Fe2(MoO4)3/Si3N4复合粉末还原及热压微观组织结构分析

银锐明1,2, 范景莲2,钟定铭1,刘勋2,张曙光2

(1. 湖南工业大学 冶金工程学院,湖南 株洲,412008;

2. 中南大学 粉末冶金国家重点实验室, 湖南 长沙,410083)

摘要:以α-Si3N4,Fe(NO3)3?9H2O和NH4Mo7O24?4H2O为原料,采用非均相沉淀法制备Fe2(MoO4)3/Si3N4复合粉末,采用氢气还原与热压法获得Fe-Mo/Si3N4复合粉末与烧结体,采用X线衍射仪(XRD)、电子能谱(EDS)、电镜扫描(SEM)和电镜透射(TEM)等方法对Fe-Mo/Si3N4复合粉末与烧结体物相、成分及微结构进行观察与分析。分析结果表明:Fe-Mo/Si3N4复合粉末主要成分为α-Si3N4,Mo,Si和Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N),其中Mo颗粒长大;粒径为4~7 μm的Mo5Si3大颗粒均匀镶嵌在Si3N4,Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N)及SiO2的混合物组成的粒径为1 μm左右的小颗粒之中。

关键词:原位反应;Si3N4;Mo5Si3;非均相沉淀-热还原

中图分类号:TB 333 文献标志码:A 文章编号:1672-7207(2011)04-0909-06

Microstructure of Fe2(MoO4)3/Si3N4 composite powders by reduction and hot pressing

YIN Rui-ming1, 2, FAN Jing-lian2, ZHONG Ding-ming1, LIU Xun2, ZHANG Shu-guang2

(1. College of Metallurgical Engineering, Hunan University of Technology, Zhuzhou 412008, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Fe2(MoO4)3/Si3N4 was prepared by heterogeneous precipitation-thermal reduction method using α-Si3N4, Fe(NO3)3.9H2O and NH4Mo7O24.4H2O as raw material, then through reducing by hydrogen and hot pressed, Fe-Mo/Si3N4 composite powder and its sintering body were obtained. Their phases, composition and microstructure were observed and analyzed by XRD,EDS,SEM and TEM. The results show that the Fe-Mo/Si3N4 composite powder consists of α-Si3N4, Mo, Si and Fe-Mo nitride(Fe6Mo7N2, Fe3Mo3N), in which Mo particle grows, while large Mo particles with size of 4-7 μm are embedded into those small particles composed of Si3N4 and Fe-Mo nitride (Fe6Mo7N2 and Fe3Mo3N) and SiO2 in the microcosmic fracture of Fe-Mo/Si3N4 cermet.

Key words: in-situ reaction; Si3N4; Mo5Si3; heterogeneous precipitation-thermal reduction

Si3N4陶瓷具有密度低、高温强度高、高温蠕变小、导热系数低、热膨胀系数小、抗热震性能好、化学性能稳定、硬度高(莫氏硬度为9)、耐高温磨损等优点,应用于航空航天发动机涡轮叶片等耐高温、耐磨损材料,但其存在脆性较大、韧性较差和抗冲击性差等缺点[1-3]。目前,强韧化Si3N4多采用晶须和纤维增强增韧[4-5]、颗粒弥散增强增韧[6]、相变增韧等技术[7],但没有从根本上解决问题。采用由金属或者合金与同一种或者几种陶瓷相所组成的非均质复合金属陶瓷材料,利用金属塑性相韧化[8-9],为Si3N4陶瓷材料补强增韧提供了一种新的技术。但是, Si3N4陶瓷与大多数金属的润湿性不好,导致制备高致密度的Si3N4基金属陶瓷复合材料比较困难。与WC-CO,TiC和Ti(C,N)等碳化物金属陶瓷相比,人们对Si3N4基金属陶瓷复合材料的研究和应用较少。采用双金属作为陶瓷的金属相有可能解决Si3N4基金属陶瓷所面临的问题。Fe具有成本低廉、韧性高、膨胀系数高、与Si3N4具有良好的润湿性以及黏结性等性能,并具有Mo熔点高、膨胀系数低、高温性能优异等性能。目前,已有将Fe-Mo双金属应用到其他体系陶瓷并取得很好性能的报道[10-11],制备Fe-Mo/Si3N4金属陶瓷可能获得性能优良的新型金属陶瓷。材料性能与其微观组织结构紧密相关,简单地将金属与陶瓷粉末混合烧结,会造成材料成分不均匀,材料性能极不稳定。采用特殊的混合方法获得的特殊结构的粉体,烧结后有可能获得性能优异或其他特殊性能的材料。在此,银锐明 等[12-13]采用非均相沉淀法制备Fe2(MoO4)3/Si3N4复合粉末,采用氢气还原,然后,经热压制得Fe-Mo/Si3N4金属陶瓷,能使材料中成分均匀混合,有利于提高复合陶瓷界面润湿性,大大提高了显微结构的均匀 性,从而获得高性能的结构复合材料。本文作者着重研究Fe2(MoO4)3/Si3N4复合粉末还原与热压过程中微观组织结构演变过程与原因,以便为获得高性能Fe-Mo/Si3N4金属陶瓷提供理论指导。

1 实验方法

1.1 原料

原料为:日产ube sn-e10型α-Si3N4粉末; Fe(NO3)3?9H2O,NH4Mo7O24?4H2O,NH3?H2O和PEG400,均为分析纯;蒸馏水。

1.2 实验步骤

将Si3N4悬浮溶液配制成质量浓度为28.8 g/L;按Fe和Mo元素在Fe-Mo/Si3N4金属陶瓷粉末中质量分数为12%,Fe和Mo的物质的量比n(Fe):n(Mo)=2:3配比,称取Fe(NO)3?9H2O与NH4Mo7O24?4H2O试剂;将称量的NH4Mo7O24?4H2O试剂与溶液浓度5 mL/L PEG400加入质量浓度为28.8 g/L的Si3N4悬浮溶液中,经机械搅拌、超声震荡40 min;将称量的Fe(NO)3?9H2O配制水溶液(溶液质量浓度为40 g/L),缓慢加入上述混溶溶液,再经超声、机械搅拌10 min,经过滤烘干和手工研磨,制得Fe2(MoO4)3/Si3N4复合 粉末。

将1号粉末置入铁容器中,推入氢气还原炉中还原,升温速度为5 ℃/min,在900 ℃保温2 h,冷却至室温后手工研磨,制得Fe-Mo/ Si3N4复合粉末。

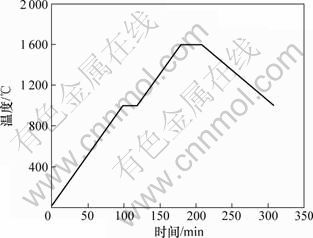

将Fe-Mo/Si3N4复合粉末置于高纯封闭内壁涂有BN粉的石墨模具,置入热压炉中进行烧结,所施加压力为25 MPa,烧结气氛为0.1 MPa氮气,烧结温度为1 600 ℃,保温30 min,制得Fe-Mo/ Si3N4复合材料。升温工艺如图1所示。

图1 热压升温曲线

Fig.1 Relationship between temperature and time in hot press

1.3 性能表征

采用美国FEI公司生产的Tecnai G2 20AEM型透射电镜观察粉末微观结构。将待测粉末经酒精分散,滴加至铜网上,经太阳灯照射烘干后测试;采用日本理学电机株式会社的D/max 2550型XRD衍射仪,Cu Kα辐射,采用连续扫描方式采样,扫描速度为4 (°)/min,二次电子成像模式采用XRD衍射图谱进行分析;采用 JEOL公司的JSM-6360LV型电子扫描显微镜对二次电子与背散射成像模式观察材料的微观结构;采用LEDAX公司的EDX-GENESIS 60S型能谱仪分析材料元素成分。

2 结果与讨论

2.1 Fe2(MoO4)3/Si3N4复合粉末还原后微观组织结构

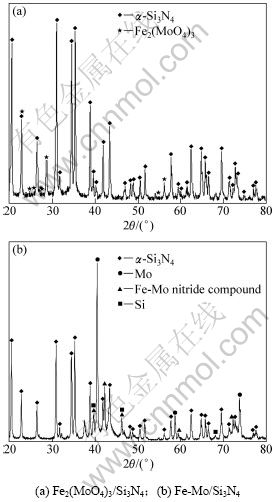

图2所示为Fe2(MoO4)3/Si3N4和Fe-Mo/Si3N4复合粉末X线衍射图。从图2(a)可见:Fe2(MoO4)3/Si3N4粉末衍射图主要存在Si3N4衍射峰及微弱的Fe2(MoO4)3衍射峰,认为NH4Mo7O24溶液与NH4Mo7O2溶液发生反应生成了Fe2(MoO4)3沉淀物,其方程式如下:

Fe(NO3)3+(NH4)6Mo7O24→

Fe2(MoO4)3+NH4NO3 (1)

图2 Fe2(MoO4)3/Si3N4和Fe-Mo/Si3N4粉末的X线衍射图

Fig.2 XRD patterns of Fe2(MoO4)3/Si3N4 and Fe-Mo/Si3N4 powders

从图2(b)可见:Fe-Mo/Si3N4复合粉末X线衍射图中主要存在Si3N4,Mo和Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N)以及Si衍射峰,说明在氢气热还原条件下,Fe2(MoO4)3能与Si3N4发生反应,生成Mo和Fe-Mo氮化物(Fe6Mo7N2和Fe3 Mo 3N)以及Si,其方程式如下:

Fe2(MoO4)3+Si3N4+H2→

Fe3Mo3N+3Si+Mo+H2O↑ (2)

Fe2(MoO4)3+ Si3N4+H2→

Fe6Mo7N2+3Si+Mo+ H2O↑ (3)

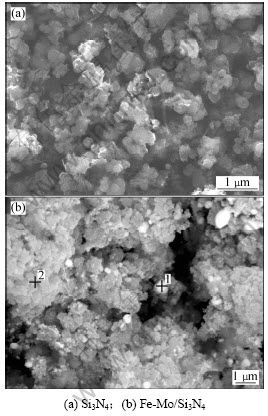

图3所示为喷金处理后Si3N4与Fe-Mo/Si3N4复合粉末的SEM图,发现Si3N4与Fe-Mo/Si3N4复合粉末颗粒形貌存在差异。从图3(a)可见:Si3N4粉末呈块状,表面不规则;从图3(b)可见:Fe-Mo/Si3N4复合粉末表现有2种不同明暗的颗粒,明亮颗粒粒径较大,形貌接近球状;灰暗颗粒表面粒径较小,表面成形较Si3N4更加不规则,表面纳米颗粒黏附物的团聚比图3(a)中Si3N4颗粒的团聚明显。

图3 Si3N4和Fe-Mo/Si3N4复合粉末的SEM图

Fig.3 SEM images of Si3N4 and Fe-Mo/Si3N4 powders

根据电子扫描背散射原理,背散射电子数与原子序数有关,所以,利用背散射信号能反映出样品不同组分的原子序数反差,通常元素原子序数高的较 亮[14]。综合前面X线衍射与SEM图分析,认为Fe-Mo/Si3N4复合粉末中明亮颗粒主要成分是原子序数较高的Mo,灰暗颗粒主要成分是原子序数较低的Si3N4。

分别对明亮颗粒(图3(b)中位置1)与较暗颗粒(图3(b)中位置2)进行能谱分析,结果如图4所示。从图4可见:明亮颗粒的Fe和Mo元素含量偏高,而灰暗颗粒的Fe和Mo元素含量偏低,从而验证了上述推测。

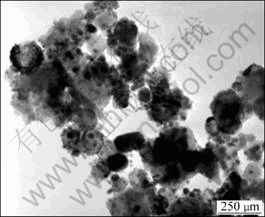

图5所示为Fe-Mo/Si3N4复合粉末的TEM图,图中存在颜色不同的2种颗粒。根据透射电镜显微图像衬度原理[14],入射电子透过试样某区域的原子数愈多(试样厚),密度愈大,则被散射到物镜光阑外的电子就愈多,而通过物镜光阑孔参与成像的电子数愈少,所以,该区域形成的像较暗。图中存在粒径只有数纳米并未重叠的黑色颗粒,可见黑色颗粒并非是由粉末厚度过大造成此区域成像较暗。X线衍射结果表明:Fe-Mo/Si3N4复合粉末主要存在Si3N4,Mo及Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N)与Si等化合物,其中 Mo颗粒密度比其他化合物的密度高2~3倍,故Mo颗粒TEM成像最暗,黑色颗粒形貌与SEM图像中明亮颗粒球状较接近,故认为黑色颗粒成分主要为Mo。而浅色颗粒形貌不规则,复合材料的SEM图中灰暗颗粒形貌较接近,故认为浅色颗粒为密度相对较低的Si3N4,Si及Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N)混合物。

图4 图3(b)中位置1和2的能谱分析结果

Fig.4 EDS of points 1 and 2 in Fig. 3(b)

图5 Fe-Mo/Si3N4复合粉末的TEM照片

Fig.5 TEM image of Fe-Mo/Si3N4 powders

综上所述,Fe2(MoO4)3与 Si3N4在氢气还原条件下发生反应,生成Mo和Fe-Mo氮化物与Si,其中Mo颗粒长大。

2.2 热压Fe-Mo/Si3N4复合粉末微观组织结构

图6所示为热压Fe-Mo/Si3N4复合粉末断口的X线衍射图与SEM图。从在图6(a)可见:X线衍射中存在α-Si3N4,Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N),Mo5Si3及SiO2等衍射峰。与热压前的粉末X线衍射图相比,热压后Si和Mo峰消失,出现了新峰Mo5Si3与SiO2。

Mo与Si3N4或Si均有可能在高温反应生成Mo5Si3,反应方程式如下:

Mo+Si→Mo5Si3 (4)

Mo+Si3N4→Mo5Si3+N2↑ (5)

图6 热压Fe-Mo/Si3N4金属陶瓷X线衍射图(XRD)与SEM图像

Fig.6 XRD pattern and SEM image of broken section of Fe-Mo/Si3N4 compound by hot pressing

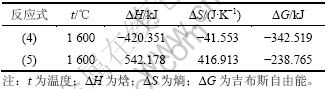

采用HSC Chemistry 5.0热力学软件进行计算,得到上述方程在实验温度为1 600 ℃时的热力学参数,结果如表1所示。结果表明,反应式(4)和(5)中的Gibbs自由能ΔG均为负,但反应式(5)比反应式(4)中的ΔG绝对值要低得多;同时, Si的衍射峰消失,也表明Mo与Si之间发生了完全反应。故认为Mo5Si3应主要由反应式(4)得到。

表1 各反应的热力学参数

Table 1 Thermodynamic parameters of different reactions

SiO2衍射峰的出现,表明Si3N4表面通常被一层无定形非晶态SiO2氧化层包覆[15],其在经历高温后SiO2由非晶态转变为晶态。

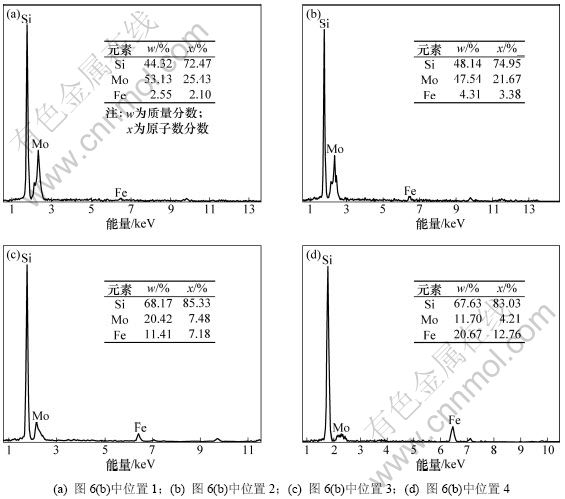

在图6(b)所示的SEM图可见:热压Fe-Mo/Si3N4复合粉末断口主要由2种不同粒径的颗粒组成,大颗粒粒径为4~7 μm,小颗粒粒径为1 μm左右,大颗粒镶嵌在小颗粒之中。分别对大颗粒(图6(b)中位置1与2)与小颗粒(图6(b)中位置3与4)进行EDS能谱分析,结果如图7所示。从图7可见:大颗粒晶粒具有高含量的Si与Mo元素,Fe元素的含量很低,可忽略;小颗粒晶粒具有高含量的Si元素与含量中等偏低的Mo和Fe元素。

由于大颗粒主要存在Si与Mo元素,结合前面的分析,认为大颗粒主要成分为Mo5Si3,其发生长大的原因是实验温度超过了Si的熔点温度1 410 ℃,故Si转化为液相而与Mo发生液相反应,从而促使Mo5Si3晶粒长大。断口组织除了存在Mo5Si3外,还存在α-Si3N4,Fe-Mo氮化物和SiO2等化合物,它们均属共价键化合或离子键化合物,都具有较高熔点且难以扩散,晶粒难以长大,故认为小颗粒为它们的混合物,热压Fe-Mo/Si3N4复合粉末断口微观结构应该是粒度为4~7 μm的Mo5Si3大颗粒均匀镶嵌在Si3N4,Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N)及SiO2的混合物组成的小颗粒之中。

图7 在图6(b)中4个不同位置的能谱分析

Fig.7 EDS of four points in Fig. 6(b)

3 结论

(1) Fe2(MoO4)3与 Si3N4在氢气还原条件下发生反应,生成Mo,Fe-Mo氮化物与Si,其中Mo颗粒发生长大现象,并较均匀地分布在Si3N4,Si及Fe-Mo氮化物混合物之中。

(2) 热压Fe-Mo/Si3N4复合粉末中的Mo与Si发生反应生成Mo5Si3。

(3)粒径为4~7 μm的Mo5Si3大颗粒均匀镶嵌在Si3N4,Fe-Mo氮化物(Fe6Mo7N2和Fe3Mo3N)及SiO2的混合物组成的粒径为1 μm左右的小颗粒之中。

参考文献:

[1] YAN Fa-qiang, CHEN Fei, SHEN Qiang, et al. Spark plasma sintering of α-Si3N4 ceramics with MgO-Al2O3 as sintering additives[J]. Key Engineering Materials, 2007, 351: 176-179.

[2] CHEN Fei, SHEN Qiang, YAN Fa-qiang, et al. Pressureless sintering of α-Si3N4 porous ceramics using a H3PO4 pore-forming agent[J]. Journal of the American Ceramic Society, 2007, 90(8): 2379-2383.

[3] Woetting G, Caspers B, Gugel E, et al. High-temperature properties of SiC-Si3N4 particle composites[J]. Journal of Engineering for Gas Turbines and Power, 2000, 122(1): 8-12.

[4] Baldacim S A, Santos C, Strecker K, et al. Development and characterization by HRTEM of hot-pressed Si3N4-SiC(w) composites[J]. Journal of Materials Processing Technology, 2005, 169(3): 445-451.

[5] Wada M, Kashiwagi K, Kitaoka S, et al. Tribological characteristics of carbon nano-fiber dispersed silicon nitride based composites in high-temperature fuel[J]. Key Engineering Materials, 2009, 403: 239-240.

[6] Tatami J, Chen I W, Yamamoto Y, et al. Fracture resistance and contact damage of TiN particle reinforced Si3N4 ceramics[J]. Journal of the Ceramic Society of Japan, 2006, 114(1335): 1049-1053.

[7] Zang J B, Han W, Wang M I, et al. Zirconia-toughened S13N4 bonding polycrystalline cubic boron nitride(PCBN)[J]. Key Enqineering Materials, 2001, 202/203: 177-180.

[8] ZHOU Shi-quan, ZHAO Wei, XIONG Wei-hao. Microstructure and properties of the cermets based on Ti(C, N)[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(1): 26-32.

[9] ZHANG Xiao-bo, LIU Ning, RONG Chun-lan, et al. Microstructure and mechanical properties of TiC-TiN-Zr-WC- Ni-Co cermets[J]. Ceramics International, 2009, 35(3): 1187-1193.

[10] 韩杰胜, 王静波, 张树伟, 等. Fe-Mo-CaF2高温自润滑材料的摩擦学特性研究[J]. 摩擦学学报, 2003, 23(4): 306-310.

HAN Jie-sheng, WANG Jing-bo, ZHANG Shu-wei, et al. Study on the tribological properties of Fe-Mo-CaF2 high temperature self-lubricating material[J]. Tribology, 2003, 23(4): 306-310.

[11] 苗明清, 傅正义, 张金咏, 等. TiB2/FeMo陶瓷的显微结构与力学性能[J]. 无机材料学报, 2005, 20(2): 499-502.

MIAO Ming-qing, FU Zheng-yi, ZHANG Jin-yong, et al. Microstructure and mechanical properties of TiB2/FeMo cermet[J]. Journal of Inorganic Materials, 2005, 20(2): 499-502.

[12] 银锐明, 范景莲, 刘勋, 等. 采用非均相沉淀-热还原法制备铁包覆氮化硅复合粉末[J]. 中南大学学报: 自然科学版, 2008, 39(1): 7-11.

YIN Rui-ming, FAN Jing-lian, LIU Xun, et al. Preparation of Fe-coated Si3N4 composite powder by heterogeneous precipitation-thermal reduction process[J]. Journal of Central South Unviersity: Science and Technology, 2008, 39(1): 7-11.

[13] Kishimoto S, Shinya N. Development of metallic closed cellular materials containing polymers[J]. Mater Des, 2000, 21(6): 575-578.

[14] 张有纲. 电子材料现代分析概论: 第二分册[M]. 北京: 国防工业出版社, 1993: 149-154.

ZHANG You-gang. Generality of electronic materials: The second fascicule[M]. Beijing: National Defense Industry Press, 1993: 149-154.

[15] 张其土. Si3N4陶瓷材料的氧化行为及其抗氧化研究[J]. 陶瓷学报, 2000, 21(1): 23-27.

ZHANG Qi-tu. Study on oxidation behavior and oxidation resistance of si3N4 ceramics[J]. Journal of Ceramic, 2000, 21(1): 23-27.

(编辑 陈灿华)

收稿日期:2010-01-07;修回日期:2010-05-06

基金项目:国家自然科学青年基金资助项目(50804016);湖南省教育厅科研项目(02C659);长沙市科技计划重点项目(K1005168-11)

通信作者:银锐明(1973-),男,湖南邵阳人,教授,硕士生导师,从事粉末冶金、金属陶瓷材料的研究;电话:13974119516;E-mail:yin_ruiming@126.com