文章编号:1004-0609(2013)S1-s0387-04

原位热压合成Eu2O3掺杂Al2O3/TiAl复合材料

王晓凤1,王 芬2,王兰芳1,朱忠忍1,杨 勇1,王淑塬1,田伟华1

(1. 宝钛集团有限公司,宝鸡 721014;

2. 陕西科技大学 材料科学与工程学院,西安 710021)

摘 要:以Ti、Al、TiO2和Eu2O3为起始原料,原位热压合成Eu2O3掺杂Al2O3/TiAl复合材料。通过DSC、XRD及SEM分析,研究Eu引入对合成Al2O3/TiAl复合材料的微观结构和力学性能的影响。结果表明:体系在较低温度下烧结,其反应温度在900 ℃前后,复合材料主要由γ-TiAl、α2-Ti3Al、Al2O3和EuAlO3组成;含Eu相和Al2O3颗粒主要分布在基体相晶界处,Eu2O3的引入使基体及增强颗粒的晶粒细化,晶粒分布更均匀;当Eu2O3添加量为0.01 mol时,复合材料的弯曲强度和断裂韧性最大,其值分别为439 MPa和9.13 MPa·m1/2。

关键词:TiAl合金;Eu2O3掺杂;复合材料;显微组织;力学性能

中图分类号:TG146.4 文献标志码:A

Synthesis of Al2O3/TiAl composites doped with Eu2O3 by in-situ hot-pressing processes

WANG Xiao-feng1, WANG Fen2, WANG Lan-fang1, ZHU Zhong-ren1, YANG Yong1, WANG Shu-yuan1, TIAN Wei-hua1

(1. Bao Ti Group Co., Ltd., Baoji 721014, China;

2. School of Materials Science and Engineering, Shaanxi University of Science & Technology, Xi’an 710021, China)

Abstract: Al2O3/TiAl composites were synthesized from the powder mixture of Ti, Al, TiO2, and Eu2O3, using the hot pressing reaction synthesis technique. The effect of the Eu2O3 doping on microstructures and mechanical properties of the Al2O3/TiAl composites was analyzed by thermal analysis (DSC), X-ray diffractometry (XRD), scanning electron microscopy (SEM). The results show that the reaction temperature of start materials is about 900 ℃. The phases of composites consist of γ-TiAl, α2-Ti3Al, Al2O3 and EuAlO3. The Eu containing phases and Al2O3 particles distribute at grain boundary of the matrix. The grains of the composites are remarkably refined and the distribution of Al2O3 particles are more uniform and dispersed;When the Eu2O3 content is 0.01 mol, the flexural strength and fracture toughness reach the maximum values of 439 MPa and 9.13 MPa·m1/2, respectively.

Key words: TiAl alloy; Eu2O3 doping; composites; microstructure; mechanical properties

TiAl金属间化合物具有轻质、耐磨及耐高温等优良性能,使用温度可达到700~1 000 ℃,在航空航天高温结构材料领域具有广阔的应用前景[1-4]。但室温 塑性低,加工难度大的缺点限制了TiAl金属间化合物的应用。向基体材料中引入第二增强相(如Al2O3和TiC等)是一种提高材料力学性能的方法[5]。稀土元素属表面活性类物质,容易在晶界和相界面上吸附偏 聚,减少晶核与液体间的接触面积,填补界面上的缺陷,阻碍晶粒生长,增大形核率,细化晶粒,强化基体等[6]。在TiAl合金内添加稀土元素,容易形成细小、弥散分布的金属间化合物相,其具有良好的热稳定性,对TiAl合金晶粒的细化效果明显,对晶界和晶粒有强化作用。

本文作者采用工艺程序简单的原位反应热压技术,以Ti-Al-TiO2为基础系统,以Eu2O3为添加剂,利用体系的铝热反应过程,在较低温度下合成了Al2O3/TiAl复合材料。

1 实验

实验采用Ti粉(粒度<56 μm,纯度>99%),Al粉(粒度<74 μm,纯度>99%),TiO2(粒度<0.5 μm,纯度>99%)和Eu2O3(粒度<30 μm,纯度>99%)为原料。配料组成见表1。

表1 复合材料的配料组成

Table 1 Components of tested composites

不同配合料分别以乙醇为保护介质,采用湿法混料。球磨过程的各项参数分别如下:粉料、氧化铝球石和无水乙醇的质量比为1:3:1,球磨机的转速为800 r/min,球磨时间为1 h。球磨后的粉料进行干燥,过筛(筛孔直径为75 μm)后,装入密封袋备用。将混合粉料装入内径为12 mm的高强钢磨具中,并在20 MPa的压力下预压。将所压制的圆片装入模型内,周围用Al2O3包裹,将石磨纸作为隔垫物,压实,然后一并放入ZT(Y)系列真空热压碳管炉中进行热压烧结。将烧结所得的试样在磨盘上打磨除去表面层,以备物理性能及其他性能测试使用。为了制备符合力学性能测试标准的样品,选用孔径为30 mm的石墨模型,称取15 g混合粉料装入其中。装完后将石墨模型置入真空热压碳管炉内,采用真空热压烧结。烧结温度达到1 250 ℃,压力调节至25 MPa,然后在此压力和温度条件下保温2 h后随炉自然冷却。合成的试样打磨去除表面层,以备性能测试用。

采用CRY-2P型差热分析系统,根据差热分析结果推断材料制备过程的反应机理和过程。

以日本理学D/max 2200PC型X射线衍射仪测定烧成产物的物相组成。工作参数为Cu Kα、40 kV、40 mA,扫描速度为8 (°)/min。采用PHENOM扫描电镜观察材料的断口形貌。以JED2200 Series能谱仪进行点扫描分析。烧成后的试样经切割、磨抛后,采用HRD-150维氏硬度仪测量材料的维氏硬度,所用载荷为9.8 N,加载时间为15 s,每个硬度值为5点平均值。采用PT-1036PC万能材料试验机进行材料的抗弯强度测试,试样尺寸为25 mm×4 mm×3 mm,测试跨距为20 mm, 加载速度为5 mm/min。采用单边刃口法(SENB)测定其表观断裂韧性,3点弯曲标准试样的尺寸为b×w×l=3 mm×6 mm×30 mm,利用DK7725A-5型电火花数控线切割机切一深度a=0.45 w (mm)、宽度为0.12 mm的切口,测试的跨距S=30 mm,压头移动速度为0.06 mm/min。

2 结果与讨论

2.1 球磨粉体的差热分析

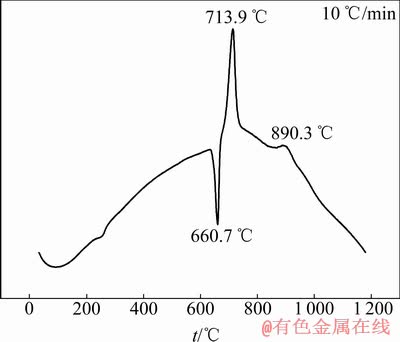

通过DSC分析对球磨后的粉体进行了差热分析。图1所示为反应体系球磨粉体的热分析结果。从图1中可以看出,掺杂Eu2O3的复合粉体在高温下有明显的吸放热现象(本曲线中吸热峰为下)。

图1 反应体系的DSC曲线

Fig. 1 DSC pattern of reaction system

从图1中可以看出,在400~1 200 ℃的范围内有一个吸热峰,对应温度为660.7 ℃左右,在710 ℃和890 ℃之间均有两个放热峰,随着温度继续升高,未发现有明显的吸放热现象,表明系统的反应温度在900 ℃前后,该体系材料能够在较低温度下达到致密化烧结,减少了基体的烧损。从XRD测试可以看出,产物物相由主晶相TiAl和Ti3Al、Al2O3相和少量含稀土相组成,尚未发现单质Al、Ti、过剩TiO2、中间相TiAl3、REO以及RE等物相,说明反应进行得比较彻底[7]。

2.2 复合材料的物相组成

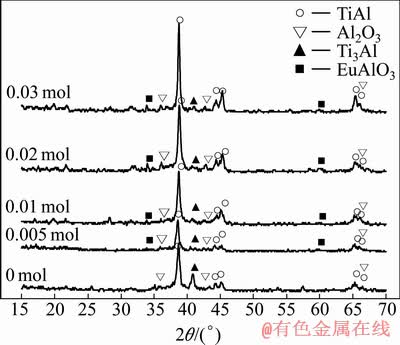

图2所示为掺杂不同量Eu2O3的粉体经1 250 ℃烧结保温2 h试样的XRD谱。

图2 不同Eu2O3掺杂量烧结试样的XRD谱

Fig. 2 XRD patterns of composites with various Eu2O3 contents

从图2中可以看出:Ti-Al-TiO2系统和掺Eu系统的主晶相均由TiAl、Ti3Al和Al2O3相组成,掺Eu系统中还生成了EuAlO第二增强相。第二增强相的衍射峰强度与Eu2O3的添加量呈正比关系。

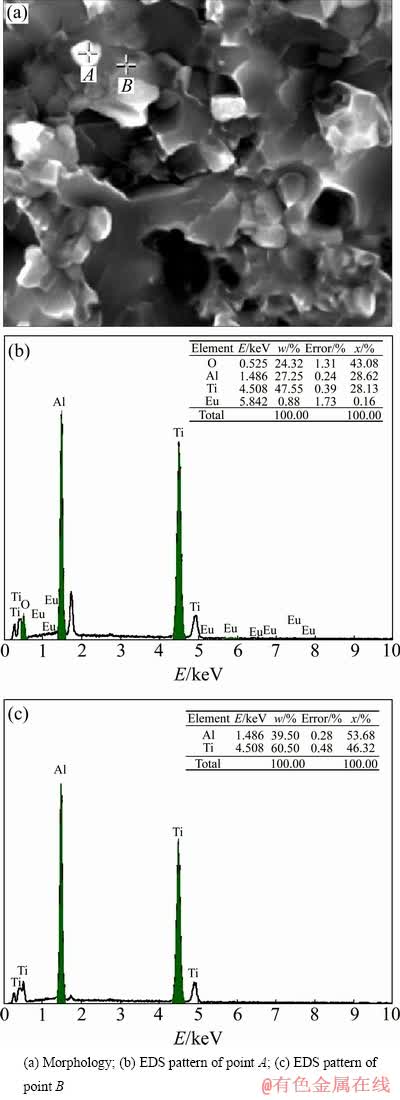

2.3 复合材料的显微结构

图3所示为含Eu体系的断口形貌和EDS分析图谱。从图3中可以看出,材料主要由暗色的TiAl基体部分和亮色的增强相部分组成,亮色增强相分基体布在晶界处,起到阻碍基体长大、细化晶粒的作用[8]。

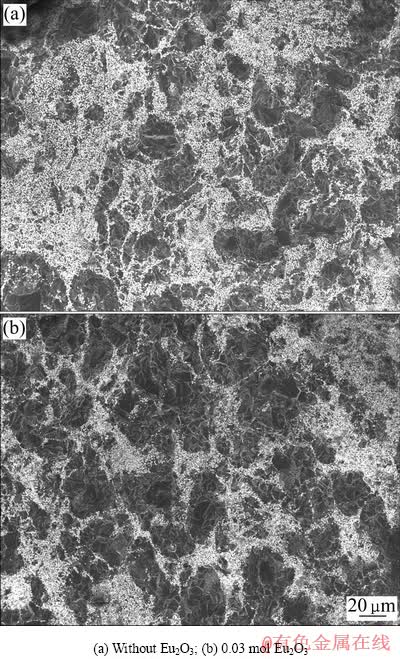

图4(a)和(b)所示分别为基础系统和掺杂0.03 mol Eu2O3试样经1 250 ℃烧结保温2 h的断口微观形貌。

可以发现,材料的断口主要由黑色基体和白色增强体部分组成,图4(a)中,白色增强体团聚比较明显,存在较大的黑色基体区域;图4(b)中反应物Eu2O3的引入使复合材料增强相粒子的分布情况也发生了变化,变成了弥散型分布。材料中生成的增强相承现连续、均匀的空间网络结构,网络结构之间包裹着的基体晶粒也变小,大大减弱了晶粒的团聚现象[5]。且断口表面高低不平,说明断裂时路径曲折,需要消耗更多的断裂能[9-10]。

图3 复合材料形貌和EDS谱

Fig. 3 Morphology and EDS patterns of composites

2.4 力学性能分析

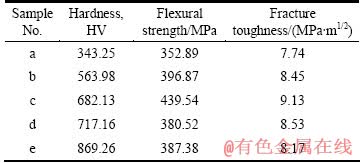

表2列出了复合材料室温力学性能。从表2中可以看出,Eu的引入使复合材料的各项力学性能均得到改善,复合材料的维氏硬度随着Eu含量的增加而增大,掺杂0.01 mol Eu2O3的复合材料的弯曲强度和断裂韧性最大,分别为439.54 MPa和9.13 MPa·m1/2,是未掺杂Eu2O3系统的1.2倍和1.18倍。

图4 不同Eu2O3含量复合材料的断口SEM像

Fig. 4 SEM images of composites with various Eu2O3 contents

表2 复合材料的室温力学性能

Table 2 Mechanical properties of composites at room temperature

3 结论

系统主要反应发生在710~890 ℃之间,表明所有反应均能够较早进行,易于实现低温度致密化烧结,同时也减少了基体的烧损;合成的产物主要由γ-TiAl、α2-Ti3Al、Al2O3和EuAlO3相组成,其中Al2O3和含Eu相分布在基体交界处,起到细化基体的作用;Eu的引入使复合材料中晶粒的团聚现象减弱,掺杂0.01 mol Eu2O3的复合材料的弯曲强度和断裂韧性最大,分别为439.54 MPa和9.13 MPa·m1/2。

REFERENCES

[1] 林均品, 陈国良. TiAl基金属间化合物的发展[J]. 中国材料进展, 2009, 28(1): 31-36.

LIN Jun-pin, CHEN Guo-liang. Development of TiAI intermetallic based compound [J]. Materials China, 2009, 28(1): 31-36.

[2] 陈玉勇, 李宝辉, 孔凡涛. Y(0.3 at%)对Ti-45Al-5Nb合金铸态显微组织的影响[J]. 稀有金属材料与工程, 2006, 35(1): 1-4.

CHEN Yu-yong, LI Bao-hui, KONG Fan-tao. Effect of rare earth Y (0.3 at%) on as-cast microstructure of Ti-45Al-5Nb alloy [J]. Rare Metal Materials and Engineering, 2006, 35(1): 1-3.

[3] TJIONG S C, MA Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites [J]. Materials Science and Engineering, 2000, 29(3/4): 49-113.

[4] WU Xin-hua. Review of alloy and process development of TiAl alloys [J]. Intermetallics, 2006, 14: 1114-1122.

[5] LI Quan-an, LI Ke-jie, JING Xiao-tian, CHEN Jun, ZHANG Xing-yuan. Effects of Sm on microstructure and mechanical properties of AZ61 alloy [J]. Transactions of Material and Heat Treatment, 2010, 31(1): 100-104.

[6] MA Xing-wei, JIN Zhu-ji, YAN Shi. Effect of La2O3 on microstructure and high-temperature wear property of hot-press sintering FeAl intermetallic compound [J]. Journal of Rare Earths, 2009, 27(6): 1031-1036.

[7] 陈艳飞, 陈玉勇, 田 竟, 肖树龙, 徐丽娟. 离心熔模精铸TiAl合金与ZrO2型壳的界面反应[J]. 中国有色金属学报, 2010, 20(1): 193-197.

CHEN Yan-fei, CHEN Yu-yong, TIAN Jing, XIAO Shu-long, XU Li-juan. Interfacial reactions between TiAl alloys and ZrO2 mould under centrifugal investment casting conditions [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 193-197.

[8] YAN Zhi-qiao, CHEN Feng, CAI Yi-xiang, YIN Jian. Influence of particle size on property of Ti-6Al-4V alloy prepared by high-velocity compaction [J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 361-365.

[9] 王 刚, 徐 磊, 崔玉友, 杨 锐. 粉末冶金TiAl基合金高温变形行为及其本构模型[J]. 中国有色金属学报, 2010, 20(1): 269-273.

WANG Gang, XU Lei, CUI Yu-you, YANG Rui. High temperature deformation behavior of powder metallurgy TiAl alloy and its constitutive model [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 269-273.

[10] 曹京霞, 何书林, 石卫民, 王宏武, 王 新. 热处理对Ti3Al基合金板材拉伸性能与微观组织的影响[J]. 中国有色金属学报, 2010, 20(1): 207-210.

CAO Jing-xia, HE Shu-lin, SHI Wei-min, WANG Hong-wu, WANG Xin. Effect of heat treatment on tensile properties andmicrostructures of Ti3Al based alloy sheet [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 207-210.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51171096)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:王晓凤,助理工程师;电话:0917-3382588;E-mail: wang3164153@126.com