文章编号:1004-0609(2016)-05-1075-09

Sr变质对ADC12合金摩擦磨损性能的影响

王志伟1, 2,闫 洪1, 2,熊俊杰1, 2

(1. 南昌大学 机电工程学院 材料加工工程系,南昌 330031;

2. 南昌市轻合金材料制备与加工重点实验室,南昌 330031)

摘 要:利用MMD-1型销盘式磨损试验机,采用OM、SEM和EDS研究不同负载对Sr变质ADC12合金的摩擦磨损性能的影响,并探究其与合金显微组织及力学性能的关系。结果表明:当添加0.05%Sr(质量分数)时,合金显微组织中共晶Si相以颗粒状或纤维状均匀分布在晶界,富铁相则呈短棒状,此时合金力学性能最佳,且同一负载下其磨损量和摩擦因数均最低。当负载为100N时,因受到严重挤压变形,合金表面氧化膜发生破坏;基体合金以塑性屈服和严重剥层磨损为主要磨损机理;而当Sr添加量为0.05%时,合金的磨损程度最低,以粘着磨损和磨粒磨损为主要磨损机理,其摩擦磨损性能最优异。

关键词:Sr变质;ADC12合金;摩擦磨损;磨损机理

中图分类号:TG146.2 文献标志码:A

ADC12作为一种近共晶Al-Si合金,因其具有密度小、比强度高、流动性好、热膨胀系数低及切削性能好等优点[1-3],在汽车制造业已获得广泛应用。然而在铸造工艺条件下,该合金显微组织中粗大的共晶Si相会造成力学性能和耐磨性的显著降低[4-5],这也限制了其更广泛的应用前景。

研究表明,在Al-Si系合金中添加少量的变质剂(如:Na、K、RE、Sr等元素)不仅能达到良好的变质细化效果,还具有净化熔体和除气的作用[6-8]。Sr作为一种理想的高效变质剂,能将Al-Si系合金中的片状共晶Si相转变为细纤维状结构[9]。通常,合金显微组织的改善能有效提升其力学性能和耐磨性。BASAVAKUMAR等[10]向Al-7Si-2.5Cu合金中添加0.02%Sr(质量分数),观察发现变质后均匀分布的α(Al)晶粒、枝晶间细化的铝硅共晶结构和CuAl2颗粒,并表明合金变质后的耐磨性较基体有明显提升。KORI等[5]研究亚共晶和共晶Al-Si合金的干滑动磨损行为时发现,经Sr变质后,粗大的柱状α(Al)枝晶转变为细小的等轴晶,且片状共晶Si相细化为颗粒状,合金的力学性能和摩擦性能改善,磨损率降低。LIU等[11]研究了Sr对Al-20%Si合金在干往复滑动条件下的磨损性能,发现在Sr添加量为0.04%~0.06%时,合金的磨损行为最佳。然而,至今有关Sr变质对近共晶Al-Si合金的摩擦磨损性能的影响的详细报道甚少。

本文作者主要研究干滑动磨损条件下,ADC12合金经不同含量Sr变质后较基体合金的磨损行为的变化,并探究其与显微组织、力学性能之间的关系,旨为提升铝合金的耐磨性及拓宽其应用领域奠定基础。

1 实验

1.1 材料准备

原材料选用商业ADC12铝锭(Si 11.48,Cu 3.15,Fe 0.63,Mn 0.32,Zn 0.68,Mg 0.07,Ni 0.11,Sn 0.01,其余为Al(质量分数,%))和Al-10%Sr中间合金,首先称取一定质量的ADC12铝锭放入石墨坩埚中加热至750℃至其完全熔化,接着用六氟乙烷精炼、除渣,然后分批次加入Al-Sr中间合金块,配成不同Sr添加量的变质铝合金(0.00%、0.01%、0.05%、0.09%Sr),接着随炉升温至770 ℃再保温25 min,然后降温至720 ℃浇注至预热温度为200~300 ℃的金属型模具中,待冷却后取出铸件。

1.2 摩擦磨损实验

实验采用销盘接触式,在干滑动室温条件下进行,并重复3次。首先将浇铸获得的棒状铸件采用线切割技术加工成若干d4.5 mm×11 mm的圆柱状销试样;再将销试样与材质为45号钢、硬度为45HRC的盘试样均依次使用600号、1200号、1500号、2000号的SiC金相砂纸进行打磨和清洗,再抛光、清洗并烘干,以保证试样接触表面粗糙度和清洁度。本实验采用MMD-1型磨损试验机,参数设定如下:负载为15 N、30 N、50 N、100 N;滑行速度为100 r/min(线速度为0.188 m/s);滑行时间为15 min(滑行距离为169.56 m)。

实验前后采用FA2204B型电子天平(精度为±0.1 mg)称量销试样的质量;并应用Archimedes原理计量其密度ρ。

1.3 性能检测

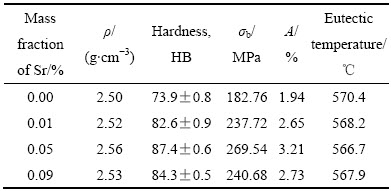

利用Nican-M300型光学显微镜观察合金试样显微组织形貌,金相试样采用体积分数为0.5%的HF溶液腐蚀;为进行拉伸性能测试,每种合金铸件均按照ASTM B557M标准规范加工成d6 mm×30 mm的拉伸试棒,拉伸速率设定为1.0 mm/min;通过差热分析法(DTA:DZ3320A)获得不同Sr含量的ADC12合金的共晶温度,升温速率为10 ℃/min;运用HB-3000B型布氏硬度计测量试合金硬度,实验载荷为2450 N,保压时间为30 s。合金的部分性能数据详见表1。

采用场发射扫描电镜(SEM,JEOL JSM-6701F)及配套能谱仪(EDS)观察试样磨损面和收集到的磨屑,并分析有关磨损机理。

表1 不同Sr添加量的ADC12合金的性能

Table 1 Properties of ADC12 alloys with different Sr additions

2 结果与讨论

2.1 显微组织

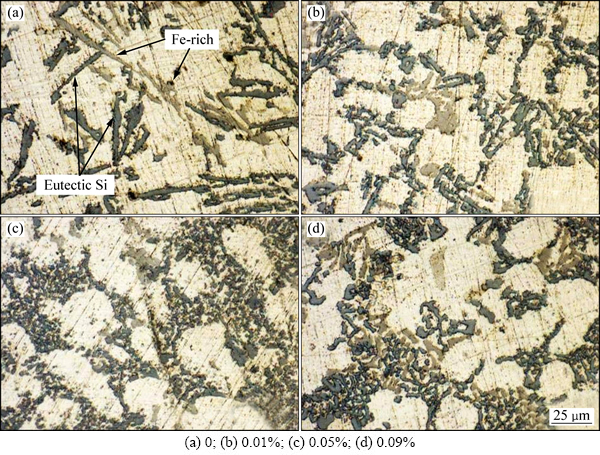

图1所示为Sr添加量对ADC12铝合金显微组织的影响,组织中白色的为α(Al)相,深黑色的为共晶Si相,灰褐色的为富Fe相。从图1(a)可以看出,α(Al)晶粒没有明显的轮廓,说明其尺寸粗大且呈无规则分布;共晶Si相和富Fe相呈粗针状或片状,且排列不规则,这使合金铸件于此处易产生应力集中,受力变形时割裂基体,从而降低铸件的力学性能。当添加0.01%Sr后,α(Al)晶粒轮廓变得逐渐清晰,形貌趋于圆整化,见图1(b);共晶Si相和富Fe相开始由粗针状或片状转变为短棒状,且在少部分区域呈颗粒状。如图1(c)所示,当Sr的添加量至0.05%时,可以明显观察到形貌圆整的α(Al)晶粒,共晶Si相也以颗粒状或纤维状均匀分布在晶界,而富Fe相的形态变化并不明显,此时变质效果最佳,合金抗拉强度为269.54 MPa,伸长率达到3.21%,分别比基体合金提高了47.48%和65.46%;当Sr添加量达到0.09%时,α(Al)晶粒和富Fe相的形貌变化均不明显,但局部出现共晶Si相的团聚和长大。

图1 不同Sr添加量时ADC12合金的显微组织

Fig. 1 Microstructures of ADC12 alloys with different additions of Sr

Sr变质ADC12合金能使显微组织得以改善、力学性能显著提升,究其原因,可以从两方面来分析:其一,根据Hume-Rothery原理[12],当溶质和溶剂的原子半径相对差大于15%时,只能形成低固溶度的固溶体,故Sr原子(rSr=0.215 nm)进入初生α(Al) (rAl=0.143 nm)晶格内的概率较低,大部分富集在晶界处,从而导致成分过冷;另外,结合表1列出的由差热分析(DTA)获得的不同Sr添加量ADC12合金的共晶温度发现,经变质处理后,ADC12合金的共晶温度均有所下降,这表明合金在共晶反应时过冷度增大,当添加Sr含量为0.05%时相比基体下降幅度最大,达到3.7 ℃;较大的过冷度在熔体凝固时将促进α(Al)形核率的提升,使晶粒变得细小,此外,共晶Si相和富Fe相的生长将受到周围α(Al)相的限制,为破坏其沿轴向生长创造了有利条件。这就解释了α(Al)相轮廓随Sr添加量增加而逐渐清晰,共晶Si相和富Fe相由粗针状或片状转变为短棒状、进而转变为颗粒状或纤维状。

其二,Sr是典型的吸附类变质元素[13],既能毒化共晶Si相固有的生长台阶限制其粗化[11],又能引起Si相孪晶边界能降低[14];当Sr添加到一定量后,Si相孪晶边界能降低明显,使得产生孪晶的几率大幅度提升,这也促使Si相在更多的方向上生长,并产生弯折、分叉,其形态向纤维化或颗粒状转变。

然而,添加过量的Sr会造成过变质现象,不但会恶化合金显微组织,还会降低其力学性能;本实验在Sr添加量达到0.09%时观察到这一特征,这可能是因为此时Sr原子引发的成分过冷偏离了最佳状态,从而破坏固液界面的稳定造成的。再者,在Al-Si合金体系中,随着Sr添加量的增加,生成锶化物的可能性越大,其主要以SrSi2、SrAl2Si2等形式存在,并会使合金塑性显著降低。SRIRANGAM等[15]采用扩散X射线吸收精细结构光谱(EXAFS)和3D原子探针装置(APT)检测到团聚的SrAl4和SrAl2Si2金属间化合物。

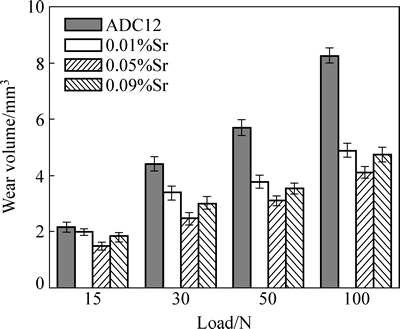

2.2 磨损量

图2所示为不同负载下添加不同Sr含量的ADC12合金的体积磨损量变化。可以发现,所有合金的磨损量均随着负载提升而增多,经Sr变质的ADC12合金的磨损量在任一负载下均要低于基体合金的。随着Sr添加量增加合金磨损率逐渐降低,当Sr添加量为0.05%时合金磨损量达到最低值,然而,随着Sr添加量继续增加至0.09%,合金磨损量开始有所增多。

图2 在不同负载下不同Sr添加量的ADC12合金的磨损量

Fig. 2 Wear volume values for ADC12 alloys with different Sr additions under various loads

一般而言,合金的磨损量与其硬度成反比[16-17]。由表1可以看出,当Sr添加量为0.05%时,合金硬度最高可达87.4HB,所以在任一负载下的磨损量均为最低。不管是合金硬度还是受其影响的磨损量,在滑动磨损的过程中,都与合金的显微组织特征密切相关。未变质的ADC12合金的共晶Si相和富Fe相呈粗针状或片状,这就造成其与α(Al)基体界面处的应力集中,在磨损过程中不能很好地阻止在界面处产生的裂纹,由此将产生大量的磨屑脱落,提升合金磨损量;然而,伴随着Sr含量的增加,共晶Si相和富Fe相均发生明显细化,Sr添加量为0.05%时的Si相更是大部分转变为颗粒状,这能降低二次相与基体界面间的应力集中,并提升二者的结合力,从而改善合金的耐磨性,降低磨损量。那么,当Sr添加过量时(0.09%),共晶Si相的团聚和粗化就能很好地解释合金硬度降低(84.3HB)以及磨损量有所增加的现象。

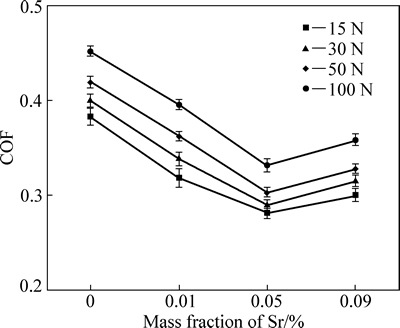

2.3 摩擦因数

图3所示为ADC12合金的摩擦因数与Sr添加量以及负载之间的关系。摩擦因数(COF)是合金在磨损过程中进入稳定磨损阶段后的动摩擦因数的平均值,本实验取磨损5 min时为开始稳定磨损的时间节点。经变质处理的ADC12合金的摩擦因数明显低于未变质处理的合金,且在Sr添加量达到0.05%、负载为15 N时,摩擦因数降到最低值,为0.2816;尽管摩擦因数曲线在Sr添加量为0.09%时有上升趋势,但仍处于较低状态。

基于Bowden和Tabor的摩擦模型[18],摩擦力可以看作是一对滑动摩擦副间的表面微凸体发生相对滑动所受的阻力。如上所述,同一负载下,当合金Sr添加量为0.05%时的磨损量最低,这表明磨屑的脱落程度较轻,即集聚在微凸体间的磨屑数量也大为减少,故而较容易使磨面间产生滑动(摩擦力降低),在法向负载不变的情况下,将导致摩擦因数降低。这也佐证了KORI等[5]和AN等[19]的研究成果。

图3 在不同负载下不同Sr添加量的ADC12合金的摩擦因数

Fig. 3 Coefficient of friction (COF) values for ADC12 alloys with different Sr additions under various loads

此外,合金的摩擦因数随负载的提升而增加。这是因为在宏观光滑的摩擦副接触表面间,只有少数的微凸体上发生接触;施加法向负载后,微凸体发生足够的塑性变形直至足以承受外加负载。那么,随法向负载的提升,摩擦副接触表面微凸体实际接触面积也会随之增加,从而导致滑动表面摩擦力的提升;另一方面,合金高负载下磨损量的增加表明磨屑的脱落程度变得恶劣,集聚在磨损面间的大量磨屑便阻碍了摩擦副的相对滑动,从而提升磨面间的摩擦力和摩擦因数。

2.4 磨损机理

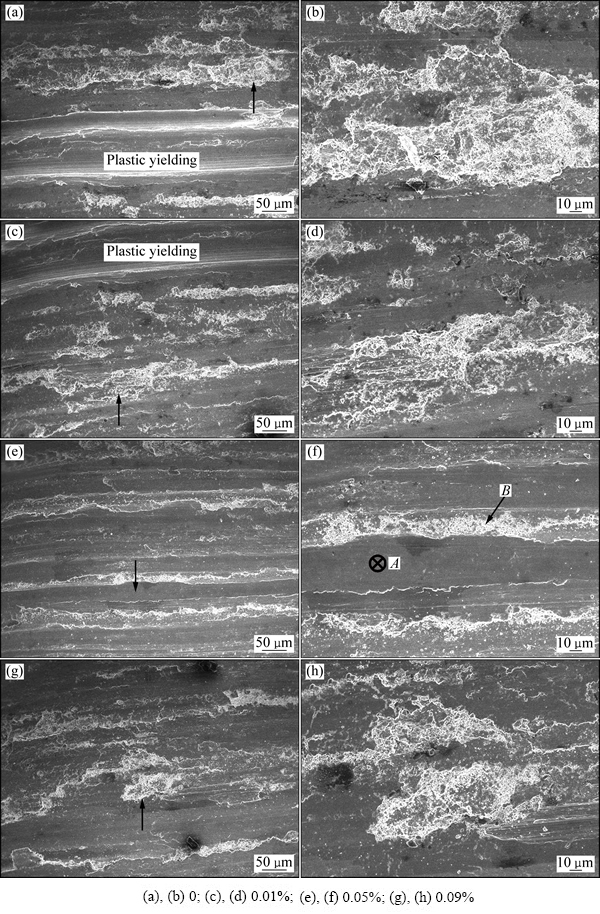

图4所示为100N负载下、不同Sr添加量的ADC12合金磨面的SEM像,图4(b)、(d)、(f)、(h)分别为图(a)、(c)、(e)、(g)中黄色箭头所指处的局部放大图。结合图5中磨屑形貌和EDS结果分析表明,合金的主要磨损机理包括氧化磨损、磨粒磨损、粘着磨损、剥层磨损和塑性屈服。

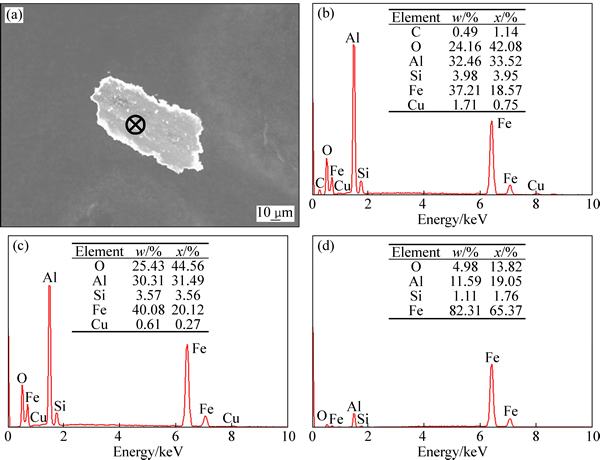

铝作为一种极易氧化的金属,能够与大气中的氧发生反应生成致密的氧化膜:4Al+3O2→2Al2O3。在高负荷滑动磨损过程中,摩擦热的释放是不可避免的,且销盘摩擦副界面间由于存在微凸体而不可能达到绝对贴合,这就促使销试样合金磨面上氧化膜的生成。根据图4(f)中点A的EDS结果表明,可以推断出磨面上暗色区域存在氧化铝薄膜,因为图5(c)中O和Al原子比约为1.5。氧化膜的存在不仅能作为润滑剂改善合金磨损行为、降低摩擦因数[20],同时也能防止金属粗糙表面间的直接接触、降低磨损量[21]。然而,如果施加足够大的法向外力,合金表面将通过发生塑性屈服和变形来承受,同时氧化膜也会发生破碎。图4(a)、(c)中的光滑凹槽表明合金已发生塑性屈服,也说明合金的承载能力超出其自身极限;另外,光滑凹槽上平行排列的划痕可被认为是由于较硬的盘试样表面微凸体对较软合金表面产生擦伤导致的。此外,磨面上发现大面积剥落坑,见图4(b)和(d),这表明剥层磨损的发生,它是一种疲劳磨损,是由于合金受到反复的滑动磨损引发了亚表面裂纹的生成、生长及扩展,当多条裂纹延伸至磨损表面并由于应力集中汇聚到一起时将造成材料局部脱落[22]。

因氧化膜本身具有脆性,当合金已在超越其承载极限的情况下承受外力时,氧化膜将发生破碎且不再能有效防止金属粗糙表面间的直接接触,磨损量开始明显增大。对比图4(b)和(d)发现,基体合金磨面上的剥落坑要比添加0.01%Sr变质合金磨面上的更宽更深,这与合金的显微组织密切相关;合金变质处理后,共晶Si相和富Fe相由基体合金中不规则排列的粗针状或片状转变为短棒状,且少量Si相已呈现颗粒状,这使得二次相与基体的界面结合力明显增加,它不仅能阻碍晶界滑动,还能有效防止磨盘上较硬微凸体对较软合金的剪切,减少裂纹的生成、生长及扩展。

如图4(e)、(f)所示,当Sr添加量为0.05%时,不能观察到明显的塑性屈服和剥落坑。针对图4(f)中点B进行EDS分析,发现犁沟中白色片状物的Fe含量较高,且存在一定量的O、Al、Si元素,这说明它是一种以氧化铝、氧化硅、氧化铁为主要的机械混合物。这类机械混合物是粘着磨损和磨粒磨损综合作用的结果。存在于磨损界面处的表面微凸体在法向载荷下会于接点处发生冷焊即粘着效应[20],相对的切向运动会导致接点剪短,这些被剪短的微凸体在界面处于载荷作用下会发生机械混合,经历钝化—锐化—钝化的反复过程,并由此对较软表面产生犁沟效应即磨粒磨损[23]。另外,见图5(a)和(b),在添加0.05%Sr的变质合金于磨损实验后收集到的磨屑中发现片状磨屑[24],表明剥层磨损实际上是存在的。

当Sr添加量达到0.09%时,尽管不能明显观察到塑性屈服,但合金磨面上又出现大面积剥落坑,这意味着剥层磨损再次成为主要磨损机理,这也说明Sr对ADC12合金的变质效果已偏离最佳状态,然其磨损严重程度仍较基体合金要轻。

综上所述,添加Sr含量为0.05%时ADC12合金的摩擦磨损性能最优,以粘着磨损和磨粒磨损为主要磨损机理,以剥层磨损为次要磨损机理,粘着磨损被认为可有效降低磨损量,因为这种磨损仅仅发生材料的转移,而剥层磨损则恰恰相反,会引起较软合金表面大块材料的脱落,显著提升磨损量。

图4 100 N负载下不同Sr添加量的ADC12合金磨面的SEM像

Fig. 4 SEM images of ADC12 alloys with different additions of Sr on worn surface under load of 100 N

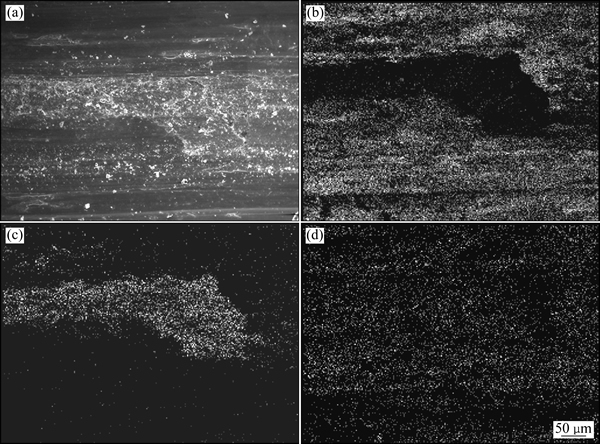

伴随着实验负载的提升,合金磨面将产生更大的塑性变形和磨损。图6所示为当负载为15 N时、添加0.05%Sr的变质合金的磨面形貌和Al、Fe及O元素的分布图,可以看出O元素均匀分布在磨面上,对降低合金磨损量和摩擦因数起到关键作用;然而,Fe元素和Al元素的分布情况是相互映衬的,说明此负载下也发生了粘着磨损,但未观察到清晰的裂纹和明显的材料转移,表明合金表面破坏并不严重。

图5 100 N负载下添加0.05%Sr的ADC12合金片状磨屑及图4(f)中点A、B的能谱分析结果

Fig. 5 Flake-like wear debris (a) and its EDS result (b) of ADC12 alloy with 0.05%Sr, EDS results of points A (c) and B (d) in Fig. 4(f)

图6 在15 N负载下添加0.05%Sr的ADC12合金磨面的SEM像及Al、Fe、O元素的分布图

Fig. 6 SEM image (a) and Al (b), Fe (c) and O (d) element distribution images of ADC12 alloy with 0.05%Sr under load of 15 N

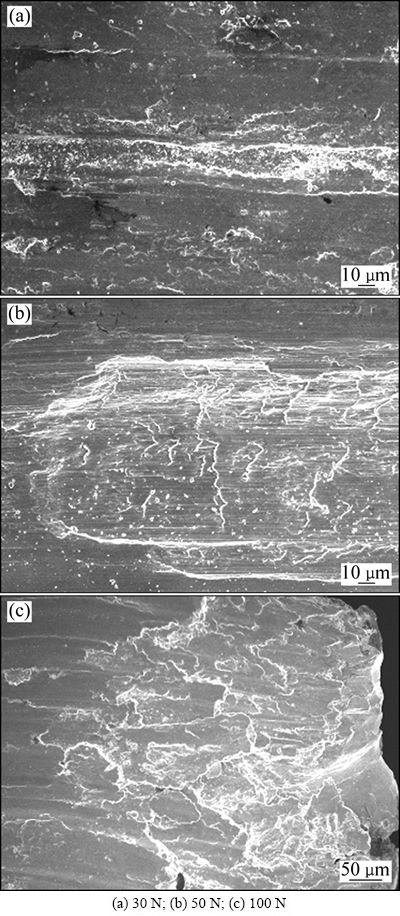

当负载为30 N时,如图7(a)所示,合金表面观察到犁沟、脱落并经转移后压实的层状物,这表明同时发生了粘着磨损和磨粒磨损。当负载提升为50 N时,磨面上出现大面积垂直于滑动方向的裂纹,这预示着剥层磨损即将发生[5]。当负载达到100 N时,发现合金磨面沿滑动方向在边缘处呈现不规则形状,这是合金磨面在高负载下受挤压发生塑性变形及软化,并在随后的滑动过程中向磨面边缘推移造成的[25]。

图7 在不同负载下添加0.05%Sr的ADC12合金磨面的SEM像

Fig. 7 SEM images of ADC12 alloys with 0.05%Sr on worn surfaces under various loads

3 结论

1) ADC12合金中添加适量的Sr能获得明显细化的显微组织。当Sr添加量为0.05%时,组织中共晶Si相以颗粒状或纤维状均匀分布在晶界,富铁相则呈短棒状,这很好地增强了二次相与α(Al)基体之间的结合力,从而使力学性能达到最优,抗拉强度、伸长率及布氏硬度分别较基体合金提升了47.48%、65.46%、18.27%。

2) 合金的磨损量和摩擦因数均随负载提升而增加,当Sr添加量为0.05%时,同一负载下合金磨损量最低,摩擦因数也最低,这也表明Sr含量对ADC12合金的变质效果达到最佳效果。

3) 低负载下(15 N,30 N)合金的磨损机理主要为氧化磨损、粘着磨损和磨粒磨损;当负载为50 N时开始有剥层磨损的迹象;高负载下(100 N),因受到严重挤压变形,合金表面氧化膜发生破坏并不能再有效阻止金属粗糙表面间的直接接触,基体合金以塑性屈服和严重剥层磨损为主要磨损机理,变质后合金的塑性屈服恶劣程度有所改善,且当加入0.05%的Sr时,磨损程度最低,以粘着磨损和磨粒磨损为主要磨损机理,其摩擦磨损性能最优异。

REFERENCES

[1] RAO Yuan-sheng, YAN Hong, HU Zhi. Modification of eutectic silicon and β-Al5FeSi phases in as-cast ADC12 alloys by using samarium addition[J]. Journal of Rare Earths, 2013, 9(31): 916-922.

[2] 闫 洪, 李正华, 黄 昕. 镧对ADC12铝合金固溶时效组织的影响[J]. 稀土, 2013, 5(34): 1-5.

YAN Hong, LI Zheng-hua, HUANG Xin. Effect of Lanthanum on microstructure of ADC12 aluminum alloy solid solution and aging treatments[J]. Chinese Rare Earths, 2013, 5(34): 1-5.

[3] HU Zhi, YAN Hong, RAO Yuan-sheng. Effects of samarium addition on microstructure and mechanical properties of as-cast Al-Si-Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3229-3234.

[4] OKAYASU M, OTA K, TAKEUCHI S, OHFUJI H, SHIRAISHI T. Influence of microstructural characteristics on mechanical properties of ADC12 aluminum alloy[J]. Materials Science and Engineering: A, 2014, 592: 189-200.

[5] KORI S A, CHANDRASHEKHARAIAH T M. Studies on the dry sliding wear behavior of hypoeutectic and eutectic Al-Si alloys[J]. Wear, 2007, 263(1/6): 745-755.

[6] TIMPEL M, WANDERKA N, GROTHAUSMANN R, BANHART J. Distribution of Fe-rich phases in eutectic grains of Sr-modified Al-10wt.%Si-0.1wt.% Fe casting alloy[J]. Journal of Alloys and Compounds, 2013, 558: 18-25.

[7] 王连登, 朱定一, 陈永禄, 魏喆良, 李秋菊, 黄利光, 宋 伟, 吴海彬. 熔体温度处理及变质对Al-20%Si合金凝固组织的影响[J]. 中国有色金属学报, 2011, 21(9): 2075-2083.

WANG Lian-deng, ZHU Ding-yi, CHEN Yong-lu, WEI Zhe-liang, LI Qiu-ju, HUANG Li-guang, SONG Wei, WU Hai-bin. Effects of melt thermal treatment and modification on solidification microstructure of Al-20%Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2075-2083.

[8] 李双寿, 唐靖林, 曾大本. Sr变质对A356合金细化效果的影响[J]. 铸造, 2004, 53(8): 599-601.

LI Shuang-shou, TANG Jing-lin, ZENG Da-ben. Effect of Sr modification on refinement of A356 alloy[J]. Foundary, 2004, 53(8): 599-601.

[9] MCDONALD S D, NOGITA K, DAHLE A K. Eutectic nucleation in Al-Si alloys[J]. Acta Materialia, 2004, 52(14): 4273-4280.

[10] BASAVAKUMAR K G, MUKUNDA P G, CHAKRABORTY M. Influence of grain refinement and modification on dry sliding wear behavior of Al-7Si and Al-7Si-2.5Cu cast alloys[J]. Journal of Materials Processing Technology, 2007, 186(1/3): 236-245.

[11] LIU Gang, LI Guo-dong, CAI An-hui, CHEN Zhao-ke. The influence of Strontium addition on wear properties of Al-20wt%Si alloys under dry reciprocating sliding condition[J]. Materials and Design, 2011, 32(1): 121-126.

[12] ROTHERY H W, RAYNOR G V. The structure of metals and alloys (4th Ed)[M]. London: Institure of Metals, 1962.

[13] LIAO Heng-cheng, SUN Yu, SUN Guo-xiong. Correlation between mechanical properties and amount of dendritic α-Al phase in as-cast near-eutectic Al-11.6% Si alloys modified with strontium[J]. Materials Science & Engineering A, 2002, 335(1/2): 62-66.

[14] XU D, SRIRAM V, OZOLINS V, YANG J M, TU K N, STAFFORD G R, BEAUCHAMP C, ZIENERT I, GEISLER H, HOFMANN P, ZSCHECH E. Nanotwin formation and its physical properties and effect on reliability of copper interconnects[J]. Microelectronic Engineering, 2008, 85(10): 2155-2158.

[15] SRIRANGAM P, CHATTOPADHYAY S, BHATTACHARYA A, NAG S, KADUK J, SHANKAR S, BANERJEE R, SHIBATA T. Probing the local atomic structure of Sr-modified Al-Si alloys[J]. Acta Materialia, 2014, 65: 185-193.

[16] MAZAHERY A, SHABANI M O. Microstructural and abrasive wear properties of SiC reinforced aluminum-based composite produced by compocasting[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 1905-1914.

[17] 陈聪聪, 陈 刚, 严红革, 苏 斌. 颗粒增强铝基梯度复合材料的摩擦磨损性能[J]. 中国有色金属学报, 2011, 21(6): 1258-1264.

CHEN Cong-cong, CHEN Gang, YAN Hong-ge, SU Bin. Friction and wear properties of particle reinforced graded aluminum matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1258-1264.

[18] BOWDEN F P, TABOR D. The friction and lubrication of solids[M]. Oxford: Clarendon Press, 1964.

[19] AN J, LI R G, LU Y, CHEN C M, XU Y, CHEN X, WANG L M. Dry sliding wear behavior of magnesium alloys[J]. Wear, 2008, 265(1/2): 97-104.

[20] LASHGARI H R, SUFIZADEH A R, EMAMY M. The effect of strontium on the microstructure and wear properties of A356-10%B4C cast composites[J]. Materials and Design, 2010, 31(4): 2187-2195.

[21] DWIVEDI D K, ARJUN T S, THAKUR P, VAIDYA H, SINGH K. Sliding wear and friction behavior of Al-18%Si-0.5%Mg alloy[J]. Journal of Materials Processing Technology, 2004, 152(3): 323-328.

[22] SUH N P. An overview of the delamination theory of wear[J]. Wear, 1977, 44(1): 1-16.

[23] 朱学卫, 王日初, 王小锋, 彭 健. 高硅铝合金的摩擦磨损性能[J]. 功能材料, 2015, 46(9): 8063-8071.

ZHU Xue-wei, WANG Ri-chu, WANG Xiao-feng, PENG Jian. Investigation of friction behavior and wear mechanism of high-silicon content Al-Si alloy[J]. Journal of Functional Materials, 2015, 46(9): 8063-8071.

[24] AUNG N N, ZHOU WEI, LIM L E N. Wear behavior of AZ91D alloy at low sliding speeds[J]. Wear, 2008, 265(5/6): 780-786.

[25] ASL K M, MASOUDI A, KHOMAMIZADEH F. The effect of different rare earth elements content on microstructure, mechanical and wear behavior of Mg-Al-Zn alloy[J]. Materials Science & Engineering A, 2010, 527(7/8): 2027-2035.

Effect of Sr modification on friction and wear properties of ADC12 alloy

WANG Zhi-wei1, 2, YAN Hong1, 2, XIONG Jun-jie1, 2

(1. Department of Materials Processing Engineering, School of Mechanical and Electrical Engineering,

Nanchang University, Nanchang 330031, China;

2. Key Laboratory of Light Alloy Preparation & Processing in Nanchang City, Nanchang 330031, China)

Abstract: The effect of applied load on the friction and wear properties of Sr modified ADC12 alloys, and its relationship with microstructure and mechanical properties were investigated by MMD-1 pin-on-disc wear testing machine, OM, SEM and EDS. The results show that, in the microstructure of alloy modified with 0.05%Sr (mass fraction), eutectic Si phases distribute uniformly at grain boundaries in morphologies of particle-like or fiber-like, and shape of Fe-rich intermetallics transforms to short rod-like, giving rise mechanical properties to the highest. Also the alloy wear volume and friction coefficient reach to the lowest under invariable load. At 100 N, oxide films on worn surface are broken due to the serious extruded deformation. Plastic yielding and severe delamination are mainly in the matrix alloy, while adhesive and abrasive wear characterize in the modified alloy with 0.05%Sr. The wear degree of the latter one is the minimum, and its friction and wear properties are the optimal.

Key words: Sr modification; ADC12 alloy; friction and wear; wear mechanism

Foundation item: Project (51364035) supported by the National Natural Science Foundation of China; Project (20133601110001) supported by the Ministry of Education Tied up with the Special Research Fund for the Doctoral Program for Higher School; Project (KJLD14003) supported by the Landing Program of education department of Jiangxi Province; Project (2012-CYH-DW-XCL-002) supported by the Cooperation Project on the Integration of Industry, Education and Research of Outside Experts and Doctors

Received date: 2015-07-22; Accepted date: 2015-11-05

Corresponding author: YAN Hong; Tel: +86-791-83968873; E-mail: yanhong_wh@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助(51364035);教育部高等学校博士学科点专项科研基金联合资助课题(20133601110001);江西省教育厅落地计划项目(KJLD14003);党外专家博士产学研合作计划(2012-CYH-DW-XCL-002)

收稿日期:2015-07-22;修订日期:2015-11-05

通信作者:闫 洪,教授,博士;电话:0791-83968873;E-mail:yanhong_wh@163.com