钛金属固体法渗硼新技术

贾宝平1,贺跃辉1,汤义武2,刘业翔3

(1.中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

(2.长沙力元新材料股份有限公司,湖南 长沙,410100;

3.中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘要: 对传统固体粉末法渗硼工艺进行改进,用B4C和无水Na2B4O7代替非晶态硼作为供硼剂,制备出以TiB2为主要成分的表面渗层,并研究了原料成分和反应条件对渗层相结构及厚度的影响。研究结果表明:渗硼剂配料中Na2B4O7和B4C的质量分数比对渗层有很大影响,当w(Na2B4O7)∶w(B4C)=2∶6时,渗层厚度和表面清洁程度等综合性能最优;填充剂Al2O3能导致TiB2渗层脱落,且脱落程度随Al2O3含量的增加而加重;渗层厚度随处理时间的平方根呈线性增加;渗硼层厚度与试验温度的关系为d=aT2+bT+c。

关键词: 钛; 硼化钛; 渗硼; 固体粉末法

中图分类号:TG156.87; TG166.5 文献标识码:A 文章编号: 1672-7207(2005)02-0179-04

New Technique of Pack Boronizing of Titanium

JIA Bao-ping1, HE Yue-hui1, TANG Yi-wu2, LIU Ye-xiang1

(1.State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2.Changsha Lyrun New Material Corporation Limited, Changsha 410100, China;

3.School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Using B4C and anhydrous Na2B4O7 instead of amorphous boron as the boron offer, the boride layer of TiB2 was prepared in the pack boronizing method. Effects of powder component and experiment condition on the phase structure and thickness of boride layer were discussed. The results show that the mass ratio of Na2B4O7 to B4C has an obvious effect on the performance of layer. When w(Na2B4O7)∶w(B4C)=2∶6, the integrative performance of boride layer is the best as for as the thickness and cleanliness are concerned. The Al2O3 padding makes the layer desquamate from the matrix. With the heat-treatment time extending,the thickness of layer has linear relation with the square root of time. And the relationship between the thickness and the temperature can be given by d=aT2+bT+c.

Key words: Ti; TiB2; boronizing; pack boronizing method

钛金属具有密度小,比强度高,耐腐蚀性强等优点,被广泛地应用于航空航天以及飞机制造业等领域。钛金属的主要缺点是表面硬度低(HB=200~280)、耐磨性差,这使得钛制零件在使用中容易与对件发生咬合,造成损耗[1]。国内外研究人员对此进行了大量的研究[2-7]。采用钛金属渗硼工艺制得的TiB2表面层不仅硬度高、耐磨性能好,而且还具有电阻率低、导热性好等优异性能[8]。目前,研究钛金属渗硼的主要方法有固体粉末法[9]、熔盐浸渍法[10]和熔盐电解法[11]。新兴的等离子束熔炼渗硼法由于技术要求高、设备复杂且昂贵等[12],没有得到广泛的应用;固体粉末法具有工艺简单、可控度高的优势,但固体粉末法用昂贵的非晶态硼作为供硼剂,使得此法难以推广;熔盐法存在渗硼效果不稳定、影响因素多、产品表面粘结熔盐严重、难清理等缺陷。在此,作者对传统固体粉末法进行改进,用廉价的碳化硼(B4C)和无水硼砂(Na2B4O7)作为供硼剂,对Ti进行表面渗硼处理,制得以TiB2为主要成分的表面渗层,并研究了试验条件对渗层相组成和厚度的影响。

1 试验材料及方法

1.1 试验材料及其预处理

试验用钛材为冷轧板,纯度达99%(西北有色金属研究院提供),试样尺寸(长×宽×厚)为10 mm×10 mm×2 mm。渗硼前先经600号金刚砂纸磨光,再浸入30%HNO3+2%HF(体积分数)的水溶液中腐蚀去除表面氧化膜。用蒸馏水洗净,真空干燥后待用。

以碳化硼(B4C,纯度>99%)和无水硼砂(Na2B4O7,纯度>99%)作供硼剂;KBF4(纯度>97%)作活化剂;SiC作填充剂(纯度>98.5%)。试验前分别将B4C和Na2B4O7在900 ℃真空加热2 h,脱去水分。将各配料按一定比例混合后,研磨搅拌均匀。

1.2 试验方法

将经过预处理的钛块埋入按一定比例混合均匀的粉料中,在150 ℃下真空加热1 h排除水分。通入高纯氩气,分别升温至900 ℃,950 ℃和1000 ℃,保温2~8 h后水冷或空冷至室温。清除试样表面粘结的粉料。用环氧树脂按标准制样过程,制成金相样品。用XJX-1型光学显微镜观察试样渗层的组织结构,用RIGAKU D/MAX-3A型X射线衍射仪(Cu靶,Kα辐射)分析渗层表面成分及物相组成。

2 试验结果及分析

2.1 原料对渗层的影响

2.1.1 Na2B4O7与B4C质量分数比对渗层的影响

试验以KBF4作活化剂;SiC作填充剂,w(Na2B4O7)∶w(B4C)分别为:0∶8,1∶7,2∶6,3∶5。在950 ℃保温6 h渗硼制得的渗层X射线图谱如图1所示。可见,当配料中不含Na2B4O7时,试样表面除极少量TiB2峰外,其余几乎全为Ti峰,其丰度达到90%以上。随着Na2B4O7含量的增加,Ti峰逐渐减少直至消失,而TiB2峰则不断增强;当w(Na2B4O7)∶w(B4C)=3∶5时,TiB2丰度达到80%,Ti丰度为10%。可知,Na2B4O7与B4C的质量分数比对于渗硼反应有重要影响,随着Na2B4O7含量的增大,渗层中TiB2相逐渐增加。

图 1 渗层相成分XRD图

Fig. 1 XRD patterns of boride layer

试样表面熔盐粘结情况如图2所示,可见,当w(Na2B4O7)∶w(B4C)=3∶5时,试样表面粉料粘结严重,较难清除。因此,w(Na2B4O7)∶w(B4C)=2∶6为最优比例。

2.1.2 Al2O3对渗层的影响研究结果表明,Al2O3作为填充剂时,渗层都有不同程度的脱落。其脱落程度随Al2O3含量的增加而加重。这是因为TiB2沉积膜与Al2O3基体会发生反应,影响其性能[7]。因此,SiC比Al2O3更合适作填充料。

图 2 试样表面熔盐粘结结构形貌

Fig. 2 superficial patterns of specimen

2.2 反应条件对渗层的影响

Ti-B系属于典型的间隙型互扩散。其中B原子向Ti基体中的扩散过程是整个反应速度的控制因素。C. FELDMAN等对Ti-B系扩散机理进行了一系列研究[13],并利用扩散机理总结出下列公式:

d=Ct1/2。(1)

其中:d为渗层厚度,μm;t为热处理时间,s;C为反应常数,反应常数C和温度的关系可以用下式表示:

C=eA+BT。(2)

其中:A和B为常数;T为热力学温度,K。

2.2.1 温度对渗层的影响

当w(Na2B4O7)∶w(B4C)=2∶6时,分别在900 ℃,950 ℃和1000 ℃保温6 h后,得到的渗硼层表面的XRD图谱如图3所示。可见,随着反应温度的升高,渗层中逐渐生成TiB2相和TiB相,其X射线衍射强度随温度升高而增强,Ti衍射强度则随之减弱。1000 ℃时,TiB2相丰度达到70%,Ti相丰度为15%。

图 3 不同温度处理时渗层相成分XRD图谱

Fig. 3 XRD patterns of boride layer at different temperatures

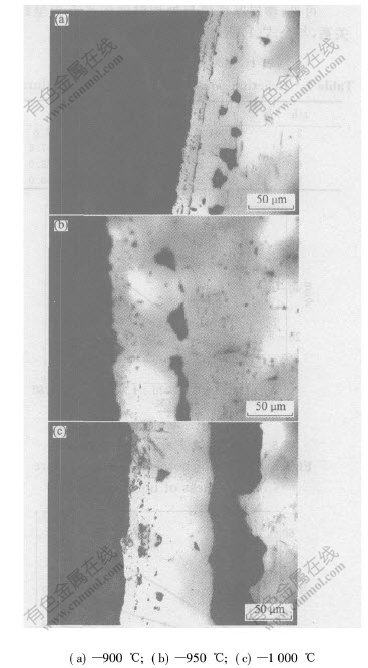

图4所示为900 ℃,950 ℃和1000 ℃时经6 h渗硼试样的截面SEM照片,照片中从左至右依次为:镶样料(黑色部分),渗层部分,钛基体。可以看出,渗层厚度随反应温度的升高而增加。同时,渗层和基体的结合部位有不同程度的孔洞和裂纹生成,其原因是:渗层和基体热膨胀系数不匹配;试验用冷轧钛板中残存的大量内应力在渗层和基体结合处集中并释放,导致产生孔洞或裂纹。孔洞或裂纹对渗层性能有明显的影响。

图 4 不同温度处理后渗硼层截面SEM照片

Fig. 4 Cross-section metallographs of boride layer heat-treated at different temperatures

温度和保温时间对渗层厚度的影响如图5所示。对实验数据进行线性回归,厚度随反应温度变化符合以下公式:

d=aT2+bT+c。

其中:a,b和c为反应常数。可见,渗硼层的厚度与反应温度呈二次函数关系。随着反应时间的延长,反应常数呈规律性变化。不同反应时间对应的反应常数如表1所示。

2.2.2 保温时间对渗层的影响

不同保温时间对渗层厚度的影响如图6所示。可见:随时间的延长,渗层厚度相应增加。在900 ℃,950 ℃和1000 ℃保温8 h,渗层厚度分别达到17 μm,32 μm和68 μm。将实验数据进行线性回归,得到方程:

d=e-15.34+0.0144Tt1/2。

可见,渗层厚度值与处理时间的平方根呈线性关系,与公式(1)所表示的变化关系相符。

表 1 不同反应时间下的反应常数

Table 1 Reaction constants under different duration

图 5 热力学温度T对渗层厚度d的影响

Fig. 5 Effect of boronizing temperature on thickness of boride layer

图 6 保温时间对渗硼层厚度的影响

Fig. 6 Effect of heat-treated time on thickness of boride layer

3 结 论

a. 对传统固体粉末法渗硼工艺进行改进,用B4C和无水Na2B4O7代替非晶态硼作为供硼剂,制备出以TiB2为主要成分的表面渗层。

b. Na2B4O7与B4C的质量分数比对结果有重要影响,渗层中TiB2相含量随Na2B4O7含量的增加而增加。当w(Na2B4O7)∶w(B4C)>2∶6时,试样表面粘结粉末严重,不利于清理;w(Na2B4O7)∶w(B4C)=2∶6为最佳比例。

c. 填充剂Al2O3导致TiB2渗层脱落,且脱落程度随Al2O3含量的增加而加重,因此,SiC比Al2O3更适合作为填充料。

d. TiB2渗层厚度随试验温度的升高和反应时间的延长而增加。渗硼层的厚度与处理温度呈二次函数关系;与处理时间的平方根呈线性关系。

参考文献:

[1]孙荣禄,郭立新,董尚利,等.钛及钛合金表面耐磨热处理[J].宇航材料工艺,1999,(5):15-19.

SUN Rong-lu,GUO Li-xin,DONG Shang-li,et al.Surface Abrasion Resistance Heat Treatment of Titanium and Titanium Alloys[J].Aeronautic Materials and Techniques,1999,(5):15-19.

[2]虞炳西,高树浚.纯钛泵轴表面渗氮强化处理[J].表面技术,1996,25(5):32-35.

YU Bing-xi,GAO Shu-jun.Surface Nitriding Reinforcement of Titanium Axis in Pump[J].Surface Technology,1996,25(5):32-35.

[3]戴舸,张荣军.TC4钛合金高频渗氮工艺研究[J].金属热处理,1990,(8):10-15.

DAI Ge,ZHANG Rong-jun.Study on the High Frequency Induction Nitriding Press for TC4 Titanium Alloy[J]. Heat Treatment of Metal, 1990,(8):10-15.

[4]PANG W.Elastic Properties of Titanium Nitride Hard Films at Ambient and Elevated Temperatures[J]. Metal Powder Report, 1998,53(2):38-44.

[5]WEI C H,LIN J F, JIANG T W. Tribological Characteristics of Titanium Nitride and Titanium Carbonitride Multilayer Films: Part I—The Effect of Coating Sequence on Material and Mechanical Properties[J].Thin Solid Films,2001,381(1):94-103.

[6]WEI C H,LIN J F, JIANG T H.Tribological Characteristics of Titanium Diboride and Titanium Carbonitride Multilayer Films[J]. Thin Solid Films,2001,381(1):104-108.

[7]REISSE G,EBERT R. Titanium Nitride Thin Film Deposition by Laser CVD[J].Applied Surface Science,1996,106(8):268-274.

[8]SHACKELFORD J, ALEXANDE W, PORK J S. CRC Materials Science and Engineering Handbook[M]. New York:CRC Press Inc,2002.

[9]MOMOSE O.Pack Boronizing of Titanium with Amorphous B and KBF4[J].Surface Technology,1987,40(1):120-121.

[10]SHIBUYA Y.Boronizing of Titanium by Immersion Pross in Fused Salts[J].Metal Surface Technology,1986,37(10):611-615.

[11]KAWAKAI M.Electro-boronizing of Titanium[J].Metal Surface Technology,1987,38(11):540-543.

[12]KAESTNER P,OLFE J,RIE K T.Plasma-assisted Boriding of Pure Titanium and TiAl16V4[J].Surface and Coating Technology,2001,142(8):248-293.

[13]FELDMAN C,GSATIKIEWICZ F,JONES G. The Behavior of TiB2 Thin Film Electrodes in Polycrystalline Silicon Thin Film Solar Cell[J]. Journal of the Less-Common Metals, 1981,82: 183-191.

收稿日期:2004-11-06

基金项目:国家重点基础研究发展规划项目(G1999064903)

作者简介:贾宝平(1979-),男,甘肃白银人,硕士,从事钛金属表面强化技术的开发与应用研究

论文联系人: 贾宝平,男,硕士;电话:0731-8877391(O); E-mail:jbp_pm_csu@hotmail.com