摘 要:以LY12铝合金为研究对象,对常规搅拌头作用下的回填式搅拌摩擦点焊的材料流动规律进行数值模拟,并利用焊点的宏观形貌与显微组织进行试验验证;讨论不同搅拌头形状对材料流动行为的影响。结果表明:材料的高速流动区域主要位于套筒内外壁附近;流动速度值在外壁凹槽处出现最大值,且随着离套筒壁距离的增加而减小。流动规律的模拟结果由位于焊点中心的中间较宽、两端较窄的韧带与焊点内部不同区域晶粒的不同所证实。从减小焊点内韧带宽度的角度考虑,双凹槽搅拌头优于常规搅拌头、小槽宽搅拌头和大直径搅拌头。

关键词:回填式搅拌摩擦点焊;搅拌头形状;数值模拟;材料流动

中图分类号:TG453 文献标志码:A

Effect of tool geometry on material flow behavior during friction spot welding process

YUE Yu-mei1, LI Zheng-wei1, JI Shu-de1, CHAI Peng2, MA Yi-nan1, WANG Yue1

(1. Faculty of Aerospace Engineering, Shenyang Aerospace University, Shenyang 110136, China;

2. School of Mechanical Engineering and Automation, Beihang University, Beijing 100191, China)

Abstract: Choosing LY12 aluminum alloy as the research object, the material flow behavior of friction spot welding (FSpW) using conventional tool was simulated and verified by macrostructure and microstructure of welding spot. Meanwhile, the effects of tool geometries on material flow behavior during FSpW process were mainly discussed. The results show that the material near the inner and outer walls of sleeve attains high flow velocity. The maximum flow velocity appears in the groove region of the outer wall. And the velocity decreases as the distance from the walls of the sleeve becomes bigger. Bonding ligament with bigger width in the center and smaller width in two ends and different microstructures in different regions agree with the simulation results. From the viewpoint of decreasing the width of the bonding ligament, the double groove tool is better than the conventional tool, small width groove tool and big diameter tool.

Key words: refill friction stir spot welding; tool geometry; numerical simulation; material flow

钥匙孔是常规搅拌摩擦点焊(Friction stir spot welding, FSSW)接头普遍存在的缺陷[1]。为了消除匙孔,德国GKSS研究中心提出了回填式搅拌摩擦点焊技术(Friction spot welding, FSpW)。此方法经过摩擦加热、下扎、回填与焊接成型4个过程获得表面成型美观的焊点,是一种可代替电阻点焊的新型固相连接技术,在航空、汽车等领域有着广阔的应用前景[2]。

与搅拌摩擦焊(Friction stir welding, FSW)和FSSW相同,FSpW过程中的材料流动行为是决定其接头质量的最关键因素[3-7]。根据搅拌头不同组件的运动方式的不同,FSpW技术可分为两种类型:搅拌针下扎式与套筒下扎式。与搅拌针下扎式FSpW相比,套筒下扎式FSpW可获得更大面积的焊点。近年来,国内外的学者对FSpW过程的材料流动进行了试验或数值模拟研究。KALAGARA等[3]利用材料标识试验得到了FSpW过程典型位置处材料的运动路径。孙学敏[4]利用Fe粉嵌入法对FSpW过程的材料流动行为进行试验研究。 等[5]与ITAPU等[6]利用有限元软件Abaqus进行了搅拌针下扎式FSpW过程的材料流动行为仿真。

等[5]与ITAPU等[6]利用有限元软件Abaqus进行了搅拌针下扎式FSpW过程的材料流动行为仿真。

与FSW和FSSW相比[7-9],有关FSpW过程材料流动行为方面的研究较少,国内外学者将更多的精力集中于FSpW过程的温度、显微组织与力学性能的研究[10-13]。本文作者以套筒下扎式FSpW为例,利用FLUENT软件研究焊接过程的材料流动行为,并加以试验验证,重点分析搅拌头的形状参数对材料流动速度的影响规律。

1 FSpW的三维有限元模型

1.1 实体模型与网格划分

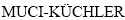

FSpW所用搅拌头由压紧环、套筒及搅拌针3部分组成。在实际焊接过程中,不旋转的压紧环的作用主要是固定工件,因此在模拟过程中不考虑。同时,假定搅拌针的外径与套筒的内径相同。为了考虑搅拌头的形状参数对材料流动规律的影响,本文作者设计4种搅拌头(即常规搅拌头、小槽宽搅拌头、双槽搅拌头和大直径搅拌头),其实体模型如图1所示。

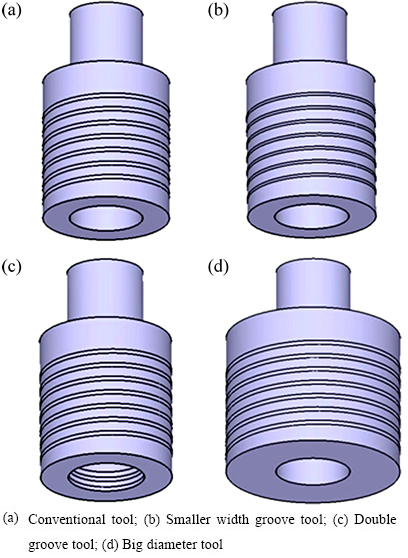

图1(a)的常规搅拌头结构最为常见,即套筒的内壁光滑而外壁带凹槽,且槽宽为0.3 mm;套筒的外径与内径分别为9 mm与5.2 mm。与图1(a)相比,图1(b)中小槽宽搅拌头的套筒外壁的槽宽为0.2 mm;图1(c)中双槽搅拌头的套筒的内壁有宽为0.4 mm的凹槽;图1(d)中大直径搅拌头的套筒外径为12 mm。除上述特征不同外,图1中4种搅拌头的其他特征与尺寸均相同。利用CATIA建立搅拌头的实体模型,在Gambit里进行网格划分,如图2所示。其中,模型沿Z向的尺寸为3.2 mm,用来描述上板为1.2 mm及下板为2 mm的点焊接头。

1.2 边界条件的设置

由相关文献[14]可知,下扎过程与回填过程是影响 FSpW 焊点质量的主要阶段,这也是本研究中的主要讨论对象,即忽略摩擦产热过程与焊接成型过程。

图1 模拟用4种搅拌头的实体模型

Fig. 1 Solid models of four tools used in simulation

图2 常规搅拌头的有限元网格划分

Fig. 2 Mesh generation using conventional tool

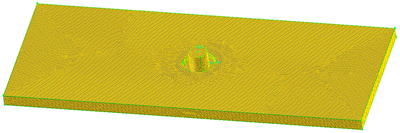

在下扎及回填过程中,套筒与搅拌针既同向同步旋转,又沿搅拌头的轴线做相对直线运动以实现高温塑性金属的填腔与回填。因此,套筒与搅拌针运动的合理描述是非常重要的。本研究中将表征搅拌头的网格假定为旋转墙来描述搅拌头的旋转运动;而将表征搅拌头周围金属材料的网格假定为移动墙来描述材料的填腔与回填过程。

图3所示为套筒下扎阶段的材料流动模拟的示意图。其中,将模拟区域的下表面设置为流体入口,上表面设为流体出口,且流体的流动速度与套筒下扎速度大小相等;左右和前后侧面的边界条件均设置为移动墙,移动速度与流体的流动速度相同,方向相同;搅拌头的边界条件设置为旋转墙,旋转速度与搅拌头旋转速度相同,旋转方向为顺时针。

另外,对于FSpW过程的回填阶段来说,塑性材料从上表面流入,从下表面流出,其他边界条件都与下扎过程相同。

图3 下扎阶段材料流动模拟示意图

Fig. 3 Schematic diagram of flow simulation region at plunging stage

1.3 材料参数及焊接工艺参数

本研究曾以LY12铝合金为研究对象,选取了RNG k-e湍流模型作为FSpW三维流场的计算模型。在计算过程中,搅拌头内部与外部的金属均假定为流体,且焊接过程是温度恒定的稳态过程[15]。因此,模拟过程中涉及的LY12铝合金的比热容、热导率、密度及黏度的数值分别为1172 J/(kg·K)、176 W/(m·K)、2.7 g/cm3与400 Pa·s[15-16]。

在FSpW过程的下扎阶段与回填阶段,影响焊点质量的焊接工艺参数主要包括搅拌头旋转速度、下扎速度、回填速度及套筒最大下扎深度,其值分别为1000 r/min、7.2 mm/s、7.2 mm/s与1.8 mm。

1.4 计算方法的选取

在FSpW过程中,搅拌区塑性金属的流动是一种单相流体的复杂湍流现象,该现象具有随机性、扩散性、有涡性和耗散性等流动特征。同时,考虑到非线性求解的需要,本模型对压力项、动量方程和能量方程均采用二阶迎风格式进行求解;对于速度和压力的耦合,FLUENT采用压力的隐式算子分割算法(Pressure implicit with splitting of operators,PISO)来 求解。

2 结果与讨论

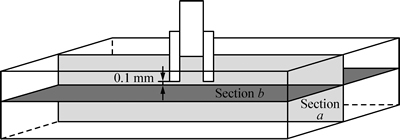

为了实现材料流动规律的清晰描述,本研究中除提供三维流场外,还讨论水平截面与垂直截面上的材料流动规律,截面位置见图4。其中,垂直截面a过焊点中心且与点焊的搭接界面垂直;水平截面b平行于搭接界面;且当套筒达到最大下扎深度时,截面b到套筒端面的距离为0.1 mm。焊接过程中套筒端面两次经过搭接界面,因此,水平截面b的材料流动规律可用来说明搭接界面处的材料流动规律。

2.1 焊接过程流场的模拟及试验验证

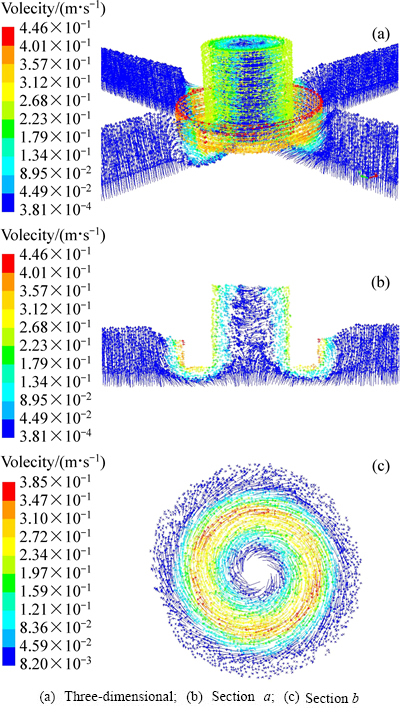

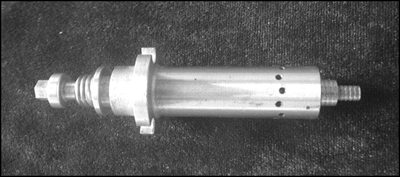

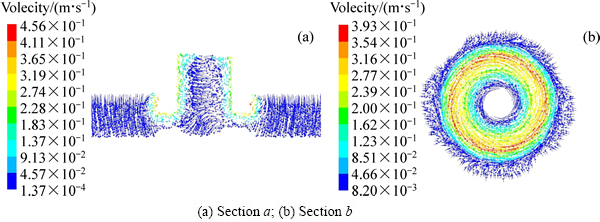

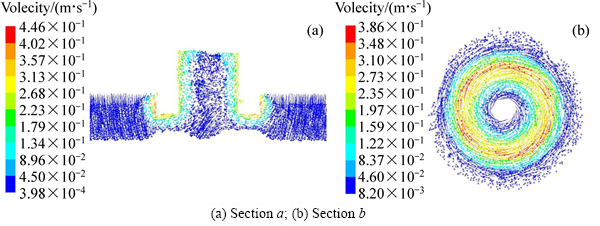

图5和6所示分别为常规搅拌头下扎与回填阶段的材料流动规律。其中,为了清晰地显示高速流动区域,本研究中截面b的材料流动规律图中的标尺最小值均比下扎/回填速度大1 mm/s。通过分析可知,焊接过程中材料的流动方向可分解成两个:沿水平方向的顺时针旋转流动与沿垂直方向的流动,且垂直流动方向与套筒的运动方向相反。在FSpW的模拟过程中,由于采用刚性无滑移边界条件,与搅拌头的套筒及搅拌针相接触的材料会随着搅拌头的旋转而旋转,且其值与接触点的线速度成正比;与搅拌头直接接触的材料会带动周围材料的流动,而材料的黏度会影响非直接接触材料的流动速度。因此,在焊接过程中,与套筒内壁或外壁接触处的材料流动速度较高;无论是套筒内部还是外部,随着到套筒壁距离的增加,材料的流动速度变小(见图5和6);在套筒中心位置的材料流动速度极低,且垂直方向的流动速度大于平面旋转速度。考虑到水平截面b到套筒端面的距离为0.1 mm,实际紧贴搅拌针端面的旋转速度比图5(c)中所示的值略大。

图4 不同截面位置示意图

Fig. 4 Schematic diagram of positions of different sections

图5 常规搅拌头下扎阶段的材料流动规律

Fig. 5 Material flow behavior using conventional tool at plunging stages

图6 常规搅拌头回填阶段的材料流动规律

Fig. 6 Material flow behavior using conventional tool at refilling stages

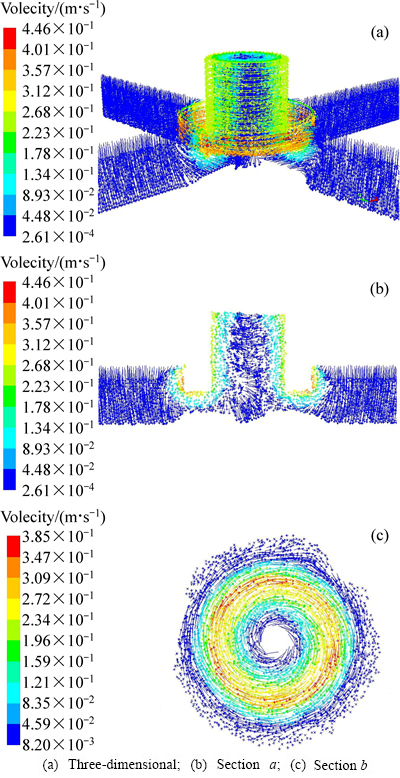

为了验证数值模拟结果的合理性,在型号为RPS100 SK10的FSpW设备上进行了LY12铝合金的点焊试验。板厚与如图2所示的模型相同,搅拌头尺寸与如图1(a)所示的常规搅拌头模型尺寸相同。图7所示为试验用搅拌头的整体结构,其中套筒内部的搅拌针的直径略小于套筒内径,其值为5 mm。焊后的试件经过砂纸打磨、抛光、金相腐蚀等处理,利用光学显微镜对焊点的横截面形貌及显微组织进行分析。

图7 试验用搅拌头照片

Fig. 7 Photo of rotational tool used in experiment

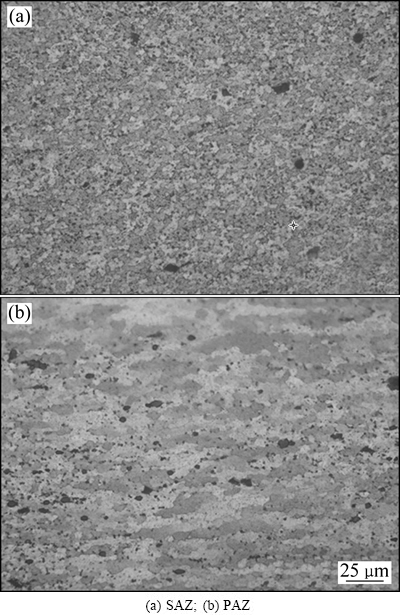

图8所示为常规搅拌头作用下焊点横截面的宏观形貌图。由图8可以看出,匙孔基本被填满,整个焊点呈“盆”状;焊点中心有一条中间较宽、两端较窄的白色韧带。白色韧带是由原LY12试板表面覆盖的包铝层形成的。由于FSpW搅拌头的特殊结构,焊点不同区域的材料被打碎的程度是不同的。在焊点的中间区域,材料由于未受到搅拌头的直接搅拌作用而未被充分打碎,韧带较厚,此区域可被称作搅拌针作用区(Pin affected zone, PAZ);在焊点外围区域,材料受到套筒的直接搅拌作用,被打碎的包铝层和LY12铝合金混合程度大,因此,韧带厚度较薄,此区域可被称作套筒作用区(Sleeve affected zone, SAZ)。由图5和6可以看出,材料流动速度随着到套筒内壁的距离增加而减小,此模拟结果与图8所示的试验验证结果相一致。

图9所示为FSpW接头不同区域的显微组织。由图9可以看出,SAZ的晶粒尺寸明显小于PAZ的。与FSW等固相焊方法相同,尽管FSpW过程的温度未超过材料熔点,但其值必定超过材料熔点温度的40%,即再结晶温度。同时,在焊接过程中,搅拌区的材料经历了大的应变及应变速率,因此,FSpW过程中必产生动态再结晶,在搅拌区形成细小的等轴晶(见图9(a))。而SAZ材料经历的材料流动速度远大于PAZ材料的,进而使搅拌区不同区域的材料经历的应变与应变速率不同。一般来讲,材料流动速度的提高有利于增加材料所受到的应变速率,进而增加形核率。这也就是SAZ区的动态再结晶晶粒小于PAZ区的原因。综上,图8与9的试验结果均验证本研究中模拟结果的合理性。

图8 FSpW焊点横截面的宏观形貌

Fig. 8 Macro morphology of cross section of FSpW welding spot

图9 焊点搅拌区的显微组织

Fig. 9 Microstructures of stir zone of welding spot

2.2 搅拌头形状参数对材料流动的影响

在FSpW过程中,SAZ的包铝层被较大程度打碎并与LY12铝合金发生充分混合,利于固相焊合效果。同时,白色韧带由纯Al组成,其延展性与LY12存在较大差异。当接头承受拉剪载荷时,韧带与LY12出现由变形不同而导致的应力集中,不利于接头强度,所以减少或消除韧带是完全有必要的。因此,增强焊接过程中的材料流动,充分打碎韧带,是提高FSpW 接头性能的重要途径之一。而改善焊接过程中材料流动的一个重要途径是改变搅拌头的结构。通过前面的分析可知,FSpW过程的下扎与回填阶段的材料流动行为相类似,因此,以下以回填阶段的材料流动行为来重点讨论搅拌头形状参数对FSpW材料流动行为的影响。

在FSpW过程中,处于高温的低流动应力的塑性材料可视为流体。因此,不可压缩介质的连续性定理亦适用于FSpW过程,即遵循质量守恒定律:单位时间内在密闭的通道内流过的材料质量是相等的。换句话说,在FSpW过程中,材料的流动速度与材料流经的通道截面积成反比。套筒外壁凹槽附近的材料在向下或向上的流动过程中,会出现部分材料流入凹槽内的情况,这使材料的流动通道变窄,造成材料的流动速度增加。同时,套筒外壁的半径大于内径,因此,外壁上点的线速度大于内壁上点的线速度,进而影响与其接触的材料流动速度。上述两者的原因造成如下规律:在套筒外壁的凹槽处出现材料流动速度最大值(见图5(a)与6(a))。因此,搅拌头上凹槽的合理设计对于材料流动有着极大的影响。

图10和11所示分别为回填阶段小槽宽搅拌头(见图1(b))及双凹槽搅拌头(见图1(c))的材料流动规律。根据流体连续性定理可知,流体的流动路径截面积变小会提高流体的流动速度。图1(b)中套筒外壁上凹槽宽为0.2 mm,小于图1(a)中凹槽宽度。由于其他条件不变,因此,小槽宽搅拌头的材料流动速度最大值大于常规搅拌头的(见图10(a)与图6(a))。当使用双凹槽搅拌头时,槽的存在会大幅度提高套筒内壁附近的材料流动速度,这会对周围材料的流速度产生加速的影响,造成材料流动速度最大值的提高(见图11(a)与6(a))。事实上,尽管小槽宽搅拌头与双凹槽搅拌头均可以提高搅拌区材料的流动速度最大值,但对焊点中间位置材料速度及焊点面积的影响是不同的。当使用小槽宽搅拌头时,焊点中间位置的材料流动速度由使用常规搅拌头的2.3 mm/s变为3.5 mm/s;当使用双凹槽搅拌头时,焊点中间的流动速度升到4.5 mm/s。因此,从提高焊点中间位置的材料流动以打碎包铝层的角度讲,双凹槽搅拌头的效果较佳。同时,通过对比图6(b)、10(b)与11(b)可知,套筒外壁槽变窄及内壁带凹槽均可使高速流动区域(焊点面积)有稍小的增加,而小槽宽搅拌头的增加效果较好。上述结果主要与外/内壁槽的位置有关。

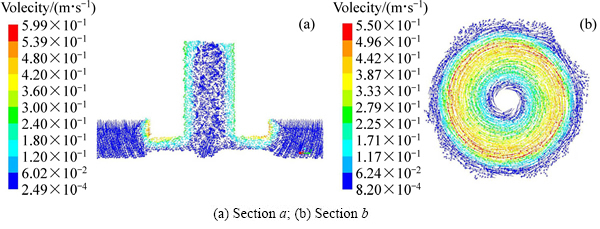

图12所示为图1(d)所示大直径搅拌头的材料流动规律。在FSpW过程中,套筒外径的增加会提高外壁点的线速度,进而提高与其接触的材料流动速度。由于搅拌头的其它结构不变,因此,与图6(a)相比,大直径搅拌头的材料流动速度最大值增加(见图12(a)),且焊点中间位置的流动速度提高到3.2 mm/s。本研究中使用套筒下扎式的搅拌头,套筒外径的增加会使高速流动区域范围明显增加(见图12(b)),且流动速度最大值由原来的0.446 m/s增加到0.599 m/s。然而,与本研究中提及的常规、小槽宽与双凹槽搅拌头相比,套筒外径的增加会较大幅度地增加实际焊接过程中的温度峰值,进而增加焊接接头的热影响区宽度与软化程度,这对于接头的性能是不利的。此外,大的套筒外径会使下扎过程需要更大的下扎力,而且会造成焊接过程中发生位移的材料过多而难以回填的现象。因此,在实际焊接过程中选择合理的套筒外径非常关键;本研究中所用常规搅拌头的尺寸与国内外报道的相符,而改变套筒直径的文献未见报道。综上所述,由于套筒内或外壁槽的改变对温度的影响较小,因此,槽的合理设计对于提高焊点的质量是非常有利的。

图10 小槽宽搅拌头回填阶段材料流动规律

Fig. 10 Flow behavior of material at refilling stage using smaller width groove tool

图11 双凹槽搅拌头回填阶段材料流动规律

Fig. 11 Flow behavior of material at refilling stage using double groove tool

图12 大直径搅拌头回填阶段材料流动规律

Fig. 12 Flow behavior of material at refilling stage using big diameter tool

3 结论

1) 对FSpW过程的材料流动行为进行了数值模拟。结果表明:当套筒外壁带凹槽时,材料流动速度的最大值出现在凹槽处;随着到套筒内或外壁距离的增加,材料的流动速度变小;通过白色韧带(纯Al)的中间部分较宽而两端较窄以及SAZ和PAZ区域的显微组织等试验现象验证上述材料流动规律。

2) 改变搅拌头形状的模拟结果表明:双凹槽搅拌头、小槽宽搅拌头和大直径搅拌头均可提高材料的流动速度最大值及高流动速度区域。从改善焊点内部的材料流动行为来看,双凹槽搅拌头的效果较优。

REFERENCES

[1] 周 利, 周炜璐, 杜正勇, 赵瑞峰, 孟凡新, 冯吉才. 搅拌摩擦点焊技术研究现状[J]. 航天制造技术, 2014(5): 1-5.

ZHOU Li, ZHOU Wei-lu, DU Zheng-yong, ZHAO Rui-feng, MENG Fan-xin, FENG Ji-cai. Research status of friction stir spot welding technology[J]. Aerospace Manufacturing Technology, 2014(5): 1-5.

[2] 申志康, 杨新岐, 张照华, 尹玉环. 铝合金回填式搅拌摩擦点焊组织及力学性能分析[J]. 焊接学报, 2013, 34(6): 73-76.

SHEN Zhi-kang, YANG Xin-Qi, ZHANG Zhao-hua, YIN Yu-huan. Analysis of microstructure and mechanical properties of refill friction stir spot welded aluminum alloy[J]. Transactions of the China Welding Institution, 2013, 34(6): 73-76.

[3] KALAGARA S,  K, ARBEGAST W. Visualization of material flow in a refill friction stir spot welding process using marker materials[J]. SAE International Journal of Materials and Manufacturing, 2010, 3(1): 628-651.

K, ARBEGAST W. Visualization of material flow in a refill friction stir spot welding process using marker materials[J]. SAE International Journal of Materials and Manufacturing, 2010, 3(1): 628-651.

[4] 孙学敏. 铝合金搅拌摩擦点焊温度场及流场研究[D]. 兰州: 兰州理工大学, 2014.

Sun Xue-min. Temperature field and flow field of friction spot welded aluminum alloy[D]. Lanzhou: Lanzhou University of Technology, 2014.

[5]  K H, KAKARLA S S T, ARBEGAST W J, ALLEN C D. Numerical simulation of the friction stir spot welding process[R]. SAE Technical Paper. Warrendale, USA: SAE International, 2005.

K H, KAKARLA S S T, ARBEGAST W J, ALLEN C D. Numerical simulation of the friction stir spot welding process[R]. SAE Technical Paper. Warrendale, USA: SAE International, 2005.

[6] ITAPU S K,  K H. Visualization of material flow in the refill friction stir spot welding process[R]. SAE Technical Paper. Warrendale, USA: SAE International, 2006.

K H. Visualization of material flow in the refill friction stir spot welding process[R]. SAE Technical Paper. Warrendale, USA: SAE International, 2006.

[7] 王希靖, 韩晓辉, 李常锋, 包 孔, 郭瑞杰. 厚铝合金板搅拌摩擦焊塑性金属不同深度的水平流动状况[J]. 中国有色金属学报, 2005, 15(2): 198-205.

WANG Xi-jing, HAN Xiao-hui, LI Chang-feng, BAO Kong, Guo Rui-jie. Horizontal flow status of plastic metal in different depth during friction stir welding for thick aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(2): 198-205.

[8] 赵衍华, 林三宝, 贺紫秋, 吴 林. 二维搅拌摩擦焊接过程的数值模拟[J]. 中国有色金属学报, 2005, 15(6): 865-869.

ZHAO Yan-hua, LIN San-bao, HE Zi-qiu, WU Lin. Numerical simulation of 2D friction stir welding process[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 865-869.

[9] YANG Q, MIRONOY S, SATO Y S, OKAMOTO K. Material flow during friction stir spot welding[J]. Materials Science and Engineering A, 2010, 527(16/17): 4389-4398.

[10] 杨洪刚, 赵 欣. 铝合金回填式搅拌摩擦点焊工艺试验[J]. 焊接技术, 2012, 41(11): 24-27.

YANG Hong-gang, ZHAO Xin. Experimental study on refill friction stir spot welding of aluminum alloy[J]. Welding Technology, 2012, 41(11): 24-27.

[11] SHEN Z K, YANG X Q, ZHANG Z H, CUI L, LI T L. Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints[J]. Materials and Design, 2013, 44: 476-486.

[12] SUHUDDIN U, FISCHER V, KROEFF F. Microstructure and mechanical properties of friction spot welds of dissimilar AA5754 Al and AZ31 Mg alloys[J]. Materials Science and Engineering A, 2014, 590: 384-389.

[13] VENUKUMAR S, YALAGI S, MUTHUKUMARAN S. Comparison of microstructure and mechanical properties of conventional and refilled friction stir spot welds in AA 6061-T6 using filler plate[J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 2833-2842.

[14] ZHAO Y Q, LIU H J, CHEN S X, LIN Z, HOU J C. Effects of sleeve plunge depth on microstructures and mechanical properties of friction spot welded Al clad 7B04-T74 aluminum alloy[J]. Materials and Design, 2014, 62: 40-46.

[15] 王训宏, 王快社, 沈 洋, 徐可为, 胡 锴. 搅拌摩擦焊焊缝塑性流动规律的数值模拟[J]. 材料导报, 2006, 20(12): 127-131.

WANG Xun-hong, WANG Kuai-she, SHEN Yang, XU Ke-wei, HU Kai. Numerical simulation of flow pattern in friction stir weld[J]. Materials Review, 2006, 20(12): 127-131.

[16] 王希靖, 韩晓辉. 基于FLUENT的铝合金搅拌摩擦焊三维流场数值模拟[J]. 电焊机, 2006, 36(1): 48-50.

WANG Xi-jing, HAN Xiao-hui. Numerical simulation based on software FLUENT of 3-D flow field in friction stir welding of aluminum alloy[J]. Electric Welding Machine, 2006, 36(1): 48-50.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51204111);辽宁省自然科学基金资助项目(2013024004);辽宁省科技厅项目(2013222007)

收稿日期:2015-01-25;修订日期:2015-05-25

通信作者:姬书得,教授,博士;电话:024-89723472;E-mail:superjsd@163.com