烧结参数对温压Fe-2Ni-2Cu-1Mo-1C材料抗拉强度的影响

肖志瑜, 张菊红, 吴苑标, 温利平, 李元元

(华南理工大学 机械工程学院, 广州 510640)

摘 要: 采用温压方法制备了高密度Fe-2Ni-2Cu-1Mo-1C材料, 并研究了烧结温度和烧结时间对温压Fe-2Ni-2Cu-1Mo-1C材料烧结密度和抗拉强度的影响。 结果表明: 常规温压和模壁润滑温压的烧结密度和抗拉强度随烧结温度和时间的变化而变化, 模壁润滑温压的烧结密度和抗拉强度均大于常规温压的; 温压材料的抗拉强度为烧结温度和烧结时间的函数, 常规温压和模壁润滑温压的抗拉强度随烧结温度和时间变化的线性回归方程(R为相关系数)分别为σb =575+2111536f(t, T), R=0.972和σb =595+2086883f(t, T), R=0.997。

关键词: Fe-2Ni-2Cu-1Mo-1C; 温压铁基材料; 抗拉强度; 烧结; 回归方程 中图分类号: TF12

文献标识码: A

Influence of sintering parameters on tensile strength of warm compacted Fe-2Ni-2Cu-1Mo-1C material

XIAO Zhi-yu, ZHANG Ju-hong, WU Yuan-biao, WEN Li-ping, LI Yuan-yuan

(College of Mechanical Engineering,South China University of Technology, Guangzhou 510640, China)

Abstract: The high density Fe-2Ni-2Cu-1Mo-1C material was fabricated by warm compaction method, and the influence of sintering temperature and sintering time on the density and tensile strength of warm compacted Fe-2Ni-2Cu-1Mo-1C sintered material were studied. The results show that the sintered density and tensile strength of the conventional warm compacted and die wall lubricating warm compacted samples change with the change of sintering temperatures and time. The sintered density and tensile strength of the die wall lubricating warm compacted material are larger than those of conventional warm compacted samples. The tensile strengths of warm compacted ferrous materials are functions of sintering temperatures and time. The regression for conventional warm compaction conditions and die wall lubricating warm compaction conditions are that σb =575+2111536f(t, T), R=0.972 and σb =595+2086883f(t, T), R=0.997, respectively.

Key words: Fe-2Ni-2Cu-1Mo-1C; warm compacted ferrous material; tensile strength; sintering; regression function

粉末冶金结构材料及其零件是粉末冶金行业中量大面广的产品, 约占整个粉末冶金材料及制品产量的60%以上, 其重要性是显而易见的。 汽车工业对粉末冶金结构零件的强度要求越来越高, 提高强度成了粉末冶金材料工作者的重要课题[1]。 合金化技术是显著改善和提高铁基粉末冶金材料强度的有效途径之一。 在铁基烧结材料中, 常用的合金元素为C、 Cu、 Ni、 Mo、 Cr、 P和Mn等。 对铁基粉末冶金材料来说, 只有密度和合金成分一起被考虑, 才能获得最佳的力学性能[2]。 为了获得高密度、 高性能及高精度的粉末冶金零部件, 同时又能降低生产成本, 粉末冶金界的研究者们进行了长期不懈的探索。 1994年首次报道的温压(Warm compaction, WC)成形技术是采用一次压制/一次烧结工艺制造的高密度、 高强度粉末冶金结构零件的一项经济可行的新技术[3-6]。 它以较低的成本就能实现铁基粉末冶金材料的高密度而受到国际粉末冶金界的广泛关注。 目前, 温压工艺已用于制造齿轮和连杆等高密度、 高强度的粉末冶金零件, 并获得了实际应用[7, 8]。 烧结是粉末冶金技术中一个极其重要的工艺环节。 通过烧结过程, 使金属粉末聚合体由很弱的生坯连接状态变成牢固结合在一起的结构材料。 合金化技术和温压工艺的结合弥补了传统粉末冶金工艺中因密度不高造成的强度及韧性不足的缺陷, 为生产高性能低成本的粉末冶金齿轮创造了机会, 从而大大改善粉末冶金齿轮材料的力学性能, 提高粉末冶金齿轮在同类产品中的竞争力。 高密度和高强度的温压铁基粉末冶金材料也不断被报道[9-13], 如温压涡轮毂采用扩散合金化的Fe-4Ni-1.5Cu-0.5Mo材料, 密度达7.25g/cm3以上, 抗拉强度为807MPa。 含Cr的铁基粉末冶金材料通过温压成形并经一次烧结, 烧结态强度可高达1299MPa。 针对高性能温压铁基粉末冶金材料的发展和应用, 本文作者主要研究了烧结温度和烧结时间对高性能温压Fe-2Ni-2Cu-1Mo-1C材料抗拉强度的影响。

1 实验

实验采用的水雾化铁粉的化学成分、 粒度组成和工艺性能如表1所列。 采用的合金元素粉为胶体石墨粉、 粒径不大于75μm的电解铜粉、 3~5μm羰基镍粉、 粒径不大于75μm的钼粉。 材料的化学成分为Fe-2Ni-2Cu-1Mo-1C。 采用ZF-0.02型二维混料机混合1.5h。 采用的温压润滑剂为自制的多组元聚合物润滑剂。 当采用模壁润滑时, 使用质量分数为5%的聚四氟乙烯乳化液。 传统温压(无模壁润滑)时, 粉末中加入的润滑剂量为0.6%(质量分数); 有模壁润滑时, 粉末中加入的润滑剂量为0.25%。 当温压温度为120~125℃, 压力为700MPa时, 常规温压生坯密度为7.31g/cm3, 模壁润滑温压的密度为7.38g/cm3。 烧结在RSJ-13高温钼丝炉中进行, 烧结气氛为分解氨。 密度ρ根据国家标准GB5163—1985, 采用排水法测量。 抗拉强度σb根据国家标准GB7963—1987, 采用扁平试样, 直接由粉末压制和烧结制成。 在CMT5105型带微机控制的万能材料试验机上测量抗拉强度σb。

2 结果与分析

2.1 烧结温度的影响

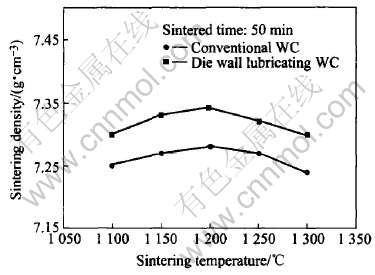

在粉末冶金工业中对铁基制品进行高温烧结的兴趣不断地增长, 这主要归因于高温烧结能促进合金的均匀化。 图1所示为烧结时间为50min时烧结温度对烧结密度的影响。 由图1可看出, 有模壁润滑温压的烧结密度均大于常规温压; 当温度小于1200℃时, 烧结密度随烧结温度升高而增大, 烧结膨胀却减少; 当温度高于1200℃后, 烧结密度随烧结温度升高而降低, 烧结膨胀增加。 这主要是由于在1200℃之前, 铜粉熔化形成液相, 由Fe-Cu二元相图可知, 铁可溶于铜中。 这样, 随着烧结的进行, 铁粉颗粒的连接会由于产生的液相而消失, 在毛细管力作用下, 铁粉颗粒会发生滑动重排而使之致密化, 从而导致烧结密度提高。 温度达到1200℃之后, 烧结密度降低主要是由于合金中形成的钼碳化物在1230℃熔化产生瞬时液相而形成二次孔洞所致[14]。 此外还发现, 烧结坯密度均较原生坯密度有所降低。 这主要是由于粉末经温压后, 密度较高, 许多润滑剂存在于封闭孔洞中, 在烧结的升温阶段, 润滑剂分解出的气体难以排除出孔洞中而造成压坯体积的稍微膨胀, 采用真空预烧脱气处理能有效地克服这一缺点。

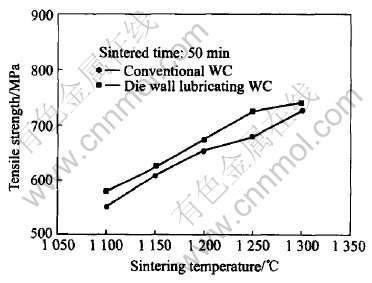

图2所示为温压材料的抗拉强度随烧结温度变化的趋势。 从图2中可看出, 材料的抗拉强度随着烧结温度的提高而增大。 当温度为1300℃时, 抗拉强度达到最大值, 且高温烧结时间越长, 越有利于提高材料的力学性能, 这主要由于烧结时间有助于增强粉末结合, 孔隙球化和合金元素的扩散均匀化所致。

表1 水雾化铁粉的化学成分及工业特性

Table 1 Chemical composition and properties of water atomization iron powder

图1 烧结温度对温压压坯烧结密度的影响

Fig.1 Effect of sintering temperature on sintered density of warm compacted material

图2 烧结温度对温压材料抗拉强度的影响

Fig.2 Effect of sintering temperature on tensile strength of warm compacted material

2.2 烧结时间的影响

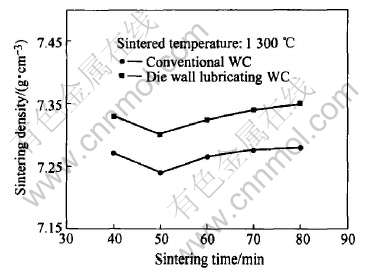

图3所示为烧结密度随烧结时间的变化趋势。 从图3中可见, 有模壁润滑温压的烧结密度均大于常规温压的, 且随着烧结时间的延长, 烧结密度先下降随后逐渐提高; 在50min时, 烧结密度最低。 铜由于在烧结过程中熔化而产生液相烧结。 当烧结温度达到铜的熔点时, 液相铜会在毛细管的作用下沿着粉末颗粒表面铺展, 填充孔洞。 由于粉末颗粒在温压成形时获得了高的密度, 粉末之间形成较强的机械啮合, 铜液膜在烧结的初期难以迅速浸入粉末颗粒的结合面, 而原先铜粉颗粒占据的空间就成了新孔隙, 导致压坯膨胀。 且随着烧结时间的延长, 合金元素之间相互溶解, 当烧结进行到50min时, 铜液完全渗透入原始粉末颗粒间的界面, 破坏了颗粒间原有的机械联结, 导致粉末颗粒间的相对距离增大, 表现出压坯密度降低。 随着烧结过程的继续进行, 会进一步发生粉末颗粒的滑动、 旋转、 重排, 并伴随着合金元素的溶解、 析出和扩散, 残留压坯的弹性内应力得以充分释放, 进而达到烧结致密化效果, 同时又提高了烧结密度。

图3 烧结时间对温压材料烧结密度的影响

Fig.3 Effect of sintering time on sintered density of warm compacted material

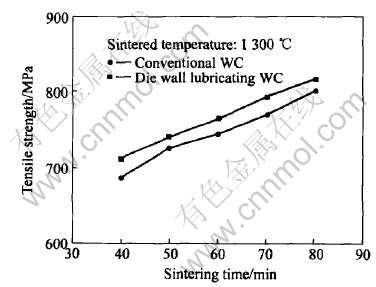

图4所示为温压材料的抗拉强度随烧结时间的变化规律。 由图4可见, 随着烧结时间的延长, 材料的抗拉强度得到提高。 当烧结时间从40min延长到80min时, 抗拉强度提高了103~115MPa。

图4 烧结时间对温压材料抗拉强度的影响

Fig.4 Effect of sintering time on tensile strength of warm compacted material

3 讨论

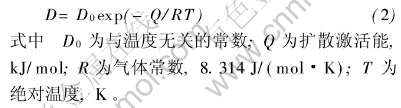

由上述分析确定了烧结温度和时间对混合元素粉末压坯获得高的抗拉强度的重要性。 在整个烧结过程中, 强度的提高均围绕着合金元素的扩散均匀化进行的。 合金元素在烧结体内扩散得是否均匀, 对粉末烧结合金的性能是至关重要的。 Heckel等[15、 16]经研究认为, 扩散均匀度F与合金的互扩散系数D, 合金元素粉末粒度r和烧结时间t有关, 且

温度影响均匀化速度, 混合粉末压坯的高温均匀化主要是通过晶内扩散来实现的, 温度对于过程动力学的主要影响表现在相互扩散系数上, 扩散系数为

因此, 扩散均匀度F为

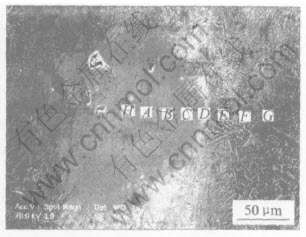

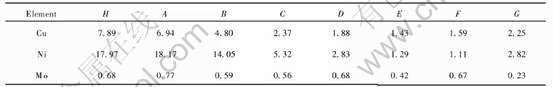

当颗粒尺寸一定时, 扩散距离r视为常数。 这样, 在1300℃烧结80min, 扩散均匀化的速率将比1100℃烧结40min提高约19倍。 图5所示为温压材料经1200℃烧结50min后的不均匀显微区域。 相应Cu、 Ni和Mo元素的电子显微探针成分[CM(22]变化如表2所列。 由表2可看出Cu、 Ni和Mo元素的分布不均匀现象及其变化趋势。

图5 温压Fe-2Ni-2Cu-1Mo-1C材料于1200℃烧结50min后的不均匀显微组织

Fig.5 Non-homogeneity microstructure of warm compacted Fe-2Ni-2Cu-1Mo-1C material after sintered at 1200℃ for 50min

从扩散均匀化方程(3)可知, 元素混合粉末压坯的合金元素扩散均匀化在烧结过程中直接影响材料的力学性能, 因此温压材料的抗拉强度可认为是烧结温度和烧结时间的函数[17], 可引入参数:

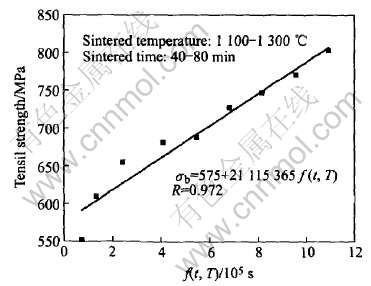

根据图2和4的数据, 采用线性回归分析可获得如下方程(R为相关系数):

常规温压:

模壁润滑温压:

图6 常规温压压坯的抗拉强度与f(t, T)之间的线性关系

Fig.6 Linear relationship between tensile strength and f(t, T) of conventional warm compacted material

图6所示为其中的常规温压的元素粉末混合压坯在1100~1300℃烧结40~80min的抗拉强度σb与计算的f(t, T)间的线性回归关系曲线。 由图6可看出, 随着f(t, T)的提高, 温压材料的抗拉强度σb得到线性提高。

表2 图5中不同点元素的含量变化情况

Table 2 Compositions at different positions in Fig.5(mass fraction, %)

4 结论

1) 温压Fe-2Ni-2Cu-1Mo-1C材料经不同温度烧结50min, 模壁润滑温压的烧结密度均大于常规温压的, 在1200℃之前, 烧结密度随烧结温度升高而增大; 当温度达到1200℃之后, 烧结密度随烧结温度升高而降低; 温压材料的抗拉强度随着烧结温度的提高而增大。

2) 温压Fe-2Ni-2Cu-1Mo-1C材料于1300℃烧结不同时间时, 模壁润滑温压的烧结密度均大于常规温压的; 温压材料的抗拉强度随着烧结时间的提高而增大。

3) 温压材料的抗拉强度是烧结温度和烧结时间的函数, 常规温压和模壁润滑温压抗拉强度的线性回归方程(R为相关系数)分别为: σb =575+2111536f(t, T), R=0.972; σb =595+2086883×f(t, T), R=0.997。

REFERENCES

[1]易建宏, 吕海波, 马福康. MCM和MVM烧结钢强化机理及其性能[J]. 中国有色金属学报, 1995, 5(2): 116-119.

YI Jian-hong, L Hai-bo, MA Fu-kang. Strengthened mechanism and performance of MCM and MVM sintering steels[J]. The Chinese Journal of Nonferrous Metals, 1995, 5(2): 116-119.

[2]Shivanath R, Jones P K, Lawcock R. On the synergies of high temperature sintering and alloy development for high endurance P/M powder train components[A]. Cadle T M, Narasimhan K S. Advances in Powder Metallurgy and Particulate Materials[C]. Princeton, NJ: MPIF, 1996. 427-434.

[3]James W B. Recent developments in ferrous powder metallurgy alloys[J]. The International Journal of Powder Metallurgy, 1994, 30(2): 157-162.

[4]Rutz H G, Hanejko F G. High density processing of high performance ferrous materials[J]. The International Journal of Powder Metallurgy, 1995, 31(1): 9-17.

[5]XIAO Zhi-yu, KE Mei-yuan, CHEN Wei-ping, et al. A study on warm compacting behaviors of 316L stainless steel powder[J]. Materials Science Forum, 2004, 471-472: 443-447.

[6]LI Yuan-yuan, XIAO Zhi-yu, Ngai T L, et al. Warm compacted NbC particulate reinforced iron-based composite (Ⅰ)—effect of fabrication parameters[J]. Trans Nonferrous Met Soc China, 2002, 12(4): 659-663.

[7]Capus J. Warm compacted turbine hub leads new PM thrust[J]. Metal Powder Report, 1997, 61(9): 19-20.

[8]Veltl G, Oppert A, Petzoldt F. Warm flow compaction fosters more complex PM parts[J]. Metal Powder Report, 2001, 56(2): 26-28.

[9]Lindberg C, Johansson B, Maroli B. Mechanical properties of warm compacted Astaloy CrM[A]. Howard F, Donald T. Advances in Powder Metallurgy and Particulate Materials—2000, Part 6[C]. Princeton, NJ: MPIF, 2000. 6-81.

[10]Degoix C N, Griffo A, German R M. Effect of lubrication mode and compaction temperature on the properties of Fe-Ni-Cu-Mo-C[J]. The International Journal of Powder Metallurgy, 1998, 34(2): 29-33.

[11]Rutz H G, Hanejko F G. High density processing of high performance ferrous materials[J]. The International Journal of Powder Metallurgy, 1995, 31(1): 9-17.

[12]LI Yuan-yuan, Ngai T L, XIAO Zhi-yu, et al. Study on mechanical properties of warm compacted iron-base materials[J]. Journal of Central South University of Technology, 2002, 9(3): 154-158.

[13]Ngai T L, CHEN Wei-ping, XIAO Zhi-yu, et al. Die wall lubricated warm compaction of iron-based powder metallurgy material[J]. Trans Nonferrous Met Soc China, 2002, 12(6): 1095-1098.

[14]Danninger H. Sintering of Mo P/M steels prepared from elemental powders, I-sintering temperature and mechanical properties[J]. Powder Metallurgy International, 1992, 24(2): 79-85.

[15]German R M. Liquid Phase Sintering[M]. New York: Plenum Press, 1985. 234-235.

[16]果世驹. 粉末烧结理论[M]. 北京: 冶金工业出版社, 2002. 153-155.

GUO Shi-ju. Theory of Powder Sintering[M]. Beijing: Metallurgical Industry Press, 2002. 153-155.

[17]Degoix C N, Griffo A, German R M. Effects of sintering parameters on the mechanical properties of a Fe-2Cu-2Ni-0.9Mo-0.8C steel[J]. The International Journal of Powder Metallurgy, 1990, 24(6): 57-66.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50574041); 新世纪优秀人才资助项目(NCET-05-0739); 广东省科技计划资助项目(2004B10301018)

收稿日期: 2005-11-29; 修订日期: 2006-06-11

通讯作者: 肖志瑜, 教授, 博士; 电话: 020-87111983; 传真: 020-87112948; E-mail: zhyxiao@scut.edu.cn