DOI:10.19476/j.ysxb.1004.0609.2017.06.010

TiAl基合金热轧板材的各向异性

陈永辉1,肖泽一2,李慧中1, 2, 3,梁霄鹏1, 3,范爱一1,齐叶龙1,刘 咏3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 冶金与环境学院,长沙 410083;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:利用光学显微镜(OM)、扫描电子显微镜(SEM)、X射线衍射仪(XRD)和拉伸力学试验等方法对铸锭冶金Ti-45Al-7Nb-0.3W合金热轧板材力学性能的各向异性进行研究。结果表明:Ti-45Al-7Nb-0.3W合金热轧板材具有明显的力学性能各向异性,在室温条件下,沿轧制方向的屈服强度σRD为445 MPa,高于沿横向的屈服强度σTD;在800 ℃条件下,σRD为522 MPa,低于σTD。织构和显微组织表明:经热轧变形后,板材中存在明显{100}<010>立方织构,即面心四方γ晶胞的c轴平行于横向;在轧制纵截面上,板材显微组织表现为拉长的γ晶粒和α2/γ层片晶团;在横截面上,板材显微组织表现为等轴的γ晶粒和α2/γ层片晶团。Ti-45Al-7Nb-0.3W合金热轧板材力学性能的各向异性是由织构和显微组织的差异所致。

关键词:TiAl基合金;各向异性;织构;显微组织

文章编号:1004-0609(2017)-06-1148-07 中图分类号:TG146.2 文献标志码:A

TiAl基合金具有密度低、比强度和比刚度高、高温抗氧化及抗蠕变性能优异等优点,是航空航天、汽车工业等领域的优秀候选高温结构材料[1-3]。TiAl基合金板材不仅可以直接作为结构件使用,而且可以通过超塑性成形和近净成形制备航空航天发动机的零部件,或先进飞行器的蒙皮和壳体等[4-6]。因此,通过轧制加工工艺获得综合性能良好的TiAl合金板材是其最终实现工程化应用的关键。众所周知,合金的力学性能不仅取决于显微组织,而且还依赖于热加工过程中产生的织构[7]。而TiAl基合金在挤压、锻造和轧制过程中形成的织构会对TiAl基合金的力学性能造成影响[8]。在TiAl基合金变形过程中,常见的变形织构有<110>和<301>丝织构、<302>面织构、{110}<112>黄铜型织构等[9-11]。变形织构在TiAl基合金中扮演着很不同的角色,TiAl基合金板材的力学性能强烈依赖于合金的显微组织和晶体学织构[12-13]。然而,国内外大多数研究主要关注显微组织对TiAl基合金板材力学性能的影响,而忽略织构对TiAl基合金轧制板材的力学性能的影响规律。本文作者从显微组织和织构两方面入手,对铸锭冶金TiAl基合金热轧板材力学性能的各向异性进行研究,探明显微组织和织构对合金力学性能的影响规律。

1 实验

实验材料的名义成分为Ti-45Al-7Nb-0.3W(摩尔分数,%),采用真空非自耗电弧熔炼法制备尺寸为d 60 mm×50 mm的铸锭,然后经预锻后,最终经热包套轧制获得形状良好的TiAl基合金板材。轧制温度为1270 ℃,道次变形量为10%,总变形量为75%。

合金的金相显微组织(OM)观察在4XC-II型显微镜上进行,试样采用电解腐蚀的方法制备。电解腐蚀液为4%(体积分数)氢氟酸+0.15%(摩尔分数)硼酸+蒸馏水,电解腐蚀的电压为18 V,时间为150 s. 观察位置为RD-ND面(即轧制纵截面)和TD-ND面(即横截面)。电子显微观察(SEM)在Sirion200型场发射扫描电镜上进行,观察面与金相一致。力学性能测试在Instron 8032力学拉伸试验机上进行,室温和高温拉伸的速率均为0.5 mm/min,拉伸方向分别为轧向(RD)和横向(TD)。

宏观织构测试在D8 Discover 2500型X射线衍射仪上完成。极图数据采用LaboTex软件进行处理,利用Bunge球函数谐分析与级数展开法获得取向分布函数(ODF),并由ODF得到完整的极图和反极图[14]。由于TiAl基合金的变形主要由γ相承担,故本实验主要对γ相进行织构分析。

2 结果与讨论

2.1 力学性能

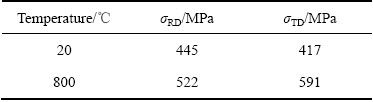

铸锭冶金Ti-45Al-7Nb-0.3W合金热轧板材不同方向的室温和800 ℃的拉伸力学性能如表1所列。从表1可以看出,无论在室温条件下,还是800 ℃条件下,TiAl基合金板材均表现出明显的力学性能各向异性;在室温拉伸时,板材沿轧向的屈服强度σRD为445 MPa,而横向的屈服强度σTD为417 MPa;在800 ℃拉伸时,板材的轧向屈服强度σRD为522MPa,低于横向屈服强度591 MPa。同时,无论在轧向还是横向,TiAl基合金板材的高温屈服强度均高于其室温屈服强度,出现了反常屈服的现象。

反常屈服行为最早在Ni3Al中发现,这种反常屈服机制与{111}<101>滑移系相关[15]。目前普遍认为金属间化合物的反常屈服行为是位错、超位错运动和热激活机制的共同作用的结果。TiAl合金在较低温度下变形时,超位错发生交滑移,并在滑移面之间形成不可动的非平面位错核心结构,同时对位错进行钉扎[16-17]。在较高温度下变形时,部分超位错因位错锁而停止滑移,普通位错在热激活条件下产生交滑移,也形成许多非平面位错结构,进一步对位错产生钉扎[16-17]。交滑移是典型的热激活过程,随着温度升高,非平面位错增多,对位错钉扎也越强。因此,在宏观上表现为合金的屈服强度随拉伸温度的升高而提高。

表1 TiAl合金热轧板材室温和高温力学性能

Table 1 Mechanical properties of TiAl alloy rolling sheet at room and high temperature

2.2 显微组织

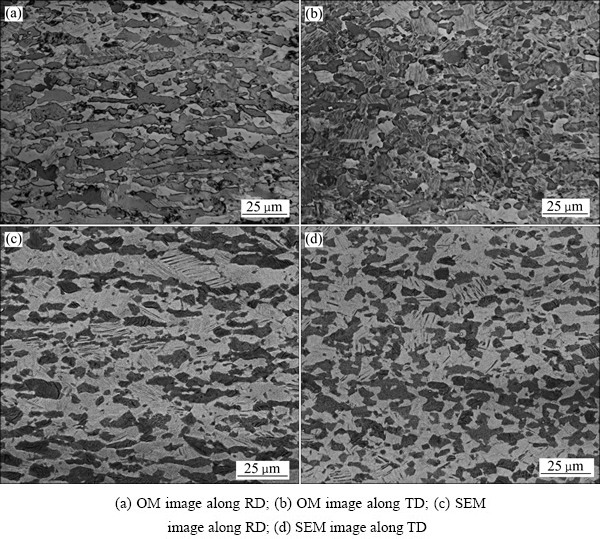

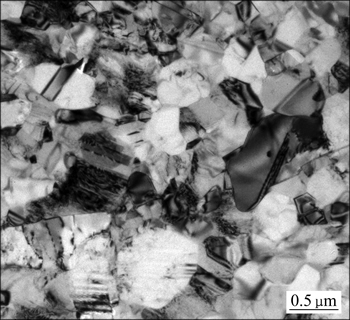

铸锭冶金Ti-45Al-7Nb-0.3W合金轧制板材的显微组织如图1所示。图1(a)和1(b)所示分别为板材RD-ND面和TD-ND面的金相显微组织,图1(c)和1(d)所示分别为其对应的SEM显微组织。由图1可见,热包套轧制后TiAl基合金板材组织为双态组织,主要由γ相和α2/γ层片组成。在RD-ND面(即轧制纵截面)上,板材组织中的γ晶粒和α2/γ层片晶团沿轧制方向明显被拉长,呈现流线型组织特征;在TD-ND面(即横截面)上,板材组织表现为等轴状的γ晶粒和α2/γ层片晶团。可见,经包套热轧的TiAl基合金板材不同方向的组织特征存在明显差异,这种显微组织的差异是导致该合金板材力学性能各向异性的原因之一;在通常情况下,由于平行于轧制方向上的变形量大,加工硬化的程度高,变形抗力大,而垂直于轧制方向的变形量较小,变形抗力小,因此具有流线型组织特征的板材沿轧向的屈服强度高于横向的屈服强度。在室温拉伸条件下,这样的显微组织分析与力学性能测试的结果相符,但高温条件下则存在差异。

图1 Ti-45Al-7Nb-0.3W合金热轧板材的显微组织

Fig. 1 Microstructures of Ti-45Al-7Nb-0.3W alloy hot-rolling sheet

2.3 织构

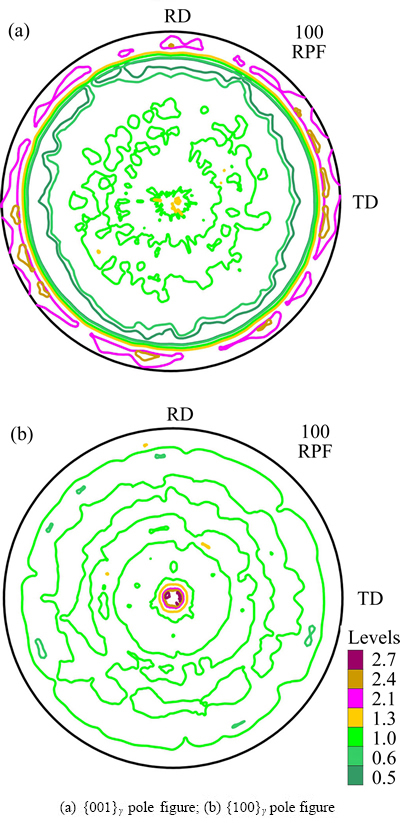

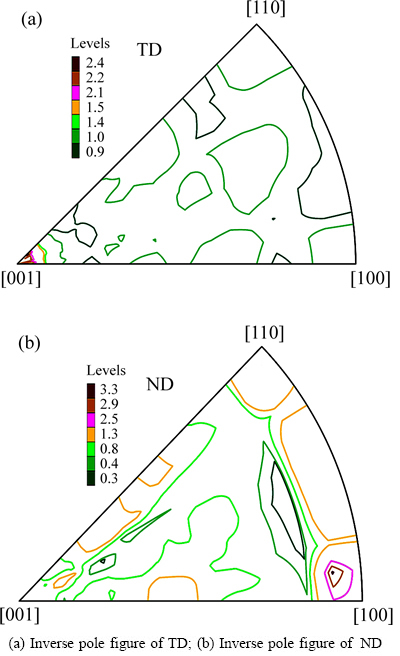

铸锭冶金Ti-45Al-7Nb-0.3W合金热轧板材的{001}γ极图和{100}γ极图如图2所示。由极图结果可知,Ti-45Al-7Nb-0.3W合金在热包套轧制后产生了较强的{100}<010>立方织构,即面心四方γ晶胞的c轴平行于轧制TD方向(见图3);图4所示为该TiAl 基合金板材横向(TD)反极图和法向(ND)反极图,由反极图可以很直观地看出,板材中存在较明显的轧制立方织构{100}<010>,其中图4(a)的TD反极图直观地证实了面心四方γ晶胞的c轴择优于TD方向;图5所示为该TiAl基合金轧制板材在φ2=90°的ODF截面图。从图5可知,在重要取向位置的欧拉角分别为{0°,90°,90°}和{180°,90°,90°},其对应的密勒指数分别为{100} 和{100}<010>,ODF图同样表明TiAl基合金轧制板材中存在较强的立方织构。这种热轧过程中产生的立方织构会造成Ti-45Al-7Nb-0.3W合金板材力学性能各向异性。

和{100}<010>,ODF图同样表明TiAl基合金轧制板材中存在较强的立方织构。这种热轧过程中产生的立方织构会造成Ti-45Al-7Nb-0.3W合金板材力学性能各向异性。

图2 Ti-45Al-7Nb-0.3W合金轧制板材{001}γ极图和{100}γ极图

Fig. 2 Recalculated {001}γ and {100}γ pole figures of Ti-45Al-7Nb-0.3W alloy rolling sheet

图3 具有立方织构的TiAl基合金板材中面心四方γ晶胞及其滑移系示意图

Fig. 3 Schematic diagram of tetragonal γ-TiAl unit cell and its slip systems in textured TiAl alloy sheet

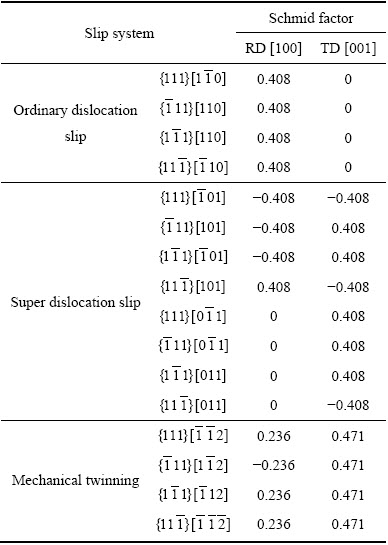

从微观变形机制的角度讲,晶体学织构对TiAl 基合金力学性能的影响,主要通过不同取向的γ相晶粒拥有不同的施密特因子(Schmid因子)而影响TiAl基合金变形过程中滑移系的启动来实现,Schmid因子越大,该取向越软,更容易产生滑移,也就是说TiAl基合金板材拉伸变形中产生的各向异性由Schmid因子在不同拉伸方向上的大小决定。在大多数情况下,γ-TiAl基合金的变形主要通过普通位错滑移矢量b=1/2<110]、超位错矢量b=1/2<101] 以及孪生1/6{111} 来完成[18-20]。在Ti-45Al-7Nb-0.3W合金板材中,由于变形织构的存在,面心四方γ晶胞的c轴即[001]平行于板材TD方向,a轴平行于板材RD和ND方向。这种织构化的γ晶粒滑移系示意图如图3所示。不同拉伸方向上滑移系和孪生对应的Schmid因子值如表2所示。由表2可知,当板材在RD方向加载时,普通位错滑移系的Schmid因子大于孪生的Schmid因子,而超位错Schmid因子可能为0;而且,相比普通位错滑移和机械孪生而言,超位错变形更难发生[20],因此,合金在RD方向拉伸发生屈服时,只有普通位错滑移<110]可以被启动;而在TD方向加载时,普通位错滑移系的Schmid因子为0,孪生Schmid因子虽然较高,但为了不改变γ相有序的L10结构,由于孪生具有单向性,其反方向不能发生孪生,故在[001]方向拉伸时,孪生不可能发生[18-19],而滑移没有极性,其反方向也可以开动,因此,合金在TD方向拉伸发生屈服时,只有超位错滑移<101]可以开动。从表1可知,室温下轧向的屈服强度σRD大于横向的屈服强度σTD,因此可以推断室温下普通位错滑移<110]的临界分切应力CRSS高于超位错<101]的CRSS;而高温800 ℃下轧向的屈服强度σRD低于横向的屈服强度σTD,与室温相反,即高温下超位错<101]的临界分切应力CRSS高于普通位错滑移系的CRSS。可见,晶体学织构对TiAl基合金板材变形过程中滑移系的启动具有很大的影响,这也是造成Ti-45Al-7Nb-0.3W 合金热轧板材室温和高温力学性能各向异性的主要原因。

来完成[18-20]。在Ti-45Al-7Nb-0.3W合金板材中,由于变形织构的存在,面心四方γ晶胞的c轴即[001]平行于板材TD方向,a轴平行于板材RD和ND方向。这种织构化的γ晶粒滑移系示意图如图3所示。不同拉伸方向上滑移系和孪生对应的Schmid因子值如表2所示。由表2可知,当板材在RD方向加载时,普通位错滑移系的Schmid因子大于孪生的Schmid因子,而超位错Schmid因子可能为0;而且,相比普通位错滑移和机械孪生而言,超位错变形更难发生[20],因此,合金在RD方向拉伸发生屈服时,只有普通位错滑移<110]可以被启动;而在TD方向加载时,普通位错滑移系的Schmid因子为0,孪生Schmid因子虽然较高,但为了不改变γ相有序的L10结构,由于孪生具有单向性,其反方向不能发生孪生,故在[001]方向拉伸时,孪生不可能发生[18-19],而滑移没有极性,其反方向也可以开动,因此,合金在TD方向拉伸发生屈服时,只有超位错滑移<101]可以开动。从表1可知,室温下轧向的屈服强度σRD大于横向的屈服强度σTD,因此可以推断室温下普通位错滑移<110]的临界分切应力CRSS高于超位错<101]的CRSS;而高温800 ℃下轧向的屈服强度σRD低于横向的屈服强度σTD,与室温相反,即高温下超位错<101]的临界分切应力CRSS高于普通位错滑移系的CRSS。可见,晶体学织构对TiAl基合金板材变形过程中滑移系的启动具有很大的影响,这也是造成Ti-45Al-7Nb-0.3W 合金热轧板材室温和高温力学性能各向异性的主要原因。

图4 Ti-45Al-7Nb-0.3W合金热轧板材TD反极图和ND反极图

Fig. 4 Inverse pole figures of transverse direction(TD) and normal direction(ND) of Ti-45Al-7Nb-0.3W alloy hot-rolling sheet

图5 Ti-45Al-7Nb-0.3W合金热轧板材中γ相φ2=90° ODF截面图

Fig. 5 φ2=90° section of ODFs of γ phase in Ti-45Al-7Nb- 0.3W alloy hot-rolling sheet

表2 不同拉伸取向上滑移系和孪生对应的Schmid因子

Table 2 Schmid factors of different slip systems and twinning at different tensile orientations

2.4 织构的形成机制

在通常情况下,合金在热塑性变形过程中会产生变形织构和再结晶织构。Ti-45Al-7Nb-0.3W 合金热轧板材中的立方织构{100}<010>属于再结晶织构,该再结晶织构是在轧制时道次间保温过程中产生。图6所示为该合金板材的TEM像,可以发现合金板材中存在许多细小的晶粒,这也说明合金在热轧过程中发生了再结晶。TiAl合金热轧板材中的这种再结晶织构已经得到许多研究学者的证实[10-11]。再结晶织构的形成机制主要有两种:定向形核和定向生长机制[21]。但由于再结晶织构的产生受许多因素的影响,如原始晶粒大小、合金固有的晶体结构、加工和退火温度、变形程度以及合金元素等,因此再结晶织构的形成机制具有多样性和复杂性。目前,大多数人认为再结晶织构的形成是定向形核和定向生长两种机制共同作用的结果。

图6 Ti-45Al-7Nb-0.3W合金板材的TEM像

Fig. 6 TEM image of Ti-45Al-7Nb-0.3W alloy hot-rolling sheet

在TiAl合金塑性变形过程中,变形织构是晶粒在外力作用下发生转动和定向流动所致。在拉应力条件下,滑移方向逐渐转到拉伸方向,形成丝织构;在单向压缩条件下,滑移面逐渐转到与压缩轴垂直的方向,形成面织构;在轧制变形条件下,轧向受到拉应力作用,法向受到压应力作用,因此晶体的滑移方向趋向于轧向,滑移面趋向于平行于轧面,从而形成板织构[21-22]。此外,机械孪生也能改变晶粒的取向并导致变形织构的产生。由图4(b)中的法向(ND)反极图可知,Ti-45Al-7Nb-0.3W 合金板材中存在较弱的<111>基面织构,这是晶体滑移和转动所产生的。HARTING等[23]在400 ℃条件下对Ti-50Al合金热压缩织构的研究表明,当压缩量为46%时,合金中存在两个平行于压缩轴的<110]和<101>丝织构;采用Taylor模型对压缩织构的演变进行模拟后,发现普通位错和超位错滑移是该合金变形织构产生的主要原因。由此可见,变形织构(如丝织构和面织构)主要受变形机制的影响,而滑移和孪生主要受变形温度、变形程度、变形速率等工艺参数以及晶体结构和合金元素等内部因素的综合影响。

3 结论

1) 铸锭冶金Ti-45Al-7Nb-0.3W合金板材力学性能呈现显著的各向异性,在室温条件下,板材轧向的屈服强度高于横向屈服强度,在高温800 ℃下,板材横向屈服强度高于轧向屈服强。

2) 铸锭冶金Ti-45Al-7Nb-0.3W 合金包套热轧后,板材显微组织为双态组织,在轧制纵截面上表现为明显被拉长的γ晶粒和和α2/γ层片晶团,在横截面上表现为等轴状的γ晶粒和α2/γ层片晶团;显微组织特征的不同是造成板材力学性能各向异性的原因之一。

3) 包套热轧后的Ti-45Al-7Nb-0.3W合金板材中存在较强的{100}<010>立方织构,该织构是板材道次间保温过程中再结晶所产生的;织构对TiAl基合金板材变形过程中滑移系启动的影响,是引起Ti-45Al-7Nb-0.3W 合金轧制板材室温和高温力学性能各向异性的主要原因。

REFERENCES

[1] WANG Yan, LIU Yong, YANG Guang-yu, LI Hui-zhong, TANG Bei. Microstructure of cast γ-TiAl based alloy solidified from β phase region[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 215-222.

[2] 陈玉勇, 韩建超, 肖树龙, 徐丽娟, 田 竟. 稀土Y在γ-TiAl 基合金及其精密热成形中应用的研究进展[J]. 中国有色金属学报, 2014, 24(5): 1241-1250.

CHEN Yu-yong, HAN Jian-chao, XIAO Shu-long, XU Li-juan, TIAN Jing. Research progress of rare earth yttrium application in γ-TiAl based alloy and precision thermal forming[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1241-1250.

[3] 朱冬冬, 董 多, 倪成员, 周兆忠, 张德丰, 魏尊杰. 热处理对高压凝固Ti-48Al合金组织演变的影响[J]. 中国有色金属学报, 2015, 25(1): 58-62.

ZHU Dong-dong, DONG Duo, NI Cheng-yuan, ZHOU Zhao-zhong, ZHANG De-feng, WEI Zun-jie. Effect of heat treatment on microstructure evolution of Ti-48Al alloy solidified under high pressure[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 58-62.

[4] 王 刚, 徐 磊, 崔玉友, 杨 锐. Ti-47Al-2Cr-2Nb-0.2W- 0.15B合金板材的制备及其拉伸性能[J]. 中国有色金属学报, 2010, 20(S1): s274-s276.

WANG Gang, XU Lei, CUI Yu-you, YANG Rui. Fabrication and tensile property of Ti-47Al-2Cr-2Nb-0.2W-0.15B alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s274-s276.

[5] 罗媛媛, 毛小南, 奚正平, 杨英丽, 吴金平, 苏航标. 新型γ-TiAl基合金在高温变形过程中的组织演变[J]. 中国有色金属学报, 2014, 24(2): 403-408.

LUO Yuan-yuan, MAO Xiao-nan, XI Zhen-ping, YANG Ying-li, WU Jin-ping, SU Hang-biao. Microstructure evolution of new γ-TiAl alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 403-408.

[6] 赵 堃, 刘 咏, 黄 岚, 刘 彬, 李建波, 梁霄鹏, 贺跃辉. 热变形粉末冶金Ti-45Al-7Nb-0.3W合金热处理过程的组织演变[J]. 中国有色金属学报, 2014, 24(10): 2506-2512.

ZHAO Kun, LIU Yong, HUANG Lan, LIU Bin, LI Jian-bo, LIANG Xiao-peng, HE Yue-hui. Microstructure evolution of hot-deformed powder metallurgy Ti-45Al-7Nb-0.3W alloy during heat treatment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2506-2512.

[7] 李成铭, 李 萍, 赵 蒙, 甘国强, 薛克敏. TA15钛合金的热变形微观组织与织构[J]. 中国有色金属学报, 2014, 24(1): 91-96.

LI Cheng-ming, LI Ping, ZHAO Meng, GAN Guo-qiang, XUE Ke-min. Microstructures and textures of TA15 titanium alloy after hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 91-96.

[8] SCHILLINGER W, LORENZEN B, BARTELS A. Anisotropic mechanical behavior of textured γ-TiAl caused by the direction of twinning[J]. Materials Science and Engineering A, 2002, 329/331: 644-648.

[9] ZHANG Shu-zhi, KONG Fan-tao, CHEN Yu-yong, LIU Zu-yan, LIN Jun-pin. Evolution of grain boundary and texture in as-forged Ti-45Al-9Nb-Y alloy during tensile test at different temperature[J]. Intermetallics, 2012, 27: 31-37.

[10] BYSTRZANOWSKI S, BARTELS A, STARK A, GERLING R, SCHIMANSKY F P, CLEMENS H. Evolution of microstructure and texture in Ti-46Al-9Nb sheet material during tensile flow at elevated temperature[J]. Intermetallics, 2010, 18(5): 1046-1055.

[11] 王 兴, 林均品, 张来启, 王艳丽, 陈国良. 高铌TiAl基合金板材制备包套热轧工艺及组织控制[J]. 稀有金属, 2010, 34(5): 658-662.

WANG Xing, LIN Jun-ping, ZHANG Lai-qi, WANG Yan-li, CHEN Guo-liang. Hot packed-rolling process of high-Nb TiAl alloy and its microstructure evolution[J]. Chinese Journal of Rare Metals, 2010, 34(5): 658-662.

[12] KIM Y W. Microstructure evolution and mechanical properties of a forged gamma titanium aluminide alloy[J]. Acta Metallurgica Materialia, 1992, 40(6): 1121-1134.

[13] TAKEYAMA M. Microstructure evolution and tensile properties of titanium-rich TiAl alloy[J]. Materials Science and Engineering A, 1992, 152(1/2): 269-276.

[14] BUNGE H J. Texture analysis in materials science mathematical methods[M]. London: Butterworths, 1982: 47.

[15] 李 影, 苏 彬. 镍基单晶高温合金的反常屈服行为与变形机制[J]. 材料工程, 2004(3): 45-48.

LI Ying, SU Bin. Abnormal yield behavior and deformation mechanism of nickel base single crystal superalloy[J]. Materials Engineering, 2004(3): 45-48.

[16] 杨 非, 陈玉勇, 孔凡涛, 肖树龙, 徐丽娟. 包套锻造对Ti-45Al-5.4V-3.6Nb-0.3Y合金组织和性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s315-s319.

YANG Fei, CHEN Yu-yong, KONG Fan-tao, XIAO Shu-long, XU Li-juan. Effect of canned-forging on microstructure and properties of Ti-45Al-5.4V-3.6Nb-0.3Y alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s315-s319.

[17] 彭超群, 黄伯云, 贺跃辉. TiAl基合金的工艺-显微组织-力学性能关系[J]. 中国有色金属学报, 2001, 11(4): 527-540.

PENG Chao-qun, HUANG Bai-yun, HE Yue-hui. Relationships among technologies, microstructures and mechanical properties of TiAl-based alloys[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 527-540.

[18] 卢 山, 李子然, 昝 祥. 晶界对近片层TiAl高温动态力学行为的数值模拟[J]. 中国有色金属学报, 2012, 22(2): 379-387.

LU Shan, LI Zi-ran, ZAN Xiang. Numerical simulation of dynamic mechanical behavior of near lamellar TiAl at elevated temperature with influence of grain boundary[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 379-387.

[19] 陆永浩, 张永刚, 乔利杰, 王燕斌, 褚武扬. γ-TiAl片层界面在裂纹形核中的双重作用[J]. 中国有色金属学报, 2000, 10(6): 774-778.

LU Yong-hao, ZHANG Yong-gang, QIAO Li-jie, WANG Yan-bing, CHU Wu-yang. Twofold effects of lamellar interface on crack nucleation in fully lamellar TiAl based alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 774-778.

[20] RESTER M, FISCHER F D, KIRCHLECHNER C, SCHMOELZER T, CLEMENS H, DEHM G. Deformation mechanism in micron-sized PST TiAl compression samples: Experiment and model[J]. Acta Materialia, 2011, 59(9): 3410-3421.

[21] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[22] 毛卫民. 金属材料的晶体学织构与各向异性[M]. 北京: 科学出版社, 2002: 28-63.

MAO Wei-min. Crystallograthic texture and anisotropy of metal materials[M]. Beijing: Science Press, 2002: 28-63.

[23] HARTING C, FANG X F, MECKING H, DAHMS M. Textures and plastic anisotropy in γ-TiAl[J]. Acta Metallurgica Materialia, 1992, 40(8): 1883-1894.

Anisotropy of TiAl alloy hot-rolling sheet

CHEN Yong-hui1, XIAO Ze-yi2, LI Hui-zhong1, 2, 3, LIANG Xiao-peng1, 3, FAN Ai-yi1, QI Ye-long1, LIU Yong3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The anisotropy of mechanical properties of ingot metallurgical Ti-45Al-7Nb-0.3W alloy hot-rolling sheet was investigated by optical microscopy(OM), scanning electron microscopy(SEM), X-ray diffractometry and tensile test. The results indicate that the hot-rolling sheet presents significant anisotropy of mechanical properties, at room temperature, the yield strength of rolling direction(RD) is 445 MPa, which is higher than that of the transverse direction(TD); while at 800 ℃, the yield strength of rolling direction(RD) is 522 MPa, which is lower than that of the transverse direction(TD). The texture and microstructure analysis results indicate that there exists a strong cube texture {100}<010> in the rolling sheet, i.e., the <001> c-axes of the tetragonal γ-TiAl unit cells parallel to the TD. And along the rolling direction the microstructure of TiAl alloy hot-rolling sheet are composed of elongated γ grains and α2/γ lamellar colonies, while along the transverse direction the microstructure is composed of elongated γ grains and α2/γ lamellar colonies. The existing texture and difference of microstructure result in the mechanical anisotropy of Ti-45Al-7Nb-0.3W alloy hot-rolling sheet.

Key words: TiAl alloy; anisotropy; texture; microstructure

Foundation item: Projects(51174233) supported by the National Natural Science Foundation of China; Projects (2011CB605505) supported by the National Key Basic Research Program of China

Received date: 2016-04-12; Accepted date: 2016-08-30

Corresponding author: LI Hui-zhong; Tel: +86-731-88830377; E-mail: lhz606@csu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51174233);国家重点基础研究发展计划资助项目(2011CB605505)

收稿日期:2016-04-12;修订日期:2016-08-30

通信作者:李慧中,教授,博士;电话:0731-88830377;E-mail : lhz606@csu.edu.cn