文章编号:1004-0609(2013)11-3064-11

2E12铝合金在冷轧和退火过程中织构和显微组织的演变

汪 波1,易丹青1, 2,陈宇强1,王 斌1, 2,李泽英1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用取向分布函数(ODF)和背散射电子衍射技术(EBSD)研究冷轧和退火对2E12铝合金织构的影响,并采用透射电镜(TEM)分析亚结构在冷轧与退火过程的演变规律。结果表明:2E12合金热轧板在冷变形过程中,随着冷轧变形量从40%增加到80%,黄铜织构(Brass){011}<211>和S型织构{123}<634>逐渐增多,立方织构(Cube){001}<100>明显减少。在退火过程中残留的立方取向亚晶通过晶界迁移吞噬周围的S取向亚晶而优先长大。在470℃退火0.5h后,立方织构(Cube){001}<100>成为主要取向,其体积分数为36%。在相同的退火工艺条件下,随着冷变形量的增加,退火后2E12合金的立方织构体积分数增大。

关键词:2E12铝合金;冷轧;退火;织构;亚结构

中图分类号:TG146.2 文献标志码:A

Evolution of texture and microstructure of 2E12 aluminum alloy during cold rolling and annealing

WANG Bo1, YI Dan-qing1, 2, CHEN Yu-qiang1, WANG Bin1, 2, LI Ze-ying1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The effects of cold rolling and annealing on textures of 2E12 aluminum alloy were investigated by means of orientation distribution function (ODF) and electron backscattered diffraction (EBSD). In addition, the evolution of substructure during cold rolling and annealing was analyzed by TEM. The results show that, with the increase of the deformation from 40% to 80%, main conclusions are presented as follow: Brass texture{011}<112> and S texture {123}<634> increase during the cold rolling, while cube texture {001}<100> significantly reduces. In the annealing process, the residual cube sub-grains devour surrounding sub-grains of S orientation through the grain boundary migration and preferentially grow up. The cubic texture becomes major orientation and its volume fraction is 36% at 470 ℃ for 0.5 h. Under the same annealing process conditions, the volume fraction of recrystallization texture in the annealing alloy increases with the increase of the deformation.

Key words: 2E12 aluminum alloy; cold rolling; annealing; texture; substructure

Al-Cu-Mg系合金具有良好的室温力学性能及优良的断裂韧性与抗疲劳性能,在航空航天工业中应用十分广泛,其中2E12铝合金是疲劳性能优异的Al-Cu-Mg系合金之一[1-3]。由于合金的织构对合金的力学性能和疲劳性能都有重要的影响[4-5],所以研究2E12合金的织构在变形和退火过程的演变规律有重要意义。

多晶体金属经过冷加工会产生变形织构,经过再结晶退火后会出现再结晶织构。再结晶主要包括形核和晶粒长大两个主要过程,而晶粒长大主要靠大角度晶界的迁移,所以影响形核和大角度晶界迁移的所有因素都会影响再结晶织构的形成。关于再结晶织构的形成,尤其是面心立方合金中立方织构的形成,目前主要有两种理论。DILLAMORE等[6]研究了立方金属的立方过渡带中特定亚结构的形成过程和对再结晶形核的影响,认为非立方取向的晶粒在形变时沿特定的取向路径转到立方取向,成为再结晶晶核,最终形成了很强的立方织构,在此基础上他们提出了定向形核理论;IBE等[7]发现,如果立方晶粒与变形基体有特定的位向关系,它们的晶界有很大的迁移速率,他们提出了定向长大理论,这个理论很好地解释了立方织构的形成机制。该理论也在其他人的研究中得到证明,YANG[8]研究发现Al-Mn合金的再结晶过程中,由于取向钉扎,立方晶粒的长大速度大于其他取向的晶粒;DUGGAN等[9]观察到了再结晶初期立方晶核优先在S取向基体生长,而很少向其他取向基体生长,这是由于40°<111>关系显微优先生长。最近的研究主要集中于Al合金的再结晶织构的演变模型,如CRUMBACH等[10]基于再结晶的驱动力依赖于变形储能,建立一个定向选择模型很好地解释了再结晶织构的演变规律。目前,在实验和理论上还没开展对Al-Cu-Mg系合金在冷变形与退火过程中织构的演变规律的研究,退火温度与时间、变形量等因素对2E12合金织构的影响也需作进一步研究。

本文作者采用取向分布函数(ODF)和背散射电子衍射技术(EBSD),并结合透射电镜(TEM)分析亚结构在冷轧与退火过程的演变规律,从实验角度研究冷轧及退火过程2E12铝合金织构的演变规律。

1 实验

1.1 材料成分

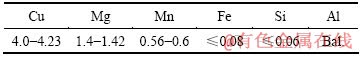

实验材料为西南铝业集团提供的6 mm厚的2E12铝合金热轧薄板,包铝层厚度约为0.1 mm,合金化学成分如表1所列。

表1 2E12合金化学成分表

Table 1 Chemical composition of 2E12(mass fraction, %)

1.2 实验方法

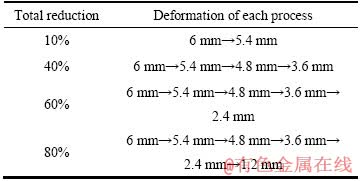

将6 mm厚度的2E12热轧板样品进行冷轧,通过控制每个道次轧制前后的厚度来控制其变形量,每道次的变形量如表2所列。每次轧制变形之后放入智能箱式高温炉中进行退火处理。

表2 冷轧工艺中的道次变形量

Table 2 Deformation of each cold rolling process

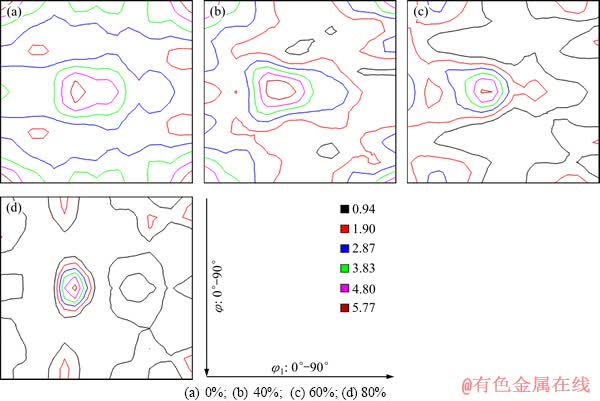

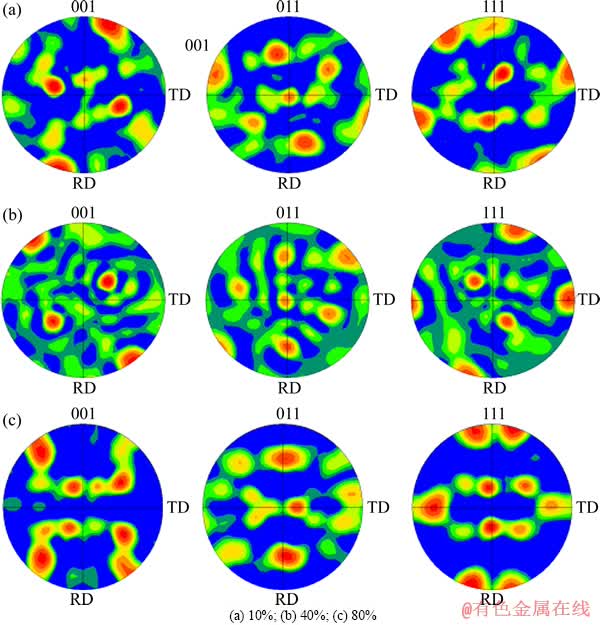

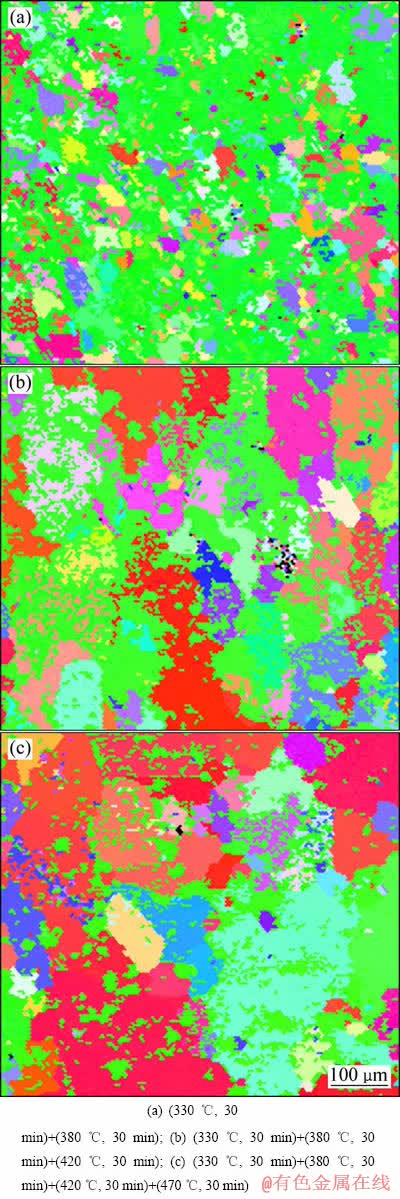

图1 2E12合金冷轧板的ODF截面图(φ2=0°)

Fig. 1 Sections of ODFs of 2E12 aluminum alloy after different reductions (φ2=0°)

织构测定所用试样经过400、600至1 000号的砂纸打磨后即可进行电解抛光。抛光液的成分(体积分数)为33%硝酸+67%甲醇溶液,工作温度为-20 ℃,工作电压为20 V,电流为0.5 A,抛光时间约为40 s。样品抛光后立即用酒精反复冲洗、吹干,并放干燥皿内保存。织构测定在Bruker D8 Discover X射线衍射仪上进行,管电压为40 kV,管电流为40 mA。采用Cu Kα辐射,极图测量范围:α为5°~85°,β为0°~360°。

EBSD样品采用上述相同的电解抛光后立即用酒精反复冲洗、吹干。 EBSD数据采集在JSM-5600LV型场发射型扫描电子显微镜配带的EBSD探测系统上进行,采用的步径根据放大倍数视情况选择,数据采集后通过TSL公司提供的分析软件对采集的数据进行分析。

透射样品首先机械减薄至0.1 mm左右,在MT-PI型双喷电解减薄仪上进行双喷减薄,双喷时采用的电压为15~20 V,工作电流控制在50 mA左右,双喷液采用(体积分数)为25%硝酸+75%甲醇混合溶液,用液氮冷却至-25 ℃以下,然后在TecnaiG220型高分辨透射电子显微镜上进行微观组织观察。

2 结果分析

2.1 织构和亚结构在冷变形过程中的演变规律

采用X射线衍射法分析原始热轧板和不同的变形量的冷轧板的织构分布,研究冷变形过程中织构的演变过程。图1所示为取向函数分布截面图(φ2=0°),图2所示为织构体积分数图。

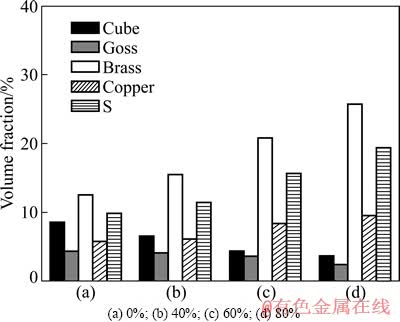

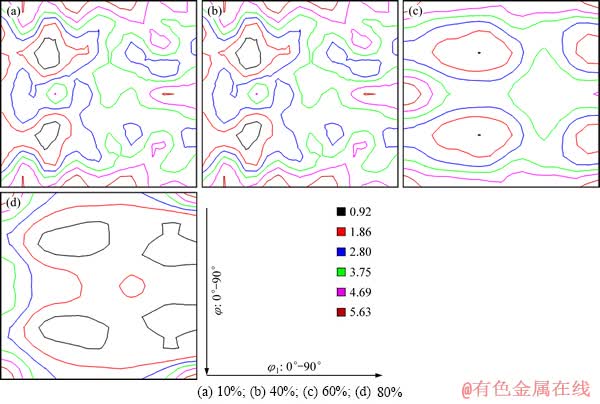

图2 2E12合金热轧板在不同变形量条件下的织构体积分数

Fig. 2 Volume fractions of texture in 2E12 aluminum alloy after different reductions

图3 2E12合金热轧板在不同变形量条件下的EBSD像(绿色为黄铜织构,紫色为S织构,红色为立方织构)

Fig. 3 EBSD orientation maps of 2E12 aluminum alloy after different reductions (The green part is brass texture, the purple part is S texture, the red part is cube texture.)

从图1可以看出,变形前热轧板中主要存在黄铜织构(Brass){011}<211>、S型织构{123}<634>,也存在立方织构(Cube){001}<100>。随着变形量的增加, 黄铜织构(Brass){011}<211>、S型织构{123}<634>增多,立方织构(Cube){001}<100>明显减少。从图2可以看出,变形量为80%时,黄铜织构(Brass){011}<211>和S型织构{123}<634>的体积分数分别约为25%和20%,立方织构的体积分数仅为4%。

为了分析微观组织在冷变形及退火过程中的演变规律,采用EBSD分析不同变形量的冷轧板(未中间退火)的织构分布和晶粒形貌,图3 所示为热轧板经不同冷变形后的EBSD像,图4所示为热轧板在不同变形量条件下的极图。

从图3和4可以看出,随着变形量的增加,晶粒逐渐破碎为细小的亚晶,晶粒尺寸逐渐减小,黄铜织构(Brass){011}<211>和S型织构{123}<634>明显增加,而立方织构(Cube){001}<100>则显著减少。当变形量为80%时,少量的立方织构仍然保留,且这部分立方取向的亚晶分布于S取向和黄铜取向的亚晶之间。

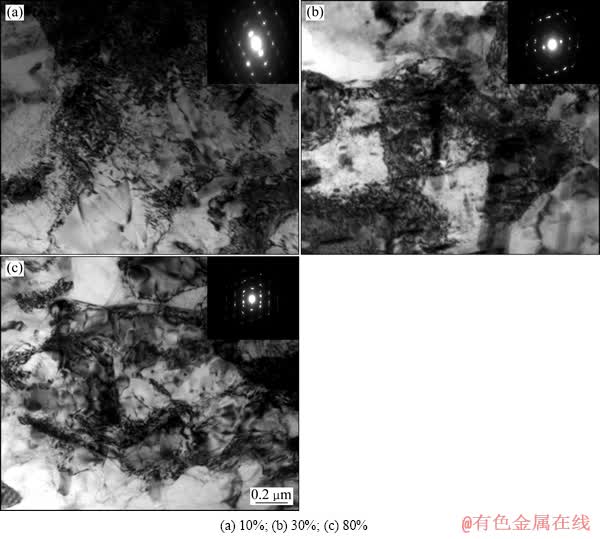

为研究冷变形对亚结构的影响,选取不同变形量冷轧板的TEM像进行对比分析,如图5所示。

如图5所示,晶粒内的位错组态呈现许多不均匀的、局部位错高密度区。由于这些亚晶与基体呈一定取向差,因此,这些亚晶的衍射斑与基体的衍射斑会存在一定的偏离。随着变形量的增加,发生的偏移程度明显加大,说明亚晶的取向差明显增大。衍射斑点原本呈圆形状分布,在变形后呈小圆弧形分布,且随着变形量的增加,圆弧的弧度逐步增加。这种变化主要是变形后合金基体破碎形成许多细小的亚晶所造成的。

2.2 织构和亚结构在退火过程中的演变规律

为研究2E12合金在退火过程中织构的演变规律,选择经过80%冷变形的冷轧板,采用不同的退火制度,然后采用X射线衍射法分析退火板材中的织构分布。图6所示为织构取向分布函数的截面图,图7所示为织构体积分数图。

图4 2E12合金热轧板在不同变形量条件下的极图

Fig. 4 Pole figures of 2E12 aluminum alloy after different reductions (The green part is brass texture, the purple part is S texture, the red part is cube texture.)

图5 不同变形量的冷轧板样品的TEM像与衍射花样

Fig. 5 TEM images and diffraction patterns of cold rolled plates after different reductions

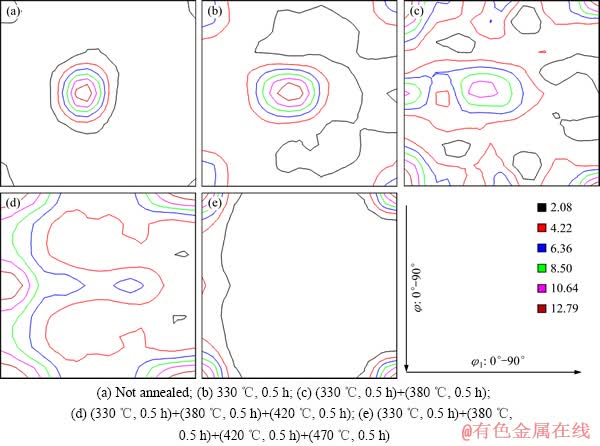

图6 2E12合金经80%的冷变形后逐步退火过程中的ODF截面图(φ2=0°)

Fig. 6 Sections of ODFs of 2E12 aluminum alloy after 80% reduction annealed under different conditions(φ2=0°)

图7 2E12合金经80%冷变形后在不同退火制度下的织构体积分数

Fig. 7 Volume fractions of texture in 2E12 aluminum alloy after 80% reduction annealed under different conditions

从图6可以看出,在330 ℃退火0.5 h时,黄铜织构(Brass){011}<211>减少,立方织构(Cube){001}<100>增多;然后继续在380 ℃退火0.5 h时,黄铜织构继续减少,立方织构继续增加,部分黄铜织构转换为Goss戈斯织构{110}(001);然后在420 ℃退火0.5 h时,黄铜织构继续减少,立方织构和戈斯织构成为主要取向;然后在470 ℃退火0.5 h后,立方织构为主要取向,黄铜织构和S织构很少。如图7所示,当选用(330 ℃, 0.5 h)+(380 ℃, 0.5 h)+(420 ℃, 0.5 h)+(470 ℃, 0.5 h)的退火制度时,立方织构(Cube){001}<100>和戈斯织构(Goss){110}<001>的体积分数分别为36%和17%,黄铜织构(Brass){011}<211>和S型织构{123}<634>的体积分数仅为8%和3%。

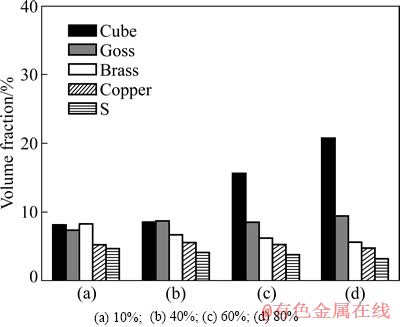

采用EBSD分析冷轧变形量为80%的板材在不同退火制度下的织构分布和晶粒形貌,结果如图8所示。

从图8可以看出,2E12合金在变形量为80%的冷变形后,随着退火温度的升高和退火时间的延长,立方织构(Cube){001}<100>逐渐占据明显优势,出现尺寸较大的立方取向的晶粒。这也说明升高退火温度和延长退火时间,有利于立方织构的形成。

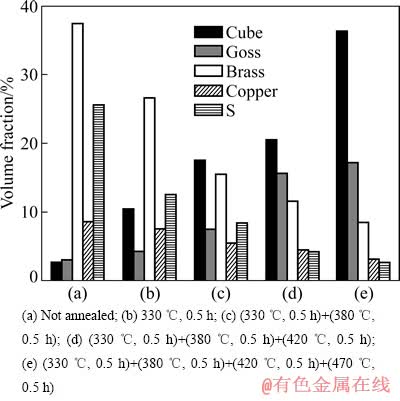

为研究变形量对退火过程中的织构类型和含量的影响,选择不同变形量的冷轧板在470 ℃退火0.5 h时,其取向函数截面图和织构体积分数如图9和10所示。

由图9和10可以看出,随着变形量的增加,退火后的立方织构(Cube){001}<100>增多。从图10可知,变形量为10%和40%时,退火后立方织构体积分数约为8%;变形量为60%和80%时,立方织构体积分数分别为15%和20%。

图8 冷轧变形量为80%的2E12合金在不同退火制度下的EBSD像

Fig. 8 EBSD images of 2E12 aluminum alloy after 80% reduction annealed under different conditions (The green part is brass texture, the red part is cube texture.)

图9 不同冷变形量的2E12合金在470 ℃退火0.5 h后的ODF截面图(φ2=0°)

Fig. 9 Sections of ODFs of 2E12 aluminum alloy after different reductions annealed at 470 ℃ for 0.5 h (φ2=0°)

图10 不同冷变形量的2E12合金在470 ℃退火0.5 h后的织构体积分数

Fig. 10 Volume fractions of texture in 2E12 aluminum alloy after different reductions annealed at 470 ℃ for 0.5 h

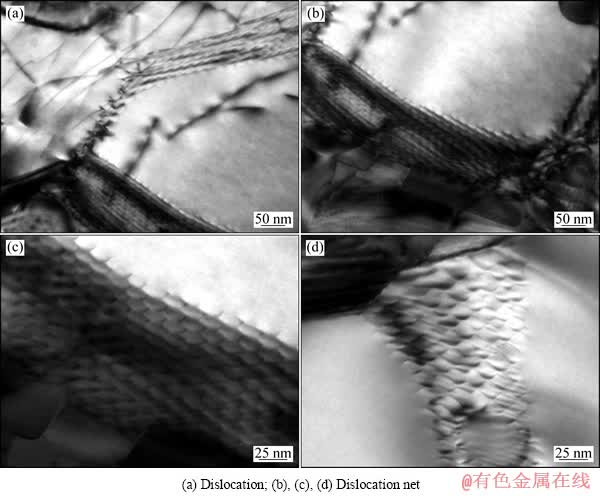

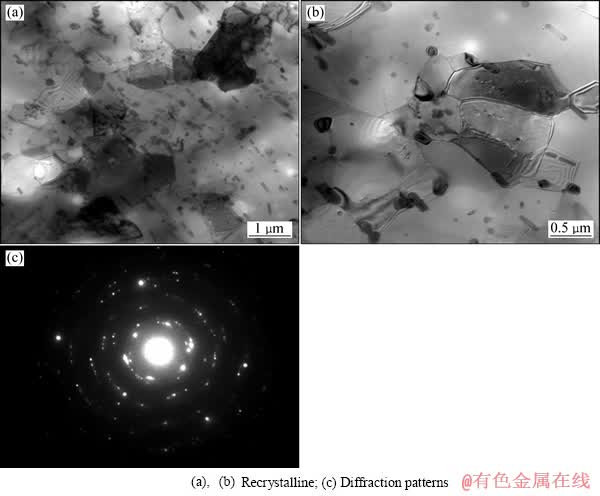

为研究亚结构在退火过程中的演变规律,对变形量较小(10%)的冷轧板退火后的TEM像进行分析,结果如图11所示。

对比冷轧板的TEM像,随着退火的进行,首先发生回复过程,位错变得比较平直和规整(如图11(a)所示),胞内变得几乎无位错,胞壁变得更清晰,亚晶界有更多的位错形成位错网络(如图11(b),(c),(d)所示)。

变形量很大(80%)的冷轧板退火后的微观组织TEM像如图12所示。

如图12所示,衍射斑呈环状分布,说明发生了明显的再结晶。从图12(a)、(b)中可观察到尺寸较大的再结晶晶粒。

综合以上透射电镜的实验结果,2E12合金的亚结构在冷变形和退火过程发生一系列的变化。在冷变形过程中,位错密度增加,位错通过交互作用缠结在一起,形成了胞状组织。在退火中首先发生回复,由于胞状组织内的位错与胞壁的异号位错相互抵消,使位错密度降低,从透射电镜下观察到胞状组织更加规整,胞壁变薄且清晰,亚晶界上出现了能量较低的位错网络。在再结晶形核过程中,一般认为是通过亚晶粒的合并来实现的,相邻的亚晶粒某些边界上的位错,通过攀移和滑移,转移到两个亚晶外边的亚晶界上,导致两个亚晶之间的亚晶界消失,合并为一个大的亚晶,合并后的较大亚晶的晶界上有更多的位错,逐渐转化为易动性大的大角度晶界,就成为再结晶晶核。

3 讨论

3.1 变形织构的演变

对于面心立方金属,形成强的立方织构需满足以下条件:在变形基体中存在立方取向的亚晶,立方亚晶能够成为再结晶晶核,这些晶核通过大角度晶界的迁移迅速长大,得到尺寸较大的立方晶粒,最后形成较强的立方织构。

图11 2E12合金冷轧板退火后的TEM像

Fig. 11 TEM images of cold rolled plates after annealed at 380 ℃ for 5 min

图12 2E12合金冷轧板退火后的TEM像和衍射花样(变形量80%,退火温度380 ℃ ,退火时间5 min)

Fig. 12 TEM images and diffraction patterns of cold rolled plates after 80% reduction at 380 ℃ for 5 min

立方织构在变形过程是不稳定的取向,立方取向通常可以旋转到{124}<211>、{123}<624>和{011}<100>,但是在很大的变形之后仍然观察到存在立方晶粒。在O-RD-TD-ND的坐标系里,设1、2、3分别代表RD、TD、ND 3个方向。立方晶粒在变形过程中有四种滑移系: 、

、 、

、 和

和 。SIDOR等[10]认为在大变形的条件下,由于与立方晶粒相邻的其他晶粒的阻碍作用,4种滑移系的开动都不会改变立方晶粒的取向,此时产生的应变ε11>0,ε33=-ε11,ε12=ε13=ε23=0。由于4种滑移系的开动,立方亚晶在变形过程中受到周围亚晶很小的应力作用,同时与4种滑移系对应的两个伯氏矢量是相互垂直的,所以在变形过程中立方亚晶不易发生位错的扭曲、塞积与反应,立方亚晶的位错易发生滑移,导致位错密度降低,最后立方亚晶的位错密度明显低于其他亚晶。在退火过程中,立方亚晶与其他亚晶的位错密度的差异使立方亚晶优先成为再结晶晶核,在大变形的条件下,变形基体中仍然存在立方晶粒。从图2中也可以看出,在变形量为80%时,仍存在体积分数为2%的立方织构。从图3的EBSD照片可以看出:在变形量为80%的变形之后,变形基体中仍存在立方晶粒,实验很好地证明以上结论。

。SIDOR等[10]认为在大变形的条件下,由于与立方晶粒相邻的其他晶粒的阻碍作用,4种滑移系的开动都不会改变立方晶粒的取向,此时产生的应变ε11>0,ε33=-ε11,ε12=ε13=ε23=0。由于4种滑移系的开动,立方亚晶在变形过程中受到周围亚晶很小的应力作用,同时与4种滑移系对应的两个伯氏矢量是相互垂直的,所以在变形过程中立方亚晶不易发生位错的扭曲、塞积与反应,立方亚晶的位错易发生滑移,导致位错密度降低,最后立方亚晶的位错密度明显低于其他亚晶。在退火过程中,立方亚晶与其他亚晶的位错密度的差异使立方亚晶优先成为再结晶晶核,在大变形的条件下,变形基体中仍然存在立方晶粒。从图2中也可以看出,在变形量为80%时,仍存在体积分数为2%的立方织构。从图3的EBSD照片可以看出:在变形量为80%的变形之后,变形基体中仍存在立方晶粒,实验很好地证明以上结论。

3.2 再结晶织构的形成

在退火过程中,一般同时伴随着定向形核和定向长。定向形核指优先在特定取向的位置优先形成再结晶晶核,由于形核位置和变形基体的储能之差,位错的抵消导致低位错密度区域的产生。如图11所示的TEM像中,位错胞内变得几乎无位错。定向长大指再结晶晶粒和变形基体有特定的位向关系,两者之间的晶界有较大的迁移速率,这样有利于再结晶晶核的长大。从图11和12所示的TEM像中可以看到,在再结晶形核和长大过程中,亚晶通过合并,形成较大尺寸的再结晶晶粒。

在前面的讨论中提到,变形后变形基体中仍存在少量稳定的立方亚晶,然而其中大部分立方取向转向其他取向。立方取向一般转到Goss{011}<100>取向或S{123}<624>取向。SIDOR等[10]认为,在变形过程中与稳定的立方亚晶相邻的立方晶粒,更易于偏离立方取向,最终导致这些转向晶粒和稳定立方亚晶的取向差变得很大。在退火过程,容易形成大角度晶界,成为再结晶晶核。从前面的图1和2中可以看出,冷变形之后,主要含有黄铜织构(Brass){011}<211>、S型织构{123}<634>。这些取向的变形晶粒和立方晶核都有大角度晶界,所以变形基体中残余的立方亚晶更容易长大。

对于冷变形金属,再结晶长大是通过亚晶的迁移进行的,而亚晶的晶界迁移速率正比于晶界的净迁移驱动力,则晶界的迁移速率V可表示为[11-13]:

(1)

(1)

式中:m为晶界的可动系数,Pi为晶界迁移的驱动力与约束力(正值时为驱动力,负值时为约束力)。

冷变形金属再结晶时,晶界迁移的驱动力主要有再结晶驱动力Pd和界面能提供的驱动力Pg。其中,再结晶驱动力Pd是晶界迁移前后的位错应变能的下降。相邻的亚晶的储能差越大,相邻亚晶之间的晶界迁移的再结晶驱动力越大。

对于界面能提供的驱动力Pg可表示为

Pg=2g/R (2)

式中:g为单位面积晶界的界面能,R为晶界的曲率半径。

综合式(1)和(2),可得到晶界的迁移速率为

V=m(Pd+2g/R) (3)

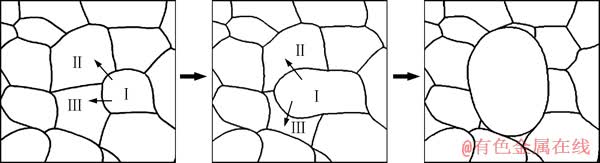

当变形量为80%,但仍然保留有少量立方织构,且这部分立方取向的亚晶分布于S{123}<624>取向的亚晶之间。一是S取向的较高的储存能,S取向和立方取向的亚晶之间的储能差较大,所以晶界迁移的再结晶驱动力Pd较大[14]。二是立方取向与S取向的夹角分别为33.6°,对于面心立方金属,具有40°<111>关系显微优先生长,S取向和立方取向的亚晶晶界的界面能g较大,故晶界的界面能驱动力Pg较大[9]。由式(3)可知,冷轧板中分布于S取向亚晶之间的部分立方取向亚晶在微观尺寸范围内有较大的晶界迁移速率,在再结晶过程中,立方取向的亚晶通过吞噬周围S取向和黄铜取向的亚晶迅速再结晶并长大,界面移动的示意图如图13所示。综上所述,变形之后变形基体中残余的稳定立方亚晶容易形成再结晶晶核,并且优先长大,最后形成明显的立方织构,很好地解释实验中的立方织构的演变规律。

从图7中可以得出,在相同的变形量条件下,随着退火时间的延长和退火温度的升高,由于有利于形核的大角度晶界的迁移速率增大,再结晶更加充分,形成更多的再结晶立方织构。退火工艺对织构的影响,这与众多的研究结果是一致的[16-19]。

从图10中可以得出,在同一退火工艺下,随着冷变形量的增加,退火后2E12合金的再结晶织构增多。由于随着冷变形程度的增加,畸变储能增加,变形基体有更多的缺陷,再结晶驱动力Pd更大,晶界迁移速率更大,更有利于立方取向择优长大,所以形成更多的立方织构。

图13 不同取向的亚晶界面移动示意图(其中晶粒Ⅰ为立方取向,晶粒Ⅱ、Ⅲ为S取向,箭头表示界面移动方向)

Fig. 13 Sketch map of subboundary migration at different orientations (The orientation of grain Ⅰ is cube orientation, the orientations of grain Ⅱ and grain Ⅲ are S orientation.)

4 结论

1) 2E12合金热轧板在冷变形过程中,随着变形量的增加,黄铜织构(Brass){011}<211>和S型织构{123}<624>的体积分数逐渐增大,当变形量为80%时,黄铜织构(Brass){011}<211>和S型织构{123}<634>的体积分数分别约为25%和20%,立方织构的体积分数仅为4%,这部分立方取向的晶粒分布于变形晶粒周围。

2) 相比于立方晶粒与其他变形晶粒的晶界,立方晶粒与S取向晶粒的晶界有较大的晶界迁移速率,所以在退火过程中立方取向的亚晶通过吞噬周围的S取向亚晶而优先长大,形成很强的立方织构。

3) 在退火过程中,大的变形量、退火时间的延长和退火温度的提高均有利于2E12合金立方织构的形成。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1714.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1714.

[2] 杨守杰, 戴圣龙. 航空铝合金的发展回顾与展望[J]. 材料导报, 2005, 19(2): 76-80.

YANG Shou jie, DAI Sheng long. glimpse at the development and application of aluminum alloys in aviation industry[J]. Materials Review, 2005, 19(2): 76-80.

[3] 周明哲, 易丹青, 王 斌, 黄道远. 固溶处理对2E12铝合金组织及疲劳断裂行为的影响[J]. 中南大学学报: 自然科学版, 2012, 43(1): 66-73.

ZHOU Ming zhe, YI Dan qing, WANG Bin, HUANG Dao yuan. The effect of solution treatment on fatigue behavior of 2E12 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2012, 43(1): 66-73.

[4] MALIK M A, SALAM I, MUHAMMAD W, EJAZ N. Role of extruded texture on fatigue crack growth in a high strength aluminum alloy thick-walled cylinder[J]. Journal of Mechanical Science and Technology, 2009, 23: 1261-1269.

[5] WUA L, AGNEWB S R, RENC Y, BROWND D W, CLAUSEND B, STOICAA G M, WENKE H R, LIAW P K. The effects of texture and extension twinning on the low-cycle fatigue behavior of a rolled magnesium alloy, AZ31B[J]. Materials Science and Engineering A, 2010, 527: 7057-7067.

[6] DILLAMORE I L, KATOH H. The mechanisms of recrystallization in cubic metals with particular reference to their orientation-dependence[J]. Metal Science, 1974, 8: 73-78.

[7] IBE G, DIETZ W, FRAKER A C,  K. Vorzugsorientierungen bei der Rekristallisation Gedehnter Einkristalle aus Reinst-Aluminium, Z[J]. Metallkd, 1970, 61: 498-507.

K. Vorzugsorientierungen bei der Rekristallisation Gedehnter Einkristalle aus Reinst-Aluminium, Z[J]. Metallkd, 1970, 61: 498-507.

[8] YANG P. The formation of cube texture during recrystallization in cold rolled Al-Mn alloy[J]. Acta Metallurgica Sinica, 1999, 35(3); 226-231.

[9] DUGGAN B J, LEE C S. Deformation banding, original grain size and recrystallisation in FCC intermediate-to-high SFE metals[J]. Scripta Metal Mater, 1992, 27: 1503.

[10] SIDOR J J, PETROV R H, KESTENS L A I. Modeling the crystallographic texture changes in aluminum alloys during recrystallization[J]. Acta Materialia, 2011, 59: 5735-5748.

[11] MAO W. Formation of recrystallization cube texture in high purity FCC metal sheets[J]. J Materials Engineering & Performance, 1999, 8: 556-560.

[12] 周善佑. 晶界迁移的驱动力与约束力[J]. 上海金属, 1991, 2: 50.

ZHOU Shan-you. The driving force and resistance of boundary migration[J]. Journal of Shanghai Metals, 1991, 2: 50.

[13] 蒋奇武, 王存胜, 王 福. 电场作用下高纯铝箔再结晶织构[J]. 中国有色金属学报, 2001, 11(4): 598-602.

JIANG Qi-wu, WANG Cun-sheng, WANG Fu. Recrystallization textures of high-purity aluminum foil annealed with an electric field[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 598-602.

[14] 贺永东, 陈明安, 张新明. Al-Zn-Mg-Cu合金第二相粒子及其无析出区与晶界的作用过程研究[J]. 稀有金属材料与工程, 2009, 38(12): 2093-2099.

HE Yong-dong, CHEN Ming-an, ZHANG Xin-ming. Study on interaction course between second phase particle and its precipitate free zone and grain boundary for Al-Zn-Mg-Cu alloy[J]. Rare Metal Materials and Engineering, 2009, 38(12): 2093-2099.

[15] SAMAJDAR I, DOHERTY R D. Cube recrystallization texture in warm deformed aluminum: Understanding and prediction[J]. Acta Materialia, 1998, 46(9): 3145-3158.

[16] 张德芬, 黄 涛, 胡卓超, 左 量, 王 福. 3104铝合金再结晶织构的研究[J]. 材料工程, 2004(11): 28-31, 36.

ZHANG De-fen, HUANG Tao, HU Zhuo-chao, ZUO Liang, WANG Fu. Study of Recrystallization texture of aluminium alloy 3104[J]. Journal of Materials Engineering, 2004(11): 28-31, 36.

[17] 郭加林, 尹志民, 唐 蓓, 商宝川, 何振波. 不同取向条件下Al-Cu-Mg-Sc-Zr合金薄板的组织与性能[J]. 中南大学学报: 自然科学版, 2011, 42(7): 1923-1927.

GUO Jia-lin, YIN Zhi-min, TANG Pei, SHANG Bao-chuan, HE Zhen-bo. Microstructure and properties of Al-Cu-Mg-Sc-Zr aluminum alloy sheet at different orientations[J]. Journal of Central South University: Science and Technology, 2011, 42(7): 1923-1927.

[18] 陈志永, 才鸿年, 常亚喆, 张新明, 刘楚明. 多晶铝轧制变形的织构演变Ⅰ.实验研究[J]. 金属学报, 2008, 44(11): 1316-1321.

CHEN Zhi-yong, CAI Hong-nian, CHANG Ya-zhe, ZHANG Xin-ming, LIU Chu-ming. Texture evolution of polycrystaline aluminum during rolling deformation I. Experimental study[J]. Acta Metallurgica Sinica, 2008, 44(11): 1316-1321.

[19] 唐建国, 张新明, 徐 敏, 欧 军. 3104铝合金热粗轧板的织构梯度及其对热压缩变形后退火织构演变的影响[J]. 中国有色金属学报, 2010, 20(10): 1932-1940.

TANG Jian-guo, ZHANG Xin-ming, XU Min, OU Jun. Texture gradient in rough-rolled plate of aluminum alloy 3104 and its effect on annealing textures evolution after hot compression[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1932-1940.

(编辑 何学锋)

基金项目:国家重点基础研究发展规划资助项目(2005CB623705)

收稿日期:2012-11-01;修订日期:2013-06-24

通信作者:易丹青,教授,博士;电话:0731-88830263;E-mail:yioffice@mail.csu.edu.cn