Mechanism of high pressure roll grinding on compression strength of oxidized hematite pellets

来源期刊:中南大学学报(英文版)2012年第9期

论文作者:范建军 邱冠周 姜涛 郭宇峰 郝海正 杨永斌

文章页码:2611 - 2619

Key words:hematite concentrate; pellet; high pressure roll grinding (HPRG); specific surface area; lattice defect; dispersion degree; micro-sized particle

Abstract: The mechanism of high pressure roll grinding on improvement of compression strength of oxidized hematite pellets was researched by considering their roasting properties. The results indicate that oxidized hematite pellets require higher preheating temperature and longer preheating time to attain required compression strength of pellets compared with the common magnetite oxidized pellets. It is found that when the hematite concentrates are pretreated by high pressure roll grinding (HPRG), the compression strengths of preheated and roasted oxidized hematite pellets get improved even with lower preheating and roasting temperatures and shorter preheating and roasting time. The mechanism for HPRG to improve roasting properties of oxidized pellets were investigated and the cause mainly lies in the increase of micro-sized particles and the decrease of dispersion degree for hematite concentrates, which promotes the hematite concentrate particles to be compacted, the solid-phase crystallization, and finally the formation of Fe2O3 bonding bridges during subsequent high temperature roasting process.

J. Cent. South Univ. (2012) 19: 2611-2619

DOI: 10.1007/s11771-012-1318-5![]()

FAN Jian-jun(范建军)1,2 , QIU Guan-zhou(邱冠周)1, JIANG Tao(姜涛)1,

GUO Yu-feng(郭宇峰)1, HAO Hai-zheng(郝海正)1, YANG Yong-bin(杨永斌)1

1. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Taiyuan Iron and Steel (Group ) Co. Ltd., Taiyuan 03003, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract: The mechanism of high pressure roll grinding on improvement of compression strength of oxidized hematite pellets was researched by considering their roasting properties. The results indicate that oxidized hematite pellets require higher preheating temperature and longer preheating time to attain required compression strength of pellets compared with the common magnetite oxidized pellets. It is found that when the hematite concentrates are pretreated by high pressure roll grinding (HPRG), the compression strengths of preheated and roasted oxidized hematite pellets get improved even with lower preheating and roasting temperatures and shorter preheating and roasting time. The mechanism for HPRG to improve roasting properties of oxidized pellets were investigated and the cause mainly lies in the increase of micro-sized particles and the decrease of dispersion degree for hematite concentrates, which promotes the hematite concentrate particles to be compacted, the solid-phase crystallization, and finally the formation of Fe2O3 bonding bridges during subsequent high temperature roasting process.

Key words: hematite concentrate; pellet; high pressure roll grinding (HPRG); specific surface area; lattice defect; dispersion degree; micro-sized particle

1 Introduction

Over the last several years, compared with damp-grinding, high pressure roll grinding (HPRG) has received considerable popularity in mineral processing industry because of its advantages of low energy consumption [1-4], high productivity and easy maintaining [5-7]. Its potential to improve balling performance also attracts much attention in pellets industry, especially for the treatment of coarse-sized iron concentrates. It was reported [8-9] that particle morphology of iron concentrates was altered and balling performance got better when iron concentrates were pretreated by HPRG. The corresponding studies attributed this function to the improvement of specific surface area and wetting heat [10], so it is confirmed that coarse-sized iron concentrates become easy to be agglomerated into green pellets when HPRG is applied properly, which results in the reduction of bentonite consumption rate and the improvement of total iron content of pellets correspondingly. Other studies also revealed that the compression strength of preheated and roasted pellets increased when magnetite concentrates were pretreated by HPRG, for which the mechanism was investigated and the causes were proved to be the reduction of apparent activation energy, lattice deformation, increase in micro-sized particles, huge specific surface area, and greatly increased oxidation reaction rate during magnetite oxidation process, which finally enhance the formation and crystallization of Fe2O3 lattices during high temperature roasting process [11-13]. For hematite pellets, compared with magnetite pellets, the roasting property is quite different. The findings show that the structure of hematite pellets always keeps their original state if the roasting temperature is less than 1 200 ℃. The Fe2O3 grains are not enlarged, nor the Fe2O3 lattice crystallized until the temperature is over 1 300 ℃. At higher temperature, initial connecting bridges are formed between crystal grains and re-crystallized grains of Fe2O3 [14]. Therefore, it is evident that thermal requirements for hematite pellets are higher than those for magnetite pellets. The related research also covered the effect of HPRG on improving the compression strength of preheated and roasted pellets [15]. However, there is little specific study focusing on the mechanism of this effect, and the cause is just based on the assumption that new cracks on particle surface facilitate the formation of bonding lattices. Since magnetite and hematite pellets exhibit different roasting features, in order to reveal the function of HPRG on the compression strength of hematite pellets and use hematite concentrates properly in the production system of rotary kiln pellets, a series of experiments were conducted on pellets for hematite pretreated by HPRC. The results showed that the compression strength for preheated pellets reaches over 400 N only with roasting temperature being higher than 1 070 ℃, so it is difficult for such preheated pellets to withstand the mechanical collision during the initial roasting process in rotary kiln. However, it was found that the compression strengths of preheated and roasted pellets increase even at lower preheating and roasting temperature for shorter time after the hematite concentrates are subjected to HPRG. Consequently, the present work focuses on the effect of HPRG pretreatment on the changes of specific surface area, dispersion degree, lattice defects, microstructure and the micro-sized particles etc, and more emphases are concentrated on the mechanism of HPRG on the improvement of compression strength of pellets by comparing HPRG pretreatment with ball mill grinding.

2 Experiment and method

2.1 Working principles of high pressure roll grinding

The HPRG was designed initially according to the theory of “Inter-particle comminution [16]”, while the conventional crusher was based on the theory of “Impact breakage”. Instead of being broken as single pieces of particle by conventional crusher, the material particle is broken or comminuted as a compacted material bed or cake in HPRG process, so the material particles squeeze with adjoining particles and many micro-cracks and edges are caused subsequently under high pressure compression. The schematic diagram of HPRG is shown in Fig. 1.

Fig. 1 Schematic diagram of HPRG

2.2 Basic studies on iron concentrates

2.2.1 Chemical composition of iron concentrates

The chemical compositions of iron concentrates are listed in Table 1.

Table 1 Chemical compositions of iron concentrates (mass fraction, %)

Table 1 shows that the iron ore is hematite since FeO content is only 6.13%.

2.2.2 Size distribution and specific surface area of iron concentrates

The size distribution and specific surface area of the hematite concentrates are listed in Table 2. The specific surface area was determined by using Brunauer-Emmett- Teller method.

Table 2 Size distribution and specific surface area of hematite concentrate

The hematite concentrates are very fine with a 91.79% portion being less than 0.044 mm in size, and the specific surface area is as high as 1 723.0 cm2/g.

2.3 Methods of experiment

The hematite concentrates prepared for experiments were ground by HPRG and ball mill grinding, respectively. The specification of high pressure roll is d 250 mm×120 mm, while the grinding (compression) pressure is 1 MP and the moisture content of iron concentrates is 8.0%. In order to get the required specific surface area, recycled grinding was carried out. The specification of ball mill is d 500mm × 500 mm with 12% of media occupancy at 25-40 r/min. Green pellets were prepared using a laboratory balling disc with a diameter of 600 mm, an edge height of 200 mm and a tilting angle of 45° at 25 r/min. After balling, green pellets were screened with 10 mm and 12.5 mm screens to get 10-12.5 mm pellets.

The roasting of pellets was finished in an corundum crucible set in an electric tube furnace with 35 mm in diameter, where the temperature profile was divided into three continuous zones: preheating (oxidizing) at 600- 1 000 ℃, roasting at 1 150-1 300 ℃ and cooling at 600-900 ℃. The parameters of roasting process include preheating temperature and time, and roasting temperature and time. The quality indices of pellets are expressed by compression strength of preheated pellets and roasted pellets for an individual pellet.

3 Results and discussion

3.1 Effect of HPRG on compression strength of preheated and roasted pellets

The experiments were first focused on the effect of HPRG on compression strength of preheated pellets and roasted pellets. In order to evaluate the effect of HPRG on compression strength of pellets, the lower limit of required compression strength for preheated and roasted pellets are stipulated to be over 400 N and 2 500 N, respectively.

The hematite concentrates were ground by HPRG and the specific surface area increased from 1 723.0 cm2/g (base case) to 2 201.1 cm2/g. Then, the green pellets were prepared and roasted at preheating temperatures of 950, 970, 1 000, 1 020 and 1 070 ℃, roasting temperatures of 1 180, 1 200, 1 220 and 1 250 ℃, and preheating and roasting time of 10 min. The effects of preheating and roasting temperatures on compression strength of pellets are presented in Figs. 2 and 3. The effects of preheating and roasting time on the compression strength of pellets are illustrated in Figs. 4 and 5.

Fig. 2 Effect of HPRG on compression strength of preheated pellets

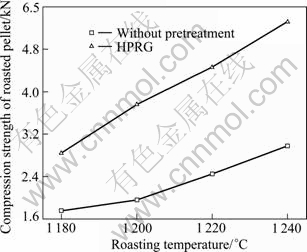

Fig. 3 Effect of HPRG on compression strength of roasted pellets

Fig. 4 Effect of preheating time on compression strength of preheated pellets

Fig. 5 Effect of roasting time on compression strength of roasted pellets

Figure 2 indicates that, for the hematite concentrates, without being pretreated (base case), the compression strength of preheated pellets improves slowly with the increase of preheating temperature. The compression strength of pellets reaches 404 N only when temperature reaches 1 070 ℃, so the preheating temperature is higher than that of pellets made from common magnetite concentrates, for which the preheating temperature is always in the range of 850-1 000 ℃. Therefore, it is difficult for such preheated pellets to withstand the mechanical collision during the initial roasting process in rotary kiln. However, when the hematite concentrates are ground by high pressure roll, the specific surface area reaches 2 201.1 cm2/g, and the compression strength for preheated pellets improves sharply with the increase of preheating temperature and reaches 482 N when preheating temperature is only 1 000 ℃. Figure 4 indicates that the compression strength for preheated pellets even reaches 425 N when preheating time decreases to 8 min with preheating temperature being 1 000 ℃. Therefore, for HPRG-pretreated hematite concentrates, the preheating temperature and time of pellets decrease by 70 ℃ and 2 min, respectively, compared with those for the untreated concentrates.

As for the compression strength of roasted pellets, in the base case, Fig. 3 indicates that it is only 1 658 N when pellets are roasted at 1 200 ℃ and it reaches 2 707 N when roasting temperature reaches 1 250 ℃. According to the requirements for pellets making processes, the lower limit of required compression strength for roasted pellets should be higher than 2 500 N. Therefore, it is confirmed that hematite pellets require higher roasting temperature. However, when the hematite concentrates are ground by high pressure roll, the compression strength for roasted pellets increases sharply with the increase of roasting temperature and reaches 2 846 N when roasting temperature is only 1 180 ℃. Figure 5 indicates that the compression strength for roasted pellets even reaches 3 055 N when roasting time decreases to 8 min with roasting temperature being 1 200 ℃. Therefore, for HPRG-pretreated hematite pellets, the roasting temperature and time of pellets have been decreased by at least 50 ℃ and 2 min, respectively, compared with those of the base case.

Therefore, for hematite pellets, it is confirmed that HPRG pretreatment improves not only the compression strength of preheated pellets, but also that of roasted pellets even with lower preheating and roasting temperatures and shorter preheating and roasting time.

3.2 Mechanism of HPRG pretreatment on pellets compression strength

A series of experiments were conducted to determine the effect of changes in hematite concentrates properties after HPRG on compression strength of pellets. The concerned changes were focused on specific surface area, lattice defects, content of micro-sized particles, dispersion degree and microstructure.

In order to evaluate the effect of HPRG pretreatment on the compression strength of pellets, the hematite concentrates were pretreated both by ball mill grinding and HPRG, so as to get the concentrates with close specific surface area. Here, the obtained specific surface area of the hematite reached 2 191.6 cm2/g and 2 201.1 cm2/g after being pretreated by ball mill grinding and HPRG, respectively. The green pellets were prepared and roasted with the same operating parameters.

3.2.1 Effect of specific surface area on compression strength of pellets

In order to evaluate the effect of specific surface area changes on compression strength of pellets, the experiments were conducted with preheating temperatures being 950, 970, 1 000 and 1 020 ℃, roasting temperatures being 1 180, 1 200, 1 220 and 1 250 ℃, and preheating and roasting time being 10 min. The results are shown in Figs. 6 and 7.

Fig. 6 Effect of different pretreatment measures on compression strength of preheated pellets

Fig. 7 Effect of different pretreatment measures on compression strength of roasted pellets

Figures 6 and 7 indicate that when the hematite concentrates are pretreated by ball mill and HPRG and reach nearly same specific surface area, the compression strength of preheated and roasted pellets is improved compared with that of base case, but the effect from HPRG appears to be greater than that of ball mill grinding even with the same preheating and roasting parameters. For example, in the case of preheating temperature and time being 1 000 ℃ and 10 min, roasting temperature and time being 1 250 ℃ and 10 min, respectively, when the hematite concentrates are pretreated by ball mill grinding, the compression strength for preheated and roasted pellets increase from 258 and 2 979 to 296 and 3 448 N, by 38 and 4 69 N, respectively, compared with those of base case. However, when being pretreated by HPRG, the compression strengths for preheated and roasted pellets increase to 482 and 5 025 N, by 224 and 2 046 N, respectively, compared with base case.

So, it is confirmed that the increase of specific surface area promotes the improvement of compression strength for pellets, but it isn’t the decisive factor in determining the pellets strength.

3.2.2 Effect of lattice defects on compression strength of pellets

In order to determine the effect of lattice defect on compression strength of pellets, the hematite concentrates were identified by X-ray diffraction (D/max-rA model, Japan) after being ground by ball mill and HPRG. The diffraction patterns are shown in Fig. 8.

In order to evaluate the effect of pretreatment measures on lattice defects, the concept of lattice disorder degree is introduced, which is calculated according to the X-ray diffraction results by computer program. The results for calculation of lattice disorder degree are given in Table 3 according to Eq. (1):

![]() (1)

(1)

where I1 refers to diffraction intensity of the hematite concentrates without being ground by ball mill or HPRG; I2 refers to diffraction intensity of the hematite concentrates after being ground by ball mill or HPRG. Generally speaking, the integrated lattice material always presents higher diffraction intensity or lower disorder degree; however, the defected lattice material always presents lower diffraction intensity or higher disorder degree.

Fig. 8 X-ray diffraction patterns of hematite after being pretreated by ball mill and HPRG: (a) Hematite without pretreatment; (b) Hematite pretreated by ball-grinding; (c) Hematite pretreated by HPRG

Table 3 Effect of pretreatment measures on lattice disorder degree

Table 3 indicates that when the hematite concentrates are pretreated by ball mill grinding and HPRG, the lattice disorder degrees reach 15.91% and 20.85%, respectively, based on the assumption that the lattice disorder degree of original hematite concentrates is zero. So, it is illustrated that the lattice of hematite concentrates gets defected after the hematite concentrates are pretreated by ball mill grinding and HPRG.

It is found that compared with ball mill pretreatment, the lattice disorder degree of hematite concentrates increases by only 4.94% after being pretreated by HPRG. However, the compression strength of preheated and roasted pellets increases significantly as discussed.

So, it is confirmed that the increase of lattice disorder degree contributes to the improvement of compression strength for preheated and roasted pellets, but doesn’t affect significantly.

3.2.3 Effect of dispersion degree on compression strength of pellets

When the hematite concentrates are preheated by HPRG, the material particles squeeze with each other and finally form compacted material cake, which is difficult to be disintegrated into fine particles completely during subsequent balling process. Such compacted material particles may affect the pellets strength during roasting process. So, the experiments were carried out to determine the effect of compacted material on compression strength of pellets by measuring the changes of dispersion degree for hematite concentrates.

The hematite concentrates were prepared as the following three batches: namely, the first batch refers to original concentrates (base case), the second batch refers to HPRG-pretreated hematite concentrates (the specific surface area being 2 201.6 cm2/g), the third batch refers to the HPRG-pretreated hematite concentrates cake as that of the second batch, which were then soaked into water and disintegrated intentionally by agitator.

In order to evaluate the dispersion degree of three different hematite concentrates, the porosity of green pellets made from these three kinds of hematite concentrates was tested and the results are given in Table 4. Generally speaking, the lower the porosity of green pellets, the lower the dispersion degree for material particles. Table 4 indicates that the hematite concentrate particles definitely become compacted after being pretreated by HPRG or further being disintegrated intentionally since the porosity of green pellets decreases accordingly compared with that of base case, which also indicates that hematite particles still squeeze with adjoining particles even being disintegrated intentionally. Then, the green pellets were roasted at the designed roasting parameters. The results are shown in Figs. 9 and 10.

Table 4 Effect of pretreatment measures on porosity of green pellets

Fig. 9 Effect of dispersion degree on compression strength of preheated pellets

Figures 9 and 10 indicate that when the hematite concentrate cake is disintegrated, the compression strengths of preheated and roasted pellets decrease slightly compared with those of the HPRG-pretreated case. In the case of preheating temperature and time being 1 000 ℃ and 10 min, and roasting temperature and time being 1 250 ℃ and 10 min, respectively, Figs. 9 and 10 indicate that the compression strengths of preheated and roasted pellets decrease from 482 and 5 322 to 462 and 4 622 N, by 20 and 800 N or 4.1% and 13.1%, respectively.

Fig. 10 Effect of dispersion degree on compression strength of roasted pellets

So, it is confirmed that the decrease of dispersion degree definitely promotes the improvement of compression strength for pellets.

3.2.4 Effect of micro-sized particles on compression strength of pellets

In order to evaluate the effect of micro-sized particles on compression strength of pellets, the hematite concentrates were pretreated both by ball mill grinding and HPRG, so as to get the concentrates with nearly same specific surface area as previous, then the size distributions of the hematite concentrate were determined by laser grain analyzer. The results are listed in Table 5.

Table 5 Cumulative contents of micro-sized particles of hematite concentrates pretreated by different measures (mass fraction, %)

Table 5 shows that the cumulative contents of micro-sized particles increase after the hematite concentrates are pretreated by ball mill grinding and HPRG. For cumulative content of <0.010 mm, there is an increase of 6.17% and 12.48%, respectively, compared with base case; in the case of 0.005 mm, there is an increase of 2.9% and 8.89%, respectively, compared with base case. So, it is confirmed that the content of micro-sized particles increases when the hematite concentrates are pretreated by ball mill grinding and HPRG. The HPRG even demonstrates more remarkable effect than ball mill grinding.

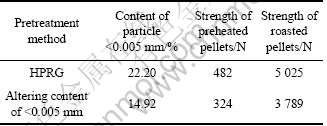

In order to determine the effect of micro-sized particle content on compression strength of pellets, the HPRG-pretreated hematite concentrates were further processed by altering the content of <0.005 mm with sediment measures. Then, the green pellets were prepared and roasted according to the following roasting parameters: preheating temperature and time being 1 000 ℃ and 10 min, and roasting temperature and time being 1 250 ℃ and 10 min, respectively. The results are shown in Tables 6 and 7. It is indicated that the compression strengths of preheated and roasted pellets decrease from 482 and 5 025 to 324 and 3 789 N, by 158 and 1 236 N or 32.8% and 24.6%, respectively, when the content of <0.005 mm is altered from 22.2% to 14.92%, which demonstrates that the decrease of <0.005 mm particles affects pellets strength significantly.

Table 6 Cumulative content of micro-sized particles of hematite concentrates by altering content of <0.005 mm (mass fraction, %)

Table 7 Effect of micro-sized particles on compression strength of preheated and roasted pellets

So, it is confirmed that the increase of micro-sized particles definitely promotes the increase of compression strength for pellets after the hematite concentrates are pretreated by HPRG.

3.2.5 Effect of HPRG on changes of microstructure for preheated and roasted pellets

In order to evaluate the effect of HPRG on the changes of microstructure for preheated and roasted pellets, the determination was carried out with optical microscope. The results are shown in Figs. 11 and 12, where the preheating temperature and time are 1 000 ℃ and 10 min, and roasting temperature and time are 1 250 ℃ and 10 min, respectively.

Figure 11 indicates that for pellets without being pretreated by HPRG, most of the Fe2O3 particles array in initial-singled form, and there are little bonding bridges among particles but the clearance and void are very clear among particles. However, for pellets pretreated by HPRG, most of the Fe2O3 particles connect with each other, bonding bridges are formed among particles, and the clearance and void among particles decrease accordingly. Figure 12 also demonstrates similar results when pellets are pretreated by HPRG and roasted at higher temperature. Most Fe2O3 particles are fully developed, which promote the formation of bigger Fe2O3 particles and Fe2O3 bonding bridges net, which finally promotes the solid-phase crystallization.

Fig. 11 Effect of HPRG on changes of microstructure of preheated pellets (H—Fe2O3): (a) Without pretreatment; (b) Pretreated by HPRG

Fig. 12 Effect of HPRG on changes of microstructure of roasted pellets (H—Fe2O3): (a) Without pretreatment; (b) Pretreated by HPRG

So, it is confirmed that HPRG definitely promotes the development of Fe2O3 bonding bridges and the compression strength for pellets.

3.3 Discussion

3.3.1 Effect of specific surface area on compression strength of pellets

It is always taken for granted previously that the increase of compression strength for preheated and roasted pellets should be attributed primarily to the increase of specific surface area, but the results indicate that it isn’t the case as expected. HPRG pretreatment is definitely conducive to the improvement of compression strength for pellets, but the increase of specific surface area isn’t the decisive factor by comparing the effect with that of ball mill pretreatment. In fact, the earlier studies on physical property of solid particles reveal that the specific surface area of the material isn’t always in direct proportion to particle size, particle shapes and crystallization degree [17]. Furthermore, the measurement of specific surface area for fine-sized material is conducted under static condition, which only represents the surface area of particles, but the distribution behavior, accumulation model and contact way of particles are difficult to determine. So, the hematite concentrate particles may distribute or disperse in different ways even with nearly same specific surface area after being pretreated by ball mill grinding or HPRG. That is to say, the increase of specific surface area from HPRG pretreatment is just the superficial effect on the compression strength of pellets. The true mechanism may be laid in the change of lattice defects, accumulation model, contact area and micro-sized particle content etc.

3.3.2 Effect of lattice defects on compression strength of pellets

As for the changes of lattice defects, the results indicate that the hematite concentrate lattice definitely gets defected by calculating the lattice disorder degree. The related theories on solid chemistry indicate that the mechanical energy is always absorbed by material grains and material grains then exist in disordered state with the increase of lattice disorder degree, which will promote the increase of chemical energy and the migration of lattice, finally improve the formation of grain bridges and the compression strength for pellets during subsequent high temperature roasting process. So, the increase of lattice disorder degree benefits the improvement of compression strength for pellets, but it isn’t the main factor by comparing the effect of HPRG with that of ball mill pretreatment.

3.3.3 Effect of dispersion degree on compression strength of pellets

As for the effect of dispersion degree, the results indicate that the hematite concentrates get compacted and dispersion degree decreases after being pretreated by HPRG or even being further disintegrated intentionally. The decrease of dispersion degree for hematite concentrates or decrease of green pellet porosity means the increase of contact surface area for hematite concentrates particles, which makes it easy for particles to migrate and crystallize, and promotes the formation of grain bridges during subsequent high temperature roasting process, finally improves the compression strength for pellets. Since the compression strength decreases slightly even the HPRG-pretreated hematite concentrates are disintegrated intentionally, the decrease of dispersion degree definitely plays an important role in the improvement of compression strength of pellets.

3.3.4 Effect of micro-sized particles on compression strength of pellets

As for the effect of micro-sized particles, the results indicate that the micro-sized particles affect pellets strength significantly. The previous studies on oxidized pellets indicate that for hematite concentrates, the Fe2O3 particles contact with each other initially during roasting process at high temperature, then the Fe2O3 bonding bridges form with the help of migration of Fe2O3 particles because of the increase of tensile stress from surface tension [18]. Furthermore, the micro-sized particles even demonstrate higher surface activity and stronger tensile stress, which finally promotes the formation of Fe2O3 bonding bridges. This phenomenon is confirmed by determining the changes of microstructure for preheated and roasted pellets. So, the increase of content of micro-sized particles definitely facilitates the improvement of compression strength of pellets.

4 Conclusions

1) For hematite oxidized pellets, the compression strengths of preheated and roasted get improved after the hematite concentrates are pretreated by HPRG.

2) The compression strength of pellets increases even with lower preheating and roasting temperature and shorter preheating and roasting time with HPRG pretreatment.

3) The mechanism for HPRG to improve the compression strength of pellets lies in the increase of content of micro-sized particles and the decrease of dispersion degree, which promote the pellets becoming compacted and the solid-phase crystallization and finally the formation of Fe2O3 bonding bridges during subsequent roasting process.

4) The increase of specific surface area and lattice disorder degree contribute to the improvement of compression strength of pellets, but don’t affect significantly.

References

[1] WILLS B A, NAPIER-MUM T J. Wills’ mineral processing technology [M]. Changsha: Central South University Press and Elsevier Ltd, 2008: 134-137.

[2] ABDEL-ZAHER M A, DOUGLS W F. Grinding of mineral mixtures in high-pressure grinding rolls [J]. Int J Miner Process, 2009, 93: 59-65.

[3] FUERSTENAU D W, ABOUZEID A Z M. Role of feed moisture in high-pressure roll mill comminution [J]. Int J Miner Process, 2007, 82: 203-204.

[4] FUERSTENAU D W, SHUKL A, KAPUR P C. Energy consumption and product size distribution in choke-fed, high-compression roll mills [J]. Int J Miner Process, 1991, 32: 59-79.

[5] TAVARES L M. Particle weakening in high-pressure roll grinding [J]. Minerals Engineering, 2005, 18: 651-657.

[6] LIM I L, VOIGT W, WELLER K R. Particles size distributionand energy expenditure in grinding minerals and ores in high-pressureroll mills [J]. Int J Miner Process, 1996, 44: 539-541.

[7] FUERSTENAUA D W, DEB A, KAPURE P C. Linear and nonlinear particle breakage processes in comminution systems [J]. Miner Process, 2004, 745: 317-327.

[8] LIU Shu, WANG Yong-qing. The application of HPRG (RP3.6-120/50B) at Chengchao pellet plant [J]. Pellet Technology, 2006(1): 38-39. (in Chinese)

[9] ZHANG Yan-bin, Grinding test of iron ore concentrates by high pressure roll mill [J]. Sintering and Pelletizing, 2005, 30(3): 14-16. (in Chinese)

[10] WANG Chang-an, XIONG Shou-an, ZHU De-qin. Effect of high pressure roller mill pre-treatment concentrates on green ball property [J]. Sintering and Pelletizing, 2002, 27(6): 12-15. (in Chinese)

[11] QIU Guan-zhou, ZHU De-qin, PAN Jian, WANG Chang-an, GUO Yu-feng, JIANG Tao, HU Chen-fan, CLOUT J, SHU Tang-hua. Improve the oxidizing kinetics of pelletization of magnetite concentrate by high press roll grinding [J]. ISIJ International, 2004, 44(1): 69-73.

[12] ZHU De-qing, PAN Jian, QIU Guan-zhou, CLOUT J, WANG Chang-an, GUO Yu-feng. Mechano-chemical activation of magnetite concentrate for improving its pelletability by high pressure roll grinding [J]. ISIJ International, 2004, 44(2): 3l0-3l5.

[13] ZHU De-qin, TANG Yan-yun, VINICIUS MENDES, PAN Jian, ZHAI Yong. Pretreatment of Brazilian specularite before pelletization by high pressure roller grinding [J]. Metal Mine, 2008(4): 10-11. (in Chinese)

[14] JIANG Tao, ZHANG Yuan-bo, HANG Zhu-cheng, LI Guang-hui, FAN Xiao-hui. Preheating and roasting characteristics of hematite-magnetite (H-M) concentrate pellets [J]. Ironmaking and Steelmaking, 2008, 35(1): 21-23.

[15] TANG Yan-yun. Study of HPRG on PFC specularite pellet [D]. Changsha: Central South University, 2008.

[16] Tavares L M. Particle weakening in high-pressure roll grinding [J]. Minerals Engineering, 2005, 18(7): 651-657.

[17] ZEN Fan, HU Yong-ping, YANG Yi. The principle on mineral process of particle [M]. Xuzhou: China University of Mining and Technology Press, 2001: 16-31. (in Chinese)

[18] XIAO Qi. The theory and production of pellet [M]. Changsha: Central South University of Technology Press, 1990: 106-110. (in Chinese)

(Edited by YANG Bing)

Foundation item: Project(50725416) supported by the National Natural Science Funds for Distinguished Young Scholars of China

Received date: 2011-07-18; Accepted date: 2012-05-18

Corresponding author: FAN Jian-jun, PhD Candidate; Tel: +86-15935102760; E-mail: fanjj1@tisco.com.cn