文章编号:1004-0609(2009)08-1488-05

溶胶?凝胶法制备的Al2O3涂层及其

对γ-TiAl合金的高温氧化防护

任保轶1, 2,张学军2,冯乃祥1,高 枫1, 2

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 沈阳化工学院 应用化学学院,沈阳 110142)

摘 要:以异丙醇铝(Al(OC3H7)3)为原料,采用溶胶?凝胶法在γ-TiAl基合金表面制备Al2O3涂层。以空白样品做对照,研究涂层的作用机制以及涂层对γ-TiAl基合金1 000 ℃高温氧化行为的影响。结果表明:采用浸涂工艺制备的涂层表面均匀、无裂纹,主要由γ- Al2O3相组成,厚度约为0.8 μm;等温氧化110 h后,空白试样和Al2O3涂层试样的氧化抛物线速率常数分别为4.85×10?12 和 3.31×10?13 g2/(cm4?s),涂层明显提高合金的抗氧化能力及抗循环氧化能力;空白样品上形成的氧化膜出现分层现象,而在涂层样品的Al2O3涂层中存在金红石型TiO2和α-Al2O3混合物。

关键词:Al2O3涂层;溶胶?凝胶法;γ-TiAl基合金;高温氧化

中图分类号:U 177.2 文献标识码: A

Al2O3 coating prepared by sol-gel method and its oxidation protection for γ-TiAl based alloy at high temperature

REN Bao-yi1, 2, ZHANG Xue-jun2, FENG Nai-xiang1, GAO Feng1, 2

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. College of Applied Chemistry, Shenyang Institute of Chemical Technology, Shenyang 110142, China)

Abstract: With aluminum isopropoxide (Al(OC3H7)3) as precursor, an Al2O3 film was deposited on a γ-TiAl based alloy by sol-gel method. In comparison with the uncoated specimens, isothermal and cyclic oxidations at 1 000 ℃ were performed to test its effect on the oxidation behavior of the alloy. The possible mechanism of the thin film on the oxidation behavior of the alloy was discussed. The results show that the thin film synthesized using a dip-coating process is uniform and crack-free. The thin film mainly consists of γ-Al2O3 after heat treatment. The average thickness of the coating is about 0.8 μm. Oxidized for 110 h in air at 1 000 ℃, the average parabolic rate constants (kp) for the blank and coated specimens are 4.85×10?12 and 3.31×10?13 g2?cm?4?s?1. The Al2O3 film exhibits beneficial effects on the oxidation resistance of the alloy. The oxide scales formed on the uncoated specimens are delaminated. For the coated samples, beneath the Al2O3 film, a mixture layer of rutile TiO2 and α-Al2O3 exists.

Key words: Al2O3 coating; sol-gel method; γ-TiAl based alloy; high temperature oxidation

TiAl合金由于具有优良的力学性能,如高温条件下的高强度和高弹性模量等,被认为是理想的高温结构材料。但研究人员发现,当温度超过900 ℃后,TiAl合金的抗氧化能力较弱[1?2],为此,研究者做了大量工作以提高TiAl合金的高温抗氧化性能,通过对Ti合金进行表面处理和合金化添加组元的方法来改善其氧化变脆现象和抗氧化性能,如合金元素Mo、Nb和W加入到二元Ti-Al合金中可以提高其抗氧化性[3?6]。很多涂层能为钛合金提供保护并在高温条件下有效阻止氧的渗入[7?11]。最近报道的表面处理主要有陶瓷涂 层[12]、铝涂层[13]和硅涂层[14?16]。但大部分的涂层和基材之间存在粘附性差和扩散严重等缺点[17],如果要进一步提高Ti-Al合金的抗氧化性,必须研究新的技术或涂层体系。

溶胶?凝胶法被广泛用于制备各种涂层,与其他方法相比,该方法具有工艺设备简单、成本低、能耗小的特点,可以在低温条件下改善基材的表面性质而不改变其原有的强度和韧性[18?19],但将其用于制备γ-TiAl合金保护涂层的研究尚未见报道。本文作者采用溶胶?凝胶法在γ-TiAl合金表面制备Al2O3涂层,研究涂层对合金抗氧化性能的影响,并探讨该涂层的作用机制。

1 实验

合金采用纯金属原料(99.9%)在氩气保护下经非自耗电弧炉反复熔炼,并在氩气保护下于1 200 ℃退火72 h,以消除残余应力和获得均匀的合金组织。合金主要由γ-TiAl相构成,并含少量α2-Ti3Al相。合金的实际组成为Ti-46.2Al-2Cr-2Nb-0.15Ba-1Si(摩尔分数,%)。合金锭切割成尺寸为12 mm×10 mm×1.5 mm的试片,并在边缘钻一直径2 mm左右的孔,以便于在浸涂时拿取。试样的各表面用1200# SiC砂纸水磨抛光,放在丙酮中超声震荡去污,蒸馏水洗净后空气中干燥,备用。

Al2O3溶胶按文献[20]的方法制备:将20 g异丙醇铝(纯度>98%)溶解在270 mL蒸馏水中,在80 ℃搅拌1 h,加入HNO3调节pH值到3左右。在90 ℃下搅拌5 h,得到透明溶胶。Al2O3溶胶中固体含量约为5%。

将试片浸在Al2O3溶胶中,以10 cm/min的速度提拉出液面,室温下干燥20 min,然后在75 ℃的真空干燥箱中干燥40 min。浸涂5次后,将试片放在管式炉中,在氩气保护下进行热处理。管式炉内的初压为0.2 Pa,以流速0.5 L/min的氩气作为保护气,以5 ℃/min的速率将炉温升到300 ℃,在此温度下保温 1 h。重复上述操作并升温到500 ℃,保温2 h。最终将温度升至1 000 ℃,保温1 h。经过以上过程,试片被浸涂15次,烧结处理3次。样品随炉冷却至室温得到氧化铝薄膜。

等温氧化采用不连续称量方法,在1 000 ℃空气条件下氧化110 h。样品置于氧化铝坩埚中,在空气中静态氧化,每间隔5~20 h取出后在室温下冷却。循环氧化同样在1 000 ℃时空气中进行,将样品置于1 000 ℃的炉中氧化1 h,取出后在空气中冷却10 min,定义为一个周期,连续操作100个周期。用灵敏度为10?5 g的分析天平称量氧化一定时间间隔的等温氧化和循环氧化样品的质量变化。

采用SEM/EDAS表征氧化后样品的表面形貌和截面形貌,氧化膜的物相采用X射线衍射仪进行分析(Cu Kα辐射)。

2 结果与分析

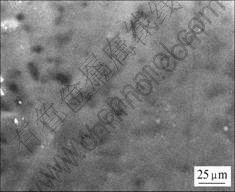

2.1 涂层的表面形貌

图1所示为γ-TiAl合金表面制备的Al2O3涂层表面形貌。由图1可知,该涂层表面均匀、无裂纹,但在高倍下观察到样品表面氧化铝层有黑斑。由于涂层是分步制备的,每涂5次做一次热处理;最内层烧结3次,而最外面的涂层仅烧结1次。因此,内层微裂纹应该很少。即使先前烧结的涂覆层出现微裂纹,大部分也会因溶胶?凝胶浸涂的渗透作用被随后的浸涂层填满。采用X射线衍射仪分析得到涂层的主要成分为γ-Al2O3,根据热处理前后试片的质量变化得到涂层的厚度大约为0.8 μm。

图1 溶胶?凝胶法制备涂层的表面形貌

Fig.1 Surface morphology of Al2O3 coating prepared by sol- gel method

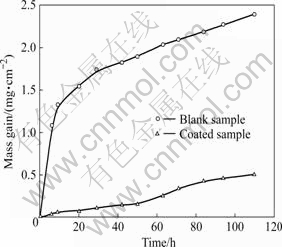

2.2 氧化动力学

图2所示为空白样品和涂层样品在1 000 ℃空气条件下的等温氧化动力曲线。从图2可以看出,Al2O3涂层样品的质量增加比γ-TiAl合金空白样品的质量增加慢得多。抛物线速率常数(kp)可以通过Δm/S=kpt1/2+A线性拟合获得,式中S为样品表面积,A为常数,空白样品和涂层样品的kp分别为4.85×10?12 和 3.31×10?13 g2/(cm4?s)。Al2O3涂层的存在使合金抛物线速率常数降低90%以上。

图2 涂层试样和对照试样于1 000 ℃空气中时的等温氧化动力学曲线

Fig.2 Isothermal oxidation dynamic curves of blank and coated γ-TiAl at 1 000 ℃ in air

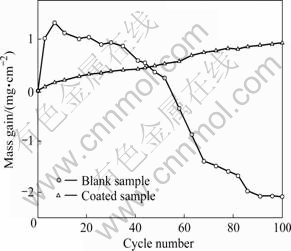

图3所示为空白样品和涂层样品在空气条件下循环氧化100次的氧化动力学曲线。由图3可以看出,剥落之后,新的合金表面暴露在空气中,因此,随后的氧化速率增加。γ-TiAl合金氧化7个周期后发生剥落,氧化30个周期之后,开始出现大面积的剥落,导致样品的质量减少。相反,涂层样品的循环氧化动力学与其等温氧化动力学相似,呈现平滑的质量增加趋势。在循环氧化中,涂层样品的质量增加保持上升趋势,在涂层样品上形成的氧化物没有剥落,所以动力学曲线比较平滑。

图3 在1 000 ℃空气中涂层试样和对照样品的循环氧化动力学曲线

Fig.3 Cyclic oxidation kinetic curves of blank and coated γ-TiAl based alloy at 1 000 ℃ in air

循环氧化和等温氧化的测试结果表明:在1 000 ℃空气条件下,不论是循环氧化还是等温氧化,Al2O3薄膜对合金均起到保护作用。

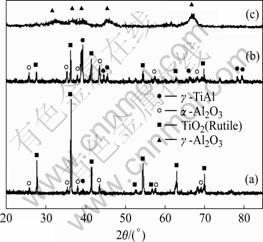

2.3 氧化膜组成

图4所示为空白样品和涂层样品静态氧化110 h后氧化物物相组成。未氧化的Al2O3薄膜的XRD谱如图4(c)所示。由图4可知,空白样品和涂层样品的氧化膜均由金红石型TiO2和α-Al2O3组成。相比而言,涂层样品(见图4(b))的Al2O3特征峰的强度比空白样品(见图4(a)) Al2O3特征峰的强度要强;而涂层样品TiO2特征峰的强度比空白样品的弱。由于循环氧化样品的XRD谱与等温氧化的相似,因此未列出。这表明:该涂层在氧化过程中形成更多的Al2O3,并抑制了γ-TiAl合金高温氧化时TiO2的形成。

图4 涂层和空白试样氧化膜的XRD谱

Fig.4 XRD patterns of samples oxidized in air at 1 000 ℃ for 110 h: (a) Blank sample; (b) Coated sample; (c) Unoxidized Al2O3 coating

2.4 氧化膜的形貌

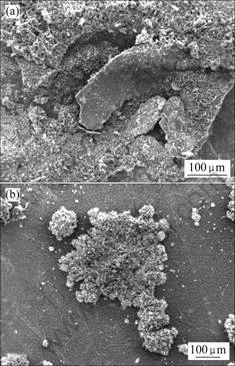

图5所示为样品1 000 ℃时经过100次循环氧化后氧化膜的表面形貌。由图5可看出,空白样品出现非常严重的开裂和剥落现象(见图5(a));而涂层样品中则未出现这些现象;涂层样品中只在局部可以观察到类似TiO2的瘤状物(见图5(b))。EDAS结果表明:该瘤状物主要为TiO2,但比空白样品中的TiO2薄得多。

图5 试样于1 000 ℃循环100次后的表面形貌

Fig.5 Surface morphologies of samples after 100 cycles at 1 000 ℃: (a) Blank sample; (b) Coated sample

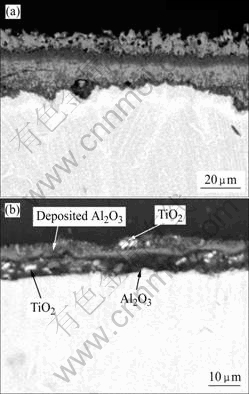

图6所示为样品经等温氧化110 h后横截面的形貌。由图6可看出,空白样品上形成的氧化物出现分层并且比涂层样品上的氧化物厚得多(见图6(a))。空白样品的氧化膜从气体/氧化物界面到基材分为3层,最外层是疏松多孔的TiO2,中间层是Al2O3层,最内层是TiO2和Al2O3混合物,并且内氧化现象严重;而涂层样品仅在涂层顶部形成极少量的TiO2,涂层底部出现富集和Al2O3的混合氧化层涂层样品的氧化膜合金界面无明显内氧化现象(见图6(b))。

图6 涂层样和空白样于1 000 ℃空气中氧化110 h后的截面形貌

Fig.6 Cross-sectional morphologies of specimens oxidated at 1 000 ℃ for 110 h: (a) Blank sample; (b) Coated sample

3 讨论

γ-TiAl合金的氧化行为在文献[1?2]中有详细叙述。在高温条件下,合金表面形成的是Al2O3和保护作用较差的金红石型TiO2的混合物,而不是连续的α-Al2O3保护膜。随着氧化的进行,氧扩散到内部与钛发生反应,在不连续的Al2O3底部形成金红石型TiO2。部分氧化铝镶嵌在金红石型TiO2中,而其余的形成在氧化膜上面。随着温度的增加,氧化速率增大,氧化物层增厚,氧扩散区域加深。

就二元合金A-B合金而言,根据合金的组成,在空气气氛中合金氧化时可能生成两种氧化物,即AO和BO,在合金表面上生成何种氧化物膜取决于合金中的各个成分在合金和氧化物中的扩散速度。假设BO的稳定性大于AO的,在气相中氧压固定的情况下,BO在混合氧化膜中的体积分数会随着B在合金中含量的增加而增大。气相中氧压的变化不但会影响两种氧化物的增长,还会影响每种氧化物在氧化膜中的体积分数。这样,涂层的作用就是避免裸露的合金与氧气接触,从而降低了界面氧压。事实上,在涂层存在的情况下,氧气仍能顺着孔洞、裂纹穿透涂层,甚至发生固态扩散。不论如何,氧的内扩散都会在涂有涂层的合金上受到阻碍。氧化物表面氧气压力的降低是由于涂层的存在降低了两氧化物的生长速率,由于TiO2的分解压要比Al2O3的分解压高,抑制作用更明显,因此,涂层试样氧化膜中的Al2O3的体积分数要比空白试样的大,而TiO2的体积分数则小,这与实验所得结果一致(见图4),也与文献[21]的报道相符合。

溶胶?凝胶法制备的Al2O3涂层提高了γ-TiAl合金在1 000 ℃下的抗循环氧化能力。循环氧化过程中,Ti可能通过固态扩散或沿周期性热循环造成的微裂纹向涂层表面扩散,在气相/涂层界面与O反应生成TiO2,同时侧向生长在涂层表面形成瘤状物。与此同时,O以相同的路径向内扩散,在涂层/基材界面与Al和Ti反应生成TiO2和Al2O3。由于薄膜的存在,涂层样品中Ti的外扩散和O的内扩散的驱动力比空白样品中的受到限制。所以涂层试样的抗氧化性能提高,氧化速率下降。

4 结论

1) 等温氧化时,Al2O3涂层试样的抛物线速率常数比空白样品的降低90%以上。

2) 循环氧化时,γ-TiAl合金空白样氧化7个周期后发生剥落,氧化30个周期之后,开始出现大面积剥落,导致样品的质量减小,而涂层样品的循环氧化动力学与其等温氧化动力学相似,呈现平滑的质量增加趋势。

3) 合金氧化膜主要由TiO2和α-Al2O3组成,涂层试样氧化膜中TiO2的体积分数比空白试样的少,说明涂层抑制了TiO2的生长。

4) 涂层通过隔绝合金基体与外界环境的接触抑制了Ti的外扩散和O的内扩散。

REFERENCES

[1] XIONG Yu-ming, ZHU Sheng-long, WANG Fu-hui, LEE Chang-hee. Effect of vitreous enamel coating on the oxidation behavior of Ti6Al4V and TiAl alloys at high temperatures[J]. J Coat Technol Res, 2008, 1: 93?98.

[2] Yoshihara M, Kim Y W. Oxidation behavior of gamma alloys designed for high temperature applications[J]. Intermetallics, 2005, 13: 952?958.

[3] RAHMEL A, SPENCER P J. Thermodynamic aspects of TiAl and TiSi2 oxidation: The Al-Ti-O and Si-Ti-O phase diagrams[J]. Oxid Met, 1991, 35: 53?68.

[4] JIANG H R, HIROHASI M, LU Y, IMANARI H. Effect of Nb on the high temperature oxidation of Ti-(0-50at%)Al[J]. Scr Mater, 2002, 46: 639?643.

[5] SHIDA Y, ANADA H. The effect of various ternary additives on the oxidation behavior of TiAl in high temperature air[J]. Oxid Met, 1996, 45: 197?219

[6] BECKER S, RAHMEL A, SCHORR M, SCH?TZE M. Mechanism of isothermal oxidation of the intel-metallic and TiAl alloys[J]. Oxid Met, 1992, 38: 425?464.

[7] DU H L, DATTA P K, BURNELL-GRAY J S, LWEIS G B. Effect of Nb coating on the sulphidation/oxidation behavior of Ti and Ti-6Al-4V alloy[J]. Mater Sci, 1995, 30: 2640?2647.

[8] MCKEE D W, LUTHRA K L. Plasma-sprayed coating for titanium alloy oxidation protection[J]. Surf Coat Technol, 1993, 56: 109?117.

[9] CLARK R K, UNNAN J, WIEDEMANN K E. Effect of coating on oxidation of Ti-6Al-2Sn-4Zr-2Mo foil[J]. Oxid Met, 1987, 28: 391?405.

[10] FUJISHIRO S, EYLON D. Improvement of Ti alloy fatigue properties by Pt ion plating[J]. Metall Trans A, 1980, 11: 1259?1263.

[11] TANIGUCHI S, SHIBADA T, TAMADA T, LOU H, WANG F, WU W. Oxidation behavior of TiAl coated with a fine-grain Co-30Cr-4Al film [J]. Oxid Met, 1993, 39: 457?473.

[12] XIONG Y M, ZHU S L, WANG F H. The oxidation behavior and mechanical performance of Ti60 alloy with enamel coating[J]. Surf Coat Technol, 2005, 190: 195?199.

[13] CHU M S, WU S K. The improvement of high temperature oxidation of Ti-50Al sputtering Al film and subsequent interdiffusion treatment[J]. Acta Mater, 2003, 51: 3109?3120.

[14] LIANG W, ZHAO X G. Improvement in the oxidation resistance of TiAl-based alloy by siliconizing[J]. Scr Mater, 2001, 44: 1049?1054.

[15] XIONG H P, XIE Y H, MAO W, MA W L, CHEN Y F, LI X H, CHANG Y Y. Improvement in the oxidation resistance of the TiAl-based alloy by liquid-phase siliconizing[J]. Scr Mater, 2003, 49: 1117?1122.

[16] LI X Y, TANIGUCHI S, MATSUNAGA Y, NAKAGAUM K, FUJITA K. Influence of siliconizing on the oxidation behavior of a γ-TiAl based alloy[J]. Intermetallics, 2003, 11: 143?150.

[17] CHU M S, WU S K. Improvement in the oxidation resistance of α2-TiAl by sputtering Al film and subsequent interdiffusion treatment[J]. Surf Coat Technol, 2004, 179: 257?264.

[18] LI H, LIANG K, MEI L, GU S, WANG S. Oxidation protection of mild steal by zirconia sol-gel coatings[J]. Mater Lett, 2001, 51: 320?324.

[19] ZHANG S, LEE W E, EUR J. Improving the water-wettability and oxidation resistance of graphite using Al2O3/SiO2 sol-gel coating[J]. Ceram Soc, 2003, 23: 1215?1221.

[20] YOLDAS B E. Alumina sol preparation from alkoxides[J]. Am Ceram Soc Bull, 1975, 54: 286?290.

[21] KOBAYASHI E, YOSHIHARA M, TANAKA R. Improvement in oxidation resistance of the intermetallic compound titanium aluminide by heat treatment under a low partial pressure oxygen atmosphere[J]. High Temp Technol, 1990, 8: 179?184.

收稿日期:2008-08-21;修订日期:2009-02-12

通讯作者:张学军,副教授,博士;电话:024-89383297;E-mail: xjzhang_syict@163.com

(编辑 龙怀中)