文章编号:1004-0609(2008)01-0078-07

泡沫铝二次发泡工艺用先驱体中TiH2发泡剂的分散性

左孝青,梅 俊,熊 恒,周 芸,孙加林

(昆明理工大学 材料与冶金工程学院,昆明 650093)

摘 要:研究二次发泡泡沫铝工艺用熔体路径发泡先驱体中TiH2的分散性,包括熔体粘度测量、工艺参数对发泡剂分散性影响等。结果表明,610 ℃是ZLD104合金熔体粘度变化的转折点,低于610 ℃熔体粘度随温度的变化较大,高于610 ℃熔体粘度随温度的变化较小;随分散温度、搅拌速度、分散时间的提高,发泡剂分散均匀性提高,但在3 000 r/min,分散30 s的条件下,发泡剂的团聚现象仍然存在;在粘度?温度非敏感区分散发泡剂,并采用挤压使发泡先驱体致密化,以及采用3 000 r/min以上的搅拌速度分散发泡剂,可提高熔体路径发泡先驱体发泡剂均匀性。

关键词:TiH2发泡剂;熔体路径先驱体;分散性;泡沫铝

中图分类号:TF 125.6; TQ 427.6 文献标识码:A

Dispersion of TiH2 foaming agent in precursor for

two-step foaming process of aluminum foam

ZUO Xiao-qing, MEI Jun, XIONG Heng, ZHOU Yun, SUN Jia-lin

(Faculty of Materials and Metallurgical Engineering, Kunming University of Science and Technology,

Kunming 650093, China)

Abstract: The dispersion of TiH2 in the melt route precursor for two-step foaming process of aluminum foam was studied, including the measurement of aluminum melt viscosity, the effects of processing parameters on the dispersion of TiH2, etc. The results show that 610 ℃ is the key point of the temperature—viscosity relationship of aluminum foam. While the melt temperature is below 610 ℃, the viscosity elevates greatly with decreasing temperature. While melt temperature is above 610 ℃, the viscosity elevates slowly with decreasing temperature. The uniform of foaming agent is improved with increase of melt temperature, stirring speed and dispersing time. However, the aggregation of TiH2 still exists stirred at rotation speed 3 000 r/min for 30 s. Three approaches are found to be effective to improve the uniform of TiH2 in the melt route precursor: disperse TiH2 in the viscosity-temperature non-sensitive area of aluminum alloy, density the cast precursor by pressing, and use a rotation speed higher than 3 000 r/min.

Key words: TiH2 foaming agent; melt route precursor; dispersion; aluminum foam

泡沫铝的发展已有50多年的历史,具有轻质、能量吸收、吸音、阻尼、可在较高温下使用、可回收等特性,在建筑、汽车、机械、包装、航天航空等行业都有巨大的应用前景[1?5]。

近来,在Formgrip工艺[6?7]的基础上,从熔体路径出发获得含少量第二相的发泡先驱体,通过先驱体的二次发泡制备泡沫铝异型件的近终形二次发泡工艺受到了极大的关注并取得了一定进展,但以往的二次发泡工艺所获得泡沫铝异型件的孔结构还未达到均匀状态[8?9],也未对TiH2分散性问题进行过研究。

发泡剂的分散均匀性,直接影响到泡沫结构的均匀性。二次发泡工艺由于发泡先驱体的存在,使得发泡剂TiH2的分散性研究成为了可能。本文作者对熔体路径先驱体内TiH2的分散性进行了系统研究,对于熔体路径先驱体二次发泡以及常规熔体一次发泡泡沫铝的结构控制,都具有重要意义。

1 实验

1.1 发泡剂分散性表征

采用金相数码照片结合自行研制的BWJScan软件[10]对发泡剂的分散性进行表征,该软件采用Visual Basic语言,通过计算机图形学中的连通区域识别技术、边缘轮廓检测技术、线条细化技术、轮廓线追踪等技术编制,可分析计算不同物相(或孔隙)的数量、大小和分布情况。

对发泡剂分散性的定量描述具体过程为: 以圆形试样的不同区域(中心区、1/2半径处、边缘区)为横坐标,单位面积上TiH2质点所占面积百分数(M,%)为纵坐标作图,通过各区域TiH2质点的M分布来描述发泡剂质点分布均匀性,M分布越接近水平,说明发泡剂分布越均匀。

在TiH2的分散性表征过程中发现两个问题:一是铸件存在一定微孔隙,很难分辨微孔隙和发泡剂,为此,对铸件进行热压致密化,使其相对密度提高到99%以上消除微孔隙;二是较难分辨TiH2和基体组织,对此,利用TiH2在一定温度下氧化处理会发生色彩变化的特性,通过350~400 ℃的加热处理,可清晰观察TiH2。图1所示为一发泡剂的分布。图中的彩色颗粒为TiH2,将此图片处理后导入BWJScan软件,即可分析TiH2的分布。

图1 发泡剂的分布

Fig.1 Distribution of foaming agent

1.2 发泡剂分散性实验

采用ZLD104合金为基体材料,发泡剂采用TiH2(含量为0.75%;粒度小于44 μm)。

分散性研究用分析样品的制备过程为:将ZLD104合金熔化后,加入发泡剂TiH2并进行搅拌分散一定时间,将合金熔体与发泡剂的混合体冷却、压力加工致密化、线切割加工后可得到分析样品。

发泡剂的搅拌分散,要求发泡剂在分散可利用时间[11]内(一般不超过50 s,与发泡剂的表面状态和分解特性有关,定义为发泡剂少量分解的时间段)在铝熔体中尽可能均匀地分散。

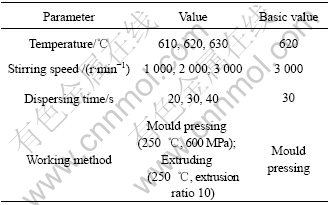

影响发泡剂分散均匀性的因素有:金属熔体的粘度(温度)、分散时间、搅拌速度、压力加工方法等,本文就这些因素对发泡剂的分散性的影响进行研究,表1所列为实验参数。由表可知,当某个参数变化时,其他参数的取值为表中的基本参数。

表1 发泡剂分散性实验参数

Table 1 Foaming-agent dispersion experimental parameters

1.3 粘度的测量

相同条件下,发泡剂在高温低粘度熔体中的分散均匀性比在低温高粘度熔体中的好。为了解温度(粘度)对发泡剂分散性的影响,首先对金属熔体的粘度进行了测量。铝熔体粘度测量的特点,一是粘度值较低,在0.7~2 mPa?s之间;二是由于高温及氧化的存在,使常用的测量方法并不适用。高温熔体粘度的测量,较方便可行的方法有电机功率法[12]、扭距测量法[13]、扭摆振动法[14]等。其中,扭摆振动法由于测量精度高、测量范围适中,现应用较多,其工作原理是根据阻尼振动的对数衰减与阻尼介质粘度的定量关系对粘度进行表征。

基于扭摆振动法,设计制作了一套铝熔体的扭摆振动测量仪,可测量的粘度范围在0.1~10 mPa?s之间,精度达0.01 mPa?s。

图2所示为扭摆振动仪示意图,在上端固定不动的弹性吊丝下悬挂惯性体、连杆和柱体,组成悬挂系统。当使弹性吊丝扭转一个角度后,悬挂系统自由扭动,若无吊丝的内摩擦力和介质摩擦力,系统将作等振幅的扭转摆动。若将该悬挂系统的柱体放入金属液体中,柱体的扭转受到液体内摩擦的阻尼作用,扭转的振幅将渐渐衰减,直至振幅为零而停止。整个系统在Ar气氛的保护下运行,以防止铝熔体表面氧化带来的测量误差。

图2 金属熔体粘度测量仪

Fig.2 Apparatus for metallic melt viscosity measurement

上述扭转衰减是对数衰减[15],其衰减大小可表示为

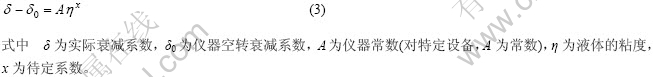

液体粘度与摆动角度衰减系数的关系十分复杂,实际应用的是一些经验或半经验公式,可写成如下通式:

用蒸馏水在不同温度下的标准粘度[15]对该扭摆振动测量仪进行了反复测试和校准,获得了本实验用扭摆振动粘度仪的粘度与衰减系数之间的关系式:

2 结果与讨论

2.1 温度与粘度的关系

利用上述扭摆振动测量仪,测量ZLD104合金粘度随温度的变化规律,获得合金粘度随温度变化的曲线(图3)。

图3 ZLD104合金粘度随温度的变化

Fig.3 Variation of viscosity of ZLD104 alloy on melt temperature

由图3可见,ZLD104合金粘度随温度的降低而提高。当温度低于605 ℃后,其粘度急剧增加,已经不能用该仪器测量;温度在605~610 ℃之间时,粘度随温度的变化较大,是粘度?温度敏感区,其粘度随温度的变化,可用二次多项式表达:

当温度高于610 ℃后,粘度随温度升高而降低的趋势渐平缓,是粘度?温度非敏感区,可用线性关系表示为

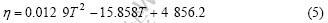

2.2 温度(粘度)对TiH2分散性的影响

金属熔体粘度随温度的降低而提高,特别是在熔点或稍高于熔点温度附近,这一影响更为显著。

发泡剂分散温度为610,620和630 ℃,其他工艺参数不变时(见表1中的基本参数),研究了不同分散温度(粘度)对发泡剂分散性的影响。

图4所示为分散温度与发泡剂分布的关系。由图4可知,随发泡剂分散温度的提高,发泡剂的分布均匀性提高。610 ℃时,由于熔体的粘度较大,出现发泡剂在R及R/2处,特别是在R/2处的数量较多,而中心处数量大幅度减少的现象,发泡剂的分布不均匀;620 ℃和630 ℃时,发泡剂的分布均匀性较610 ℃时有很大提高,表现为从心部到边部,发泡剂数量随半径增加而提高的现象,与离心力的作用有关。这说明了发泡剂分散均匀性与分散温度密切相关,提高分散温度,金属熔体粘度降低,发泡剂分散均匀,进而使泡沫铝结构均匀性提高。由粘度分析可知,610 ℃是熔体粘度变化的关键点,在该温度附近或以下,熔体粘度较高,温度的微小变化,将使粘度发生很大变化,发泡剂分散均匀性差;620 ℃以上时,粘度随温度的变化趋于平缓,发泡剂分散均匀性提高。在粘度?温度非敏感区分散,发泡剂的均匀性提高,但温度过高,发泡剂在分散时会过早的分解,特别是微细发泡剂的分解,使发泡坯中总的发泡剂数量减小,发泡剂活性降低,气泡形核率降低,泡沫孔为相对较少的气孔发展而得,使泡沫化后泡沫铝孔径增大、孔隙率下降。

图4 分散温度与发泡剂分布的关系

Fig.4 Relationships between dispersion temperature and foaming agent distribution

2.3 搅拌速度对TiH2分散性的影响

搅拌速度分别为1 000,2 000和3 000 r/min,其他工艺参数不变(见表1中的基本参数)时,研究了不同搅拌速度对发泡剂分散均匀性的影响。结果如图5所示。

由图5可见,随搅拌速度提高,发泡剂分散均匀性提高,1 000 r/min时,外圆周(R)处出现了发泡剂富集,均匀性最差,2 000 r/min与3 000 r/min时的均匀性较 1 000 r/min有很大提高。

图5 搅拌速度与发泡剂分布的关系

Fig.5 Relationships between agitating speed and foaming agent distribution

搅拌速度1 000 r/min时,没有大的中心旋涡形成,熔体向上攀升较小,搅拌器基本被熔体所包围,熔体没有形成明显的上下环流,由于搅拌速度较慢,对发泡剂颗粒的分散作用不够,在离心力的作用下,大的TiH2团聚体在外圆周处聚集;搅拌速度超过2 000 r/min后,中心旋涡形成,熔体向上攀升形成了明显的上下环流,在搅拌器高速搅拌下,对发泡剂颗粒的分散作用加强,团聚现象明显减弱,分散均匀性得到改善。

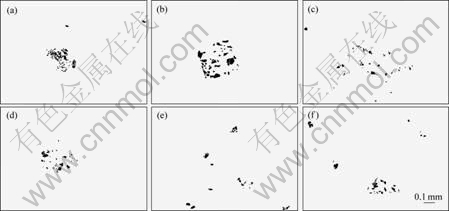

由图6可见,搅拌速度1 000 r/min时,发泡剂的团聚现象很严重,2 000 r/min时,团聚程度有所改善,中心区的分散比外圆周区好;3 000 r/min时,团聚现象进一步得到改善,大的团聚体被打散为小的团聚体,同样中心区的分散比外圆周区好。由此说明,在30 s有限的时间内,通过3 000 r/min的搅拌,发泡剂的团聚现象虽然有所改变,但并不能完全消除,也表明存在更高速搅拌充分分散发泡剂的可能性。

图6 搅拌速度对发泡剂分布的影响

Fig.6 Effects of agitating speed on foaming agent distribution: (a) 1 000 r/min, center; (b) 1 000 r/min, circumference; (c) 2 000 r/min, center; (d) 2 000 r/min, circumference; (e) 3 000 r/min, center; (f) 3 000 r/min, circumference

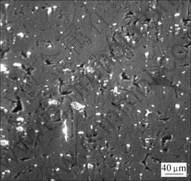

图7所示为PCF发泡先驱体中发泡剂分布的SEM照片(将粒径小于37 μm,1%的TiH2与粒径小于74 μm的铝粉混合后再压制)。由图7可见,PCF工艺制备的发泡先驱体中[16],发泡剂(白亮颗粒)基本上没有团聚现象,较熔体路径制备的发泡先驱体的分布均匀性好,优于3 000 r/min、30 s条件时的中心区发泡剂分散的均匀性,这是PCF工艺能够在室温长时间混料的结果。

图7 PCF发泡先驱体中发泡剂分布的SEM照片

Fig.7 SEM photograph of foaming-agent distribution in PCF precursor via mixed and pressed 1% TiH2 (size less than 37 μm) and Al powder (less than 74 μm)

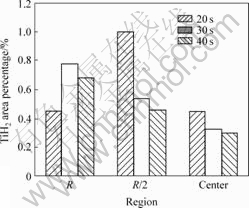

2.4 分散时间对TiH2分散性的影响

发泡剂分散时间为20,30和40 s,其他工艺参数不变时(见表1),研究了不同分散时间对发泡剂分散均匀性的影响。

由图8可见,随分散时间的延长,发泡剂分布均匀性提高,分散时间20 s时,出现发泡剂在R/2处的富集(见图9),推测与发泡分散时间短,发泡剂才被刚刚打散,离心力的作用还未能充分体现有关。搅拌时间30 s以后,出现了典型的外部多、中心少的分布,均匀性大为改善,而且随时间的延长发泡剂分散性进一步改善,但搅拌40 s时,总的发泡剂数量减少,与40 s超过了发泡剂的分散可利用时间,发泡剂出现部分早期分解有关。

图8 搅拌时间与发泡剂分布的关系图

Fig.8 Relationships between agitating time and foaming agent distribution

图9 搅拌时间20 s时发泡剂的分布

Fig.9 Foaming-agent distributions after 20 s agitating: (a) Center; (b) Half radius; (c) Circumference

2.5 加工方法对TiH2分散性的影响

采用模压、挤压不同的加工方法,其他工艺参数不变时(见表1),研究不同加工方法对发泡剂分散均匀性的影响。

由图10和11可见,挤压后发泡剂的分布得到了本质的改变,各区域的分布几乎完全相等,同时,发泡剂的团聚现象得到了明显的改善。此说明,铸态发泡坯经挤压后,除能够获得近100%致密的发泡先驱体外,还能基本上消除TiH2的团聚现象,使熔体路径获得的发泡先驱体中的发泡剂分散均匀性提高,达到或接近PCF发泡先驱体中发泡剂分散的水平(图7)。

图10 压力加工方法对发泡剂分布的影响

Fig.10 Relationships between working methods and foaming agent distribution

图11 挤压发泡先驱体内TiH2的分布

Fig.11 TiH2 distributions in extruded precursor: (a) Center; (b) Half radius; (c) Circumference

3 结论

1) 610 ℃是ZLD 104合金熔体粘度变化的转折点,低于610 ℃,熔体粘度随温度的变化较大,熔体处于粘度?温度敏感区,发泡剂分散均匀性较差;高于610 ℃,熔体粘度随温度的变化较小,熔体处于粘度?温度非敏感区,发泡剂分散均匀性较好。

2) 随搅拌速度的提高,发泡剂分散均匀性提高,1 000 r/min时的均匀性较差,2 000 r/min以上时,均匀性提高,发泡剂团聚现象减少。

3) 随分散时间的延长,发泡剂分散均匀性提高,但发泡剂的分散,受发泡剂分散可利用时间的限制。

4) 挤压可提高发泡先驱体中发泡剂的均匀性,基本消除发泡剂的团聚现象。

5) 常规分散条件(≤3 000 r/min、≤30 s)下,熔体路径发泡先驱体中发泡剂的均匀性较差,发泡剂多以团聚形式存在。提高发泡剂分散均匀性的途径主要有:①在粘度?温度非敏感区分散发泡剂;②采用挤压致密化的方法;③探索采用3 000 r/min以上的搅拌速度。

REFERENCES

[1] SOSNIK B. Process for making foamlike mass of metal. US Patent 2434775[P]. 1948.

[2] BANHAR J. Manufacture, characterization and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46(6): 609?621.

[3] H P 蒂吉斯切, B 克雷兹特. 多孔泡沫金属[M]. 左孝青,周 芸, 译. 北京: 化学工业出版社, 2005.

DEGISCHER H P, KRISZT B. Handbook of cellular metals[M]. ZUO Xiao-qing, ZHOUu Yun, transl. Beijing: Chemical Industry Press, 2005.

[4] GIBSON L J, ASHBY M F. Cellular solids: Structure and properties[M]. Oxford: Pergamon Press, 1988.

[5] 左孝青, 潘晓亮, 廖明顺. 泡沫铝气泡长大动力学[J]. 中国有色金属学报, 2006, 16(12): 2040?2046.

ZUO Xiao-qing, PAN Xiao-liang, LIAO Ming-shun. Bubble growth dynamics of aluminum foam[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2040?2046.

[6] GERGELY V, CLYNE B. The formgrip process: Foaming of reinforced metals[J]. Advanced Engineering Materials, 2000(4): 175?178.

[7] ASAVAVISITHCHAI S, KENNEDY A R. Effect of powder oxide content on the expansion and stability of PM-route Al foams[J]. Journal of Colloid and Interface Science, 2006, 297: 715?723.

[8] SHANG J T, HE D P. The two steps thermal decomposition of titanium hydride and two steps foaming of Al foam[J]. Science in China Ser B Chemistry, 2005, 48(6): 523?529.

[9] 游晓红, 王录才, 于利民, 王 芳, 李海娟. 基于发泡剂预处理的两步法泡沫铝制备工艺研究[J]. 铸造, 2005, 54(3): 286?289.

YOU Xiao-hong, WANG Lu-cai, YU Li-ming, WANG Fang, LI Hai-juan. Two-stage process of producing aluminum foams[J]. Foundry, 2005, 54(3): 286?289.

[10] 左孝青, 廖明顺, 潘晓亮. VB和计算机图形学在多孔材料中的应用[J]. 金属热处理, 2006, 31(S): 98?101.

ZUO Xiao-qing, LIAO Ming-shun, PAN Xiao-liang. Application of VB and computer graphics in cellular materials[J]. Heat Treatment of Metals, 2006, 31(S): 98?101.

[11] 左孝青. 泡沫铝制备技术基础及新方法研究[D]. 昆明: 昆明理工大学, 2006.

ZUO Xiao-qing. Study on the technique fundamentals and an innovation processing of fabricating aluminum foam[D]. Kunming: Kunming University of Science and Technology, 2006.

[12] 宋振纶, 何德坪. 铝熔体泡沫形成过程中粘度对孔结构的影响[J]. 材料研究学报, 1997, 11(3): 275?279.

SONG Zhen-Lun, HE De-ping. Effects of viscosity on pore structure in foaming process of molten aluminum[J]. Chinese Journal of Materials Research, 1997, 11(3): 275?279.

[13] 戴 戈, 何德坪, 尚金堂. 铝合金熔体泡沫化过程中粘度的变化[J]. 材料研究学报, 2005, 19(1): 35?41.

DAI Ge, HE De-ping, SHANG Jun-tang. Change of the viscosity in the foamed process of A1 alloy melt[J]. Chinese Journal of Materials Research, 2005, 19(1): 35?41.

[14] 郭景杰, 傅恒志. 合金熔体及其处理[M]. 北京: 机械工业出版社, 2005: 30.

GUO Jing-jie, FU Heng-zhi. Alloy melt and its processing[M]. Beijing: China Machine Press, 2005: 30.

[15] 川田裕郎. 粘度[M]. 陈惠钊, 译. 北京: 计量出版社, 1981: 147?152.

KAWADA Y L. Viscosity[M]. CHENG Hui-Zhao, transl. Beijing: China Metrology Press, 1981: 147?152.

[16] 刘菊芬, 刘荣佩, 史庆南, 左孝青. 新型泡沫铝制备工艺研究[J]. 材料导报, 2002, 16(8): 65?67.

LIU Ju-fen, LIU Rong-pei, SHI Qing-nan, ZUO Xiao-qing. Study of fabricating process for new type aluminum foam[J]. Materials Review, 2002, 16(8): 65?67.

基金项目:国家自然科学基金资助项目(50461003);云南省学术技术带头培养资助项目(2006PY01-06);云南省国际合作资助项目(2006GH21)

收稿日期:2007-06-21;修订日期:2007-10-25

通讯作者:左孝青,教授,博士;电话:0871-6735058;E-mail: zxqdzhhm@hotmail.com

(编辑 龙怀中)