文章编号:1004-0609(2008)02-0317-06

高温空气氧化对高硅铝合金材料组织及物理性能的影响

杨伏良,易丹青,张 伟

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用高温空气氧化对Al-12Si与Al-30Si合金粉末进行预处理,结合包套热挤压,制备出Al2O3与SiO2增强的弥散强化型铝硅复合材料,通过金相及热物性测试,对材料显微组织、密度、气密性、热膨胀系数、导热系数进行了分析。结果表明:合金粉末经高温空气氧化预处理后,Al-12Si晶粒长大不明显,而Al-30Si晶粒发生了明显长大;材料致密度随氧化时间延长略有下降,但均在97%以上,材料气密性均在1×10-9 Pa?m3/s左右;在相同工艺条件下,Al-30Si材料热膨胀系数明显低于Al-12Si材料,氧化时间对材料热膨胀系数影响不明显;导热系数随材料中硅含量增加而下降,随粉末氧化时间延长而增加,氧化24 h后,材料导热系数超过120 W/(m?K)。

关键词:高硅铝合金;高温空气氧化;热膨胀系数;导热系数

中图分类号:TF 112; TG 337 文献标识码:A

Effect of high-temperature air oxidation on microstructure and physical properties of high-silicon aluminum alloy

YANG Fu-liang, YI Dan-qing, ZHANG Wei

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The high-temperature air oxidation pretreatment process was applied to Al-12Si and Al-30Si alloy powders, and combined with hot-extrusion to fabricate SiO2 and Al2O3 dispersion strengthening composites. Optical microscopy and thermal physical testers analyzed the microstructure, density, hermeticity, coefficient of thermal expansion and thermal conductivity. The results show that: After powders oxidation, growth of Si grains in Al-30Si is more obvious than that of Al-12Si; the relative density of materials decreases with the increasing of oxidation time, but they are all higher than 97%. The hermeticity is about 1×10-9 Pa?m3/s. Under the same process condition, the coefficient of thermal expansion of Al-30Si is much lower than that of Al-12Si, and the effect of oxidation time on coefficient of thermal expansion is not obvious. The thermal conductivity decreases with increase of Si content and increases with prolonging oxidation time, after oxidation 24 h, it exceeds 120 W/(m?K).

Key words: high-silicon aluminum alloy; high-temperature air oxidation; coefficient of thermal expansion; thermal conductivity

高硅铝合金作为电子封装材料,其质量仅为传统金属基W-Cu电子封装材料的六分之一,且高硅铝合金具有很好的导热性能,线膨胀系数可控[1],能与电路板广泛使用的半导体材料相匹配,因此,作为基片衬底、机壳及盖板等材料,可保证电子器件在使用过程中不致受热或开裂而过早失效。

高硅铝合金材料制备工艺有熔铸法[2-3]、粉末冶金烧结法、喷射沉积[4-6]和溶渗法锭坯制备技术和热挤压、半固态挤压、热锻造等加工成形技术[7]。在国内,这些方法所制备材料由于其气密性、导热系数、热膨胀系数及抗拉强度所限,难以同时满足电子封装机壳与盖板的使用要求。弥散强化金属基复合材料由于微粒子阻碍金属基体的位错运动而强化基体,其典型代表为SAP等,由于其强化相多是氧化物,故也叫ODS合金。美国Glidden Metals公司发表了Al2O3粒子分散强化Cu合金的报告,将Cu-Al合金用气体雾化法雾化成粉末,对粉末进行内氧化,使其内部铝氧化成Al2O3粒子,再挤压成制品,得到了性能优良的Al2O3弥散强化铜合金材料。鉴于此,本实验采用高温空气氧化对Al-Si合金粉末进行预处理,然后结合包套热挤压,制备Al2O3与SiO2增强的弥散强化型铝硅复合材料,研究氧化对高硅铝合金材料组织及电子封装材料所要求物理性能的影响。

1 实验

1.1 合金粉末氧化

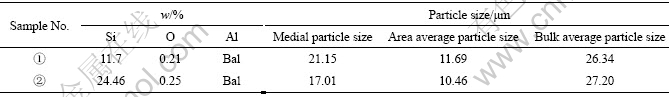

实验所用粉末为Al-12Si与Al-30Si两种,粉末采用氮气雾化水冷制备,其化学成分与粒度如表1所列。将所有粉末放入箱式电阻炉内,升温至300 ℃(空气中氧含量为21%),氧化时间(保温时间)分别设定为8、16、24与32 h,取出后让其自然冷却待用。

表1 粉末化学成分与粒度

Table 1 Chemical composition and particle size of powders

1.2 粉末包套热挤压

采用包套封装[8-10] 方法,将氧化后的合金粉末装入特制的纯铝包套内,振实后其密度可达理论密度的70%,封闭焊合包套(在包套盖板上留有一小孔,用于后续热挤压时内部气体排气)。试样加热温度为520 ℃,挤压模具加热温度为450 ℃,挤压比为21.3(挤压筒直径为d 60 mm,挤压样品直径为d 13 mm)。

1.3 性能检测

采用EOPHAT金相显微镜对材料进行显微组织观察;采用排水法测量材料密度,所用分析天平最小精度为0.1 mg;在日产HELIOT306S型He吸附试验机上进行气密性测试;在日本理学差热分析仪上进行了热膨胀系数测试;在JR-2热物性测试仪上进行热扩散率测试。

2 结果与讨论

2.1 材料微观组织

图1所示分别为原始粉末与氧化粉末挤压成材后的金相组织。从图1(a)与(c)中可以看出,合金粉末经空气预氧化后,Al-12Si共晶合金中由于初晶硅含量较少,晶粒没有发生明显长大;而从图1(b)与(d)可以看出,在Al-30Si粉末氧化后所挤压形成的材料中,晶粒尺寸较大,而粉末未经氧化所挤压形成的材料中,晶粒尺寸明显较小。这主要是由于粉末的氧化过程,是在300 ℃高温下进行长时间保温,致使合金粉末内部元素发生相互扩散,初晶硅粒子聚集长大;这种粉末组织的影响带到了随后热挤压的材料中,致使挤压后材料中硅粒子也相应较大。

图1 原始粉末与氧化粉末挤压成材后的金相组织

Fig.1 Microstructures of materials fabricated by original and oxidated powders: (a) Al-12Si original powders; (b) Al-30Si original powders; (c) Al-12Si extruded material after powder oxidation for 24 h; (d) Al-30Si extruded material after powder oxidation for 24 h

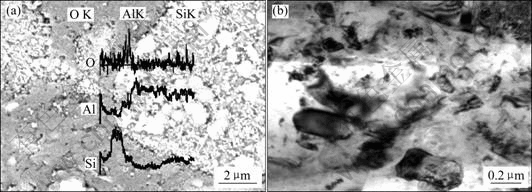

另外,从图2所示Al-30Si粉末氧化24 h后元素线扫描照片及所制备材料的TEM照片可以看出,粉末表面氧含量明显高于粉末内部,即在粉末表面形成了一层硬而脆的Al2O3和SiO2复合氧化物薄膜,氧化膜在粉末热挤压成形过程中,受三向压应力所产生的界面剪切应力的作用而破碎,分布在材料的内部组织中。

图2 Al-30Si粉末氧化24 元素线扫描照片及所制备材料的TEM照片

Fig.2 Element linear scanning image of Al-30Si powders oxidated for 24 h and TEM image of extruded material: (a) Element linear scanning image; (b) TEM image

2.2 密度与气密性

Al-12Si和Al-30Si实测硅含量分别为11.7%和22.46%,计算出理论密度分别为2.65和2.6 g/cm3。对不同氧化时间材料的密度进行测量,并由此求出材料致密度,其实测密度与致密度如表2所示。从表中数据可以看出,热挤压成形后材料致密度随着氧化时间延长略有下降,但都在97%以上,材料相当致密,表明粉末氧化对材料的冶金结合没有太大影响(在此计算材料理论密度时没有考虑氧化物质点的影响,因此,致密度的计算存在一定误差)。

表2 样品的实测密度与致密度

Table 2 Measure density and relative density of samples

粉末经不同氧化时间氧化后所制备材料气密性如表3所示。从表中数据可以看出,材料气密性均在 1×10-9 Pa?m3/s左右。高致密度是高气密性的前提。根据气密性测试方法[11],从本质上说,氦吸附检漏是检查材料微孔洞。由于氦的分子半径很小,它能透过材料微小间隙吸附于孔洞的内壁上。在抽真空检漏时,氦从小孔的内壁放出而使探头探测到氦的分压。因此,要提高材料的气密性,必须从根本上减少或消除弥散于Al-Si材料中的小孔。与热压、等静压等致密化工艺相比,实验所用热挤压成形工艺相对较好,成功解决了电子封装对材料气密性的高要求,与传统电子封装材料W-Cu[12]相当。

表3 粉末经不同氧化时间氧化后所制备材料气密性

Table 3 Material hermeticity of powders oxidated for different oxidation times (10-9 Pa?m3?s-1)

2.3 热膨胀性能

高硅铝合金材料的低热膨胀性主要与硅相的影响有关,同时也受合金粉末氧化程度的影响。增强相或弥散相的体积分数、尺寸大小、形状分布,基体材料的强度与塑性,相间的界面性质、结合强度,材料致密度以及材料内部的残余应力,都会或多或少影响到材料热膨胀系数。

不同氧化时间氧化粉末挤压成材后,Al-12Si和Al-30Si试样在100、250、400 ℃的热膨胀系数分别如表4和表5所示。从表中数据可以看出,在相同工艺条件下,Al-30Si热膨胀系数明显低于Al-12Si共晶合金的热膨胀系数。我们知道,材料中延性相是否连续分布是影响热膨胀系数的一个重要因素。随着温度升高,延性相和脆性相都会发生膨胀,但延性相的热膨胀系数一般比较大,当延性相属于不连续相时,其形变会受到周围热膨胀系数很小的脆性相颗粒的约束;当延性相连续分布时,这种约束就会很小。从图1所示金相组织可以看出,Al-30Si中硅相及氧化物较多且分布均匀,大量低膨胀系数的硅相及氧化物均匀分布能有效抑制基体的膨胀,且由于硅含量及氧化物的升高,使得材料的延性相铝相减少,易被富集的硅相或氧化物所阻断,从而使得材料热膨胀系数下降,同时,当硅含量增加时,硬脆性的硅相使得材料在挤压时变形抗力增加,从而导致材料内含有大量的微应力,使材料热膨胀系数也有所减小。

表4 Al-12Si试样分别在100、250和400 ℃的热膨胀系数

Table 4 TEC of Al-12Si at 100, 250 and 400 ℃(10-6 K-1)

表5 Al-30Si试样分别在100、250和400 ℃的热膨胀系数

Table 5 TEC of Al-30Si at 100, 250 and 400 ℃(10-6 K-1)

另外,从表中数据还可以看出,粉末经氧化处理后对挤压成形材料热膨胀系数的影响较为复杂,随氧化时间延长,没有明显的规律可循(表中数据波动在测量误差范围内)。这主要是因为,空气氧化后,粉末氧含量没有显著增加,因而相应氧化物质点增加很少,其对膨胀系数的影响也就不明显。另外,复合材料的热膨胀系数的影响因素很多,并且粉末氧化过程伴随着加热保温的过程,其对材料内部组织的影响机制非常复杂。

合金粉末氧化预处理后,氧化物在成形过程中可以抑制材料基体和硅相的长大,而硅相大小又直接影响着材料内部的应力大小[16-17],材料从成形温度冷却到常温后,存在残余应力,基体由于膨胀系数较大而受拉应力,而硅相与氧化物质点由于膨胀系数小而受压应力,应力的大小主要与硅相及氧化物的体积分数有关,但当硅与氧化物含量相同时,颗粒的界面面积与应力成反比,内部应力将抑制材料的热膨胀,单就残余应力对热膨胀性能的影响,硅相与氧化物质点越细小,材料的热膨胀系数越低。另外,TAKEI等[13, 16]研究了增强相颗粒形状对复合材料热膨胀性能的影响,结果表明,当增强体的长径比等于1,即为球形颗粒时,其增强效果最好,由于与氧化物的碰撞阻隔作用,合金中硅粒子经挤压破碎后,得到的球形颗粒较多,也会对材料的热膨胀性能产生一定的积极影响。其原因可能是,近球形的尖角比较小,在基体中造成的内压应力虽小,但较均匀,可以阻止基体伸长,因此热膨胀系数较小,多边形颗料主要在尖角处造成较大应力,其他部位造成应力较小,因而限制基体伸长效果反而更小。

另一方面,与基体合金相比,氧化物本身的热膨胀系数小很多,这种弥散分布在材料中的硬质颗粒也因受热膨胀的不同而对材料整体的热膨胀系数产生影响,其作用机理与硅相颗粒类似,只因粒径较小,且含量较少,对材料热膨胀系数影响不大。

2.4 导热系数

导热性能是电子封装壳体与盖板一个非常重要的物理性能。氧化粉末经热挤压后所测材料导热系数如表6所示。从表中数据可以看出,对于硅含量高的材料,其导热系数相应较低,即其导热系数随材料中硅含量增加而下降。对于硅含量相同的合金,材料导热系数随着粉末氧化时间延长而增加。氧化时间在16 h内,Al-12Si与Al-30Si两种材料导热系数增加幅度都不大,而氧化时间从16 h延长到24 h时,导热系数增加幅度最大,如Al-30Si氧化时间从16 h增加到24 h时,其导热系数增加了12%,而氧化时间从24h延长到32 h时,其导热系数只增加了5.4%。这主要有以下几方面原因。

表6 氧化粉末经热挤压后所测材料导热率

Table 6 TC of materials fabricated by oxidation powders (W?m-1?K-1)

首先,硅相颗粒含量、粒度、形状和分布对材料导热性能的影响是通过对声子和电子的散射实现的。声子和自由电子的传热能力,会因受到几何界面散射而减弱,从而降低材料的导热能力。颗粒含量和粒度决定着散射面积的大小,高硅铝合金材料中硅相颗粒含量越多,粒度越细,其散射面积越大,对材料导热性能的降低也愈显著。同时,当相同含量的颗粒在基体中作不同分布时,颗粒和基体形成的几何界面对导热方向上的声子和自由电子的散射效应分布愈不均匀,颗粒形态对称性愈差,其散射效应就愈会偏离这个标准。这种偏离可正可负,由此对材料导热系数产生或增或减的影响。粉末在高温氧化过程中,原子固态扩散加剧。从图1(c)和(d)的金相照片可知,晶粒与硅粒子长大十分明显,大量弥散细小的初晶硅粒子消失,其材料组织特征延续到热挤压试样中,减少了复合材料基体与增强体之间的界面,使复合材料界面热阻降低,从而提高材料导热系数。

其次,随着硅含量增加,合金中硅相数量增多、尺寸也较大。硅本身的导热性能较铝基体低得多,铝相不能很好的稳固初晶硅相,从而出现颗粒分布的不均匀性,在某些区域中,可能很少甚至没有铝基体,这样堆积的硅颗粒阻断了铝基体的连通结构,导致材料内部产生较多的缺陷;另外,硅相与自由电子的碰撞机率也逐渐增大,使自由电子定向移动的阻力增大,从而使其导热性能下降。

另外,粉末氧化后,表面氧化膜在随后热挤压过程中破碎,较均匀分布于基体组织中,将增加对声子和自由电子的散射作用,使材料导热系数降低;但这种分布的氧化物质点也可能起到填充作用,使复合材料的空隙度降低,从而提高材料导热系数。

综上所述,从本实验测量数据来看,粉末或材料在受热过程中,第二相粒子的长大,减少界面热阻的作用应该是主要的。导热系数增加幅度的减小主要是氧化物数量增多,增加了对声子和自由电子的散射作用。另外,从图1所示材料的金相照片可以看出,一方面,硅颗粒为不规则的多面体,其比表面积更大;另外,硅颗粒在基体中的分布带有不可避免的不均匀性;同时原材料铝和硅中总会含有不同程度的杂质使界面热阻增加,以及材料内部孔洞等缺陷的存在等,这些都会最终影响到材料的导热性能。

3 结论

1) 合金粉末经高温空气氧化预处理后,共晶合金Al-12Si晶粒没有发生明显长大,而过共晶合金Al-30Si晶粒尺寸长大明显。

2) 材料致密度随着氧化时间延长略有下降,但都在97%以上,材料相当致密;材料气密性均在1×10-9 Pa?m3/s左右,与传统电子封装材料W-Cu相当,完全可满足电子封装材料使用要求。

3) 在相同工艺条件下,Al-30Si材料热膨胀系数明显低于Al-12Si材料,氧化时间对材料热膨胀系数影响不明显。导热系数随材料中硅含量增加而下降,随粉末氧化时间延长而增加,氧化24 h后,所制备材料导热率≥120 W/(m?K),完全可满足电子封装材料使用要求。

REFERENCES

[1] ADOLFI S, JACOBSON D M, OGILVY A. Property measurement on ospray spray-deposited Al-Si alloys[R]. ERBFMGECT980141, Neath, SAII, INJ, UK: Aerospace and Space Materials Technology Testhouse, 2002.

[2] 廖恒成, 孙国雄. 铸造Al-Si合金中Sr与B的交互作用[J]. 中国有色金属学报, 2003, 13(2): 353-359.

LIAO Heng-cheng, SUN Guo-xiong, Interaction between Sr and B in Al-Si casting alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 353-359.

[3] 张金山, 许春香, 韩富银, 复合变质对过共晶高硅铝合金组织和性能的影响[J]. 中国有色金属学报, 2002, 12(S1): 107-110.

ZHANG Jin-shan, XU Chun-xiang, HAN Fu-yin. Effect of composite modifier on structures and properties of hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): 107-110.

[4] 傅定发, 任胜钢, 陈振华. 多层喷射沉积过共晶Al-Si-Cu-Mg合金的微观组织及力学性能[J]. 中南工业大学学报, 2000, 31(5): 445-447.

FU Din-fa, REN Sheng-gang, CHEN zhen-hua. Microstructures and mechanical properties of a hypereutectic Al-Si-Cu-Mg alloy by multi-layer spray deposition[J]. J Cent South Univ Technol, 2000, 31(5): 445-447.

[5] SRIVASTAVA V C, MANDAL R K, OJHA S N. Microstructure and mechanical properties of Al-Si alloys produced by spray forming process[J]. Mater Sci Eng A, 2001, 304/306: 555-558.

[6] 甄子胜, 赵爱民, 毛卫民, 孙 峰, 钟雪友. 喷射沉积高硅铝合金显微组织及形成机理[J]. 中国有色金属学报, 2000, 10(6): 815-817.

ZHEN Zi-sheng, ZHAO Ai-min, MAO Wei-min, SUN Feng, ZHONG Xue-you. Microstructure and formation mechanism of spray deposited hypereutectic Al-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 815-817.

[7] 赵爱民, 甄子胜, 毛卫民, 崔成林, 孙 峰, 姜春梅, 钟雪友. 喷射沉积高硅铝合金的半固态触变成形[J]. 中国有色金属学报, 2000, 10(S1): 126-131.

ZAO Ai-min, ZHEN Zi-sheng, MAO Wei-min, CUI Cheng-lin, SUN Feng, JIANG Chun-mei, ZHONG Xue-you. Semi-solid thixoforming of spray formed high silicon hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): 126-131.

[8] 张大童, 李元元, 罗宗强. 快速凝固过共晶铝硅合金材料的研究进展[J]. 轻合金加工技术, 2001, 29(2): 1-6.

ZHANG Da-tong, LI Yuan-yuan, LUO Zong-qiang. A review on the progress of rapidly solidified hypereutectic Al-Si alloy materials[J]. The Process Technology of Light Alloys, 2001, 29(2): 1-6.

[9] JUN Shen, ZHUANG De-xie, YU Lai-gao. Microstructure characteristics of a hypereutectic Al-Si alloy manufactured by rapid solidification/powder metallurgy process[J]. Journal of Materials Science Letters, 2001, 20: 1513-1515.

[10] 张大童, 李元元, 周照耀, 张 文. 快速凝固/粉末冶金(RS/PM)高硅铝合金材料的研究[J]. 材料科学与工艺, 1999, 7(S1): 41-44.

ZHANG Da-tong, LI Yuan-yuan, ZHOU Zhao-yao, ZHANG Wen. Study on rapidly solidified RS/PM hyper-eutectic Al-Si alloy materials[J]. Material Science and Technology, 1999, 7(S1): 41-44.

[11] 杨伏良, 甘卫平, 陈招科. 挤压温度对高硅铝合金材料物理性能的影响[J]. 机械工程学报, 2006, 42(6): 7-10.

YANG Fu-liang, GAN Wei-ping, CHEN Zhao-ke. Effect on extrusion temperature for physical properties of high-silicon aluminum alloy[J]. Chinese Journal of Mechanical Engineering, 2006, 42(6): 7-10.

[12] 王志法, 刘正春, 姜国圣. WCu电子封装材料的气密性[J]. 中国有色金属学报, 1999, 9(2): 324-326.

WANG Zhi-fa, LIU Zheng-chun, JIANG Guo-shen. Hermeticity of WCu composites for semiconductor package[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 324-326.

[13] 姜传海, 牟宗花, 刘 钧, 彭华新, 王德尊, 姚忠凯. SiCw/LD2复合材料零错配应力温度及其调整[J]. 材料研究学报, 1997, 11(4): 411-414.

JANG Chuan-hai, MU Zhong-hua, LIU Jun, PENG Hua-xin, WANG De-zun, YAO Zhong-kai. The zero-misfitstress- temperature of SiCw/6061Al composite[J]. Chinese Journal of Material Research, 1997, 11(4): 411-414.

[14] 钟涛兴, 吉 元, 李 英, 李惠娥. 压渗SiCp/Al电子封装复合材料的研究[J]. 铸造技术, 1997, 6: 42-43.

ZHONG Tao-xing, JI Yuan, LI Ying, LI Hui-er. Study on SiCp/Al composites for electronic packaging fabricated by squeeze casting processes[J]. Foundry Technology, 1997, 6: 42-43.

[15] TAKEI T, HATTA H. Thermal expansion behaviors of particulate-filled composites Ⅱ: Multi-reinforcing phases (Hybrid Composites)[J]. Mater Sci Eng A, 1991, 131: 145-152.

[16] TAKEI T, HATTA H. Thermal expansion behaviors of particulate-filled composites Ⅰ: Single reinforcing phase[J]. Mater Sci Eng A, 1991, 131: 133-143.

基金项目:国防科学技术工业委员会资助项目(2003-151)

收稿日期:2007-04-30;修订日期:2007-09-29

通讯作者:杨伏良,副教授,博士;电话:0731-8877713; E-mail: yangflcsu@163.com

(编辑 何学锋)