J. Cent. South Univ. Technol. (2008) 15(s1): 500-505

DOI: 10.1007/s11771-008-409-9

Rheological properties of sweet potato starch before and after denaturalization

XIAO Hua-xi(肖华西)1, LIN Qin-lu(林亲录)1, 2, XIA Xin-jian(夏新剑)2,

LI Li-hui(李丽辉)1, LIN Li-zhong(林利忠)1, WU Wei-guo(吴卫国)2

(1. Faculty of Food Science and Engineering, Center South University of Forestry and Technology,Changsha 410004, China;

2. School of Food and Science, Hunan Agricultural University, Changsha 410128, China)

Abstract: Based on the sweet potato starch, cationic starch, acetic starch and cationic-acetic compoundedly modified starch were made through chemical denaturalization. The above three kinds of static rheological parameter and dynamic rheological parameter were measured, respectively. The experimental result reveals that the thermal stability of starchy viscosity increases after chemical denaturalization. Under the condition of identical shearing rate, the shear stress of cationic-acetic ester compoundedly modified sweet potato starch paste is the largest among these kinds of sweet potato starch. This attributes to a phenomenon of shearing thinning. Furthermore, raw sweet potato starch has a larger gel intensity than that of modified starch.

Key words: sweet potato; modified starch; rheological properties; pasting; shearing rate

1 Introduction

China is abundant in sweet potatoes, whose production takes 80% of the world gross output. In recent years, the refinery and exploitation of sweet potatoes have been paid much attention, and a lot in the production variety and processing technology has been achieved, such as etherification, esterification and cross-linking starch. This kind of starchy derivative has been used to improve the properties of gelatin and pasting, which prevents the aging and retrogradation of starch[1-5]. The main ingredient of sweet potatoes is starch[6], which boasts as a kind of polymer widely applied not only because it is a kind of natural product whose price is very cheap but also its physicochemical properties are easily changed by chemical denaturalization and physical treatment[7]. By now, Chinese food industry has used a large amount of corn starch, followed by potato starch, but merely a small quantity of sweet potato starch. Sweet potato starch just confines to such small fields as the traditional vermicelli, maltose and transformed citric acid calcium. These may be connected with the lack of the basic data of the rheological properties and the poor processing stability of sweet potato starch[8]. Many practical application examples revealed that the function property of starchy production is mainly dependent on its rheological property. The starchy paste rheological property of wheat, rice, maize, sago, bananas etc at home and abroad has been studied regularly, while the rheology of sweet potato starch is studied seldomly. Up to now, there is less report at all on the research of the rhelogical property of sweet potato starch[9-10], which confines the development and utilization of industrialization of the sweet potato starch. In order to find a new way for the sweet potato starch material industrializations, we applied a research about sweet potato starch and its denaturational starch rheological property. The changing of shearing rate has an influence on the shearing stress and apparent viscosity. A research on the rheological properties of the raw sweet potato starch and the denatured sweet potato starch by contrast demonstrated that, in general, starch paste’s viscosity takes on a dynamic change with the changing of temperature, shearing rate, shearing time and shearing history. Both sweet potato starchy paste and sweet potato denaturational starchy paste had shown the rheological behavior of non-Newtonian fluid[11]. The pseudo plastic rheological property of the pasting starch is important to the application in many fields. Meanwhile, we had made a measurement of its dynamic rheological behavior and initiated a discussion of the rheological mechanism, to lay a theoretical foundation for the application of sweet potato starchy paste[12].

2 Experimental

2.1 Materials and equipment

The sweet potato raw starch (purchased from market), acetic ester starch (prepared in laboratory), cationic starch (prepared in laboratory), and cationic- acetic compound denatured starch (prepared in laboratory) were used.

The rapid visco-analyzer (RVA-4, Newport Scientific Pvt. Ltd., Australia), rotational viscometer (RheolabQC, Germany), and dynamic rheometer (AR1000, TA, Ltd, America) were used.

2.2 Methods

2.2.1 Pasting properties measurement

The pasting properties of sweet potato raw starch and its modified starch were determined with the rapid visco analyzer (RVA-4, Newport Scientific Pvt. Ltd., Australia). Viscosities of starch from sweet potato starch and its modified starch were recorded when starch suspensions (6%, mass fraction; 28 g total mass) were processed with a controlled heating and cooling cycle under the condition of constant shearing, where it was held at 50 ℃ for 1 min, heated from 50 to 95 ℃ at 5 ℃/min and held at 95 ℃ for 2.7 min, cooled from 95 ℃ to 50 ℃ at 5 ℃/min and held at 50 ℃ for 2 min. Pasting parameters such as pasting temperature (tp), peak viscosity (ηp), hot paste viscosity (ηh), viscosity at the end of a holding at 95 ℃; cold paste viscosity (ηc), viscosity at the end of holding at 50 ℃; and age resistance (CPV-HPV) were recorded.

2.2.2 Measurement of static rheological parameter

Four dried samples of sweet potato starch, acetic ester starch, cationic starch, cationic-acetic compounded denatured starch were respectively made into starch emulsion whose mass fraction is 8% with distilled water. The relevant apparent viscosity was measured at different shearing rates by rotational viscometer. The shearing stress was calculated according to the power law. Since sweet potato starch is pseudo plastic fluid, the relation between shearing stress and shearing rate can be shown by power law equation:

τ=Kγm (1)

where K is consistency index, and its numerical value is relevant with liquid consistency or concentration[13]; m is flow index, which demonstrates the extent that how liquid departs from Newtonian liquid. Liquid is Newtonian liquid when m=1. Liquid is pseudo plastic fluid when m<1. Liquid is swelling plastic fluid when m>1. Different liquids have different characteristic curves due to different relations between viscosity and shearing rate. The rheological curve of sweet potato starch and its modified starch can be described by the power law equation according to the relative theory and references [14-16].

2.2.3 Measurement of dynamic rheological parameter

The rheological properties of sweet potato raw starch and modified sweet potato were measured by dynamic rheometer. Sweet potato starch suspension of 20% was put into the testing platform of dynamic rheometer. The plane mould diameter was 40 mm and oscillation measurement procedure was selected. The clearance was set up to be 1.0 mm, the strain was 2%, and angle frequency was 5 rad/s. The experiment process was as follows. The temperature was first increased from 20 to 100 ℃, which enabled suspension system of sweet potato starch to become paste, and then decreased from 100 to 20 ℃. The changes of gelatin property of starch in the process of cooling were tested. The velocities of increasing and decreasing temperature respectively were 5 ℃/min[17].

3 Results and discussion

3.1 Pasting properties

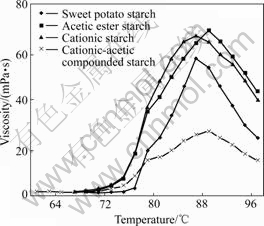

Pasting properties of sweet potato starch and its modified starch were measured using a rapid visco- analyser, as shown in Table 1. Pasting temperatures of different starches ranged from 60 to 75 ℃ with the highest for raw sweet potato starch and the lowest for cationic-acetic compounded denatured starch. Peak viscosity was found to be the lowest for cationic-acetic compounded denatured starch and the highest for acetic ester starch. The viscosity increased with increasing temperature, which attributed to the removal of water from the exuded amylose by the granules. The viscosity change curves of the raw starch and a few denatured starches with temperature are shown in Fig.1.

As shown in Table 1, the aging trend of sweet potato starch is the most apparent, and that of cationic-

Fig.1 Changing viscosity curves of raw starch and its modified starch

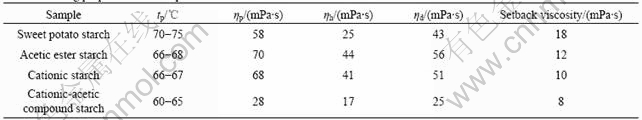

Table 1 Pasting properties of sweet potato starch and its modified starch

acetic compounded starch is the least. The larger the viscosity differences between cold viscosity and hot viscosity are, the weaker the age resistance of starch paste is. The viscosity difference of the raw starch between cold viscosity and hot viscosity is larger compared with others. This phenomenon indicates that the age resistance of raw starch is the lowest and prone to aging. The viscosity difference of cationic-acetic compounded starch is the lowest, which means that the age resistance of compounded starch is greatly improved. The aging phenomenon is largely caused by amylose that only acts on straight chain part of starch molecule, but does not work on branched structure. If the relative molecular mass of amylose reduces in the solution and the polymerization degree of glucose decreases, the age resistance of starch will be strengthened. Since the relative molecular mass of amylose in raw starch is very high, the age resistance of raw starch is very weak. Acetyl and etherifying chemical bonds are introduced in cationic-acetic compounded starch, which can make straight chain molecule and branched chain molecule form larger and more steady branched chain molecule, or straight chain molecule form branched chain molecule, or branched chain molecule form larger branched chain molecule. So the relative molecular mass of amylose reduces in compounded starch and the age resistance of compounded starch is strengthened by large degree [18].

As shown in Fig.1, The paste viscosity curve of three kinds of modified starch is gentler than that of sweet potato raw starch, and the paste viscosity curve of cationic-acetic compounded starch is the gentlest among four kinds of curves. This indicates that the modified starch of sweet potato starch has the property of thermal stability of viscosity. The reason for this phenomenon is that the molecule structure of starch was changed after denaturalization, and the intensity of starch granule structure was strengthened, which restrains the expanding and burst of granule[19]. Straight chain molecule and branched chain molecule form the larger, more steady branched chain molecule, or straight chain molecule forms branched chain molecule, or branched chain molecule forms larger branched chain molecule [17], so the average molecular mass of starch molecule increases and the viscosity of the starch is increased as well. As a result, in the process of pasting, the viscosity of high degree of substitution starch generally increases. As for compounded denatured starch, the branched chain molecules form a close-knit network in solution, which decreases the emersion, coagulation and sedimentation of straight chain molecule, while increases the stability of viscosity of the starch. The more the branched degree of starch molecules is, the stronger the space place resistance is, and the more stable the thermal stability of viscosity is.

The pasting temperature of sweet potato starch is the highest while that of cationic-acetic compounded starch is the lowest among all kinds of sweet potato starch (as shown in Table 1). The polymerization of the starch is a hydrogen-bonding process. When hydrogen bond is not destroyed, the expansion process of the starch is reversible. When hydrogen bond is destroyed, the expansion process of the starch is not reversible. For acetic ester starch, the acetyl replaces the hydrogen in hydroxyl group. Because the acetyl is much bigger than the hydrogen, the distance between the molecules obviously increases, the hydrogen bond between molecules is destroyed, the bonding force turns weaker, the energy that is required by pasting decreases, and the pasting temperature decreases accordingly, so does the cationic starch, in which etherifying bond with nitrogen takes the place of the hydrogen in hydroxyl group. Cationic-acetic compounded modified starch has more acetyl and more etherifying bond with nitrogen, which results in the larger distance between molecules, weaker bonding force and lower pasting temperature.

3.2 Static rheological behavior of sweet potato raw starch and denatured sweet potato starch

The relationship between shearing stress and shearing rate of sweet potato starch, acetic ester starch, cationic starch, cationic-acetic compounded starch of 8% concentration was tested at 25 ℃, as shown in Fig.2.

The relationship between apparent viscosity and shearing rate of sweet potato starch, acetic ester starch, cationic starch, cationic-acetic compounded starch of 8% concentration was tested at 25 ℃, as was shown in Fig.3. The rheological curve portrays that the extended lines of rheological curves of three modified sweet potato

Fig.2 Relationship between shearing stress and shearing rate of sweet potato starch and its modified starch

Fig.3 Relationship between apparent viscosity and shearing rate of sweet potato starch and its modified starch

starch pierces through the original point and are slightly convex to the shearing stress axis, so three kinds of modified starch belong to non-Newtonian fluid as sweet potato starch. Sweet potato starch and its modified starch have the property of pseudo plastic fluid, whose shearing stress increases with the shearing rate increasing. The rheological curve of raw sweet potato starch is more flexural than that of its modified starch for the amylose content of sweet potato raw starch is more than that of modified starch, and amylose molecule of long chain is effortless to tropism, which leads to the larger shear- thinning and the bigger flexural extent of rheological curve[20]. When the concentration is 8%, at the same shearing rate, the shearing stress of cationic-acetic compounded starch is apparently larger than that of other starch. For the amylopectin content of cationic-acetic compounded starch is very high, amylopectin forms the network structure by the molecule chain. The larger the resistance to the flowing is, the larger the shearing stress is.

The rheological curve (Fig.3) demonstrates that sweet potato starch and its modified starch have behavior of obvious shear thinning. Shearing thinning is the proper phenomenon of pseudo plastic fluid, in other words, the apparent viscosity of liquid decreases with the shearing rate increasing[21]. The larger the shearing rate is, the lower the apparent viscosity will be. The apparent viscosity of sweet potato raw starch takes on a quicker downtrend. As the shearing rate increases, the downtrend of acetic ester starch and cationic starch is gentler than that of sweet potato raw starch. The decline of apparent viscosity of cationic-acetic compounded starch is the slowest with the shearing rate increasing. This gave us an evidence that the shearing resistance was lifted after denaturalization of sweet potato raw starch. Because a large number of acetyl and etherifying chemical bonds are brought in big molecules after chemical denaturalization of sweet potato raw starch, the hydrogen bond action between starchy molecules is weakened or destroyed, leading to the change of starchy molecule shape and molecular mass distribution, consequently resulting in the change of rheological property. The behavior of shearing thinning is irregular clew which tangles with one another in the solution of sweet potato raw starch, and big viscosity resistance to the flowing comes into being. When the flowing happens under the circumstance of shearing stress, the curly and tangly molecule structure is drawn straightly to tropism, and tangle crunodes decreases, so does the flowing interbedded shearing stress. Accordingly, the apparent viscosity declines. The above arrangements tend to be improved as the shearing rate increases. The apparent viscosity becomes lower and lower. When the shearing rate increases to a certain extend, it is too late for starchy molecule before tropism or starchy molecule already takes tropism or starchy molecule already takes tropism fully. The apparent viscosity holds a constant[22].

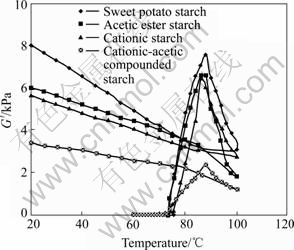

3.3 Dynamic rheological behavior of sweet potato raw starch and denatured sweet potato starch

When starch becomes starch paste and cooling gelatin, the graph of storage modulus (G′) changing with temperature shown in Fig.4 demonstrates that the pasting temperature of three categories of modified starch all slightly decreases compared with that of sweet potato raw starch. The remarkable change is that the storage modulus of three kinds of modified starch is lower than that of sweet potato raw starch at the pasting peak. In the period of decreasing temperature and cooling, the increasing of the raw starchy gel strength is larger than that of three kinds of modified starch.

Fig.4 Dynamic rheological behavior of storage modulus (G′) of raw starch and its modified starch with variation of temperature

Since sweet potato starch granule swells due to absorbance of a good deal of water, the swelling sweet potato starch granule adjoins to each other closely so that a shape of network structure forms. If temperature keeps on increasing, the amylose molecule exudes from the swelling granule and solve, the transudatory amylose molecule twists each other and forms a successive matrix phase, which makes suspension transform to solution, then the swelling sweet potato starch granule inlays in the continuous matrix phase where amylose molecule forms, and the maximum of G′ is obtained[22]. Acetyl and etherifying chemical bonds are brought in the molecules of modified starch, which decreases the amylose content in starch, so the value of G′ is lower than that of sweet potato raw starch. When temperature continues to increase, the value of G′ decreases remarkably. It is because a part of sweet potato starch granules collapses, hydrogen bonding between molecules ruptures, and the gel matrix of sweet potato starch is broken down. In the process of cooling, the amylose molecules produce crosslinking each other by hydrogen bonding and form binding domain, which strengthens the gelatin network of sweet potato starch. Because the amylose content decreases in three kinds of modified starch, and formative gelatin network of straight chain starch is quite weak, the decline of gel strength in gelatin happens.

4 Conclusions

After the process of denaturalization, the sweet potato raw starch improved the thermal stability of the starchy paste, strengthened the anti-aging ability of the starchy paste and decreased the temperature of pasting, among which, compounded denaturational starch’s pasting temperature is the lowest, whose temperatures are from the former 70-75 ℃ to the latter 60-65 ℃. Raw sweet potato starch and its denaturational starch both belong to non-Newtonian fluid. With the increasing of the shearing rate, shearing stress increases. At the same shearing rate, cationic-acetic ester compounded denaturational sweet potato starchy paste’s shearing stress is obviously larger than that of the other starchy. Moreover, the property of pseudo plastic fluid is present, which is consistent with the power law equation τ=Kγm. With the property of shearing thinning, namely the apparent viscosity of liquid decreases as the increasing of shearing rate, raw sweet potato starch’s apparent viscosity shows a quicker declining trend. The declining trend of acetic ester starch and cationic starch is gentler than that of the raw sweet potato paste. The apparent viscosity of cationic-acetic ester compounded denaturational sweet potato starch has the lowest decreasing trend with the increasing of shearing rate. All these proved that after the process of denaturalization, the anti-shearing capacity of sweet potato raw starch was improved obviously. When sweet potato starch, acetic ester starch, cationic starch and cationic-acetic ester compounded denaturational starch become paste and cool down to form gelatin, G′ changes with the variation of temperature. Among pasting peaks, the largest G′ of these kinds of denaturational starch is smaller than that of raw sweet potato starch. In the process of lowering temperature and cooling off, the increasing of raw sweet potato starch’s gelatin strength is larger than that of three kinds of denaturational starch.

References

[1] GONZALEZ-TOMAS L, BAYARRI S, TAYLOR A J, COSTELL E. Flavour release and perception from model dairy custards [J]. Food Research International, 2007, 40: 520-528.

[2] RAO M A. Rheological properties of fluid foods [M]. RAO M A, RIZVI S S H, DATTA A, eds. Engineering Properties of Foods (3rd ed). New York: Marcel Dekker Inc, 2005, 30:10-16.

[3] RODD L E, SCOTT T P, COOPER-WHITE J J, McKINLEY G H. Capillary break-up of low-viscosity elastic fluids [J]. Applied Rheology, 2005, 15: 12-27.

[4] ALBERTSON A C, GRIFFIN J C, KARL SON S. Spectroscopic and mechanical changes in irradiated starch filled LDPE [J]. Polyp Degrade Stab, 2003, 45: 173-178.

[5] LEE K Y, KIM Y R, PARK K H. Vane yield stress of starch dispersions [J]. Carbohydr Polym, 2006, 63: 347-354.

[6] OH H E, WONG D N, HEMAR Y, ANEMA S G. Effect of pH adjustment at heating on the rheological properties of acid skim milk gels with added potato starch [J]. International Dairy Journal, 2007, 17: 1384-1392.

[7] TA′RREGA A, VE′LEZ-RUIZ J F, COSTELL E. Influence of milk on the rheological behaviour of cross-linked waxy maize and tapioca starch dispersions [J]. Food Research International, 2005, 38: 759-768.

[8] BE MILLER J N, LAFAYETTE N. Starch modification [J]. Challenges and Prospects of Starch, 2005, 4(5): 127-131.

[9] GERMAIN I, DUFRESNE T, RAMASWAMY H S. Rheological characterisation of thickened beverages used in the treatment of dysphagia [J]. Journal of Food Engineering, 2006, 73: 64-74.

[10] KHALU M I. Preparation and characterization of starch acetate Starch [J]. Modified Starch, 2004, 8(10): 394-398.

[11] AHMED J, RAMASWAMY H S, ALLI I. Thermorheological characteristics of soybean protein isolate [J]. Journal of Food Science, 2006, 71: E158-E163.

[12] SINGH N, ISONO N, SRICHUWONG S, NODA T, NISHINARI K. Structural, thermal and viscoelastic properties of potato starches [J]. Food Hydrocolloids, 2008, 22: 979-988.

[13] LEE K Y, KIM Y R, PARK K H. Rheological and gelation properties of rice starchmodified with 4-glucanotransferase [J]. International Journal of Biological Macromolecules, 2008, 42: 298-304.

[14] BETANCUR A D, CHEL G L, CANIZARES H E. Acetylation and characterization of canavalia ensiformis starch [J]. Journal of Agricultural and Food Chemistry, 2003, 45(2): 378-382.

[15] XUE Tao, YU Long, XIE Feng-wei. Rheological properties and phase transition of starch under shear stress [J]. Food Hydrocolloids, 2008, 22: 973-978.

[16] THOMAS E L. Structure and properties of ice cream J food techno [J]. Modified Starch, 2001, 35(1): 41-49.

[17] SOPADE P A, HALLEY P J, CICHERO J A Y. Rheological characterisation of food thickeners marketed in Australia in various media for the management of dysphagia (II): Milk as a dispersing medium [J]. Journal of Food Engineering, 2008, 84: 553-562.

[18] TESTER R F, MORRISON W R. Swelling and gelatinization of cereal starch (I): Effects of amylopectin, amylose, and lipids [J]. Cereal Chemistry, 2005, 67: 551-557.

[19] GONZALEZ-TOMA′S L, COLL-MARQUE′S J, COSTELL E. Viscoelasticity of inulin-starch-based dairy systems.Influence of inulin average chain length [J]. Food Hydrocolloids, 2008, 22: 1372-1380.

[20] CHAN P S K, HEN J S, ETTELAIE R, LAW Z, ALEVISOPOULOS S, DAY E. Study of the shear and extensional rheology of casein, waxy maize starch and their mixtures [J]. Food Hydrocolloids, 2007, 21: 716-725.

[21] GONZALEZ-TOMAS L, BAYARRI S, TAYLOR A J, COSTELL E. Rheology, flavour release and perception of low-fat dairy desserts [J]. International Dairy Journal, 2008, 18(8): 858-866.

[22] DINTZISF R, BAGLEYE B. Shear-thickening and flowinduced structurein a system of DMSO containing waxy maize starch [J]. Journal of Rheology, 2007, 39: 1399-1409.

(Edited by YANG Bing)

Foundation item: Project(2007FJ1007) supported by the Science Foundation of Hunan Province, China

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: LIN Qin-lu, Professor; Tel: +86-731-5623241; E-mail: lql0403@yahoo.com.cn