搅拌铸造制备Al/Al2O3复合材料经挤压后的组织与力学性能

来源期刊:中国有色金属学报(英文版)2013年第5期

论文作者:H. R. EZATPOUR M. TORABI-PARIZI S. A. SAJJADI

文章页码:1262 - 1268

关键词:Al/Al2O3复合材料;搅拌铸造;挤压;显微组织;力学性能

Key words:Al/Al2O3 composite; stir-casting; extrusion; microstructure; mechanical properties

摘 要:采用一种新开发的两步混合法制备Al2O3颗粒增强铝基复合材料。在搅拌速率为300 r/min的条件下,通过惰性气体将不同体积分数的Al2O3颗粒注入到Al熔体中,然后,制备好的复合材料经过挤压加工。显微组织观察结果表明,采用这种注入和挤压工艺制备的复合材料中,增强体颗粒的分布比较均匀。密度测试结果表明,复合材料的孔隙度随Al2O3颗粒体积分数和搅拌速率的增加而升高,经挤压后孔隙度降低。经挤压后复合材料的硬度、屈服强度和抗拉强度均随材料中Al2O3颗粒体积分数的增加而升高(至7%),而未经挤压的复合材料的这些力学性能则只增加到Al2O3颗粒体积分数5%。

Abstract: A novel two step mixing method including injection of particles into the melt by inert gas and stirring was used to prepare aluminum matrix composites (AMCs) reinforced with Al2O3 particles. Different mass fractions of micro alumina particles were injected into the melt under stirring speed of 300 r/min. Then the samples were extruded with ratios of 1.77 or 1.56. The microstructure observation showed that application of the injection and extrusion processes led to a uniform distribution of particles in the matrix. The density measurements showed that the porosity in the composites increased with increasing the mass fraction of Al2O3 and stirring speed and decreased by extrusion process. Hardness, yield and ultimate tensile strengths of the extruded composites increased with increasing the particle mass fraction to 7%, while for the composites without extrusion they increased with particle mass fraction to 5%.

Trans. Nonferrous Met. Soc. China 23(2013) 1262-1268

H. R. EZATPOUR1, M. TORABI-PARIZI2, S. A. SAJJADI1

1. Department of Materials Science and Metallurgical Engineering, Engineering Faculty, Ferdowsi University of Mashhad, Mashhad, Iran;

2. Department of Materials Science and Metallurgical Engineering, Engineering Faculty, Semnan University of Semnan, Semnan, Iran

Received 9 May 2012; accepted 7 April 2013

Abstract: A novel two step mixing method including injection of particles into the melt by inert gas and stirring was used to prepare aluminum matrix composites (AMCs) reinforced with Al2O3 particles. Different mass fractions of micro alumina particles were injected into the melt under stirring speed of 300 r/min. Then the samples were extruded with ratios of 1.77 or 1.56. The microstructure observation showed that application of the injection and extrusion processes led to a uniform distribution of particles in the matrix. The density measurements showed that the porosity in the composites increased with increasing the mass fraction of Al2O3 and stirring speed and decreased by extrusion process. Hardness, yield and ultimate tensile strengths of the extruded composites increased with increasing the particle mass fraction to 7%, while for the composites without extrusion they increased with particle mass fraction to 5%.

Key words: Al/Al2O3 composite; stir-casting; extrusion; microstructure; mechanical properties

1 Introduction

Metal matrix composites (MMCs) have significantly improved properties such as high specific strength, specific modulus, damping capacity and good wear resistance compared to the unreinforced alloys. Aluminum matrix composites (AMCs) reinforced with particles and whiskers are widely used for high performance applications such as automotive, military, aerospace and electricity industries because of their improved physical and mechanical properties [1]. The particulate-reinforced composite can be prepared by injecting the reinforcing particles into liquid matrix through liquid metallurgy route by casting [2-5]. Casting route is preferred as it is less expensive and amenable to mass production. Among the entire liquid state production routes, stir casting is the simplest and cheapest one. The only problem associated with this process is the non-uniform distribution of the particulate due to poor wettability and gravity regulated segregation. Mechanical properties of the composites are affected by the size, shape and volume fraction of the reinforcement, matrix material and reaction at the interface [6]. AGHAJANIAN et al [7] studied the Al2O3 particle reinforced AMCs, with varying particulate volume fraction and reported the improvement in elastic modulus, tensile strength, compressive strength and fracture properties with an increase in the reinforcement content. The interface between the matrix and reinforcement plays a critical role in determining the properties of MMCs. Stiffening and strengthening rely on load transfer across the interface. Toughness is influenced by the crack deflection at the interface and ductility is affected by the relaxation of peak stress near the interface [8].

It is known that secondary processing of discontinuously reinforced composites can lead to the break-up of particle (or whisker) agglomerates. Moreover, the process causes the reduction or elimination of porosity and improves bonding, all of which contribute to improving the mechanical properties of MMCs. Amongst the various classical metal-forming procedures, extrusion has been used as the most common secondary processing operation because of its excellent preferential axial alignment of discontinuous fibers as well as its large compressive hydrostatic stress state [9].

Therefore, the aim of this study is to investigate the effects of different factors, such as mass fraction of the reinforcement particles, stirring speed and extrusion rate, on the microstructure and mechanical properties of the composites.

2 Experimental

In the current work, pure aluminum ingot and particulate alumina powder with size of 20 μm were used as the matrix and reinforcement, respectively. Composite specimens were manufactured by stir-casting method using mechanical mixing of the molten alloy. The particles were injected into the melt by argon gas in a graphite crucible inserted in a resistance heating furnace. The content of alumina powder injected into the composites was chosen as: 3%, 5% and 7% (mass fraction). The crucible was equipped with a bottom pouring system. In the case of stir-casting the injection temperature was 750 °C. Depending on the quantity of the added particles, the injection time was 7-15 min. The stirring continued for 30 min to produce homogenous mixture. The pouring temperature was 650 °C. The speed of impeller was selected as 200, 300 and 500 r/min. The cylindrical samples were extruded with different rates.

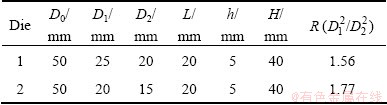

Ax-symmetric hot extrusion of the MMC billets was carried out on a material testing machine with capacity of 25 t. The hot forming process was performed at 500 °C. Two dies with extrusion ratios of 1.56 and 1.77 were employed. A graphite based high temperature lubricant was used. The shape and dimensions of the dies are shown in Fig. 1 and Table 1.

Fig. 1 Shape of conical die

Table1 Die dimensions used for hot extrusion

The specimens were cut by an automatic cutter device to study the microstructure. The specimen surfaces were prepared by grinding through 600 and 1200 grit papers and then by polishing with 3 μm diamond pastes. Microscopic examination of the composites was carried out by optical microscopy (OM). The porosity (volume fraction) of the composites was determined by comparing the measured density with their theoretical density. The Brinell hardness values of the samples were measured on the polished samples using a ball with 2.5 mm in diameter at a load of 98 N. To investigate the mechanical behavior of the composites the tensile and compression tests were carried out using Zwick 760 testing machine according to ASTM E8/E8M-11 and ASTM E9-09, respectively. The crosshead speed was set at 3 mm/min on the round specimens. Each test was repeated three times to obtain average value for each property.

3 Results and discussion

Fabrication of Al-matrix composites with alumina particles by casting process is usually difficult because of the very low wettability of alumina particles and agglomeration phenomena which results in non-uniform distribution and weak mechanical properties. In the present work, pure aluminum (Al 1000) was reinforced with micro sized Al2O3 particles in different mass fractions of 3%, 5% and 7%, respectively.

The composites were successfully produced using a stir-casting method with injection of particles by argon gas and finally extruded at different extrusion rates.

3.1 Microstructure

3.1.1 Effect of mass fraction of reinforcement on microstructure

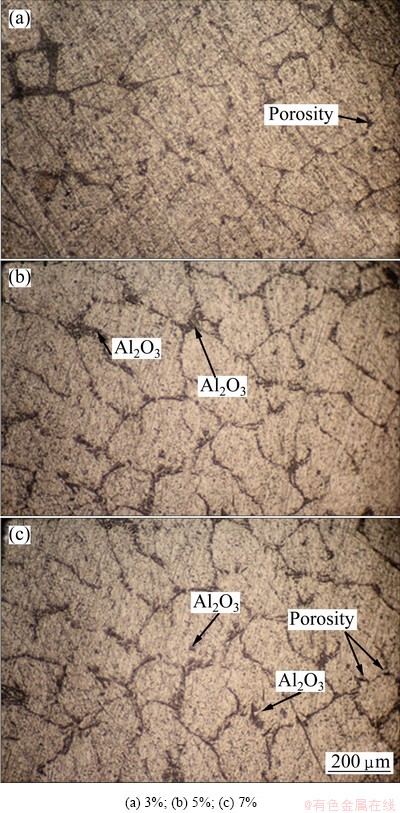

Examination of the composite microstructures shows that Al2O3 particles are uniformly distributed in the matrix, but some regional clusters of smaller particles exist in the as-cast samples. In addition, the micrographs show that the grain size of composite decreases with increasing the addition of particles because the particles act as nucleation sites (Fig. 2). When 3% and 5% alumina are added to the melt (Figs. 2(a) and (b)), the particles are dispersed uniformly with low agglomeration at the matrix, while the further addition (7% Al2O3) of particles causes the agglomeration of particles (Fig. 2(c)).

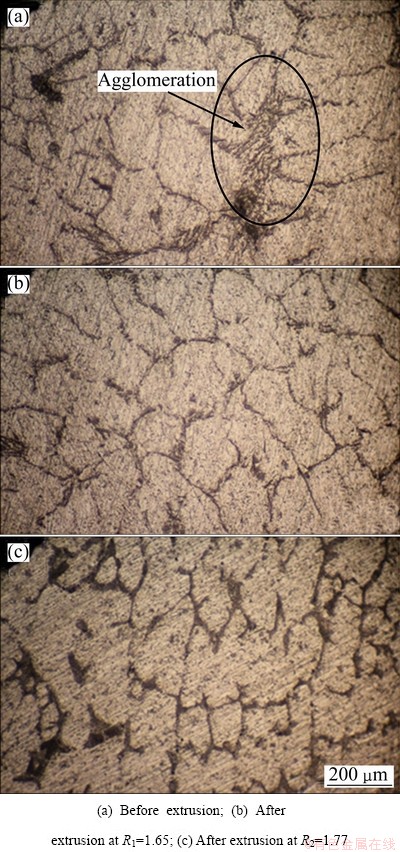

3.1.2 Effect of extrusion on microstructure

Typical optical micrographs of the composites in the as-cast condition and after the extrusion process are shown in Fig. 3. The difference between the as-cast and the hot-extruded composite microstructures is that the Al2O3 clusters which are initially presented in some areas in the as-cast composites have disappeared, giving a more uniform distribution of Al2O3. In addition, some particle orientation occurs. Majority of the previous studies [1,10-12] concerning the effect of plastic deformation on the MMCs microstructure have reported a homogeneous distribution of particles after deformation. It is evident that the particles with no preferred alignment at the die entry tend to align with the extrusion direction towards the die exit.

Fig. 2 Microstructures of composites prepared with different Al2O3 addition and stirring speed of 300 r/min after extrusion (R1=1.65)

3.2 Density and porosity

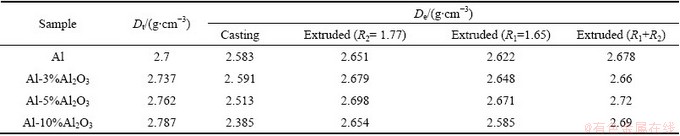

In this study, the density measurements were carried out to determine the porosity level of the samples. The experimental density of the composites was obtained by the Archimedean method through weighing small pieces cut from the composite cylinder first in air and then in water. In addition, the theoretical densities were calculated using the mixture rule [3]. The matrix and Al2O3 particles have the densities of 2.7 and 3.95 g/cm3, respectively [13]. In order to determine the porosity, density measurements were conducted for the unreinforced alloy and the composites reinforced with 3%, 5% and 7% micro Al2O3 particles. The porosity values of the composites in the as-cast state and after the extrusion are presented in Table 2. The difference between the calculated density (Dt), obtained using chemical composition of the composites and the experimental density (De) is due to the existence of pores in the structure.

Fig. 3 Microstructures of composite prepared with 7% Al2O3 at stirring speed of 300 r/min

3.2.1 Effect of mass fraction of reinforcement on porosity

The variation of porosity with Al2O3 addition is shown in Fig. 4. It is shown that the porosity increases with increasing the alumina mass fraction. This is due to the effect of low wettability and agglomeration at high content of reinforcement and pore nucleation at the matrix/Al2O3 interfaces. Moreover, decreasing of liquid metal flow associated with the particle clusters leads to the formation of porosity. Such an observation has been reported in Ref. [3].

3.2.2 Effect of extrusion on porosity

The effect of extrusion process on the porosity of composite is illustrated in Fig. 4 as a function of reinforcement content. As seen in the figure, the as-cast samples possess a higher level of porosity than the extruded ones. Therefore, the application of hot- extrusion process results in approximately 50% reduction in porosity. Plastic working can reduce the porosity and can eliminate pores if the amount of the applied deformation is over 90% [14].

Table 2 Calculated and experimental densities of unreinforced alloy and composites

Fig. 4 Variation of porosity with A2O3 particles content (Stirring speed of 300 r/min)

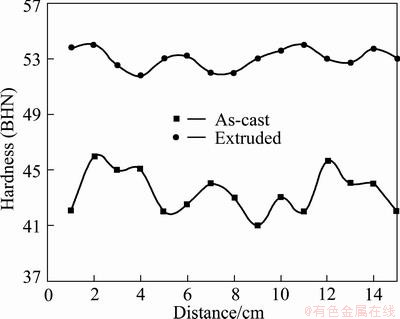

3.3 Hardness

The Brinell hardness measures the overall response of the material and is relatively insensitive to localized effects. However, for composite materials containing a soft matrix and a hard reinforcement phase, like alumina reinforced composites, the selection of region in the sample for evaluating the hardness data is very important. Therefore, in order to obtain the average values of hardness, areas predominant in the soft matrix or in the hard phase should be avoided so that the average values of hardness are attained from these measurements.

3.3.1 Effect of mass fraction of reinforcement on hardness

The hardness values of the composites in the as-cast state and after the extrusion are shown in Fig. 5. Hardness of the composites increases with increasing the particle mass fraction. Higher hardness of the composite relative to that of the Al matrix could be attributed to the reduced grain size and existence of Al2O3 hard particles acting as obstacles to the motion of dislocations [3].

Fig. 5 Variation of hardness with Al2O3 particles content, stirring speed and extrusion (R2=1.77)

3.3.2 Effect of stirring speed on hardness

Figure 5 shows that the hardness of the composite increases with increasing the stirring speed up to 300 r/min because of homogeneous distribution of Al2O3 in the metal matrix and also, partly due to the decreased grain size of the matrix. In addition, according to Fig. 5, at lower stirring speed (200 r/min) the hardness values decrease because of agglomeration and imperfect incorporation of particles. However, when the stirring speed increases too much (500 r/min), the particles are dispersed out of the crucible, so particle addition does not benefit but porosity increases.

3.3.3 Effect of extrusion on hardness

The effect of extrusion process on the hardness of the composite is illustrated in Fig. 5 as a function of reinforcement content. It is understood that the increase in hardness with extrusion can be explained by the improvement of microstructural densification, interface bonding and lowering of porosity. They cause an increase in the hardness more than 20% compared to that of the matrix metal [9]. Also Fig. 6 show that the hardness distribution in the extruded composite is uniform. This can be connected to better homogeneous distribution of Al2O3 in the Al matrix.

3.4 Strength

To investigate the strengthening effects of micro-particles on the tensile properties of the composites such as yield and ultimate tensile strengths, a model has been proposed as [4]

Δσ=Δσload+ΔσHall-Petch+((ΔσOrowan)2+(ΔσCTE)2)1/2 (1)

where Δσload is the shear transfer of load from the soft matrix to the hard ceramic reinforcements during tensile test, especially when there is a good interfacial integrity between the two phases, ΔσHall-Petch is the contribution of grain refinement to the strength levels, ΔσOrowan is the interaction of dislocations with the non-shearable particles and ΔσCTE is the effet of mismatch strain due to the difference between the coefficient thermal expansion (CTE) values of reinforcement (Al2O3) and Al matrix which generates geometrically necessary dislocations and thermally induced residual stresses.

Fig. 6 Effect of extrusion on distribution of hardness of composite with 5% Al2O3 particles prepared (BHN) at 300 r/min (R2=1.77)

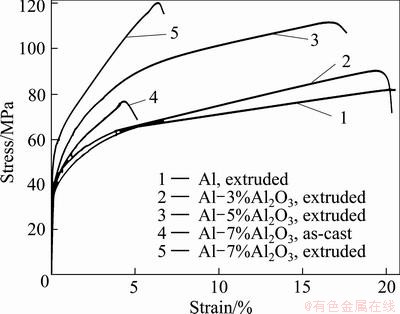

3.4.1 Effect of mass fraction of reinforcement on strength

The stress—strain curves of the composites in the as-cast state and after extrusion are shown in Fig. 7. The main feature of these curves is that the yield strength and tensile strength increase while fracture strain decreases with increasing the particle content.

Fig. 7 Stress—strain curves of composites in as-cast and extruded state (R2=1.77, 300 r/min)

Fig. 8 Variation of 0.2% yield strength (a) and ultimate tensile strength (b) of composites with mass fraction of Al2O3 before and after extrusion (R2=1.77)

Figure 8 shows the variation of 0.2% yield strength and ultimate tensile strength of the composites with different micro-Al2O3 mass fractions. At first, in the extruded composites, the yield and ultimate tensile strengths of the composites increase with Al2O3 content increasing because of increase in load stress (Eq. (1)). The enhancement in tensile strength is partly due to the higher work hardening rate of the particle containing materials [4].

The yield and ultimate tensile strengths of the composite with 7% Al2O3 without extrusion is lower than those of the extruded composites with 5% and 7% Al2O3, because further increase in Al2O3 content in casting composites leads to more agglomeration of particles and higher degree of defects and micro-porosity. Extrusion process leads to: 1) the uniform distribution of particles in matrix, 2) lowering porosity and 3) grain refinement. The results are consistent with the trends reported by other investigators [14-16].

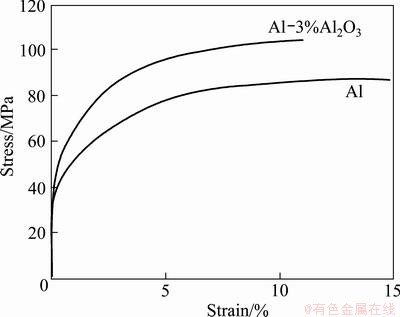

3.4.2 Effect of extrusion on strength

Application of the extrusion process gives rise to an increase in yield and ultimate tensile strengths at room temperature (Figs. 7 and 9). A similar behavior was reported for similar composites [17-20] after forging, hot extrusion and hot rolling, and the improvement in the material strength was explained with the effect of declustering of particles induced by the plastic deformation.

Fig. 9 Stress—strain curves of Al and Al-3%Al2O3 composite after two extrusion stages (R3=R1+R2)

The curves in Fig. 7 indicate that in the as-cast specimens the yield and ultimate tensile strengths increase with increasing the volume fraction of reinforcement up to 5%, but starts decreasing in the specimens containing over 5% Al2O3. In the case of extruded samples, the yield strength increases steadily with the Al2O3 mass fraction increasing. Therefore, improvement in the composite strength can be mainly attributed to the synergistic effect of microstructural changes in the matrix, such as grain refinement, porosity reduction and dissolution of brittle compound [7].

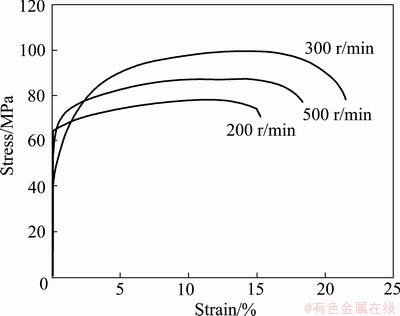

3.4.3 Effect of stirring speed on strength

Figure 10 shows the stress—strain curves of composite with 5% Al2O3 prepared at stirring speeds of 200, 300 and 500 r/min. The strength of the composite increases with increasing stirring speed up to 300 r/min because of homogeneous distribution of Al2O3 in the metal matrix and also, partly due to the decreased grain size of the matrix. Also, strength of composite prepared at 200 and 500 r/min is lower than that at 300 r/min. This might be the result of greater agglomeration of particles, higher degree of defects and micro-porosity presence in the composite and imperfect incorporation of particles.

3.5 Compression strength

The compression stress—strain curves of the Al and Al-5%Al2O3 composite are shown in Fig. 11. The compressive strength of a composite can primarily be attributed to: the significant grain refinement, the presence of reasonably distributed hard particulates, dislocation generation due to elastic modulus mismatch and coefficient of thermal expansion mismatch between the matrix and reinforcement phase, load transfer from matrix to reinforcement phase, Orowan strengthening mechanism and secondary process such as extrusion, rolling [21-23]. According to the results obtained from Fig. 11, it can be concluded that the effect of Al2O3 content and extrusion on the compressive strength is considerable. The effect of extrusion is due to the grain refining and uniform distribution of particles and lowering of defects such as cavities.

Fig. 10 Stress—strain curves of composite with 5% Al2O3 prepared at stirring speeds of 200, 300 and 500 r/min and after extrusion (R2=1.65)

Fig. 11 Compression stress—strain curves of Al and Al- 5%Al2O3 composite

4 Conclusions

1) The further addition of Al2O3 particles (>5%) caused the agglomeration of particles.

2) The hot extrusion resulted in uniform distribution of Al2O3 and particles orientation.

3) The porosity increased with increasing alumina mass fraction and decreased in the extruded ones by approximately 50%.

4) Hardness, yield and ultimate tensile strengths of the extruded composites increased with increasing stirring speed up to 300 r/min.

5) The increase in hardness, yield and ultimate tensile strengths with extrusion can be explained by the improvement of microstructural densification, interface bonding, uniform distribution and grain refining.

6) The compression strength increased with Al2O3 content increasing and extrusion.

Acknowledgment

The authors wish to express appreciation to Research Deputy of Ferdowsi University of Mashhad for supporting this project. We also acknowledge the careful assistant work of H. SADEGHI.

References

[1] CLYNE T W, WITHERS P J. An introduction to metal matrix composites [M]. Cambridge University Press, 1993: 293.

[2] AMIRKHANLOU S, NIROUMAND B. Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 788-793.

[3] SAJJADI S A, TORABI PARIZI M, EZATPOUR H R, SEDGHI A. Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties [J]. Journal of Alloys and Compounds, 2012, 511: 226-231.

[4] SAJJADI S A, EZATPOUR H R, TORABI PARIZI M. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes [J]. Materials and Design, 2012, 34: 106-111.

[5] SAJJADI S A, EZATPOUR H R, BEYGI H. Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting [J]. Materials Science and Engineering A, 2011, 528: 8765-8771.

[6] KAINER K U. Basic of metal matrix composites [M]. Weinheim, Germany: Wiley-VCH, 2006: 1-325.

[7] AGHAJANIAN M K, LANGENSIEPEN R A, ROCAZELLA M A, LEIGHTON J T, ANDERSSON C. A. The effect of particulate loading on the mechanical behaviour of Al2O3/Al metal-matrix composites [J]. Material Science, 1993, 28: 6683-6690.

[8] KUMAR S, ANANDA THEERTHAN J. Fly ash composite using stir casting method [D]. India: National Institute of Technology Rourkela, Indian, 2008: 1-57.

[9] KANG C G, KIM N H, KIM B M. The effect of die shape on the hot extrudability and mechanical properties of 6061Al/Al2O3 composite [J]. Materials Processing Technology, 2000, 100: 53-62.

[10] CESCHINI L, MINAK G, MORRI A. Forging of the AA2618/20vol% Al2O3p composite: Effects on microstructure and tensile properties [J]. Composites Science and Technology, 2009, 69: 1783-1789.

[11] LIU Y B, LIM S C, LU L, LAI M O. Fabrication of metal-matrix- particulate composites using powder metallurgy techniques [C]// Metal Matrix Composites. Vol. I. Proceedings of the ICCM/9. Spain: Woodhead Publishing Limited, 1993: 770-778.

[12] LAWERENCE C W, MUMMERY P M, WEED J H T. Observations of extrusion-induced damage of metal–matrix composites [J]. Material Science Letter, 1993, 12: 647-649.

[13] SEVIK H, CAN KURNAZ S. Properties of alumina particulate reinforced aluminum alloy produced by pressure die casting [J]. Material and Design, 2006, 27: 676-683.

[14]  K. Ductility and strength of extruded SiCp/aluminum-alloy composites [J]. Composites Science and Technology, 2002, 62: 275-282.

K. Ductility and strength of extruded SiCp/aluminum-alloy composites [J]. Composites Science and Technology, 2002, 62: 275-282.

[15] KOK M. Production and mechanical Properties of Al2O3 particle-reinforced 2024 aluminum alloy composites [J]. Materials Processing Technology, 2005, 161: 381-387.

[16] SAJJADI S A, ZEBARJAD S M. Influence of nano-size Al2O3 weight percent on the microstructure and mechanical properties of Al-matrix nanocomposite [J]. Powder Metallurgy, 2010, 8: 71-78.

[17] SEO Y H, KANG C G. Effects of hot extrusion through a curved die on the mechanical properties of SiCp/Al composites fabricated by melt-stirring [J]. Composite Science and Technology, 1999, 59: 643-654.

[18] ROSSO M. Ceramic and metal matrix composites: Routes and properties [J]. Materials Processing Technology, 2006, 175: 364-375.

[19] ROZAK G A, ALTMISOGLU A, LEZANDOWSKI J J, FALLANCE J F. Effects of casting conditions and deformation processing on A356 aluminum and A356-20vol.% SiC composites [J]. Composite Material, 1992, 26: 2076-2106.

[20]  The effect of forging on the properties of particulate SiC reinforced aluminum alloy-composites [J]. Composite Science and Technology, 2000, 60: 411-419.

The effect of forging on the properties of particulate SiC reinforced aluminum alloy-composites [J]. Composite Science and Technology, 2000, 60: 411-419.

[21] ANSARY YAR A, MONTAZERIAN M, ABDIZADEH H, BAHRAVANDI H R. Microstructure and mechanical properties of aluminum alloy matrix composite reinforced with nano-particle MgO [J]. Journal of Alloys and Compound, 2009, 484: 400-404.

[22] NGUYEN Q B, GUPTA M. Compressive response of AZ31B using nano-Al2O3 and copper additions [J]. Journal of Alloys and Compound, 2010, 490: 382-387.

[23] SASTRY S, KRISHNAB M, UCHIL J. Effect of thermal stresses on the thermal expansion and damping behavior of AZ-27/aluminite metal matrix composites [J]. Journal of Materials of Materials Engineering and Performance, 2001, 10(5): 220-224.

H. R. EZATPOUR1, M. TORABI-PARIZI2, S. A. SAJJADI1

1. Department of Materials Science and Metallurgical Engineering, Engineering Faculty, Ferdowsi University of Mashhad, Mashhad, Iran;

2. Department of Materials Science and Metallurgical Engineering, Engineering Faculty, Semnan University of Semnan, Semnan, Iran

摘 要:采用一种新开发的两步混合法制备Al2O3颗粒增强铝基复合材料。在搅拌速率为300 r/min的条件下,通过惰性气体将不同体积分数的Al2O3颗粒注入到Al熔体中,然后,制备好的复合材料经过挤压加工。显微组织观察结果表明,采用这种注入和挤压工艺制备的复合材料中,增强体颗粒的分布比较均匀。密度测试结果表明,复合材料的孔隙度随Al2O3颗粒体积分数和搅拌速率的增加而升高,经挤压后孔隙度降低。经挤压后复合材料的硬度、屈服强度和抗拉强度均随材料中Al2O3颗粒体积分数的增加而升高(至7%),而未经挤压的复合材料的这些力学性能则只增加到Al2O3颗粒体积分数5%。

关键词:Al/Al2O3复合材料;搅拌铸造;挤压;显微组织;力学性能

(Edited by Sai-qian YUAN)

Corresponding author: H. R. EZATPOUR; Tel: +98-511-8763305; E-mail: k_datam63@yahoo.com

DOI: 10.1016/S1003-6326(13)62591-1