文章编号:1004-0609(2011)03-0611-07

Yb2O3掺杂对15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷性能的影响

何汉兵1, 2, 肖汉宁2

(1. 中南大学 冶金科学与工程学院, 长沙 410083; 2. 湖南大学 材料科学与工程学院, 长沙 410082)

摘 要:采用冷压-烧结技术制备NiFe2O4-10NiO基金属陶瓷材料;通过对烧结体的显微结构和物相组成、电导率、电解试样的表层形貌、电解质和阴极铝的杂质增量等的分析检测,研究Yb2O3掺杂对15(20Ni-Cu)/ NiFe2O4-10NiO金属陶瓷致密度、导电率和耐腐蚀性能的影响。结果表明:1 300 ℃烧结的0.5%Yb2O3-15(20Ni-Cu)/ (NiFe2O4-10NiO) 金属陶瓷具有较好的性能,相对密度为98.53%,960 ℃时的电导率为53.06 S/cm,电解腐蚀后金属腐蚀层厚度为20~30 ?m,总杂质增量为0.079 g。

关键词:金属陶瓷;Yb2O3;掺杂;惰性阳极;铝电解

中图分类号:TF 821 文献标志码:A

Effect of Yb2O3 doping on performances of 15(20Ni-Cu)/(NiFe2O4-10NiO) cermets

HE Han-bing1, XIAO Han-ning2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: NiFe2O4-10NiO based cermets were prepared with the cold isostatic pressing-sintering process. Based on the study of the microstructure and phase composition after sintering, electrical conductivity, surface morphology after electrolysis, impurity increment in electrolyte and cathode aluminum, the effects of Yb2O3 doping on relative density, electrical conductivity and corrosion resistance of 15(20Ni-Cu)/(NiFe2O4-10NiO) cermets were analyzed. The results show that the cermets of 0.5%Yb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO) sintered at 1 300 ℃ has better properties: the relative density of 98.53%,the electrical conductivity at 960 ℃ of 53.06 S/cm, the thickness of metal corrosion layer of 20-30 μm after electrolysis, and the total impurity increment in electrolyte and aluminum of 0.079 g.

Key words: cermets; Yb2O3; doping; inert anode; aluminum electrolysis

NiFe2O4 基金属陶瓷由于兼有陶瓷(抗腐蚀和氧化)和金属(良好的导电性和抗热震性) 的优点,被认为是最具潜力的惰性阳极材料之一[1-8]。 但该材料的烧结致密化、导电率和耐高温熔盐腐蚀性能都有待提高。

添加烧结助剂可以提高空位浓度梯度,促进材料烧结致密化,使材料在较低烧结温度下获得较高的致密度,避免晶粒过分长大,并可以减少陶瓷材料在制备过程中烧结工艺的调控难度。目前研究较多的添加剂主要集中在BaO[5, 9-13]、CuO[14]、MnO2[15]、TiO2[16]、V5O2[17-18]和CaO[19-20]等金属氧化物,这些添加剂能促进金属陶瓷的烧结致密化进程,但它们往往会与基体相结合形成新相,且富集在晶界处或在电解质中溶解度较大,从而降低了金属陶瓷晶界的耐腐蚀性能。而添加Yb2O3解决了以上的问题,且国内外相关文献中未见报道。

本文作者通过热力学计算和相图发现,掺杂的Yb2O3与阳极组元和电解质成分发生反应的可能性较小。因此,在较佳金属陶瓷组成(15(20Ni-Cu)/ (NiFe2O4-10NiO))的基础上掺杂Yb2O3进行实验, 当添加不同含量的Yb2O3粉末后, 采用冷压-烧结技术制备了xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO)(x=0.25%, 0.5%, 0.75%, 1.0%,质量分数)金属陶瓷;研究Yb2O3的掺杂量对材料致密度、导电率和腐蚀性能的影响。

1 实验

1.1 试样制备

按质量分数为38.68%和61.32%分别称取Fe2O3粉末(分析纯)和NiO粉末(分析纯),经球磨混合均匀并干燥后,装入刚玉坩锅,并将坩锅置于电阻炉中在空气气氛下于1 200 ℃煅烧6 h,得到NiFe2O4-10NiO陶瓷粉体。分别加入0、0.25%、0.5%、0.75%和1.0%(质量分数)Yb2O3的分析纯粉末于预先制备的NiFe2O4-10NiO陶瓷粉体中。加入金属粉末20Ni-Cu、分散剂和粘结剂于不锈钢球磨罐中二次球磨150 min,混合粉末干燥后在200 MPa 压力下双向压制成型为 d 20 mm × 40 mm的生坯,坯体在含有一定氧分压的N2 气氛中, 按一定升温制度在1 300 ℃烧结4 h,得到最终烧结样品。

1.2 性能检测

采用XJP-6A型金相显微镜及JSM-6360LV型扫描电镜进行显微组织和微观形貌分析;采用石蜡法(ASTM C373288 (1999)) 测定复合陶瓷的相对密度;采用四端电极法测试复合陶瓷在空气气氛中的电阻率,测试温度范围为25~1 100 ℃。电解实验所用电 解质的组成为78.07%Na3AlF6-9.5%AlF3-5.0%CaF2- 7.43%Al2O3,电解质分子比CR(电解质中NaF与AlF3的摩尔比)为2.3、初晶温度为947 ℃、电解温度为960 ℃、圆柱形阳极底部面积为2.5 cm2、电流密度为1.0 A/cm2;采用Philips8424 TW2424型X射线荧光分析(XRF)仪检测电解质和原铝中的杂质含量。

2 结果与讨论

2.1 Yb2O3掺杂量对15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷烧结致密度的影响

图1所示为在1 300 ℃烧结的xYb2O3-15(20Ni- Cu)/(NiFe2O4-10NiO) 金属陶瓷样品的相对密度。从图1可以看出:15(20Ni-Cu)/(NiFe2O4-10NiO)、0.25% Yb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO)、0.5%Yb2O3- 15(20Ni-Cu)/(NiFe2O4-10NiO)、0.75%Yb2O3-15(20Ni- Cu)/(NiFe2O4-10NiO) 和1.0%Yb2O3-15(20Ni-Cu)/ (NiFe2O4-10NiO)的相对密度分别为96.57%、96.93%、98.53%、98.32%和98.13%,说明随着掺杂量的增大,金属陶瓷样品的致密度呈先增大后减小的趋势,当掺杂量为0.5% Yb2O3时,相对密度最大,其最大值为98.53%。

图1 在1 300 ℃烧结的xYb2O3-15(20Ni-Cu)/(NiFe2O4- 10NiO) 金属陶瓷的相对密度

Fig.1 Relative density of xYb2O3-15(20Ni-Cu)/(NiFe2O4- 10NiO) cermet sintered at 1 300 ℃

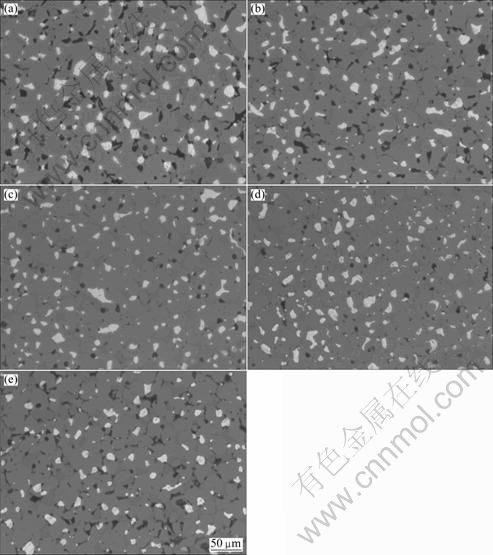

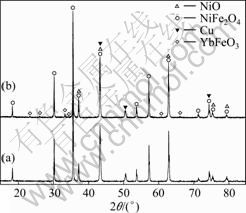

图2所示为在1 300 ℃烧结的xYb2O3-15(20Ni- Cu)/(NiFe2O4-10NiO)金属陶瓷的金相照片。从图2可以看出:随着掺杂量的增多,孔隙率先减小后增大,且当掺杂量为0.5% Yb2O3时,孔隙率最小;因此,其致密度变化关系应该是先增大后减小,在0.5% Yb2O3时致密度最大。说明随着掺杂量的增大,掺杂的Yb2O3会与NiFe2O4反应生成的YbFeO3相(见图3),同时形成Fe和O空位(见式(1)),增加了体系的点缺陷浓度,提高了体系的自由能,有利于烧结过程中原子的体积扩散,加速了物质的传质过程,从而促进了材料的烧结致密化过程,提高了致密度;但掺杂量较大后(掺杂量大于0.5%),其形成的Fe和O空位过多,对NiFe2O4相的结构稳定性产生影响,故其致密度反而降低,该结论与图1所示的烧结致密度一致。

(1)

(1)

2.2 Yb2O3掺杂量对15(Cu-20Ni)/(NiFe2O4-10NiO)基金属陶瓷导电性能的影响

图4所示为在1 300 ℃烧结的不同Yb2O3掺杂量

图2 在1 300 ℃烧结的xYb2O3-15(20Ni-Cu)/ ( NiFe2O4-10NiO)金属陶瓷的金相照片

Fig.2 OM images of xYb2O3-15(20Ni-Cu)/ (NiFe2O4-10NiO) cermets sintered at 1 300 ℃: (a) 15(20Ni-Cu)/(NiFe2O4-10NiO); (b) 0.25%Yb2O3- 15(20Ni-Cu)/(NiFe2O4-10NiO); (c) 0.5%Yb2O3- 15(20Ni-Cu)/(NiFe2O4-10NiO); (d) 0.75%Yb2O3- 15(20Ni-Cu)/(NiFe2O4-10NiO); (e) 1.0%Yb2O3- 15(20Ni-Cu)/(NiFe2O4-10NiO)

图3 在1 300 ℃烧结的未掺杂与掺杂0.5%Yb2O3样品的XRD谱

Fig.3 XRD patterns of different samples sintered at 1 300 ℃: (a) Without Yb2O3; (b) With 0.5%Yb2O3

图4 1 300 ℃烧结的xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷在不同温度下的电导率

Fig.4 Electrical conductivity measured at various temperatures for xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO) cermet sintered at 1 300 ℃

的15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷样品在不同测试温度下的电导率。由图4可以看出:对于每个样品,随着温度的提高,其导电性能都得到了不同程度的提高,呈现半导体导电特性;当Yb2O3的掺杂量分别为0.25%、0.5%、0.75%和1.0%时,960 ℃时金属陶瓷的电导率分别为45.81、53.06、37.35和32.28 S/cm。相比未掺杂样品的电导率41.58 S/cm,掺杂少量Yb2O3 (0.25%和0.5%)后,其金属陶瓷的电导率得到了较大的提高,比未掺杂样品的电导率分别提高了4.23和11.48 S/cm;但掺杂过多的Yb2O3后(0.75%和1.0%),其金属陶瓷导电率均有所下降,比未掺杂样品的导电率分别降低了4.23和9.30 S/cm。

金属陶瓷的导电性能由金属相与陶瓷基体相两者共同决定,当金属相的含量与分布状态基本相同时,陶瓷与金属相的界面结合及陶瓷基体相导电性能的变化决定体系的导电性能。当掺杂Yb2O3后,陶瓷与金属相的界面均形成了YbFeO3新相,其界面结合较为紧密。但是,当Yb2O3的掺杂量较少(0.25%和0.5%)时,陶瓷基体形成了较适宜的Fe和O空位,所以,导电性能得到了提高;而当Yb2O3的掺杂过多(0.75%和1.0%)时,陶瓷基体形成了大量的Fe和O空位,导致NiFe(2-x)O(4-3x/2)较多,其基体很不稳定,极易分解形成Ni和Fe的氧化物,因此,其导电性能降低。

2.3 Yb2O3的掺杂量对xYb2O3-15(Cu-20Ni)/ (NiFe2O4-10NiO)基金属陶瓷腐蚀性能的影响

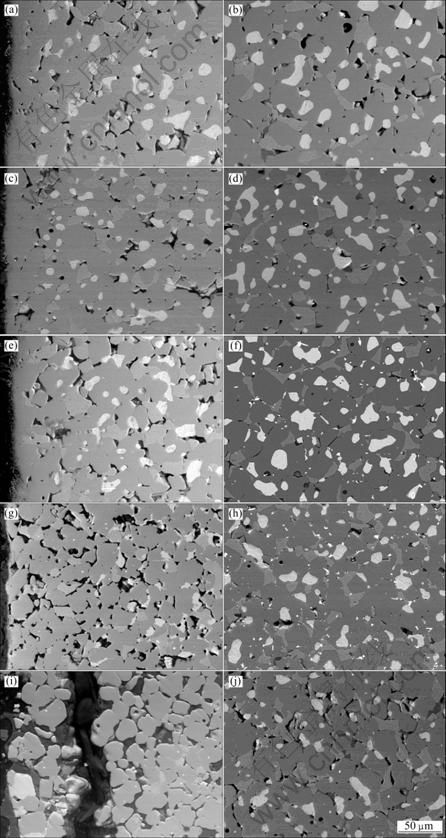

图5所示为在1 300 ℃烧结的xYb2O3-15(20Ni- Cu)/(NiFe2O4-10NiO)金属陶瓷电解腐蚀后其底部和心部的SEM像。从图5可以看出:未掺杂样品的金属腐蚀层厚度为50 ?m,当Yb2O3的掺杂量分别为0.25%、0.5%、0.75% 和1.0%时,其金属腐蚀层厚度分别为20~50、20~30、200和200 ?m,且掺杂量为

1.0%时,其阳极腐蚀层出现分层和裂纹现象。这说明当Yb2O3的掺杂量为0~0.5%时,随着掺杂量的增大,其金属腐蚀层厚度依次减小,抗熔盐腐蚀性能逐渐提高,这可能是因为在1 233 K电解温度下,Yb2O3与电解质中溶解的原铝和电解质中的氟化铝反应的吉布斯自由能变分别为184.43和2.73 kJ/mol,反应可能性较小,故耐腐蚀性能提高。而当Yb2O3的掺杂量为0.5%~1.0%时,随着掺杂量的增大,其金属腐蚀层厚度依次增大,说明其抗熔盐腐蚀性能逐渐降低,这可能是由于Yb2O3的掺杂量较大,其形成的Fe和O空位过多,对NiFe2O4相的结构稳定性产生影响,故耐腐蚀性能降低。

表1所列为xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷阳极电解腐蚀后的总杂质增量。从表1可以看出:15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷添加0.25%和0.5%的Yb2O3后提高了其阳极耐熔盐腐蚀性能,但添加较多的Yb2O3(0.75%和1.0%)将降低其阳极耐熔盐的腐蚀性能。表2所列为金属陶瓷电解后电解质和阴极铝液中阳极腐蚀元素的增量。由表2可以看出:电解质和阴极铝液中的各杂质增量都呈现先减小后增大的趋势,在样品0.5%Yb2O3-15(20Ni-Cu)/ (NiFe2O4-10NiO)中达到最小值。

表1 xYb2O3-15(20Ni-Cu)/( NiFe2O4-10NiO)金属陶瓷阳极的总杂质增量

Table 1 Net increments of impurity of xYb2O3-15(20Ni- Cu)/(NiFe2O4-10NiO) anode

表2 xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷电解后电解质和阴极铝液中阳极腐蚀元素的增量

Table 2 Net increments of elements from xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO) anode distributed in electrolyte and aluminum cathode

图5 1 300 ℃烧结的xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷电解后其底部和心部的SEM像

Fig.5 SEM images of xYb2O3-15(20Ni-Cu)/(NiFe2O4-10NiO) cermets sintered at 1 300 ℃ after electrolysis: (a) x=0, at bottom; (b) x=0, in center; (c) x=0.25%, at bottom; (d) x=0.25%, in center; (e) x=0.5%, at bottom; (f) x=0.5%, in center; (g) x=0.75%, at bottom; (h) x=0.75%, in center; (i) x=1.0%, at bottom; (j) x=1.0%, in center

3 结论

1) 在1 300 ℃烧结的xYb2O3-15(20Ni-Cu)/ (NiFe2O4-10NiO) 金属陶瓷样品随着Yb2O3掺杂量的增大,致密度呈先增大后减小的趋势,当掺杂0.5% Yb2O3时,金属陶瓷样品的相对密度最大(98.53%)。当未掺杂Yb2O3时、其在960 ℃的电导率为41.58 S/cm;当Yb2O3的掺杂量分别为0.25%、0.5%、0.75%和1.0%时,960 ℃时的电导率分别为45.81、53.06、37.35和32.28 S/cm,说明掺杂少量Yb2O3 (0.25%和0.5%)后,金属陶瓷的电导率得到了较大的提高,但Yb2O3的掺杂量(0.75%和1.0%)过多后,金属陶瓷的电导率均有所下降。

2) 当Yb2O3的掺杂量为0~0.5%时,随着掺杂量的增大,其金属腐蚀层厚度依次减小,其抗熔盐腐蚀性能得到提高;而当Yb2O3的掺杂量为0.5%~1.0%时,随着掺杂量的增大,其金属腐蚀层厚度依次增大,说明其抗熔盐腐蚀性能逐渐降低。

3) 15(20Ni-Cu)/(NiFe2O4-10NiO)、0.25%Yb2O3- 15(20Ni-Cu)/(NiFe2O4-10NiO)、0.5%Yb2O3-15(20Ni- Cu)/(NiFe2O4-10NiO)、0.75%Yb2O3-15(20Ni-Cu)/ (NiFe2O4-10NiO)和1.0%Yb2O3-15(20Ni-Cu)/(NiFe2O4- 10NiO)金属陶瓷电解腐蚀后总杂质增量分别为0.09、0.081,0.079、0.583和1.0 g,总杂质含量先下降后急剧上升,说明Yb2O3的掺杂范围为0.25%~0.5%时有利于15(20Ni-Cu)/(NiFe2O4-10NiO)金属陶瓷腐蚀性能的提高。

REFERENCES

[1] OLSEN E, THONSTAD J. The behaviour of nickel ferrite cermet materials as inert anodes[C]//HALE W. Light Metals 1996. Warrendale PA: TMS, 1996: 249-257.

[2] OLSEN E, THONSTAD J. Nickel ferrite as inert anodes in aluminum electrolysis: PartⅠ. Material fabrication and preliminary testing [J]. Journal of Applied Electrochemistry, 1999, 29(3): 293-299.

[3] LAI Yan-qing, TIAN Zhong-liang, LI Jie, YE Shao-long, LI Xin-zheng, LIU Ye-xiang. Results from 100 h electrolysis testing of NiFe2O4 based cermet as inert anode in aluminum reduction [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 970-974.

[4] LI Jie, ZHANG Gang, LAI Yan-qing, ZHANG Yong, TIAN Zhong-liang. Densification and sintering dynamics of NiFe2O4-10NiO composites doped with CaO[J]. Journal of Central South University of Technology, 2007, 14(5): 629-632.

[5] 何汉兵, 周科朝, 李志友. NiFe2O4基金属陶瓷惰性阳极的腐蚀研究进展[J]. 腐蚀与防护, 2008, 29(7): 359-364.

HE Han-bing, ZHOU Ke-chao, LI Zhi-you. Progress in studies on corrosion of NiFe2O4 based cermet inert anodes[J]. Corrosion and Protection, 2008, 29(7): 359-364.

[6] 张 雷, 周科朝, 李志友, 张晓泳. 气氛对NiFe2O4陶瓷烧结致密化的影响[J]. 中国有色金属学报, 2004, 14(6): 1002-1006.

ZHANG Lei, ZHOU Ke-chao, LI Zhi-you, ZHANG Xiao-yong. Effect of atmosphere on densification in sintering nickel ferrite ceramic for aluminum electrolysis[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 1002-1006.

[7] 焦万丽, 张 磊, 姚广春, 刘宜汉. NiFe2O4及添加TiO2的尖晶石的烧结过程[J]. 硅酸盐学报, 2004, 32(9): 1150-1153.

JIAO Wan-li, ZHANG Lei, YAO Guang-chun, LIU Yi-han. Sintering process of NiFe2O4 spinel with and without TiO2 adding[J]. Journal of the Chinese Ceramic Society, 2004, 32(9): 1150-1153.

[8] 席锦会, 姚广春, 刘宜汉. 添加物对镍铁尖晶石惰性阳极微观结构和性能的影响[J]. 东北大学学报: 自然科学版, 2005, 26: 574-577.

XI Jin-hui, YAO Guang-chun, LIU Yi-han. Effect of additives on microstructure and properties of inert anode of NiFe2O4 spinel[J].Journal of northeastern university: Natural science, 2005, 26: 574-577.

[9] HE Han-bing, ZHOU Ke-chao, LI Zhi-you, HUANG Bai-yun. Effect of BaO addition on electric conductivity of xCu/ NiFe2O4-10NiO cermets[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1134-1138.

[10] 何汉兵, 周科朝, 李志友, 黄伯云. 烧结温度对1BaO-10NiO- NiFe2O4复合陶瓷导电性能的影响[J]. 功能材料, 2008,39(9):1462-1465.

HE Han-bing, ZHOU Ke-chao, LI Zhi-you, HUANG Bai-yun. Effect of sintering temperature on electric conductivity of 1BaO-10NiO-NiFe2O4 composite ceramics[J]. Functional Material, 2008, 39(9): 1462-1465.

[11] 何汉兵, 黄伯云, 李志友, 周科朝. BaO掺杂对10NiO- NiFe2O4复合陶瓷烧结致密化的影响[J]. 中国有色金属学报,2008, 18(5): 851-855.

HE Han-bing, HUANG Bai-yun, LI Zhi-you, ZHOU Ke-chao. Effect of BaO doping on densification of 10NiO-NiFe2O4 composite ceramics[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 851-855.

[12] 何汉兵, 黄伯云, 李志友, 周科朝. BaO掺杂对10NiO- NiFe2O4复合陶瓷导电性能的影响[J]. 功能材料, 2009, 40(4): 635-638.

HE Han-bing, HUANG Bai-yun, LI Zhi-you, ZHOU Ke-chao. Effect of BaO doping on electric conductivity of 10NiO-NiFe2O4 composite ceramics[J]. Functional Material, 2009, 40(4): 635-638.

[13] HE Han-bing, LI Zhi-you, ZHOU Ke-chao, HUANG Bai-yun. Effect of BaO addition on the electrical conductivity of xNi/10NiO-NiFe2O4 cermets[J]. Journal of Central South University of Technology, 2009, 16(5): 703-707.

[14] 何汉兵, 周科朝, 李志友, 黄伯云. CuO掺杂对10NiO- NiFe2O4复合陶瓷导电性能的影响[J]. 功能材料, 2008, 39(5): 757-760.

HE Han-bing, ZHOU Ke-chao, LI Zhi-you, HUANG Bai-yun. Effect of adding CuO on electric conductivity of 10NiO-NiFe2O4 composite ceramics[J]. Functional Material, 2008, 39(5): 757-760.

[15] 席锦会, 刘宜汉, 姚广春. MnO2对镍铁尖晶石惰性阳极材料性能的影响[J]. 功能材料, 2005, 36(3): 374-376.

XI Jin-hui, LIU Yi-han, YAO Guang-chun. Effect of MnO2 doping on properties of nickel ferrite as inert anode[J]. Functional Material, 2005, 36(3): 374-376.

[16] XI Jin-hui, XIE Ying-jie, YAO Guang-chun, LIU Yi-han. Effect of additive on corrosion resistance of NiFe2O4 ceramics as inert anodes[J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 356-360.

[17] 席锦会, 姚广春, 刘宜汉, 张晓明. V2O5对镍铁尖晶石烧结机理及性能的影响[J]. 硅酸盐学报, 2005, 33(6): 683-687.

XI Jin-hui, YAO Guang-chun, LIU Yi-han, ZHANG Xiao-ming. Effect of additive V2O5 on sintering mechanism and properties of nickel ferrite[J]. Journal of the Chinese Ceramic Society, 2005, 33(6): 683-687.

[18] 席锦会, 姚广春, 刘宜汉, 张晓明. 五氧化二钒对铁酸镍基金属陶瓷惰性阳极导电行为的影响[J]. 硅酸盐学报, 2006, 34(1): 34-38.

XI Jin-hui, YAO Guang-chun, LIU Yi-han, ZHANG Xiao-ming. Effect of additive V2O5 on electrical conductivity of nickel ferrite based cermets[J]. Journal of the Chinese Ceramic Society, 2006, 34(1): 34-38.

[19] 赖延清, 张 勇, 张 刚, 李 劼, 贺跃辉, 黄伯云, 刘业翔. CaO 掺杂对10NiO-NiFe2O4 复合陶瓷烧结致密化的影响[J]. 中国有色金属学报, 2006, 16(8): 1355-1360.

LAI Yan-qing, ZHANG Yong, ZHANG Gang, LI Jie, HE Yue-hui, HUANG Bai-yun, LIU Ye-xiang. Effect of CaO doping on densification of 10NiO-NiFe2O4 composite ceramics[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(8): 1355-1360.

[20] LI Jie, ZHANG Gang, LAI Yan-qing, ZHANG Yong, TIAN Zhong-liang. Densification and sintering dynamics of 10NiO-NiFe2O4 composites doped with CaO[J]. Journal of Central South University of Technology, 2007, 14(5): 629-632.

(编辑 陈卫萍)

基金项目:国家自然科学基金创新团队资助项目(50721003); 国家重点基础研究发展计划资助项目(2005CB623703); 国家高技术研究发展计划资助项目(2008AA030501); 中央高校基本科研经费资助项目(201012200021)

收稿日期:2010-03-11;修订日期:2010-07-27

通信作者:何汉兵,博士;电话:0731-88830216; E-mail: hehanbinghhb@163.com