Flow behavior and processing map of PM Ti-47Al-2Cr-0.2Mo alloy

来源期刊:中国有色金属学报(英文版)2012年第4期

论文作者:李慧中 曾敏 梁霄鹏 李洲 刘咏

文章页码:754 - 760

关键词:粉末冶金;钛铝基合金;热压缩变形;加工图

Key words:powder metallurgy; TiAl based alloy; hot compression deformation; processing map

摘 要:采用Gleeble-1500热模拟试验机进行等温压缩实验,在变形温度为1000-1150℃、应变速率为0.001-1 s-1的条件下,研究粉末冶金Ti-47Al-2Cr-0.2Mo合金的流变行为。结果表明:变形温度和应变速率对该合金的流变行为有显著影响,流变应力随应变速率的增加和变形温度的降低而增大。不同应变条件下的加工图表明该合金的加工图对应变量很敏感。应变量为0.5时,对应的加工图表明粉末冶金Ti-47Al-2Cr-0.2Mo合金合适的加工区域是:温度1000-1050℃、应变速率0.001-0.05 s-1;温度1050-1125℃、应变速率0.01-0.1 s-1。对热变形后合金的显微组织和加工图进行分析,发现1000℃,0.001 s-1是该合金进行热变形的最佳工艺参数。

Abstract: The flow stress features of PM Ti-47Al-2Cr-0.2Mo alloy were studied by isothermal compression in the temperature range from 1000 to 1150℃ with strain rates of 0.001-1 s-1 on Gleeble-1500 thermo-simulation machine. The results show that the deformation temperature and strain rate have obvious effects on the flow characteristic, and the flow stress increases with increasing strain rate and decreasing temperature. The processing maps under different deformation conditions were established. The processing maps of this alloy are sensitive to strains. The processing map at the strain of 0.5 exhibits two suitable deformation domains of 1000-1050℃ at 0.001-0.05 s-1 and 1050-1125℃ at 0.01-0.1 s-1. The optimum parameters for hot working of the alloy are deformation temperature of 1000℃ and strain rate of 0.001 s-1 according to the processing map and microstructure at true strain of 0.5.

![]()

Trans. Nonferrous Met. Soc. China 22(2012) 754-760

LI Hui-zhong1, 2, 3, ZENG Min1, LIANG Xiao-peng2, LI Zhou1, LIU Yong2

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Key Laboratory of Nonferrous Metal Materials Science and Engineering of Ministry of Education,Changsha 410083, China

Received 9 September 2011; accepted 22 December 2011

Abstract: The flow stress features of PM Ti-47Al-2Cr-0.2Mo alloy were studied by isothermal compression in the temperature range from 1000 to 1150 ℃ with strain rates of 0.001-1 s-1 on Gleeble-1500 thermo-simulation machine. The results show that the deformation temperature and strain rate have obvious effects on the flow characteristic, and the flow stress increases with increasing strain rate and decreasing temperature. The processing maps under different deformation conditions were established. The processing maps of this alloy are sensitive to strains. The processing map at the strain of 0.5 exhibits two suitable deformation domains of 1000-1050 ℃ at 0.001-0.05 s-1 and 1050-1125 ℃ at 0.01-0.1 s-1. The optimum parameters for hot working of the alloy are deformation temperature of 1000 ℃ and strain rate of 0.001 s-1 according to the processing map and microstructure at true strain of 0.5.

Key words: powder metallurgy; TiAl based alloy; hot compression deformation; processing map

1 Introduction

TiAl-based alloys are widely used as high temperature structural materials in many fields (e.g. aerospace and automotive industries) because of their attractive properties, such as low density, high specific strength, high specific stiffness, good oxidation resistance, high resistance to oxidation and good creep properties at high temperatures [1-3]. Although remarkable progress has been made, TiAl alloys have not yet been widely applied because of their brittleness and limited workability. One of the best ways to improve the ductility of the alloys is to convert the coarse grained texture and segregated microstructure into a more homogeneous and fine-grained microstructure by thermo-mechanical processing [4-6]. Compared to ingot metallurgy (IM) route, powder metallurgy (PM) technique is attractive since it exhibits good structural homogeneity and requires deformation processing at relatively low temperatures [7, 8].

Much effort has been devoted to reveal the fundamental correlations between the composition and microstructure, processing behavior and mechanical properties of PM TiAl alloys in the last decade [7,9-13]. The flow behavior during hot working is often complex, and the hardening and softening mechanisms are both significantly affected by temperature, strain rate and strain. The number of studies performed on the hot deformation of PM TiAl alloys is limited. Especially, the studies on the flow behavior and processing map of PM Ti-47Al-2Cr-0.2Mo alloy are few.

Processing map on the basis of dynamic material model (DMM) [14] has been widely used to understand the hot workability of many materials, especially for those difficult to deform, which is made by overprinting with a power dissipation map and an instability map. The hot deformation work piece could be considered a power dissipater, and the total power P consists of two complementary parts [15,16]: G represents the power dissipation through plastic deformation, most of which is converted into the viscoplastic heat; and J represents the power dissipation through microstructure transition, such as dynamic recovery, dynamic recrystallization, superplastic flow, phase transformations, as well as damage of the material. In this phenomenological model, the contents G and J can be related by the parameter m (strain rate sensitivity) as:

![]() (1)

(1)

For the ideal linear dissipating body, m=1 and J= Jmax=σ![]() /2 =P/2, and a non-dimensional efficiency index η is used to evaluate the power dissipation capacity of the material through microstructural mechanisms and defined as [17]:

/2 =P/2, and a non-dimensional efficiency index η is used to evaluate the power dissipation capacity of the material through microstructural mechanisms and defined as [17]:

![]() (2)

(2)

The contour plot of the iso-efficiency η values on the temperature—strain rate field constitutes the processing map. In addition, an instability criterion can be proposed according to the power dissipation principles, which is expressed as follows [14]:

(3)

(3)

The variation of the instability parameter ![]() with the change of temperature and strain rate can be expressed by the instability map.

with the change of temperature and strain rate can be expressed by the instability map.

Therefore, in this work, the thermo-mechanical compression tests of PM Ti-47Al-2Cr-0.2Mo alloy were conducted under different deformation conditions. The hot processing maps were established to provide important guideline for the optimization of deformation parameters and the improvement of microstructures, and the effect of the strain on processing map was investigated.

2 Experimental

The alloy with nominal composition of Ti-47Al-2Cr-0.2Mo (molar fraction, %) was produced by a PM approach and the powders were produced by plasma rotating electrode process (PREP). Alloy powder with particle size of 100-150 μm was filled into steel can and degassed at 400 ℃, then processed by hot isostatic pressing (HIP) at 1200 ℃ for 4 h under pressure of 170 MPa. Cylindrical compacts with dimensions of approximately d50 mm×100 mm and high relative density of more than 99.6% were obtained. The specimens were cut from it with dimensions of d8 mm×12 mm. The specimens were compression deformed in a temperature range from 1000 to 1150 ℃ and strain rate range from 0.001 to 1 s-1 on a Gleeble-1500 thermo-mechanical simulator. In order to reduce the deformed friction, a graphite lubricant was used between the specimens and the crossheads. All specimens were deformed to a total true strain of about 0.5 and water-quenched from test temperature. The samples were heated by a resistance furnace to the deformed temperature at a heating rate of 5 ℃/s. Before deformation, the samples were homogenized for 180 s at the deformed temperature. Optical microscopy (OM) was used to examine the microstructure of the deformed samples, which were cut along with the compression geometric axis of the compressed sample. The specimens were etched with Kroll reagent (2 mL HF + 8 mL HNO3 + 90 mL H2O).

3 Results

3.1 Flow curves

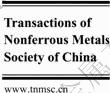

The true stress—true strain curves of Ti-47Al- 2Cr-0.2Mo alloy are illustrated in Fig. 1, which reflect the influences of temperature, strain rate and strain on flow stress. The compression curves compressed at temperatures from 1000 to 1150 ℃ show similar characteristics. All curves exhibit a sharp increase at the onset of plastic deformation and then the flow stress increases slowly with the increase in strain till a peak stress reaches. Subsequently, the stress decreases gradually and then drives to a steady value with increasing strain. Figure 1 also reveals that the flow stress is significantly affected by temperature and strain rates, namely, the flow stresses of materials are reduced with the increase of temperature, thus, the thermal activation of atom cuts down the ability for the resistance of the material to deformation, and the stress needed for the same strain would be lower than that at lower temperature. Meanwhile, the stress peak corresponding to lower temperature is higher than that corresponding to higher temperature. It can be found that flow stress decreases with decreasing strain rate, and the peak strain for the onset of flow softening increases with the strain rate of deformation. With decreasing strain rate, there is a weak effect of temperature on stress. Consequently, Ti-47Al-2Cr-0.2Mo alloy belongs to a material with positive strain rate sensitivity.

3.2 Microstructures analysis

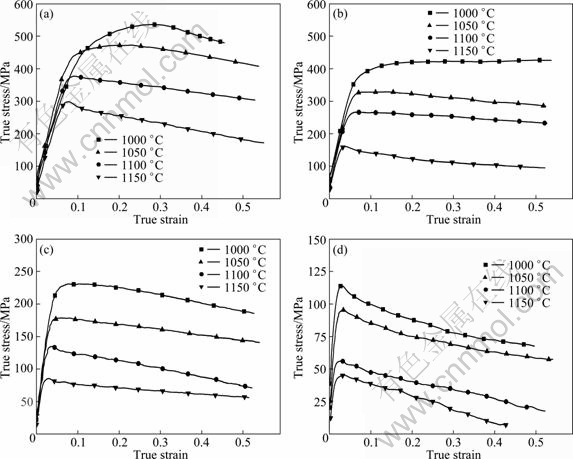

The typical optical microstructures of PM Ti-47Al- 2Cr-0.2Mo alloy after hot compression are shown in Fig. 2. The effects of high temperature on the evolution of microstructures can be seen clearly from these optical micrographs. In Fig. 2(a), some grains are elongated in the perpendicular direction of compression axis, but the boundaries of elongated grains are nearly straight and no recrystallization grain is observed. While the temperature is higher, elongated thin grains with serrations developed on the grain boundaries are observed in Fig. 2(b), where dynamic recrystallization (DRX) grains can be easily distinguished. As shown in Fig. 2(b), fine DRX grains nucleate almost exclusively at grain boundaries and only partial DRX takes place. Meanwhile, strain rate also has remarkable effect on the microstructure of the hot deformed alloy. It is evident from Figs. 2(c) and (d) that the volume fraction of recrystallization grains is greatly increased with decreasing strain rate. However, when the deformation temperature increases to 1150 ℃ at strain rate of 0.001 s-1, there is still a large quantity of elongated or coarse grains in the deformation microstructures as shown in Fig. 2(e). The results indicate that dynamic recrystallization occurs during hot deformation and the degree of DRX is dependent sensitively on the deformation temperature and strain rate.

Fig. 1 True stress—strain curves of PM Ti-47Al-2Cr-0.2Mo alloy at different strain rates: (a) 1 s-1; (b) 0.1 s-1; (c) 0.01 s-1; (d) 0.001 s-1

3.3 Processing maps

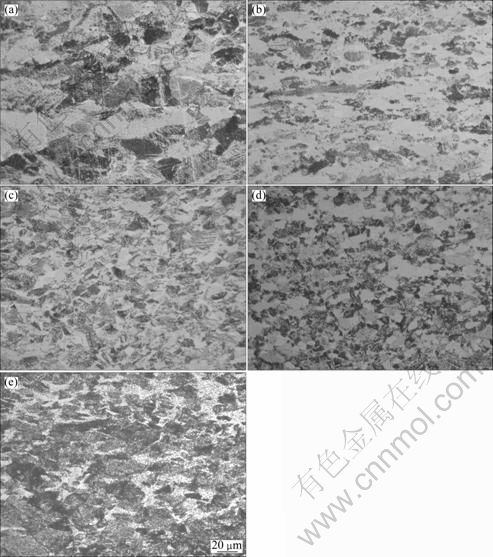

The processing maps obtained at strains of 0.1, 0.3 and 0.5 are shown in Fig. 3. The contour numbers indicate the efficiency of power dissipation, the shaded area represents the unstable region, while the white area represents the zone of safety deformation. In the map, at a strain of 0.1 (shown in Fig. 3(a)), strain rate below 0.01 s-1 and temperature between 1000-1050 ℃, there is a regime showing a peak efficiency of 0.6. When the strain increases to 0.3 and 0.5, the peak efficiency increases to 0.7 and 0.9, respectively. It is obvious that the efficiency of power dissipation less than 0.35 mainly distributes in the regions where the deformation strain rates higher than 0.1 s-1, and the domain corresponds to higher power dissipation expanding with increasing strain. From the maps, it can be seen that there are some essentially similarities among different strains, a minimum efficiency of power dissipation can be obtained at low temperature and high strain rate. The efficiency of power dissipation increases with the increase of true strain, such as zone at 1125-1150 ℃ and 0.001-0.01 s-1, while the efficiency of power dissipation at the middle temperatures and the middle strain rates is nearly invariable with the increase of true strain, such as zone at 1050-1125 ℃ and 0.01-0.1 s-1. The similar phenomenon is also shown in the zone at low temperature and low strain rate such as 1000-1050 ℃ and 0.001-0.01 s-1. Generally, a maximum efficiency of power dissipation can be gained at high deformation temperature and low strain rate, such as the deformation at the temperature of 1150 ℃ and strain rate of 0.001 s-1 at the strain of 0.5. However, a unique characteristic shown in Fig. 3(a) is that a maximum efficiency of power dissipation can be also gained at low temperature and low strain rate. Also, the domains in temperature range of 1075-1125 ℃ and the strain rate of 0.001 s-1 which enjoy a low power dissipation could not be neglected in Fig. 3. These differences among these processing maps partly reflect the effect of the strain on the processing map.

Fig. 2 Microstructures of PM Ti-47Al-2Cr- 0.2Mo alloy deformed to strain of 0.5 at different temperature and strain rates: (a) 1000 ℃, 1 s-1; (b) 1150 ℃, 1 s-1; (c) 1000 ℃, 0.01 s-1; (d) 1000 ℃, 0.001 s-1; (e) 1150 ℃, 0.001 s-1

As shown in Fig. 3(a), the unstable deformation region at strain of 0.1 mainly distributes at the zone with strain rates higher than 0.1 s-1. As the strain level increases to 0.3, the unstable flow is limited to the temperature range of 1040-1150 ℃ and strain rates higher than 0.1 s-1. However, the unstable region with strain of 0.5 shown in Fig. 3(c) is larger than that in Figs. 3(a) and (b). It should be noticed that there is a region in the temperature range of 1130-1150 ℃ with a peak efficiency of about 0.6 occurring at 1150 ℃ and 0.1 s-1. These regions are not suitable for the hot working of the material. Two safe processing domains for the hot working of PM Ti-47Al-2Cr-0.2Mo alloy at strain of 0.5 are revealed in the processing maps. One is at temperature range of 1000-1050 ℃ and strain rate range of 0.05-0.001 s-1 with a peak efficiency of 0.65; the other is at temperature range of 1130-1150 ℃ and strain rate range of 1-0.1 s-1. In the safe processing domains, the workability of material is better with increasing of η [18]. However, it should be noticed that, in the processing map of the alloy deformed at strain of 0.5, the domain at the temperature range of 1125-1150 ℃ and strain rate range of 0.01-0.001 s-1 obtains a peak efficiency of 0.9, and shows very dense contour lines of high efficiency of power dissipation. This domain is considered the metastable domain, which may be not good for consideration.

Fig. 3 Processing maps of Ti-47Al-2Cr-0.2Mo alloy at strains of 0.1 (a), 0.3 (b), 0.5 (c)

The processing maps gained at different strains show obvious difference, that is to say, the deformation mechanism and microstructure transition of the alloy deformed with different strains are different and the processing maps of the alloy are sensitive to strains. It is necessary to choose correct processing map to optimize the deformation techniques and to conduct the production of the alloy.

5 Discussion

The flow stress behavior of Ti-47Al-2Cr-0.2Mo alloy during plastic deformation is closely related to the dislocation configuration. At the initial stage, in order to accommodate plastic deformation, higher energy is needed to form and start dislocations. Owing to low stacking fault energy on the basal planes [19] and wide extended dislocation, the dislocation formed in the TiAl based alloy is hard to cross slip and climb. Dynamic recovery (DRV) caused by the cross-sliding of screw dislocations and climbing of edge dislocations is limited, and the subgrain boundaries are not well formed. Therefore, the dislocation quantity and density gradually increase, resulting in the rapid increment of stored energy, and then the stress reaches a peak. Because a few actuated slip systems and movable dislocations cannot move and pile up ahead of the phase interfaces and boundaries for TiAl alloy at low temperature, the flow stress is much higher than that at elevated temperature. At a given deformation temperature, the generation rate of dislocation rises up with strain rate. In addition, at higher strain rates, the time available for interface migration is short and hence DRX is incomplete. So the dislocation density increases in the matrix and the dynamic yield point is higher at higher strain rates. As well known, the process of DRX is prone to occur in TiAl alloys during the hot working process [20]. It can be seen from Fig. 2 that DRX is prone to occur in the hot deformation processing with the increase of deformation temperature and decrease of strain rate. These may be explained by the fact that the dislocation density of the alloy at high strain rate is higher. So, it is easy to form finer sub-grains and DRX grains. At high strain rate, the time is too short for DRX grains to grow. Inversely, with decreasing strain rate the time for deformation prolongs, so there is more time for fine DRX grains to grow. On the other hand, at higher temperature, the diffusion abilities of atoms, cross-slip of dislocation and migration of grain boundaries are enhanced, and all these conditions are beneficial to the nucleation and nucleus growth of DRX, so both the number and size of the recrystallization grains increase obviously. This is important because DRX is a favorable deformation mechanism [21]. Furthermore, the deformation capability of PM TiAl based alloy should be improved by other slip systems operated with the increase of deformation temperature and the decrease of strain rate.

Generally speaking, there are several safe regimes and unstable flow regions in the processing maps for metal materials processing. Therefore, it is necessary to separate the power dissipation from the harmful ones when using the power dissipation maps for deciding the optimum hot-working conditions. Through the processing map, the flow instability domain and the safe deformation domain can be determined. The efficiency of power dissipation η is a dimensionless parameter to indicate the power dissipation by microstructure evolution, and the material deformed under the condition with high efficiency of power dissipation shows high workability [18]. There are some studies on the metals with high stacking fault energy, the maximum efficiency of power dissipation η for DRX is about 0.5, while it is about 0.35 for metals with low stacking fault energy [22]. But unstable flow may occur as the deformation condition situates in the zone of processing map with high power efficiency, as shown in Fig. 3(c). At 1150 ℃ and 0.001 s-1, the material exhibits exceptional grain growth. In this domain, the grains grow quickly due to higher temperature and concurrently fine grains appear at grain boundaries. The microstructure is highly uneven and the flow instability is caused by uneven deformation. So the temperature and strain rate corresponding to high efficiency in safe processing domain should be chosen as the optimum parameters for hot working. Therefore, from the processing map of the alloy with the deformation strain of 0.5 in Fig. 3(c), the suitable deformation condition is in deformation temperature range of 1000-1050 ℃ and strain rate range of 0.001-0.05 s-1, or in deformation temperature range of 1050-1125 ℃ and strain rate range of 0.01-0.1 s-1. DRX is a beneficial process in hot deformation as it gives good intrinsic workability by simultaneous softening and reconstituting the microstructure. Moreover, DRX is considered an effective way to control the structure and property of the deformed alloy. Therefore, DRX is also a chosen domain for hot workability optimization and good mechanical properties control. Combining with all the microstructure deformed at strain of 0.5 under this safe condition, the microstructure at the temperature of 1000 ℃ and the strain rate of 0.001 s-1 exhibits most DRX grains in Fig. 4(c), and there is no question that this microstructure dominated by fine and homogeneous equiaxed grains is beneficial to the application of this alloy. This means that the optimum parameters for the hot-working of PM Ti-47Al-2Cr-0.2Mo alloy at the strain of 0.5 are deformation temperature of 1000 ℃ and strain rate of 0.001 s-1.

6 Conclusions

1) The processing maps of PM Ti-47Al- 2Cr-0.2Mo alloy deformed at different strains show some differences and the processing maps of the alloy are sensitive to strains according to the analysis.

2) The processing map of PM Ti-47Al-2Cr-0.2Mo alloy at strain of 0.5 exhibits two suitable processing domains for hot working of 1000-1050 ℃ at 0.001- 0.05 s-1 and 1050-1125 ℃ at 0.01-0.1 s-1.

3) The optimum parameters of hot working for PM Ti-47Al-2Cr-0.2Mo alloy at strain of 0.5 are deformation temperature of 1000 ℃ and strain rate of 0.001 s-1.

References

[1] YAMAGUCHI M, INUI H, ITO K. High-temperature structure intermetallics [J]. Acta Materialia, 2000, 48(1): 307-322.

[2] DIMIDUK D M. Gamma titanium aluminide alloys-an assessment within the competition of aerospace structural materials [J]. Materials Science and Engineering A, 1999, 263(2): 281-288.

[3] WU Xin-hua. Review of alloy and process development of TiAl alloys [J]. Intermetallics, 2006, 14(10-11): 1114-1122.

[4] LIU Yong, Huang Bai-yun, Zhou Ke-chao, HE Yue-hui, WEI Wei-feng. Canned forging process of TiAl based alloy [J]. The Chinese Journal of Nonferrous Metals, 2000, 10(s1): s6-s9. (in Chinese)

[5] SEMIATIN S L, SEETHARAMAN V, WEISS I. Hot workability of titanium and titanium aluminide alloys-an overview [J]. Materials Science and Engineering A, 1998, 243(1-2): 1-24.

[6] KONG Fan-tao, CHEN Yu-yong, LI Bao-hui. Influence of yttrium on the high temperature deformability of TiAl alloys [J]. Materials Science and Engineering A, 2009, 499(1-2): 53-57.

[7] WANG Yan-hang, LIN Jun-pin, HE Yue-hui, WANG Yan-li, LIN Zhi, CHEN Guo-liang. Reaction mechanism in high Nb containing TiAl alloy by elemental powder metallurgy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(4): 853-857.

[8] ZHANG Wei, LIU Yong, LIU Bin, LI Hui-zhong, TANG Bei. Deformability and microstructure transformation of PM TiAl alloy prepared by pseudo-HIP technology [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(4): 547-552.

[9] GERLING R, SCHIMANSKY F P, STARK A, BARTELS A, KESTLER H, CHA L, SCHEU C, CLEMENS H. Microstructure and mechanical properties of Ti-45Al-5Nb+(0-0.5C) sheets [J]. Intermetallics, 2008, 16(5): 689-697.

[10] WANG Gang, XU Lei, TIAN Yu-xing, ZHENG Zhuo, CUI Yu-you, YANG Rui. Flow behavior and microstructure evolution of a P/M TiAl alloy during high temperature deformation [J]. Materials Science and Engineering A, 2011, 528(22-23): 6754-6763.

[11] ZHANG Wei, LIU Yong, LI Hui-zhong, LI Zhou, WANG Hai-jun, LIU Bin. Constitutive modeling and processing map for elevated temperature flow behaviors of a powder metallurgy titanium aluminide alloy [J]. Journal of Materials Processing Technology, 2009, 209(12-13): 5363-5370.

[12] RAO K P, PRASAD Y V R K, SURESH K. Hot working behavior and processing map of a γ-TiAl alloy synthesized by powder metallurgy [J]. Materials and Design, 2011, 32(10): 4874-4881.

[13] LI Hui-zhong, LI Zhou, ZHANG Wei, WANG Yan, LIU Yong, WANG Hai-jun. High temperature deformability and microstructural evolution of Ti-47Al-2Cr-0.2Mo alloy [J]. Journal of Alloys and Compounds, 2010, 508(2): 359-363.

[14] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, MALAS J C, MORGAN J T, LARK K A, BARKER D R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242 [J]. Metallurgical and Materials Transactions A, 1984, 15(10): 1883-1892.

[15] PRASAD Y V R K, SASIDHARA S. Hot Working Guide: A compendium of processing maps [M]. Ohio: ASM International, Materials Park, 1997: 26-198.

[16] BOZZINI B, CERRI E. Numerical reliability of hot working processing maps [J]. Materials Science and Engineering A, 2002, 328(1-2): 344-347.

[17] NARAYANA-MURTY S V S, NAGESWARA-RAO B. On the development of instability criteria during hotworking with reference to IN718 [J]. Materials Science and Engineering A, 1998, 254(1-2): 76-82.

[18] JU Quan, LI Dian-guo, LIU Guo-quan. Processing map of hot plastic deformation of a 15Cr-25Ni-Fe base superalloy [J]. Acta Metallurgica Sinica, 2006, 42(2): 218-224. (in Chinese)

[19] SKROTZKI B, RUDOLF T, DLOUHY A, EGGELER G. Microstructural evidence for dynamic recrystallization during creep of a duplex near-gamma TiAl-alloy [J]. Scripta Materialia, 1998, 39 (11): 1545-1551.

[20] LI Shu-suo, SU Xi-kong, HAN Ya-fang, XU Xiang-jun, CHEN Guo-liang. Simulation of hot deformation of TiAl based alloy containing high Nb [J]. Intermetallics, 2005, 13(3-4): 323-328.

[21] PRASAD Y V R K. Processing maps: A status report [J]. Journal of Materials Engineering and Performance, 2003, 12(6): 638-645.

[22] PRASAD Y V R K, SESHACHARYULU T. Modelling of hot deformation for microstructural control [J]. International Materials Reviews, 1998, 43(6): 243-258.

李慧中1, 2, 3,曾 敏1,梁霄鹏2,李 洲1,刘 咏2

1 中南大学 材料科学与工程学院,长沙 410083;

2 中南大学 粉末冶金国家重点实验室,长沙 410083;

3 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083

摘 要:采用Gleeble-1500热模拟试验机进行等温压缩实验,在变形温度为1000-1150 ℃、应变速率为0.001-1 s-1的条件下,研究粉末冶金Ti-47Al-2Cr-0.2Mo合金的流变行为。结果表明:变形温度和应变速率对该合金的流变行为有显著影响,流变应力随应变速率的增加和变形温度的降低而增大。不同应变条件下的加工图表明该合金的加工图对应变量很敏感。应变量为0.5时,对应的加工图表明粉末冶金Ti-47Al-2Cr-0.2Mo合金合适的加工区域是:温度1000-1050 ℃、应变速率0.001-0.05 s-1;温度1050-1125 ℃、应变速率0.01-0.1 s-1。对热变形后合金的显微组织和加工图进行分析,发现1000 ℃,0.001 s-1是该合金进行热变形的最佳工艺参数。

关键词:粉末冶金;钛铝基合金;热压缩变形;加工图

(Edited by FANG Jing-hua)

Foundation item: Project (51174233) supported by the National Natural Science Foundation of China; Project (2011CB605500) supported by National Basic Research program of China

Corresponding author: LI Hui-zhong; Tel: +86-731-88830377; Fax: +86-731-88830257; E-mail: lhz606@mail.csu.edu.cn

DOI: 10.1016/S1003-6326(11)61241-7