DOI: 10.11817/j.issn.1672-7207.2019.05.010

一种新的直齿轮复合修形设计方法

杨硕文,唐进元

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:以直齿轮齿廓修形量、齿廓修形高度、齿廓修形幂指数、齿向修形量这4个基本参数为变量,取动态传递误差峰峰值、最大接触应力加权最小为优化目标,使用有限元方法计算接触应力;考虑轴承、轴、陀螺力等因素的影响,使用有限元节点法计算动态传递误差,以 Kriging方法为优化方法,构建一种新的直齿轮复合修形设计方法,并通过一对实际齿轮传动来验证计算模型。研究结果表明:用所提出的方法优化后得到齿轮动态传递误差峰峰值相对于优化前降低75.98%,最大接触应力降低21.48%,这表明所提出的复合修形优化方法对齿轮修形设计具有参考与应用价值。

关键词:齿轮传动;复合修形;Kriging方法;有限元节点法

中图分类号:TH132.41 文献标志码:A 文章编号:1672-7207(2019)05-1082-07

A new design method for compound modification of spur gear

YANG Shuowen, TANG Jinyuan

(State Key Laboratory of High Performance Complex Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Taking four basic parameters of the spur gear modification as the variables, and taking the peak-to-peak value of the dynamic transmission error and the maximum contact stress weighted minimum as the optimization goal, the contact stress was calculated using the finite element method. Considering the influence of factors such as bearings, shafts and gyro, etc, the finite node element method was used to calculate the dynamic transfer error. Taking the Kriging method as the optimization method, a new spur gear compound modification design method was constructed. A pair of actual gear transmissions was used to verify the method. The results show that the peak-to-peak value of the dynamic transmission error of the gear after optimization obtained by the present method is reduced by 75.98% and the maximum contact stress is reduced by 21.48%,which indicates that the proposed optimization method of compound modification has reference and application value for gear modification design.

Key words: gear transmission; compound modification; Kriging method; finite element node method

齿轮修形是降低齿轮振动、噪声和提高可靠性的重要途径[1]。在齿轮修形优化设计中,人们对齿廓修形[2]或者齿向修形[3]的研究较多,而对齿廓修形叠加齿向修形的齿轮复合修形研究较少[4]。现有的修形优化方法往往耗费大量的时间且需要重复操作[5],此外,动力学性能计算往往忽略轴承、轴和陀螺力的影响[6]:因此,研究一种设计效率高、考虑因素全面的齿轮复合修形优化设计方法很有必要。WU等[7]通过有限元静力学分析确定了最优齿廓修形类型及修形参数,通过动态接触试验证明了齿廓修形在减振方面的作用。MARCELLO等[8]提出使用随即单纯形优化算法对齿廓修形参数进行优化,使用蒙特卡洛搜索法搜索齿廓修形最优值。郭家舜等[9]基于人字齿轮弯扭轴耦合动力学模型,考虑了时变齿侧间隙距离,以动载系数来评价最优修形参数。杨丽等[10]通过有限元法建立样本点,通过Kriging优化方法和遗传算法对齿廓修形进行优化,通过算例发现该方法相对于ISO标准公式修形方法减振效果更好,验证了Kriging优化方法的优越性,但该研究只针对齿廓修形,没有涉及复合修形,复合修形变量要多于齿廓修形变量,同时,在动态性能计算方面,使用的方法没有考虑轴承、轴和陀螺力等因素对动态响应的影响。为此,本文作者基于有限元方法计算复合修形齿轮的静态传递误差、啮合刚度、最大接触应力;通过有限元节点法计算动态传递误差,并以动态传递误差峰峰值、最大接触应力最小进行多目标优化,选取实际齿轮参数用Kriging方法进行复合修形优化设计。

1 直齿轮复合修形原理与方法

齿轮需要齿廓修形来减小由加工所产生的基节误差与传动时受载变形所引起的啮入啮出冲击及高传动误差幅值,也需要齿向修形来减少边缘接触和避免应力集中,所以,在修形时,2种修形量必须同时考虑,要充分利用这2种修形量的优点。复合修形包括齿廓修形和齿向修形2种修形方式。

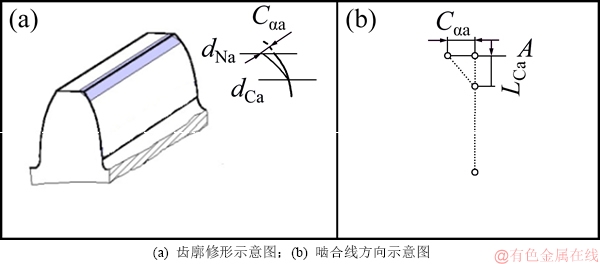

1.1 齿廓修形

齿廓修形示意图如图1所示。齿廓修形包括3个要素,即修形量、修形长度和修形曲线。图1中,Cαa为齿廓修形量,LCa为啮合线方向上修形长度,dNa为修形终止直径,dCa为修形起始直径。修形曲线一般采用以幂指数形式表示的修形曲线[11]:

(1)

(1)

式中:l为上界点至啮合始点或下界点至啮合终点的距离,l=dNa-dCa;x为啮合位置的相对坐标,x=d-dCa;d为啮合位置处直径;b为修形幂指数系数;e为某一点的齿廓修形量。

图1 齿廓修形示意图

Fig. 1 Sketch map of tooth profile modification

1.2 齿向修形

图2所示为齿向鼓形修形的示意图,Cβ为最大鼓形量,在齿宽两端取相等值。

图2 齿向修形示意图

Fig. 2 Sketch map of longitudinal modification

2 齿轮传动动态传动误差求解的有限元节点法

有限元节点齿轮动力学建模方法是一种较新的建模方法[12],相对于其他齿轮动力学建模方法,它的主要特点是:考虑了轴的柔性对齿轮系统的影响;考虑了高速齿轮系统的陀螺力,实现对齿轮系统涡动效应分析;考虑了轴承对齿轮系统的影响;可模拟振动在齿轮系统中的传递过程。

采用有限元节点法对单级直齿轮副进行动力学建模,如图3所示。该系统采用 18个节点建模,其中主动轴和从动轴各取 9个节点,每个节点含 6 个自由度,即3个平动自由度和3个转动自由度。下面根据转子动力学理论,分别得出齿轮转子、轴、轴承以及齿轮啮合作用的建模过程。

2.1 齿轮转子建模

将齿轮简化为转子(圆盘),并应用拉格朗日方法并线性化,可以得到矩阵形式的齿轮转子的运动方程:

(2)

(2)

其中:

2.2 轴的建模

利用 Timoshenko 梁单元理论对轴单元进行建模,可以得到矩阵形式的无阻尼轴的运动方程:

(3)

(3)

其中:Ms为轴的质量矩阵;Gs为陀螺矩阵;Ks为刚度矩阵,它们的表达式见文献[13-15]。

图3 齿轮轴动力学模型

Fig. 3 Dynamic model of geared shaft rotor

2.3 轴承的建模

轴承的支撑作用以无质量的弹簧和阻尼代替,其受力点假设位于轴承中点处节点。轴承的刚度矩阵和阻尼矩阵可以写成:

(4)

(4)

(5)

(5)

2.4 齿轮啮合作用建模

齿轮副的啮合作用导致2个传递力的转子之间存在明显的耦合作用,该耦合作用可根据轮齿啮合法线方向的力关联起来,以刚度的形式表达。啮合齿轮副的运动方程为

(6)

(6)

式中:

其中:b为齿侧间隙;γm0和γm1均为间隙函数;km为啮合刚度;cm为啮合阻尼;e(t)为静态传递误差。

2.5 系统动力学方程

根据式(2)~(6),最终得到系统的动力学方程为

(7)

(7)

式中: M,C,G和K分别为系统的质量矩阵、阻尼矩阵、陀螺力矩矩阵和刚度矩阵;q为节点位移矩阵;而f(q)为齿轮侧隙引起的非线性函数;Q为静态误差激励和外载荷矩阵。

3 基于Kriging优化方法的直齿轮复合修形设计方法

3.1 Kriging优化方法原理

Kriging优化方法作为一种半参数化的插值方法特别适用于强非线性问题求解,近年来在工程优化领域得到广泛应用[10],在某一点的预测是通过空间上已知所有点的数据加权求和得到。 Kriging预测优化模型包含回归部分和非参数部分,模型由多项式和随机分布2部分组成:

(8)

(8)

式中:x为设计变量;y(x)为待拟合的响应函数;f(x)为已知的回归模型,通常是多项式函数;β为相应的待定参数;Z(x)是均值为 0、方差为σ2的随机函数,表示对全局模拟的偏差。模型详细构建过程见文献[16]。

3.2 Kriging优化方法建模方法

DACE(design and analysis of computer experiments)是LOPHAVEN等利用 MATLAB 编制的Kriging工具箱[17],它有2个主要函数即dacefit和predictor。函数dacefit根据试验数据点建立Kriging模型,而函数predictor根据Kriging模型计算待测点的响应值,生成Kriging优化方法。

3.3 复合修形优化模型

针对复合修形,变量主要取齿廓修形量y1、齿廓修形高度y2、齿廓修形幂指数y3、齿向修形量y4这4个变量。然后,确定这4个变量的范围,在所确定的范围内抽取数个样本点,参考文献[18]中方法,用有限元方法计算样本点的最大接触应力G2以及啮合刚度和静态传递误差。将样本点的啮合刚度和静态传递误差导入有限元节点法动力学模型(7),计算得到动态传递误差峰峰值G1。以动态传递误差峰峰值G1、最大接触应力G2最小进行多目标优化,目标函数可表 示为

(9)

(9)

式中:yi (i=1, 2, 3, 4)为优化变量;Qimin和Qimax分别为修形量最小值和最大值;G10和G20分别为未修形的动态传递误差峰峰值和最大接触应力;w1和w2为各目标权系数,本文取w1=w2=0.5。

3.4 基于Kriging优化方法的直齿轮复合修形设计 方法

以目标函数最小为目标,在给定精度下,通过Kriging优化方法确定最佳修形参数。齿轮复合修形优化设计方法具体流程图如图4所示,其中,预测精度判别值根据设计要求确定,精度是指目标函数值计算值与Kriging方法预测值的相对误差。

图4 基于Kriging优化方法的直齿轮复合修形设计方法流程

Fig. 4 Flow chart of spur gear compound modification design method based on Kriging optimization method

4 复合修形优化设计方法的验证与应用

4.1 齿轮基本参数

以1对直齿轮为例,齿轮参数如表1所示。此外,齿轮运动精度等级为6,两齿轮轴线平面内安装误差为29.594 9 μm,垂直于两齿轮轴线平面内安装误差为29.594 9 μm,基节极限偏差为6 μm,轴段长度为10 mm,轴段外径和内径分别为30 mm和0 mm;轴承刚度kxx,kyy和kzz分别为1.49×108,1.92×108和5.22×106 N/m;轴承扭转刚度kθxθy和kθyθy分别为 2.94×103和1.74×103 N·m/rad;轴承阻尼c为1 000 N·s/m。

表1 齿轮参数

Table 1 Gear parameter table

4.2 Kriging 模型预测样本点的选取

1) 齿廓修形量△max。由ISO公式[19] △力max=KAFt/ (bεαCγ) (其中KA为使用系数,Ft为圆周力,b为齿宽,εα为重合度,Cγ为综合刚度,△力max为齿轮受力变形量)和基节极限偏差△制max可以得到经验公式齿廓修形量为△max=△力max+△制max=11.304 1 μm。齿廓修形量范围取(0.5△max,2△max),即(5.652 1,22.608 2) μm,从中取6组。

2) 齿廓修形高度。修形高度一般取短修形到长修形之间的值[20],这里修形高度定义为啮合线方向修形长度除以法向模数,齿廓修形高度范围取(0.713 9,1.427 9),从中取6组。

3) 齿廓修形幂指数。齿廓修形幂指数一般取1~2[11],从中取6组。

4) 齿向修形量Cβ。由ISO公式[21] Cβ=0.5Fβxcv= 0.5(fsh+1.5fHβ)(式中Fβxcv为等效啮合歪斜度,fsh为由弯扭变形引起的啮合歪斜度,fHβ为螺旋线斜率偏差)计算得到经验公式齿向修形量Cβ=8.348 8 μm。齿向修形量范围取(0.5Cβ,2Cβ),即(4.174 4,16.697 6) μm,从中取6组,共6×6×6×6=1 296组。

4.3 Kriging方法预测准确性验证

为了验证Kriging预测模型的准确性,一方面,从变量范围中随机抽取5组y1,y2,y3和y4,用Kriging方法得到目标函数值的预测值;另一方面,基于这5组变量,用有限元方法、有限节点方法进行计算,得到实际的目标函数计算值。将目标函数预测值与实际计算值进行对比,对比结果见表2。从表2可以看出:目标函数预测值与实际计算值相对误差均在1%以内,验证了Kriging预测的精准性。

4.4 优化结果对比

考虑y1,y2,y3和y4这4个变量,以0.01 μm为搜索精度,找到Kriging预测面上目标函数值最小的点,其所对应的变量参数便为最佳修形参数,见表3。从表3可以看出:优化前的动态传递误差峰峰值为28.162 7 μm ,优化后的动态传递误差峰峰值为 6.764 2 μm,相对于优化前动态传递误差峰峰值降低75.98%。优化前的最大接触应力为1 344.551 0 N/mm2,优化后的最大接触应力为 1 055.669 9 N/mm2,优化后相对于优化前降低21.48%。优化前后的动态传递误差曲线及其频谱图分布分别如图5和图6所示。从图5和图6可见:优化前的动态传递误差频谱图2倍频幅值较大,为11.72 μm,优化后的动态传递误差频谱图2倍频幅值为2.70 μm,较优化前有明显降低,说明此修形方法能有效减小齿轮振动。

表2 误差对比

Table 2 Error comparison

表3 Kriging优化设计结果对比

Table 3 Comparison of Kriging optimal design results

图5 优化前动态传递误差曲线及其频谱

Fig. 5 Dynamic transfer error curve and its spectrum diagram before optimization

图6 优化后动态传递误差曲线及其频谱

Fig. 6 Dynamic transfer error curve and its spectrum diagram after optimization

5 结论

1) 综合Kriging优化方法、齿轮动力学建模的有限元节点法、接触应力计算有限元方法,提出一种新的圆柱直齿轮复合修形参数设计方法。

2) 采用有限元节点法动力学分析方法计算齿轮传动动态传递误差,考虑了轴承、轴和陀螺力的影响,所得结果更接近实际情况,更具科学性。

3) 对1对齿轮传动修形参数进行实际计算,优化后的动态传递误差峰峰值相对于优化前降低75.98%,最大接触应力降低21.48%,动态传递误差频谱图2倍频的幅值明显降低,所提出的齿轮复合修形优化设计方法可为齿轮传动修形设计提供参考。

参考文献:

[1] TERAUCHI Y, NADANO H, NOHARA M. On the effect of the tooth profile modification on the dynamic load and the sound level of the spur gear[J]. Bulletin of JSME, 1982, 25(207): 1474-1481.

[2] CHEN Zaigang, SHAO Yimi. Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack[J]. Mechanism and Machine Theory, 2013, 62(4): 63-74.

[3] 唐进元, 陈兴明, 罗才旺. 考虑齿向修形与安装误差的圆柱齿轮接触分析[J]. 中南大学学报(自然科学版), 2012, 43(5): 1703-1709.

TANG Jinyuan, CHEN Xingming, LUO Caiwang. Contact analysis of spur gears based on longitudinal modification and alignment errors[J]. Journal of Central South University(Science and Technology), 2012, 43(5): 1703-1709.

[4] 徐香翠, 宋爱平, 张礼峰, 等. 齿轮综合修形方法的研究[J].机械传动, 2011, 35(11): 21-25.

XU Xiangcui, SONG Aiping, ZHANG Lifeng, et al. Research on gear comprehensive modification[J]. Journal of Mechanical Transmission, 2011, 35(11): 21-25.

[5] 袁哲, 孙志礼, 王丹, 等. 基于遗传算法的直齿圆柱齿轮修形优化减振[J]. 东北大学学报(自然科学版), 2010, 31(6): 873-876.

YUAN Zhe, SUN Zhili, WANG Dan, et al. Ga-based optimum profile modification of spur gears for vibration damping[J]. Journal of Northeastern University(Natural Science), 2010, 31(6): 873-876.

[6] 蒋进科, 方宗德, 贾海涛. 人字齿轮减振修形优化设计[J]. 振动与冲击, 2015, 34(2): 9-13,19.

JIANG Jinke, FANG Zongde, JIA Haitao. Optimization design of vibration reduction for herringbone gear[J]. Journal of Vibration and Shock, 2015, 34(2): 9-13,19.

[7] WU Yongjun, WANG Jianjun, HAN Qinkai. Static/dynamic contact FEA and experimental study for tooth profile modification of helical gears[J]. Journal of Mechanical Science and Technology, 2012, 26(5): 1409-1417.

[8] MARCELLO F, FARHAD S S, GABRIELE B, et al. Dynamic optimization of spur gears[J]. Mechanism and Machine Theory, 2011, 46(4): 544-557.

[9] 郭家舜, 王三民, 王颖. 基于解析解的人字齿轮齿廓修形动态分析[J]. 航空动力学报, 2013, 28(3): 613-620.

GUO Jiashun, WANG Sanmin, WANG Ying, Dynamic analysis of tooth profile modification to herringbone gears based on analytical solutions[J]. Journal of Aerospace Power, 2013, 28(3): 613-620.

[10] 杨丽, 佟操, 陈闯, 等. 基于Kriging模型和遗传算法的齿轮修形减振优化[J]. 航空动力学报, 2017, 32(6): 1412-1418.

YANG Li, TONG Cao, CHEN Chuang, et al. Vibration reduction optimization of gear modification based on Kriging model and genetic algorithm[J]. Journal of Aerospace Power, 2017, 32(6): 1412-1418.

[11] 李润方. 齿轮传动的刚度分析和修形方法[M]. 重庆: 重庆大学出版社, 1998: 157-159.

LI Runfang. Stiffness analysis and modified method of gear transmission[M]. Chongqing: Chongqing University Press, 1998: 157-159.

[12] 钱露露, 唐进元, 陈思雨, 等. 单级齿轮传动系统有限元节点动力学模型及高速动态性能分析[J]. 机械工程学报, 2016, 52(17): 155-161.

QIAN Lulu, TANG Jinyuan, CHEN Siyu, et al. Dynamic modeling of a one-stage gear system by finite element method and the dynamic analysis in high speed[J]. Journal of Mechanical Engineering, 2016, 52(17): 155-161.

[13] RAO J S, SHIAU T N, CHANG J R. Theoretical analysis of lateral response due to torsional excitation of geared rotors[J]. Mechanism and Machine Theory, 1998, 33(6): 761-783.

[14] HU Zehua, TANG Jinyuan, ZHONG Jue, et al. Frequency spectrum and vibration analysis of high speed gear-rotor system with tooth root crack considering transmission error excitation[J]. Engineering Failure Analysis,2016, 60(3): 405-441.

[15] CHEN Siyu, TANG Jinyuan, LI Yuanping, et al. Rotordynamics analysis of a double-helical gear transmission system[J]. Meccanica, 2015, 51(1): 251-268.

[16] 高月华. 基于Kriging代理模型的优化设计方法及其在注塑成型中的应用[D]. 大连: 大连理工大学运载工程与力学学部, 2009: 18-33.

GAO Yuehua. Optimization methods based on Kriging surrogate model and their application in injection molding[D]. Dalian: Dalian University of Technology. College of Faculty of Vehicle Engineering and Mechanics, 2009: 18-33.

[17] 谢延敏. 基于Kriging模型和灰色关联分析的板料成形工艺稳健优化设计研究[D]. 上海: 上海交通大学材料科学与工程学院, 2007: 22-23.

XIE Yanmin. Research on robust optimization of sheet metal forming based on Kriging and grey relational analysis[D]. Shanghai: Shanghai Jiao Tong University. School of Materials Science and Engineering, 2007: 22-23.

[18] 唐进元, 蔡卫星, 王志伟. 修形圆柱齿轮啮合刚度计算公式[J]. 中南大学学报(自然科学版), 2017, 48(2): 337-342.

TANG Jinyuan, CAI Weixin, WANG Zhiwei. Meshing stiffness formula of modification gear[J]. Journal of Central South University(Science and Technology), 2017, 48(2): 337-342.

[19] 仙波正庄. 高强度齿轮设计[M]. 任宏达, 译. 北京: 机械工业出版社, 1981: 149-150.

SHOBO S. Design of high strength gear[M]. REN Hongda, trans. Beijing: China Machine Press, 1981: 149-150.

[20] 杨廷力, 叶新, 王玉璞, 等. 渐开线高速齿轮的齿高修形[J]. 齿轮, 1982, 6(3): 14-24.

YANG Yanli, YE Xin, WANG Yupu, et al. Profile modification of high-speed gear teeth[J]. Gear, 1982, 6(3): 14-24.

[21] ISO 6336-1—2006, Calculation of load capacity of spur and helical gears: part 1. basic principles, introduction and general influence factors[S].

(编辑 陈灿华)

收稿日期:2018-03-07;修回日期:2018-05-07

基金项目(Foundation item):国家自然科学基金资助项目(51535012, U1604255); 国家重点研发计划项目(2017YFB1300700); 中南大学研究生自主探索创新项目(2018zzts475)(Projects(51535012, U1604255) supported by the National Natural Science Foundation of China; Project (2017YFB1300700) supported by the National Key R&D Plan; Project(2018zzts475) supported by the Independent Exploration and Innovation Program of the Graduate Students of Central South University)

通信作者:唐进元,教授,博士生导师,从事齿轮传动与智能制造研究;E-mail:jytangcsu@163.com