文章编号:1004-0609(2014)01-0179-09

温度对铸态SiCp/A356复合材料滑动摩擦磨损特性的影响

金云学1,王小丫1,童强强1,陈洪美1,Jung-Moo LEE2

(1. 江苏科技大学 江苏省先进焊接技术重点实验室,镇江 212003;

2. Korea Institute of Machinery and Materials,Changwon 641—010,Korea)

摘 要:以Al2O3陶瓷球为对偶材料,借助UMT-2摩擦磨损试验机详细研究温度变化对复合材料干滑动摩擦磨损特性的影响,并用SEM、EDS、奥林巴斯激光共焦扫描显微镜分析铸态SiCp/A356复合材料的高温摩擦磨损行为。结果表明:复合材料的磨损率对温度变化很敏感,在200 ℃以下,磨损率及其变化较小,以氧化磨损机制为主,属于轻微磨损;当温度达到250 ℃及以上时,磨损率开始急剧上升,磨损表面出现严重塑性流动痕迹,磨损面上出现磨屑粘着堆积的凸起,同时形成大量的大尺寸的磨屑,此时以粘着磨损机制为主,同时存在少量的氧化磨损。氧化磨损阶段,摩擦因数虽有变化,但相对稳定;但粘着磨损阶段,摩擦因数变得极度不稳定,出现尖锐的峰值。

关键词:SiCp/A356复合材料;制动盘;滑动摩擦;磨损

中图分类号:TH117.3;TF1 文献标志码:A

Effect of temperature on friction and wear characteristics of as-cast SiCp/A356 composite

JIN Yun-xue1, WANG Xiao-ya1, TONG Qiang-qiang1, CHEN Hong-mei1, Jung-Moo LEE2

(1. Provincial Key Laboratory of Advanced Welding Technology,

Jiangsu University of Science and Technology, Zhenjiang, 212003, China;

2. Korea Institute of Machinery and Materials,Changwon 641-010, Korea)

Abstract: The influence of temperature change on the dry sliding friction and wear characteristics of as-cast SiCp/A356 composite was investigated on UMT-2 tribometer by using Al2O3 ceramic ball as dual material. The high temperature friction and wear behavior of the composite material were analyzed by SEM, EDS and Olympus confocal laser scanning microscope. The results show that the wear rate of the composites is very sensitive to the change of temperature. When temperature is less than 200 ℃, the wear rate and its change are relatively smaller. The wear mechanism is mainly oxidation wear, which is one form of mild wear. When the temperature reaches or is above 250 ℃, the wear rate increases quickly. And on the wear surface, there are severe plastic flowing wear traces, the bulge of stacked swarf adhesion and a large number of large sized wear debris. The wear mechanism mainly is adhesive wear and there is a small amount of oxidation wear as well. At oxidation wear stage, although the friction coefficient changes, but it is relatively stable. While at adhesion wear stage, the friction coefficient becomes extremely unstable, and a sharp peak appears.

Key words: SiCp/A356 composite; brake disc; sliding friction; wear

高速化、轻量化、低能耗是当今交通运输车辆的主要发展趋势,而设法有效降低车辆自身的质量是实现高速化、轻量化、低能耗的关键,其中制动盘是列车簧下关键部位,且是质量最大的关键部件之一,对列车的加速和制动性能有着重要影响。所以,列车用制动盘材料必须满足5个方面的性能要求:1) 稳定的摩擦性能;2) 良好的耐热疲劳性能;3) 较高的耐磨损性能;4) 较高的热容量;5) 良好的导热性[1]。由于SiCp/Al复合材料具有较高的强度和刚度、优异的耐磨性能、良好的导热性能和较低的热膨胀系数等突出优点,现已成为高速列车制动盘研究的重要候选材料之一。美国Dural Aluminum公司用ZL104铝合金加入SiC颗粒制作了复合材料制动盘[2]。Knorr Bremse AG采用Duralcan生产的20%SiCp/AlSi7Mg复合材料研制了高速列车刹车盘用于德国ICE-2高铁。国内部分研制单位已经成功制备了铝基复合材料制动盘样件[3],并通过了台架实验[4]。

作为制动盘材料其滑动摩擦磨损性能无疑是非常重要的,因其影响因素多[5],且互相存在交互作用,使其磨损特性复杂化,吸引更多研究工作者从事相关研究。有关铝复合材料摩擦特性研究报道虽较多[6-9],针对其高温磨损行为也不少[10-14],但作为高速列车制动盘材料研究较多的SiCp /A356复合材料,其在高温下的摩擦特性研究远远不足,且制动盘在使用过程中,因为摩擦而产生大量热量,实际磨损更接近高温磨损。因此,本文作者选用由韩国国家材料研究院(KIMS)国家重点实验室制备的用于高速列车制动盘的SiCp/ A356复合材料,详细研究了铝基复合材料的高温摩擦磨损性能。

1 实验

1.1 试样制备

实验所用材料为韩国KIMS重点实验室提供的SiCp/Al铸锭,该复合材料用于制备高速列车制动盘样件(直径为635 mm)。增强相为SiC颗粒,其平均尺寸为20 μm,加入量为20%(体积分数),基体合金A356化学组成(质量分数,下同)如下:Si为6.58%、Mg为0.44%、Fe为0.39%、Cu为0.01%、Zn为0.01%、Ti为 0.01%。

1.2 摩擦磨损实验

采用美国CETR公司生产的UMT-2型球-盘式摩擦磨损实验装置进行高温干滑动摩擦磨损实验。复合材料试样尺寸为20 mm×20 mm×2.5 mm,对磨材料采用d 9.38 mm的Al2O3陶瓷球。实验条件如下:滑动速度150 r/min,载荷为6 N,相对滑动时间为30 min,环境温度分别为100、150、200、250和300 ℃。实验前,每个试样磨损表面均采用金相砂纸研磨到1000号,使它们具有相同的表面粗糙度。磨损实验前后,将试样浸入酒精溶液,经超声波清洗,感量为0.1 mg的分析天平检测磨损质量损失,并除以滑动距离以转换为磨损率;摩擦因数由与磨损实验机相连的计算机上的数据采集系统采集而得。采用SEM观察磨损表面及磨屑形貌,通过EDS检测相应区域的成分,用奥林巴斯激光共焦扫描显微镜OLS4000分析磨痕的粗糙度。

2 结果与分析

2.1 温度对滑动摩擦磨损率的影响

图1所示为SiCp/A356复合材料在干滑动摩擦磨损时磨损率随温度变化。由图1可知,总体上磨损率随着温度的升高而增加,但不同温度下的增加幅度不同。当温度在200 ℃以下,温度变化的影响相对很小,磨损率只增加50%(由0.028 3 μg/cm增加到0.042 5 μg/cm),曲线相对较平缓;但温度超过200 ℃时,磨损率开始大幅上升,越趋于高温区,磨损量的增加越激烈;当温度达到300 ℃时,与100 ℃下相比,磨损率增加了1348%(由0.028 3 μg/cm增加到0.41 μg/cm)。实验过程中表现为开始出现少量的细小磨屑;继续升高温度,由于磨损进入激烈磨损阶段,形成肉眼可见的块状磨屑,曲线呈线性增长,磨损率急剧上升。这是由于材料的硬度决定了接触材料表面的真实接触面积,从而与材料的耐磨性有着非常密切的联系。随着温度的升高,SiC颗粒与基体的结合强度降低,容易材料表面脱落,从而导致硬度降低,耐磨性有所下降。所以从磨损率的角度来看,温度低于200 ℃时,其主要发生轻微磨损,而温度超过250 ℃后则进入激烈的严重磨损阶段。

图1 SiCp/A356复合材料的磨损率随温度变化

Fig. 1 Variations of wear rate of SiCp/A356 composite with temperature

2.2 温度对摩擦系数的影响

作为高速列车制动盘材料,不仅要具有优良的耐磨性(为提高制动盘寿命),同时为保证制动的稳定性,要求具有大且对环境变化不敏感的摩擦因数。图2所示为摩擦因数随温度的变化曲线。由图2可见,铝基复合材料的摩擦因数随温度升高而波动,200 ℃以下基本呈现上升趋势,而200 ℃以后基本呈现下降趋势。从摩擦因数数据的均方差值看,随着温度的提高,摩擦因数的分散度增加,即摩擦稳定性是下降的。因为材料的摩擦因数与SiC颗粒与基体的结合强度有关,随着温度的升高,基体出现软化的现象,导致颗粒与基体的结合能力下降,所以摩擦因数出现波动。但总体上摩擦因数平均值的变化较小,在0.43~0.54范围内波动。

图2 SiCp/A356复合材料的摩擦因数随温度变化

Fig. 2 Variations of friction coefficient of SiCp/A356 composite with temperature

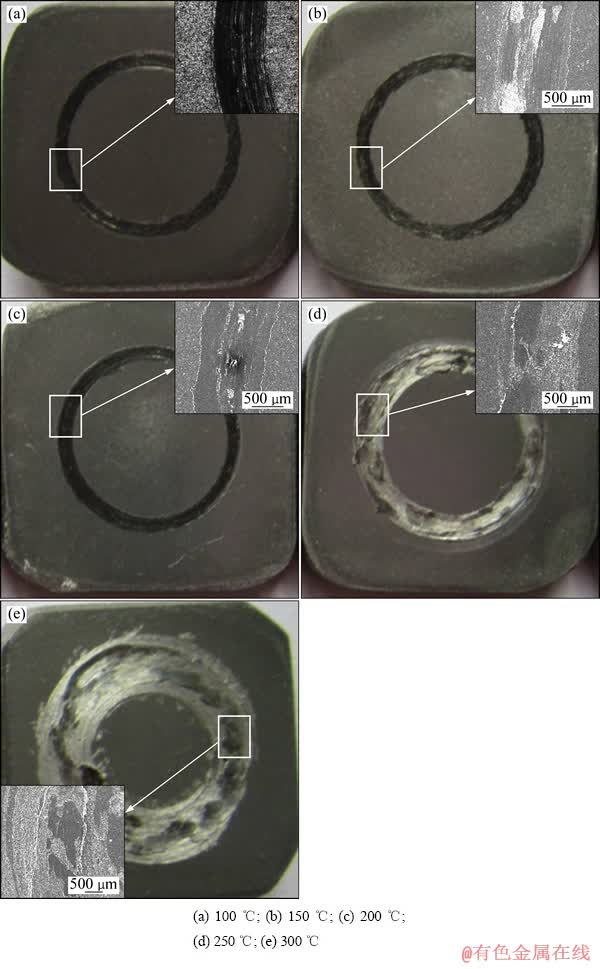

图3 SiCp/A356复合材料不同温度下磨损表面的宏观形态

Fig. 3 Macromorphologies of wear surface of SiCp/A356 composite at different temperatures

2.3 磨损面及磨屑形貌

SiCp/A356复合材料在常温下的滑动摩擦磨损的研究表明,通常多种磨损机制同时存在并对材料的摩擦磨损性能产生影响[15]。从图1的结果看,高温下滑动摩擦磨损过程,也同时存在不同的磨损机制。图3所示为SiCp/A356复合材料在不同温度下经滑动摩擦磨损实验后的磨损面的宏观形貌。从图3中可以看出,在200 ℃以下,磨痕浅且细(见图3(a)~(c)),表面光滑平整呈黑色,宏观上表现出磨损率很小(见图1)。表面的黑色表明,复合材料发生氧化,而此时磨屑很少且极细,因此可以初步推断此时主要发生氧化磨损。试样及环境温度提高到250 ℃以上时,由于温度升高使复合材料强度和硬度降低,磨损表面出现严重的塑性变形层,同时大量的磨屑粘附在摩擦轨迹不同位置,且出现堆积现象,导致表面粗糙不平,磨痕大且深呈银白色(见图3(d)~(e)),因此,出现图1所示的磨损率线性增加的现象,从中大致可以判断为出现严重的粘着磨损。

图4所示为通过OLS4000型奥林巴斯激光共焦扫描显微镜检测的不同温度下磨痕的粗糙度曲线及粗糙度测量位置。由图4可见,随着温度的升高,磨痕的粗糙度逐渐增大,由7.015 μm增大到12.035 μm(考虑到此时磨痕表面不平整,存在堆积层,此值为检测5个部位的平均值)。温度低于200 ℃时,粗糙度值变化很小(仅增加9.4%),表明此时磨损率的增加较小;而实验温度从200 ℃增加到300 ℃时,磨痕粗糙度值变化很大(增加92.5%),表明此时温度的增加带来磨损率的急剧增加,与图1的实验结果相吻合。这种摩擦磨损过程中磨痕粗糙度的变化将对制动盘的性能带来较大影响。磨损表面的粗糙度不仅影响材料的疲劳强度,还影响其耐磨性,因为随着磨损的进行,磨痕面粗糙度增大,其表面变的不平整,导致复合材料和对偶材料的有效接触面积减小,磨痕表面所受到的压力增大,滑动要克服的障碍增多,从而使摩擦因数增大,同时,磨损加快,材料损耗加速,最终可能导致制动盘使用寿命缩短。

图4 SiCp/A356复合材料磨痕的粗糙度

Fig. 4 Roughness of wear scar of SiCp/A356 composite

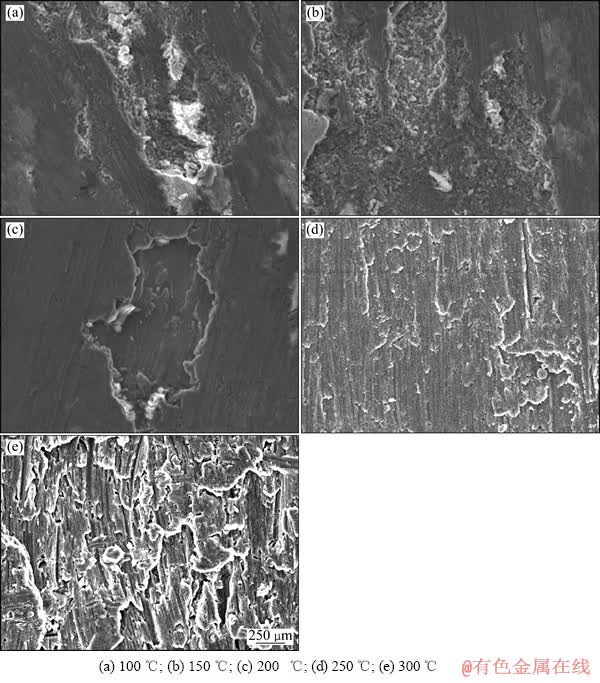

图5 不同温度下的磨损表面形貌

Fig. 5 Morphologies of worn surface of SiCp/A356 composite at different temperatures

随着温度的升高,材料的表面受到了不同程度的破坏。图5所示为材料在不同温度下磨损后的磨痕面形貌。由图5可见,对应图1的轻微磨损的温度部分的磨痕(200 ℃以下),其磨损面形态基本一致,磨损面除了较浅的犁沟外还有磨屑脱落后留下的凹坑(见图5(a)和(b))。这是由于在磨损过程中,材料表面的SiC颗粒在Al2O3陶瓷球和旋转力矩的切削作用下,产生塑性变形,在局部产生大量热量,使复合材料发生部分氧化,SiC颗粒破碎并从材料表面脱落形成磨屑,导致磨损面上出现凹坑。200 ℃时的磨损面塑性变形痕迹开始比较明显,并出现剥离痕迹(见图5(c)),剥离部分存在明显的犁沟,这是由于在磨损初期,从材料表面脱落的SiC颗粒而形成的磨屑附在Al2O3陶瓷球接触表面,形成三体磨损,犁削材料表面而成;进入磨损中期,复合材料表面开始产生细粉状磨屑经过反复地切削磨损作用,破碎为更细小的颗粒,并被碾压平铺于磨痕表面,随着磨损进行,部分被碾压堆积的磨屑剥落。250 ℃以上的磨损面形态类似,但磨损程度不同。相对于在250 ℃时的磨损面(见图5(d)),300 ℃的磨损面更粗糙,塑性流动更加严重,且形成明显的波浪纹(见图5(e))。原因是在高温磨损载荷作用下,磨损形成的磨屑由于高温影响在新的表面产生粘着、焊合,随后又被切断、转移,使磨损表面形成犁沟,产生较大的塑性变形,产生大量块状磨屑。同时,大量磨屑从磨损试样转移到Al2O3陶瓷球表面粘附,使得对偶材料表面被复合材料所覆盖,磨损材料不能与其直接接触,这样摩擦磨损在同种材料之间发生。由于高温作用使铝合金的塑性增加,摩擦因数增加,同时极易造成试样与对偶件(表层粘附着磨屑)的粘合,磨损量也大幅度增加,形成大量块状的磨屑。此阶段以粘着磨损机制为主。

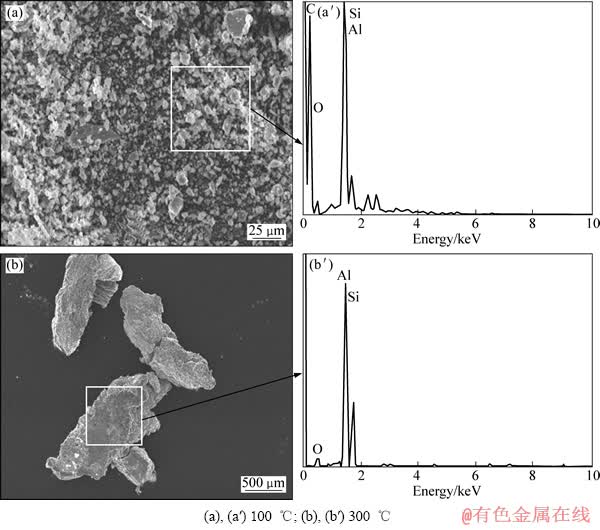

图6 不同温度下的磨屑形貌及其EDS谱

Fig. 6 Morphologies and EDS of wear debris at different temperatures

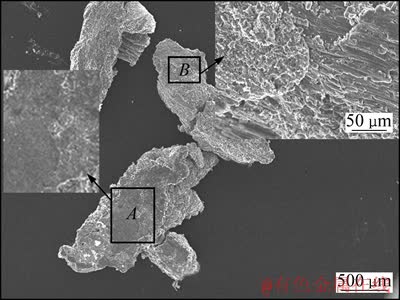

摩擦磨损过程中磨屑是摩擦副双方相互作用的结果,因此,磨屑的形貌,尺寸、数量及化学成分的变化可以反映出磨损率的大小及摩擦磨损机制。因此,通过对磨屑的分析,可以在一定程度上分析出磨损的机制。图6所示为复合材料在不同温度条件下磨损后的磨屑形貌及局部区域能谱分析图。通过摩擦磨损过程中产生的磨屑形成过程、宏观形貌及图6所示的SEM观察发现,磨屑主要有两种形态:一是在较低温度时,在图1所示的轻微磨损过程中产生的磨屑,它宏观上呈现非常细小的粉末状;二是随着温度升高,进入严重磨损阶段时产生的磨屑,宏观上呈银白色的粗大的块状,也存在一些比较小的磨屑,但它们所占体积分数甚小。100 ℃温度下形成的黑色细小磨屑尺寸在10 μm以下。由图6(a)的能谱分析结果可知,除了Al、Si外存在较多的O,这部分O来自摩擦磨损过程中表面氧化形成的Al2O3,表明这个阶段的磨损以氧化磨损为主,相同材料在常温下的干滑动摩擦磨损研究中,采用与本实验相近的载荷下,同样形成细小黑色磨屑,分析结果为氧化磨损为主的磨损过程[16],本实验从磨损面及磨屑的分析中可得出相同的结论。300 ℃温度下形成的磨屑,其形状为块状,尺寸约400~1 000 μm(见图6(b))。这些大尺寸的块状磨屑表面也明显呈两种不同形式,一种为表面呈黑色,比较光洁(见图7中A区),此表面为磨损初期复合材料和对偶材料相互摩擦形成的。表层局部凸起被碾压塑性变形,并表层氧化形成的。与对偶材料接触的表面,另一种表面为呈银白色,表面粗糙且存在明显塑形流动的痕迹(见图7中B区)。此面应为磨屑形成过程中磨屑和复合材料基体的撕裂面,此形状的磨屑为较为典型的粘着磨损磨屑,此阶段形成的磨屑都以大尺寸的块状磨屑为主,同时存在少量细小黑色磨屑。因此可推断,在高温下磨损以粘着磨损为主,同时存在微量的氧化磨损。

2.4 磨损断面分析

图7 块状磨屑表面形貌

Fig. 7 Morphology of massive debris surface

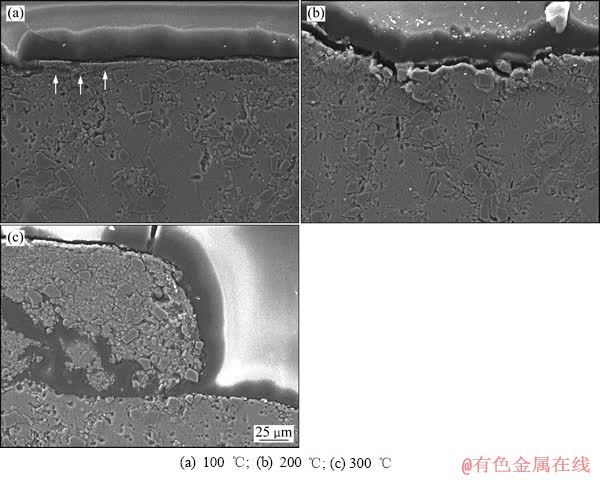

图8 不同温度下SiCp/A356复合材料磨损断面形貌

Fig. 8 Morphologies of cross-section of worn surface of SiCp/A356 composite at different temperatures

图9 不同温度时SiCp/A356复合材料的摩擦因数曲线

Fig. 9 Friction coefficients curves of SiCp/A356 composites at different temperatures

材料在摩擦磨损过程中,不仅表层遭受到一定程度的破坏,同时,由于摩擦力和旋转力矩等的作用,次表层也会受到一定程度的影响。图8所示为SiCp/A356复合材料材料在不同温度下的磨损断面形貌。由图8可见,温度为100 ℃时,复合材料出现了一定的裂纹(见图8(a)中箭头),裂纹的存在,说明材料即将开始遭到破坏脱落;当温度升高到200 ℃时,复合材料的磨损断面高低起伏不平,存在明显的磨削痕迹,还有部分SiC颗粒脱落的现象(见图8(b))。这是由于环境温度的升高,导致对磨材料之间的温度升高,基体出现变形,使得材料中的增强颗粒SiC暴露与对磨材料Al2O3陶瓷球直接接触,随着磨损过程的进行,暴露在外的SiC颗粒脱落破碎。温度进入高温区,达到300 ℃时(见图8(c)),复合材料的塑性流动痕迹非常明显,而且存在明显的SiC颗粒堆积现象。所以,随着温度的升高,材料的磨损越来严重。

2.5 摩擦因数分析

为了列车的制动稳定性,制动盘材料还要求在整个制动过程中始终具有稳定的摩擦因数值,而制动过程又是温度、载荷、速度等都在变化的动态过程,因此,研究制动盘材料的摩擦磨损性能需要同时研究不同条件下的摩擦因数变化规律。

图9所示为复合材料在不同温度下的摩擦因数在实验过程中的变化曲线。实验过程中,摩擦因数曲线越平缓,则说明该材料的摩擦性能越稳定。由图9可见,材料的摩擦因数随时间变化较大,曲线前后起伏较明显。起始阶段摩擦因数在试验的前2~10 s变化较大,随着磨损的进行摩擦因数快速上升。这是由于在试验初期,试验处于跑合阶段,SiC颗粒承载大部分的载荷,复合材料和对磨材料(Al2O3陶瓷球)之间实际接触面较小;随着磨损的进行,摩擦副间的真实接触面积增大,摩擦阻力也不断增加,从而摩擦因数明显增大。且随着温度的变化,摩擦因数存在明显的差异。温度较低时,摩擦因数曲线整体比较平缓,随着时间的波动较小,没有出现尖锐的峰,摩擦性能相对较稳定。

但随着温度的升高,摩擦因数开始出现波动,且随时间延长,呈现略微增大趋势,当温度超过200 ℃时,摩擦因数随时间变化波动很大,出现瞬间的尖锐的峰值,尖锐的峰值应对应于如图9(d)~(e)所示磨损面上出现磨屑堆积处与对偶材料的接触,摩擦时对偶材料触碰到凸起点,摩擦阻力增加,使摩擦因数出现尖锐的峰值。当磨损面上出现这些凸起时,摩擦因数变得时高时低,其稳定性相当差。总体上不同温度下的摩擦因数曲线符合温度对摩擦因数的影响规律[17-18]。制动盘在一次制动过程中,其表面温度会动态变化,因此,上述不同温度下的摩擦系数变化规律将有助于了解制动过程中制动力的变化规律。

3 结论

1) 当温度为100~200 ℃时,复合材料磨损率较小,呈现轻微磨损;但随着温度上升超过250 ℃时,其磨损率开始大幅度上升,进入严重磨损阶段。

2) 100 ℃时,复合材料摩擦因数稳定,随着温度的升高,摩擦系数呈现增加趋势;当温度超过200 ℃时,摩擦因数呈不规则变化,出现尖锐的峰值,此变化与磨损面形貌变化紧密相关。

3) 轻微磨损阶段复合材料的磨损以氧化磨损为主,形成少量细小的黑色磨屑,随着温度的升高,进入严重磨损阶段,将以粘着磨损为主,形成大尺寸的块状磨屑。

REFERENCES

[1] 杨 月. 高速列车SiCp/A356复合材料制动盘热疲劳评价方法研究[D]. 北京: 北京交通大学, 20081.

YANG Yue. Research on thermal fatigue evaluation method of SiCp/A356 composite brake disc for high-speed train[D]. Beijing: Beijing Jiaotong University, 2008.

[2] 刘 政, 刘小梅. 国外铝基复合材料的开发与应用[J]. 轻合金加工技术, 1994(1): 7-10.

LIU Zheng, LIU Xiao-mei. Foreign aluminum composite material development and application[J]. Journal of Light Alloy Processing Technology, 1994(1): 7-10.

[3] 樊建中, 石力开. 颗粒增强铝基复合材料研究与应用发展[J]. 宇航材料工艺, 2012(1): 4.

FAN Jian-zhong, SHI Li-kai. Development and application of particulate reinforced aluminum matrix composites[J]. Space material technology, 2012(1): 4.

[4] 朱龙驹, 陈喜红, 齐 斌, 陈振华, 陈 刚, 严红革. 高速列车铝基复合材料制动及其闸片的研制[J]. 电力机车与城轨车辆, 2006, 29(1): 1-4.

ZHU L J, CHEN X H, QI B T. Electric locomotives&mass transit vehicles[J]. Electric Locomotive & Mass Transit Vehicles, 2006, 29(1): 1-4.

[5] COOGAN T P, LATTA D M, SNOW E T, COSTA M. Toxicity and carcinogenicity of nickel compounds[J]. CRC Critical Reviews in Toxicology, 1989, 19: 341-384.

[6] 陈体军, 袁承人, 郝 远, 李 健. 原位自身Sip/ZA27复合材料的磨损性能[J]. 中国有色金属学报, 2008, 18(7): 1231-1236.

CHEN Ti-jun, YUAN Chen-rei, HAO Yuan, LI Jian. Wear properties of in-situ Sip/ZA27 composites[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1231-1236.

[7] 陈聪聪, 陈 刚, 严红革, 苏 斌. 颗粒增强铝基梯度复合材料的摩擦磨损性能[J]. 中国有色金属学报, 2011, 21(6): 1259-1264.

CHEN Cong-cong, CHEN Gang, YAN Hong-ge, SU Bin. Friction and wear properties of particle reinforced graded aluminum matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1259-1264.

[8] LENG L F, JIANG L T, WU G H, TIAN Shou-fu, CHEN Guo-qin. Effect of graphite particle reinforcement on dry sliding wear of SiC/Gr/Al composites[J]. Rare Metal Materials and Engineering, 2009, 38(11): 1894-1898.

[9] 杜 军, 李文芳, 刘贯军. 富Ce混合稀土对铝基混杂复合材料耐磨性能的影响[J]. 中国有色金属学报, 2006, 16(1): 85-88.

DU Jun, LI Wen-fang, LIU Guan-jun. Effect of Ce riched rare earth on wear resistance of aluminum-based hybrid compsites[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 85-88.

[10] 杨 忠, 李建平, 郭永春. SiCp增强高强耐热铝基复合材料的高温摩擦磨损行为[J]. 铸造, 2006, 55(10): 1043-1046.

YANG Zhong, LI Jian-pin, GUO Yong-chun. Friction and wear behavior at elevated temperature of SiCp paniculata reinforced high strength and heat-resistant aluminum based composites[J]. Foundry, 2006, 55(10): 1043-1046.

[11] 彭开萍, 陈文哲, 钱匡武. Al2O3-SiO2/ZL108复合材料的高温磨损性能[J]. 中国有色金属学报, 2001, 21(6): 87-90.

PENG Kai-ping, CHEN Wen-zhe, QIAN Kuang-wu. High-temperature wear resistance of Al2O3-SiO2/ZL108 composites[J]. The Chinese Journal of Nonferrous Metals, 2001, 21(6): 87-90.

[12] 李 伟, 涂铭旌, 赵晰明. 氧化铝短纤维增强铝硅合金复合材料高温摩擦磨损性能的研究[J]. 机械工程材料, 1997, 21(2): 37-39.

Study on the tribological behavior of alumina-fiber reinforced Al-Si eutectic alloy at elevated temperature[J]. Mechanical Engineering Material, 1997, 21(2): 37-39.

[13] 宋延沛, 谢敬佩, 祝要民. Al2O3P/ ZA27复合材料的高温摩擦磨损特性[J]. 中国有色金属学报, 2002, 12(1): 123-125.

SONG Yan-pei, XIE Jing-pei, ZHU Yao-min. Friction and wear behaviors of Al2O3/ZA27 composites at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(1): 123-125.

[14] 梁艳峰, 周敬恩, 董晟全, 杨 通. 原位增强Al-4.5Cu合金的高温干摩擦磨损行为研究[J]. 特种铸造及有色合金, 2006, 26(8): 515-517.

LIANG Yan-feng, ZHOU Jing-en, DONG Sheng-quan, YANG Tong. High temperature dry friction and wear behavior research of situ strengthen Al-4.5 Cu alloy[J]. Special Casting and Nonferrous Alloy, 2006, 26(8): 515-517

[15] 戴雄杰. 摩擦学基础[M]. 上海: 上海科学技术处出版社, 1984.

DAI Xiong-jie. Tribology basis[M]. Shanghai: Shanghai Science and Technology Press, 1984.

[16] 金云学, Jung-Moo LEE, Suk-Bong KANG. 铝基复合材料的干滑动摩擦磨损特性及磨损机制[J]. 特种铸造及有色合金, 2008: 347-350.

JIN Yun-xue, LEE Jung-Moo, KANG Suk-Bong. Dry sliding friction and wear characteristics and wear mechanism of aluminum matrix composite[J]. Special Casting and Nonferrous Alloys, 2008: 347-350.

[17] YEN B K, TADASHI ISHIHARA. An investigation of friction and wear mechanisms of carbon-car bon composites in nitrogen and air at elevated temperatures[J]. Carbon, 1995, 34(4): 489-498.

[18] YEN B K, TADASHI ISHIHARA. On temperature- dependent tribological regimes and oxidation of carbon- carbon composites up to 1800[J]. Wear, 1996, 196: 254-263.

(编辑 李艳红)

收稿日期:2012-11-06;修订日期:2013-10-06

通信作者:金云学,教授,博士;电话:13775361375;E-mail:jinyunxue@126.com