文章编号: 1004-0609(2006)05-0800-05

Ti(C, N)基金属陶瓷断口形貌及增韧机理

刘文俊1, 2, 熊惟皓1, 郑 勇3

(1. 华中科技大学 塑性成形模拟及模具技术国家重点实验室, 武汉 430074;

2. 三峡大学 机械与材料学院, 宜昌 443002;

3. 南京航空航天大学 材料科学与技术学院, 南京 210016)

摘 要: 采用真空烧结工艺制备Ti(C, N)基金属陶瓷, 测定了材料的力学性能。 结果表明, 其力学性能与未加纳米粉的金属陶瓷相比, 硬度略有升高, 但横向断裂韧性提高了近一倍。 断口形貌和微观组织分析表明: 金属陶瓷的断口形貌与其强韧性有着密切的关系。 纳米粉的加入降低了原始粉末的平均粒度, 使得金属陶瓷硬质相的粒度降低, 减小了晶粒间的平均自由程。 镶嵌于大颗粒环形相和弥散分布于粘结相中的细小硬质相颗粒, 对裂纹的形成和扩展起到阻碍作用, 会使金属陶瓷因裂纹扩展途径发生偏转而增韧。

关键词: Ti(C, N)基金属陶瓷; 断口形貌; 增韧机理; 力学性能 中图分类号: TG113.254

文献标识码: A

Appearance of fracture and toughening mechanisms of Ti(C, N)-based cermets

LIU Wen-jun1, 2, XIONG Wei-hao1, ZHENG Yong3

(1. State Key Laboratory of Plastic Forming Simulation and Die and Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China;

2. College of Mechanical and Materials Engineering,

China Three Gorges University, Yichang 443002, China;

3. College of Materials Science and Technology,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China)

Abstract: The Ti(C, N)-based cermets were produced by vacuum sintering technology, and the mechanical properties were measured. The results show that the hardness of nano-composite Ti(C, N)-based cermets slightly increases, while the transverse rupture strength (TRS) increases by a factor of two times compared with micron cermets. The analysis of appearance of fracture and microstructure indicates that there is compact relation between appearance of fracture and toughness. With the addition of nano-structured powders, the mean particle size of raw powders decreases, the microstructure becomes finer and distributes evenly, and the average distance between grains reduces. Some small grains are found to be embedded in binder and the rim phases of big grains obstruct the form and extend of crack. The experiment results indicate that the toughening mechanisms of nano-composite cermets is crack deflection toughening.

Key words: Ti(C, N)-based cermets; appearance of fracture; toughening mechanisms; properties

金属陶瓷具有较高的硬度、 耐磨性、 红硬性、 极低的摩擦因数, 因而受到国内外的普遍关注[1-4], 成为一类极有潜力的刀具材料。 但其自身的脆性限制了它的应用, 陶瓷刀具由于强韧性不足, 在使用中常因崩刃而失效。 因而如何使陶瓷材料增韧成为一个热点问题。 目前, 陶瓷增韧的方法有相变增韧、 晶须增韧等[5, 6], 但效果有限。 纳米复合技术是近年来发展起来的一种陶瓷增韧方法, 在基体材料中加入纳米颗粒或纳米晶须可以有效地提高基体材料的力学性能[7-11]。 本文作者曾研究了纳米粉添加量对金属陶瓷显微组织和性能的影响, 结果表明, 添加适当的纳米粉末可以显著的提高金属陶瓷的性能[12], 因而进一步研究金属陶瓷的增韧机理显得尤为重要。 目前, 纳米颗粒增韧机理的研究主要集中在异种成分第二相粒子增韧方面, 有关纳米颗粒增韧同种成分基体材料的研究还不多见。 本文作者用真空烧结法制备了纳米复合Ti(C, N)基金属陶瓷, 测定了材料的横向断裂强度和硬度, 并与未加纳米粉的金属陶瓷进行了对比。 观察了陶瓷的显微组织和断口形貌, 探讨了其增韧机理。

1 实验

实验所用材料为市售的TiC、 TiN、 Ni、 Mo、 WC、 石墨、 Cr3C2粉末, 其原始粉末条件与复合材料配比分别见表1和2。 采用QM-1SP行星式球磨机湿式混料, 球磨机转速为220r/min, 混料时间为36h。 在温度为353K的红外干燥箱中干燥料浆。 试样在CSS-2210型电子万能材料试验机上压制而成, 压制压力为300MPa, 保压时间为30s。将压坯在1420℃下真空烧结60min, 液相烧结阶段真空度控制在1~10-2Pa之间。

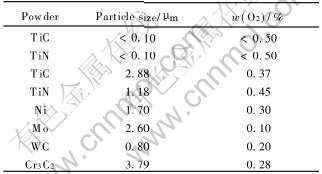

表1 原始粉末的平均粒度和氧含量

Table 1 Mean particle sizes and oxygen contents of raw powders

表2 Ti(C, N)基金属陶瓷的化学成分

Table 2 Chemical composition of Ti(C, N)-based cermets (mass fraction, %)

烧结后的试样在CSS-2210型电子万能材料试验机上进行三点弯曲实验, 试样尺寸为5.0mm×6.5mm×32mm, 跨距为14.8mm。 用洛氏硬度计测量材料的硬度。 每种成分试样取5个测定其横向断裂强度和硬度, 取算术平均值。 试样断口经超声波清洗后, 用JSM-5510LV型扫描电镜在二次电子(BEI)模式下观察试样的断口形貌, 用JSM-5600LV型扫描电镜在背散射电子(BSE)模式下观察试样的显微组织。 试样切片手工磨至约30μm后用Gatan691离子减薄仪减薄, 制得用于扫描电镜观察的薄膜, 然后在JEM-2010型透射电镜下观察试样的微观组织。

2 结果与分析

2.1 材料的力学性能

实验材料的横向断裂强度和硬度列于表3。 由表可知, 试样A的强度和硬度均较低, 通过纳米复合增韧后(B试样), 材料的强度提高近一倍。 究其原因, 主要是纳米粉的加入降低了粉体的平均粒度, 使得单位体积内可作为形核的颗粒数增多。 而在溶解-析出过程中, 从粘结相中析出的合金元素的量基本不变, 因而单个晶粒上沉积的合金元素的量减少, 也就抑制了硬质相颗粒的长大, 致使金属陶瓷硬质相的粒度比较细小, 分布也比较均匀, 因此有效地提高了其强度[12], 符合Hall-Petch关系式。 但金属陶瓷的硬度变化不大, 这与文献[13]所得结论相一致。

表3 实验材料的力学性能

Table 3 Mechanical properties of experimental materials

2.2 断口形貌

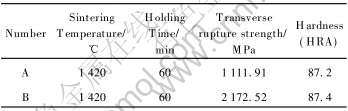

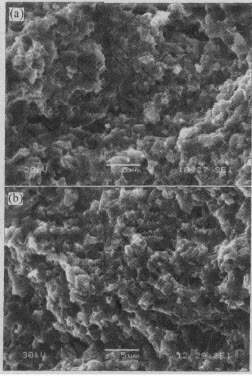

由断口形貌可知, 对于未加纳米粉的金属陶瓷A, 试样断口有近于平行分布的台阶, 并有河流状花样(图1(a)), 其裂纹快速扩展区有岭状解离棱出现(图2(a))。 从其断口裂纹源的高倍形貌可以看出(图3(a)), 硬质相大颗粒成为裂纹源, 其断面出现比较完整的晶面和河流状条纹, 断裂方式以穿晶断裂为主。

金属陶瓷B的断裂形式为沿晶和韧窝混合型。 其断口形貌呈放射状分布, 局部区域有舌形花样条纹(图1(b))。 靠近张力表面的孔洞成为裂纹源, 同时可以看到硬质相颗粒从粘结相拔出来时形成的韧窝(图3(b))。 从试样裂纹的快速扩展区可以观察到特殊的断口形貌—撕裂棱(图2(b)、 图3(b))。 这是由于在外加载荷的作用下, 在基体内原有的裂纹源(如气孔)处形成了高张力区域, 随着应力的增加, 微裂纹逐渐扩展, 在与其它微裂纹相遇时, 如果这两种不同方式的裂纹不能很好地衔接起来, 就在它们的过渡区形成了撕裂棱。 裂纹在试样内扩展的路径越长, 则其强度和韧性越好。 由此可知, 金属陶瓷B较金属陶瓷A具有较好的强度和韧性, 横向断裂强度实验也证实了这一点(表3)。

图1 金属陶瓷的断口全貌

Fig.1 Fracture surface morphologies of cermets

图2 金属陶瓷裂纹的快速扩展区

Fig.2 Fatigue crack propagation zone of cermets

图3 金属陶瓷的裂纹源

Fig.3 Fatigue crack source region of cermets

2.3 金属陶瓷的增韧机理

在金属陶瓷A中, 大块的粘结相及大颗粒的硬质相的数量较多, 当裂纹从粘结相中穿过时, 在交变应力的作用下, 裂纹尖端出现反复的钝化和变锐的过程, 导致陶瓷材料弱化, 裂纹扩展。 同时Ti(C, N)颗粒中存在较多的滑移系, 当裂纹从一个颗粒扩展到另一颗粒时很容易形成取向有利[14]。 由于裂纹总是沿着所需能量最小的路径进行, 当裂纹扩展到大颗粒的硬质相时, 必然发生穿晶断裂, 出现比较完整的晶面和河流状条纹(见图3(a))。

2.3.1 弥散强化增韧机理

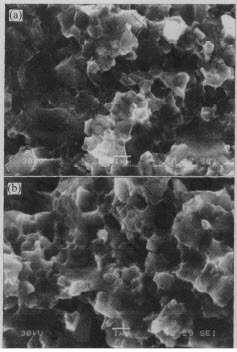

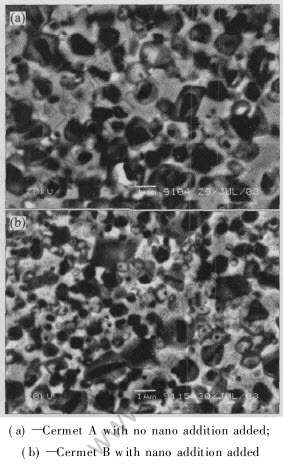

金属陶瓷B的硬质相明显比金属陶瓷A的细小(图4), 黑芯-灰壳结构的大颗粒的数量显著降低, 具有内、 外环形相的小颗粒和具有白芯-灰壳结构的小颗粒大大增加, 且弥散分布于粘接相中。 显然, 纳米粉的加入使金属陶瓷硬质相的平均粒度减小。

图4 金属陶瓷显微组织的扫描电镜像

Fig.4 SEM micrographs of cermets

根据Gurland强度理论[15], 合金强度和结构参数的关系符合弥散强化规律, 可通过包覆颗粒传播裂纹所需的应变能来估计临界断裂强度, 并且得到临界应力表达式:

式中 σ为轴应力; φ为WC的体积分数; d为WC的平均粒度; K′为常数。

对一定成分的WC-Co合金, 其强度随着WC平均粒度的减小而增大。

Ti(C, N)基金属陶瓷是与WC-Co硬质合金同类的材料。 上述理论也可以适用于金属陶瓷。 当加入一定量的纳米粉后, 材料中小颗粒的数目明显增加, 硬质相的平均粒度d降低, 由上式可知, 金属陶瓷的强度将会得到提高。

2.3.2 裂纹偏转增韧机理

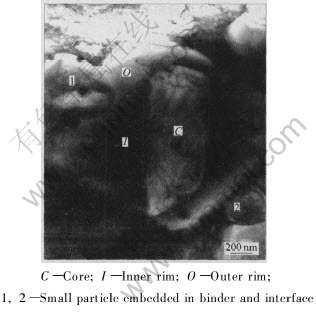

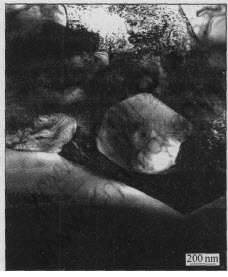

金属陶瓷在宏观上表现为脆性材料, 但在微小区域内仍可以发生一定的塑性变形。 当裂纹扩展到硬质相与硬质相界面时, 由于硬质相颗粒的硬度很高, 难以在交变应力的作用下发生损伤, 同时许多小颗粒硬质相镶嵌于大颗粒硬质相的环形相中(图5), 并与大颗粒硬质相存在部分共格关系[16], 它们之间结合牢固, 会阻碍裂纹的扩展, 使裂纹前端的走向发生曲折, 产生类似于位错被钉扎的效果。 当裂纹在粘结相中扩展时, 粘结相中弥散分布的细小硬质相颗粒会阻碍裂纹的扩展, 使裂纹前端的走向发生偏转, 延长了裂纹的扩展路径(图6)。 同时, 单个裂纹扩展到相互连接时形成撕裂棱, 粘结相在撕裂棱处产生大量的塑性变形, 金属陶瓷因消耗塑性变形功增大而增韧。

图5 金属陶瓷试样B的透射电镜明场像

Fig.5 Bright field TEM micrograph of cermet B

图6 粘结相中细小硬质相的透射电镜明场像

Fig.6 Bright field TEM micrograph of binder phase in cermet B

3 结论

1) 金属陶瓷的断口形貌与其强韧性有着密切的关系。 添加了纳米粉的金属陶瓷, 其断口形貌中可以看到撕裂棱、 韧窝等现象, 断裂方式为沿晶断裂+韧窝断裂。

2) 镶嵌于环形相和弥散分布于粘结相中的细小硬质相颗粒, 对裂纹的形成和扩展起到阻碍作用, 使裂纹的扩展途径发生偏转, 因而提高了材料的断裂能, 使材料得以增韧。

3) 断口分析表明, Ti(C, N)基金属陶瓷的增韧机理为弥散强化增韧和裂纹偏转增韧。

REFERENCES

[1]Ettmayer P, Kolaska H, Lengauer W, et al. Ti(C, N) cermets-metallurgy and properties[J]. Refractory Metals & Hard Materials, 1995, 13: 343-351.

[2]DErrice G E, Bugliosi S, Cuppini D, et al. A study of cermets wear behavior[J]. Wear, 1997, 203: 242-246.

[3]Viatte T, Bolognini S, Gutard T, et al. Investigation into the potential of a composite combining toughness and plastic deformation resistance[J]. Refractory Metals & Hard Materials, 1999, 17: 79-89.

[4]Bolognini S, Feusier G, Mari D, et al. High temperature mechanical behavior of Ti(C, N)-Mo-Co cermets[J]. Refractory Metals & Hard Materials, 1998, 16: 257-268.

[5]朱其芳, 姚伟, 孙丽虹, 等. SiC晶须有序添加角度对Si3N4基体陶瓷的增韧效应[J]. 中国有色金属学报, 2000, 10(6): 872-876.

ZHU Qi-fang, YAO Wei, SUN Li-hong, et al. Reinforcing effect of orderly additive orientation of SiC whisker in Si3N4 ceramic matrix[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 872-876.

[6]王瑞坤, 孙丽虹, 马通达, 等. Si3N4复合陶瓷材料的微观组织和断裂机制[J]. 中国有色金属学报, 2000, 10(6): 824-826.

WANG Rui-kun, SUN Li-hong, MA Tong-da, et al. Microstructure and fracture mechanism of Si3N4 composite ceramic materials[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 824-826.

[7]龚红宇, 尹衍升, 郝春成, 等. Fe3Al纳米粒子增强Al2O3陶瓷的制备及性能[J]. 中国有色金属学报, 2003, 13(1): 188-192.

GONG Hong-yu, YIN Yan-sheng, HAO Chun-cheng, et al. Fabrication and properties of Fe3Al nano-particle toughening Al2O3 matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 188-192.

[8]Stearns L C, Zhao J, Harmer M P. Processing and microstructure development in Al2O3-SiC nanocomposites[J]. J Eur Ceramic Soc, 1992, 100: 448-453.

[9]Niihara K. Development of high performance ceramic base nanocomposites[J]. J Jpn Soc Powder & Powder Metal, 1997, 44(10): 887-896.

[10]Kear B H, Colaizzi J, Mayo W E, et al. On the processing of nano crystalline and nanocomposite ceramics[J]. Scripta Mater, 2001, 44: 2065-2068.

[11]Awaji H, Choi S M, Yagi E. Mechanisms of toughening and strengthening in ceramic-based nanocomposites[J]. Mechanics of Materials, 2002, 34: 411-422.

[12]刘文俊, 郑勇, 熊惟皓. Ti(C, N)金属陶瓷中纳米粉含量对组织和性能的影响[J]. 粉末冶金技术, 2005, 23(5): 334-338.

LIU Wen-jun, ZHENG Yong, XIONG Wei-hao. The effect of nano addition on the microstructures and mechanical properties of Ti(C, N)-based cermets[J]. Powder Metallurgy Technology, 2005, 23(5): 334-338.

[13]徐智谋, 易新建, 胡茂中, 等. 纳米Ti(C, N)增强Ti(C, N)基金属陶瓷的研究[J]. 材料热处理学报, 2003, 24(3): 41-45.

XU Zhi-mou, YI Xin-jian, HU Mao-zhong, et al. Study of Ti(C, N) nanopowder reinforced Ti(C, N)-based cermets[J]. Trans Mater Heat Treat, 2003, 24(3): 41-45.

[14]李晨辉, 熊惟皓, 余立新. 硬质相粒度对Ti(C, N)基金属陶瓷断裂韧性的影响[J]. 理化检验(物理分册), 2001, 37(10): 415-419.

LI Chen-hui, XIONG Wei-hao, YU Li-xin. Effect of hard particle size on fracture toughness of Ti(C, N)-based cermets[J] . PTCA(Part A: Physical testing), 2001, 37(10): 415-419.

[15]曾德麟. 粉末冶金材料[M]. 北京: 冶金工业出版社, 1989. 152-200.

ZENG De-lin. Powder Metallurgy Materials[M]. Beijing: Metallurgical Industry Press, 1989. 152-200.

[16]LIU N, ZENG Q M, HUANG X M. Microstructure in titanium carbonitride cermets[J]. Materials Science and Technology, 2001, 17: 1050-1054.

基金项目: 国家自然科学基金资助项目(50074017, 50104006); 湖北省自然科学基金资助项目(2000J032); 湖北省教育厅科研项目计划资助项目(2001D67002); 湖北省耐火材料与高温陶瓷重点实验室开放基金资助项目(G0507)

收稿日期: 2005-09-27; 修订日期: 2005-11-18

通讯作者: 熊惟皓, 教授; 电话: 027-87556247; E-mail: whxiong@mail.hust.edu.cn

(编辑陈爱华)