流变铸造镁合金AZ31B的热/力模拟

张少明1, 杨必成1, 樊中云2, 徐 骏1, 石力开1, 陈国良3

(1. 北京有色金属研究总院 北京 100088;

2. Brunel University, Uxbridge, Middle Sex U138 3PH, UK;

3. 北京科技大学 新金属材料国家重点实验室, 北京 100083)

摘 要: 采用双螺旋流变铸造工艺制备了镁合金AZ31B的棒坯, 利用Gleeble-3000型热/力模拟机研究了流变铸造和普通连铸棒坯在变形温度为250~400℃, 变形速率为0.001~5s-1, 最大变形量为60%时的热压缩变形行为。 分析了材料流变应力与变形量、 变形温度和应变速率之间的关系, 比较了两种不同铸造工艺对热塑性变形行为的影响。 结果表明: 流变铸造坯料在变形过程中的形变均匀性明显优于普通铸造的, 因此不需预处理即可直接进行塑性成型; 350℃以上热变形流变铸造坯料的变形抗力明显小于普通铸造坯料的; 流变铸造使AZ31B合金的塑性加工性能得到改善; 产生这种差别的主要原因是普通铸造坯料组织为粗大树枝晶, 而流变铸造坯料组织为细小等轴晶。

关键词: 镁合金; 流变铸造; 热/力模拟 中图分类号: TG146.2

文献标识码: A

Hot compressive deformation simulation of rheo-cast AZ31B magnesium alloy

ZHANG Shao-ming1, YANG Bi-cheng1, FAN Zhong-yun2,XU Jun1, SHI Li-kai1, CHEN Guo-liang3

(1. General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Brunel University, Uxbridge, Middle Sex U138 3PH, UK;

3. State Key Laboratory for Advanced Metals and Materials,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The billet of magnesium alloy AZ31B was prepared by the method of twin-screw rheo-casting and normal casting. The hot compression of these two kinds of samples at 250-400℃ was performed on Gleeble-3000 hot simulator with the strain rates of 0.001-5s-1, and the maximum deformation of 60%. The relationship among the stress, deformation temperature and strain rate were analyzed and compared. The results show that the deformation of rheo-casting billet is more uniform than that of the normal casting in the compression process, so the rheo-cast billet can be hot deformed directly. The maximum stress of rheo-casting is less than that of the normal casting at above 350℃, which means that the billet made by rheo-casting can be deformed easier than normal casting. The reason of the difference is that the microstructure of rheo-casting is composed of uniform, tiny and equal-axial grains; while the microstructure of normal casting is coarse dendrite.

Key words: magnesium alloy; rheo-casting; hot compressive deformation simulation

镁合金具有密度低、 比强度和比刚度高、 抗震及减振能力强, 电磁屏蔽效果优异及易回收利用等优点, 在电子、 电器、 交通、 航空、 航天等领域具有重要的应用价值和广阔的应用前景, 被誉为是21世纪最具发展前途的金属结构材料[1, 2]。 目前大量镁合金产品主要通过铸造的方法获得。 铸造法生产的镁合金组织呈粗大枝晶状, 存在成分偏析, 难以制备出性能优良的镁合金。 通过挤压、 锻造、 轧制等工艺生产出的变形镁合金产品, 比铸造材料具有更高的强度、 更好的延展性, 因而可以满足更多结构件的需要。 由于大部分镁合金具有密排六方晶体结构, 对称性低、 室温滑移系少, 冷加工比较困难, 采用热加工工艺也需要对坯料进行长时间退火和大变形挤压等预处理过程[3], 生产效率低下, 难以得到高性能镁合金型材。 这是限制变形镁合金材料发展的关键因素。 因此, 开发变形镁合金加工新技术、 新工艺, 生产高质量的变形镁合金成为当今国际镁工业的发展趋势。 流变铸造技术使熔体在高剪切率和高强度紊流环境中形核凝固[4], 消除了铸坯中的枝晶组织, 细化了晶粒, 必然会影响坯料的塑性加工性能。 本文作者通过双螺旋流变铸造坯料的热/力模拟实验, 揭示流变铸造坯料与常规铸造坯料的热塑性变形规律差异, 为流变铸造变形镁合金的塑性加工提供依据。

1 实验

实验使用商业生产AZ31B铸态棒料为原材料, 经化学分析, 其化学成分如表1所示。 合金的固、 液相线温度分别为605和630℃。 原料在氩气保护下熔化后, 浇入双螺旋流变制浆机中进行强力搅拌, 然后在略低于液相线温度注入铁模中冷却成半固态坯料。 在原始铸态棒料(以下简称NC)和半固态坯料(以下简称RC)中分别加工出d10mm×15mm的圆柱试样, 在Gleeble-3000型热/力模拟实验机上进行一系列热压缩实验, 实验应变速率分别

表1 合金的化学成分

Table 1 Chemical composition of alloy (mass fraction, %)

为0.001、 0.01、 0.1、 1和5s-1; 变形温度分别为250、 300、 350和400℃; 变形量均为60%。 为减少压缩过程中试样端面所受摩擦力, 实验前在试样两端垫上石墨片并涂抹二硫化钼作润滑剂。 通过以上实验可以反映出两种工艺制备坯料的塑性变形规律。

2 结果与分析

2.1 坯料铸态组织

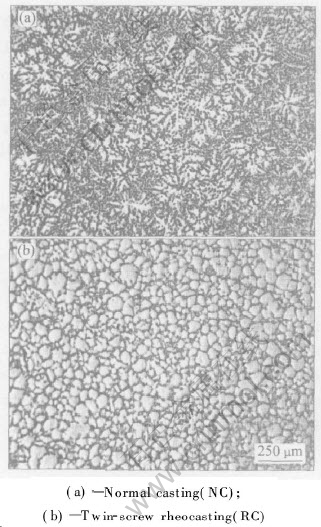

图1所示为用普通铸造(NC)工艺和双螺旋流变铸造(RC)工艺得到的坯料的内部显微组织。 从图中可以看出, 普通铸造工艺制成的坯料组织为粗大的枝晶和枝晶间的细小共晶相组成。 双螺旋流变铸造组织主要为细小均匀的等轴α-Mg, 少量第二相分布在晶界上。 在普通铸造工艺中, 过热熔体浇入冷模或结晶器中, 模壁附近的过冷熔体大量形核, 但大部分晶核都流入模具内的过热熔体中重新熔化, 只有少量(约0.3%)的晶核能保存下来并逐渐长大, 受传热、 成分过冷等因素影响, 晶核最后长大成粗大的树枝晶。 流变铸造中, 在双螺旋强

图1 AZ31B合金的铸态组织

Fig.1 Microstructures of as-cast AZ31B alloy

烈搅拌作用下, 熔体内无论温度还是成分都非常均匀, 随着熔体连续冷却至液相线以下, 熔体内各部分都同时形核, 与普通铸造相比, 实际形核率也许相差不大, 但几乎所有晶核都能保留下来, 即增加了有效形核率; 而且强烈搅拌可以分散熔体内潜在的非均匀形核核心, 增加形核点。 随后大量核心在几乎完全一致的环境中长大, 最终得到细小等轴的晶粒形貌[5, 6]。 两种工艺得到的坯料在微观组织上的差异, 必然影响到后续的塑性变形行为。

2.2 铸坯的热压缩变形行为

试样热压缩变形示意图如图2所示, 在单向压应力作用下, 圆柱体除受到变形工具的压缩力外, 在与工具接触的端部还受摩擦力作用。 此摩擦力阻碍金属质点的横向流动, 使得变形金属的整个体积大致分成三个具有不同应力状态和变形程度的区域, 其中Ⅰ区为难变形区, Ⅱ区为易变形区, III区为自由变形区。 Ⅰ区和Ⅱ区为三向压应力, III区在周向为拉应力。 这与锻造过程中锻件的受力情况基本相同。

图2 热压缩示意图

Fig.2 Model of hot compression

图3所示为两种试样热压缩变形后外观。 在实验所有变形条件下, NC试样的圆柱面都有很明显的皱褶, 相比之下, RC试样圆柱面要光滑得多。 这个差别与试样内部微观组织密切相关。 由于镁具有密排六方晶体结构, 晶体结构对称性差, 当承受单向压缩时, 会表现出明显的各向异性。 由于NC试样的原始晶粒为生长方向各异的粗大树枝晶, 加上第二相在晶间的无序分布, 导致NC试样内部各个晶粒的变形不均匀性比较严重, 某些取向有利的晶粒, 很容易产生较大形变量, 而那些取向不利于变形的晶粒, 只有在应力增加到一定水平后才会通过孪生等方式改变自身取向, 以便进一步滑移和孪生。 各个晶粒不均匀变形叠加, 使得圆柱面出现明显皱褶。 因此, 在大多数情况下, 镁合金锻造用材料都是采用挤压坯料, 而且挤压前需对原始坯料进行长时间均匀化处理, 减少力学性能的各向异性[7]。 用流变铸造制成的坯料, 不经任何预处理即可得到等轴、 细小、 均匀的初始晶粒, 在加工硬化的作用下, 晶粒的协同变形能力加强, 极大地消除了晶体结构本身带来的形变不均匀性。 使用流变铸造制成的铸锭直接进行锻造, 可以改变传统的采用一次挤压坯料来生产锻件的工艺流程, 简化镁合金锻件生产工艺, 提高生产效率。

图3 试样热压缩变形后的照片

Fig.3 Photo of sample after hot compression

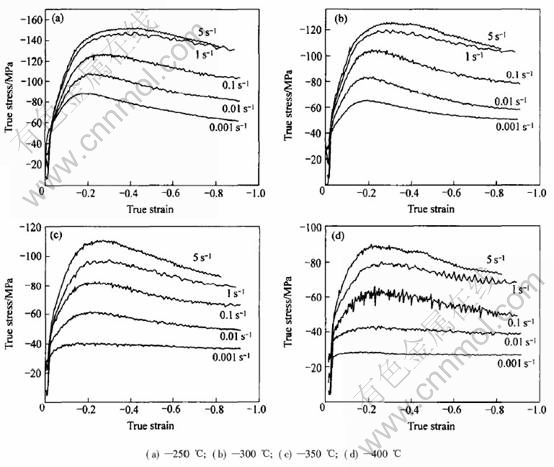

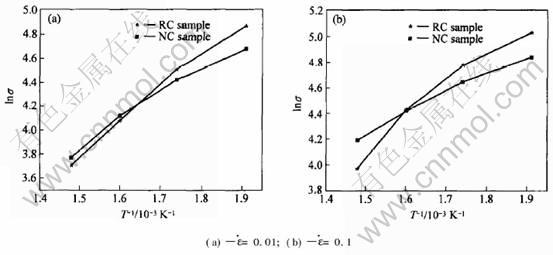

图4和5所示分别为NC和RC试样在不同温度、 不同应变速率条件下热压缩变形过程的真应力—真应变的关系曲线。 AZ31B锭坯通常作为生产镁合金挤压件原材料[8], 其典型的挤压温度为350~400℃, 应变速率为10-1~10-2s-1。 将此应变速率范围内的最大流变应力取对数, 对应温度取倒数的关系曲线如图6所示, 曲线上各点对应实际温度从左至右依次为400、 350、 300和250℃。

以上各曲线图反映了两种不同工艺制备的试样在变形过程中应变速率、 变形温度、 变形抗力和变形量等之间的关系, 其特点主要如下。

1) 变形过程中, 曲线表现为两种形式。 一种随着变形量增加, 流变应力逐渐增加到最大值, 然后逐渐下降并趋于稳定, 具有形变—再结晶特征; 另一种情况是在很小应变情况下, 应力大小就基本恒定不变, 变形进入稳态流变, 具有形变—回复特征。 从图5中看出, 300℃时, RC试样在0.001s-1条件下开始表现出稳态流变特征, 且随温度升高, 出现稳态流变的应变速率逐渐增加。 而NC试样出现稳态流变的温度更高, 应变速率更低。

2) 相同变形速率下, 镁合金变形抗力随温度

图4 NC试样在不同温度和应变速率下的真应力-真应变关系曲线

Fig.4 Relationship between true strain and true stress for NC sample at different temperatures and strain rates

增加显著下降; 在各个温度条件下, 流变应力对应变速率很敏感, 通常情况下, 变形速率增加, 流变应力相应增大[9, 10]。

3) RC试样最大流变应力对应的变形量均大于同样变形条件下NC试样的。 图6中两组曲线交点温度大约都为350℃, 在交点温度以下, NC试样的最大流变应力小于同条件下RC试样的; 交点温度以上NC试样的最大流变应力大于RC试样的, 其中在温度400℃和应变速率0.1s-1时, RC试样的最大流变应力为NC试样的80%。

两种不同试样表现出的共性和特性一方面与镁合金塑性变形机制有关, 另一方面试样原始组织的差异造成变形规律上的不同[11]。

通常在合金的热变形过程中, 一方面随变形量增加, 位错密度逐渐增加, 材料表现出加工硬化, 另一方面由于回复和再结晶过程使材料出现软化现象, 因此随变形量增加, 净加工硬化率逐渐减少, 最后趋于零。 由于镁合金的层错能较低, 其滑移面上不全位错之间的层错区较宽, 这样, 位错的滑移和攀移很难进行, 通常这种材料的动态回复速度比较慢, 一般来说, 位错密度增加速率与变形速率成正比, 所以整个变形过程中流变应力大小对应变速率表现得很敏感[12]。 位错累积产生的硬化和动态回复再结晶产生软化叠加产生应力峰值, 若二者达到平衡, 则产生稳态流变。 镁合金塑性变形过程中, 在温度较低时, 镁合金变形机制主要是基面滑移和孪晶的协调变形, 临近孪晶界的高密度位错区域的孪晶和晶格渐进扭转激发产生细小的动态再结晶晶粒; 随温度升高, 棱面滑移和锥面滑移启动, 伴随有交滑移; 温度进一步升高, 位错攀移也参与变形, 交滑移和攀移产生的位错重组导致在原始晶界附近产生小角度晶界网络。 在小角度晶界上, 位错的连续吸收引发动态再结晶[13, 14]。

图5 RC试样在不同温度和应变速率下的真应力—真应变关系曲线

Fig.5 Relationship between true strain and true stress for RC sample at different temperatures and strain rates

图6 不同应变速率下最大变形抗力和温度的关系曲线

Fig.6 Relationship between temperature and maxium deformation resistance at different strain rates

结合实验结果可以认为, 350℃以下, 位错的交滑移控制着塑性变形和动态再结晶形核, 由于NC试样存在较大的形变不均匀性, 形变量较大的晶粒内位错密度很高, 晶内位错通过交滑移率先发生再结晶形核和长大, 使变形应力得到释放; RC试样各个晶粒变形程度和位错密度差别不大, 再结晶在各个晶粒内几乎同时发生, 因此与NC试样相比, 开始发生再结晶的总变形量较高, 最大变形抗力较大。 随温度升高, 位错攀移逐渐参与并控制着整个塑性变形和动态回复再结晶, 攀移使位错可动性大大增加, 更容易摆脱与其他位错的缠绕, 使正负位错抵消或运动到原始晶界, 当进入晶界的位错密度超过晶界的吸收容量, 过量的位错就会在晶界产生应力集中, 使原始晶界变为锯齿状[15], 此时再结晶新晶粒的形核机制是晶界弓出机制。 由于RC试样的晶粒为细小等轴晶, 原始晶界面积比NC试样的大得多, 所以回复效果更加明显, 再结晶形核更容易, 热变形中更容易出现稳态流变, 同时最大变形抗力较NC试样要低。

从以上热/力模拟实验的结果和分析不难看出, 在通常的热挤压工艺条件下, 流变铸造坯料比普通铸造坯料具有明显的优越性: 1) 在变形前流变铸造坯料不需要长时间的均匀化处理; 2) 在变形过程中较普通铸造坯料获得稳态流变的应变速率要高, 使挤压工艺可以采用更高的应变速率, 同时挤压过程更稳定, 得到的加工态组织也更加均匀, 综合力学性能相应得到改善; 3) 在350℃以上变形能获得较大的变形速率或较小的变形抗力, 提高挤压效率。 这种优越性的主要原因是流变铸造极大地改善了铸态组织, 并影响到坯料热变形过程中的回复和再结晶过程。

3 结论

1) 热变形过程中, 流变铸造坯料的形变均匀性明显优于普通铸造坯料, 普通铸造坯料变形后外表面有明显皱褶, 流变铸造坯料变形后外表面光滑平整, 铸坯不需经预处理即可直接进行锻造。

2) 与普通铸造相比, 流变铸造坯料在热变形过程中获得稳态流变的温度更低, 应变速率更高。

3) 350℃以上热变形时, 流变铸造坯料的变形抗力明显小于同条件下普通铸造坯料; 在通常热加工温度范围内, 流变铸造坯料比普通铸造坯料具有更好的塑性变形能力。

REFERENCES

[1]Mordike B T, Ebert T. Magnesium properties applications potential[J]. Mater Sci Eng A, 2001, A302: 37-45.

[2]Aghion E, Bronfin B. Magnesium alloys development towards the 21st century[J]. Mater Sci Forum, 2000, 350: 19-28.

[3]Murai T, Matsuoka S I, Miyamoto S. Effects of extrusion conditions on microstructure and mechanical properties of AZ31B magnesium alloy extrusions[J]. J Mater Proce Techn, 2003, 141: 207-212.

[4]Fan Z, Ji S, Bevis M J. Twin-screw rheomoulding——a new semi-solid processing technology[A]. Chiarmetta G L, Rosso M. 6th International Conference on Semi-Solid Processing of Alloys and Composites Turin[C]. Brescia, Italy, 2000. 61-66.

[5]Fan Z, Ji S, Liu G. Development of the rheo-diecasting process for magnesium alloy and their component[A]. 8th International Conference on Semisolid Process Cyprus[C]. 2004.

[6]Das A, Fan Z. Morphological development of solidification structures under forced fluid flow experimental observation[J]. Mater Sci Technol, 2003, 19: 573-580.

[7]陈振华, 严红革, 陈吉华, 等. 镁合金[M]. 北京: 化学工业出版社, 2004.

CHEN Zheng-hua, YAN Hong-ge, CHEN Ji-hua, et al.Magnesium Alloy[M]. Beijing: Chemical Industry Press, 2004.

[8]Margam C, Yong M, Shyan J. Effect of materials and temperature on the forward extrusion of magnesium alloys[J]. Mater Sci Eng A, 2004, A381: 308-319.

[9]Watanabe H, Tsutsui T, Mukai T. Deformation mechanism in a coarse-grained Mg-Al-Zn alloy at elevated temperatures[J]. International Journal of Plasticity, 2001, 17: 387-397.

[10]余琨, 黎文献, 王日初, 等. Mg-5.6Zn-0.7Zr-0.8Nd合金高温塑性变形的热/力模拟研究[J]. 金属学报, 2003, 39(5): 492-498.

YU Kun, LI Wen-xian, WANG Ri-chu, et al. Hot compressive deformation simulation of Mg-5.6Zn-0.7Zr-0.8Nd alloy at elevated temperatures[J]. Acta Metallurgica Sinca, 2003, 39(5): 492-498.

[11]Watanabe H, Mukai T, Sugioka M. Elastic and damping properties from room temperature to 673 K in an AZ31 magnesium alloy[J]. Scripta Materialia, 2004, 51: 291-295.

[12]陈振华, 夏伟军, 严红革, 等. 镁合金材料的塑性变形理论及其技术[J]. 化工进展, 2004, 23: 127-135.

CHEN Zheng-hua, XIA Wei-jun, YAN Hong-ge, et al. Principles and technologics of plastic deformation for magnesium alloys[J]. Chemical Industry and Engineering Progress, 2004, 23: 127-135.

[13]汪凌云, 范永革, 黄光杰. 镁合金AZ31B的高温塑性变形及加工图[J]. 中国有色金属学报, 2004, 14(7): 1068-1072.

WANG Ling-yun, FAN Yong-ge, HUANG Guang-jie. Plastic deformation at elevated temperature and processing maps of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1068-1072.

[14]张娅, 马春江, 卢晨. 变形镁合金的塑性变形机制与动态再结晶[J]. 轻合金加工技术, 2003, 31(7): 35-39.

ZHANG Ya, MA Chun-jiang, LU Chen. Plastic strain mechanism and dynamic recrystallization of magnesium alloy[J]. Light Alloy Fabrication Technology, 2003, 31(7): 35-39.

[15]Tan J C, Tan M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Mater Sci Eng A, 2003, A339: 124-132.

(编辑龙怀中)

基金项目: 国家高技术研究发展计划资助项目(2005AA33H020)

收稿日期: 2005-07-15; 修订日期: 2005-08-20

作者简介: 张少明(1962- ), 男, 教授级高工

通讯作者: 张少明; 电话: 010-62055345; E-mail: shmzhang@grinm.com