文章编号: 1004-0609(2007)08-1324-06

Sc对Al-Zn-Mg-Cu-Zr合金铸态组织和力学性能的影响

戴晓元1, 2,夏长清2,马 科2,刘 娟2

(1. 长沙理工大学 材料科学与工程学院,长沙 410076;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用金相显微镜、扫描电镜和能谱分析,研究Sc对Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr合金铸态组织和力学性能的影响。结果表明,添加0.20%~0.60%的Sc,会使合金的铸态组织由粗大的树枝晶变为等轴晶,并使Cu的偏聚减轻,且Sc含量越高,合金铸态组织越细,Sc含量为0.60%的合金铸态组织最细小;随着Sc含量的增加,合金的抗拉强度升高,T6态时,Sc含量为0.60%的合金抗拉强度高达783.9 MPa。从熔体中析出的Al3(Sc,Zr)一次粒子具有与α(Al)基体相同的FCC晶格,晶格常数接近,可有效地细化合金的铸态组织。合金强化机理主要为Al3(Sc,Zr)引起的细晶强化、亚结构强化和沉淀强化。

关键词:Al-Zn-Mg-Cu-Zr合金;Sc;晶粒细化;显微组织;力学性能

中图分类号:TG 111.7;TG 166.3 文献标识码: A

Effect of Sc on as-cast microstructures and mechanical

properties of Al-Zn-Mg-Cu-Zr alloys

DAI Xiao-yuan1, 2, XIA Chang-qing2, MA Ke2, LIU Juan2

(1. School of Materials Science and Engineering,

Changsha University of Science and Technology, Changsha 410076, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The as-cast microstructures and mechanical properties of Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr alloys with and without Sc were investigated by optical microscope, scanning electron microscope(SEM) and energy spectrum analysis. The result shows that the addition of 0.20%?0.60%Sc can refine the grain size, change the growth morphology from dendritic to fine equiaxed grain, and reduce the segregation behavior of Cu. The higher the content of Sc of studied alloys, the finer the as-cast grain is. The grain size of the alloy with 0.60%Sc is the finest in the experimental alloys. The tensile strength is enhanced with the increase of Sc. The tensile strength of alloy with 0.60%Sc is 783.9 MPa in T6. The primary Al3(Sc, Zr) particles precipitate from the melt during solidification is the most effective grain refiner for α(Al) matrix, which have the same crystal structure of FCC as α(Al) matrix, whose lattice constant is very close to that of α(Al). The strengthening mechanisms of the alloy are mainly sub-structure strengthening, precipitation strengthening and solution strengthening caused by Al3(Sc, Zr).

Key words: Al-Zn-Mg-Cu-Zr alloy; Sc; grain refine; microstructure; mechanical properties

Al-Zn-Mg-Cu系超高强铝合金具有高的比强度和硬度,易于加工、耐腐蚀性能较好,韧性较高,是航天航空工业应用最多、最重要的结构材料之一。近年来,为了进一步提高合金性能,国内外学者已在该系合金中添加了微量Zr、Er、Ce、Ag、Sc等元素[1?3]。Sc是3d型过渡族金属,又是稀土金属,其化学性质与稀土族金属相同,物理性质和力学性质与过渡族元素相近,在铝合金中兼有稀土金属的净化合金、改善铸锭组织的作用和过渡金属的抑制再结晶作用,但其效果却比后两者强烈。Sc是到目前为止所发现的对优化铝合金性能非常有效的合金元素,在铝合金中添加微量Sc是当今铝合金研究的热点之一。在铝合金中添加微量的Sc或同时添加Sc、Zr能全面改善合金的组织和性能[4?6]。Sc在合金凝固过程中形成的一次Al3Sc粒子可细化铸态晶粒。Sc、Zr同时添加时,则Sc被性质接近的Zr置换,形成一次Al3(Sc,Zr)粒子,对铸态晶粒的细化效果更佳[7?11]。含钪铝合金的研究主要集中在Al-Mg、Al-Li-Mg、Al-Cu-Mg、Al-Zn-Mg合金系,有关Al-Zn-Mg-Cu-Sc-Zr的研究报道较少,在含铜量达2.5%的7系铝合金中添加Sc的研究更少。因此,本文作者研究添加不同含量的Sc对Al-9.0Zn- 2.5Mg-2.5Cu-0.15Zr合金铸态组织和力学性能的影响,探讨Sc对合金铸锭组织的细化机理和提高合金力学性能的原因。

1 实验

本实验所用原料为:工业高纯铝(99.96%)、工业纯锌(99.8%)、高纯镁(99.8%)、Al-49.8%Cu中间合金、Al-2.15%Sc中间合金、Al-4.5%Zr中间合金。采用铸锭冶金法制备了4种Al-9.0Zn-2.5Mg-2.5Cu-xSc- 0.15Zr合金,合金经石墨坩埚电阻炉熔炼后浇入d 50 mm的铁模中,其化学成分列于表1。

铸态样品经混合酸腐蚀后用PLOYVER?MET光学显微镜观察合金的显微组织,用Sirion 200型场发射扫描电镜观察高倍显微组织;透射电镜样品经机械减薄后双喷穿孔而成,电解液为4%高氯酸酒精溶液,温度为?25 ℃,在TecnaiG220透射电镜上进行显微组织观察。铸锭经450 ℃、24 h均匀化后车皮,在350~420℃保温2 h后挤压成4 mm×50 mm板材,退火后冷轧成2 mm的板材。再经固溶(455 ℃,2 h)、时效(T6:120 ℃、24 h)处理,然后加工成拉伸试样。室温拉伸实验在CSS?41100万能电子拉伸机上进行,拉伸速度为2 mm/min。

表1 合金的化学成分

Table 1 Compositions of alloys(maa fraction, %)

2 实验结果

2.1 合金的铸态组织

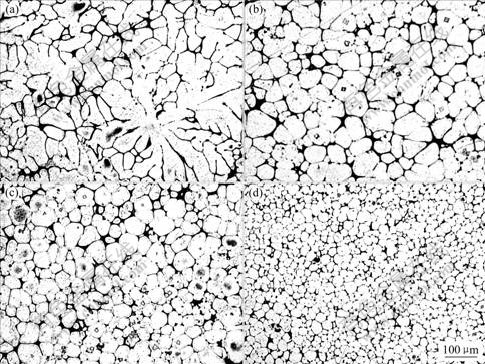

图1所示为实验合金铸态试样经混合酸腐蚀后的显微组织。从图1(a)可知,不含Sc的合金A枝晶偏析非常严重,枝晶网胞粗大;图1 (b) 、(c)、 (d)所示为含Sc合金的铸态组织。可以看到,这3种合金的铸态组织均为等轴晶,枝晶完全消失。随着Sc含量的增加,铸态组织的晶粒进一步细化,含0.60%Sc的合金D晶粒最小。从4种不同Sc含量的合金的铸态显微组织可知, 对于成分相同或相近的Al-Zn-Mg-Cu-Zr合金, Sc可以细化合金的铸态组织;Sc含量(在0~0.60%之间)越高,细化作用越明显。

图1 合金的铸态组织

Fig.1 Microstructures of as-cast alloys: (a) Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr; (b) Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr-0.20Sc; (c) Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr-0.40Sc; (d) Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr-0.60Sc

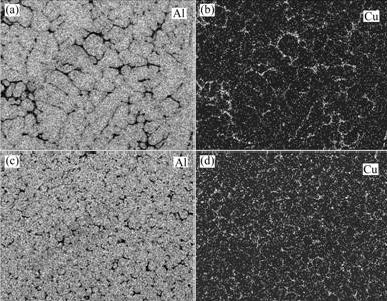

图2所示为合金A和合金D铸态组织的元素面扫描。可以看出,合金A具有粗大的枝晶结构,晶界较宽,元素分布不均匀,尤其是Cu元素在晶界处的偏聚严重,而Al在晶界处含量较低,该处多为合金元素含量较高的低熔点相;合金D的铸态组织晶粒为细小的等轴晶,晶界窄,沿晶界分布的低熔点相相对较少,且低熔点相体积较小,Al、Cu元素的分布明显比合金A的要均匀。在Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr合金中添加Sc不仅可以细化晶粒,还可以减少合金元素的偏聚,使合金元素的分布更加均匀。

图2 合金铸态组织的Al、Cu元素面扫描

Fig.2 SEM elemental maps showing distribution of Al and Cu in castings: (a) Associated element Al map of alloy A; (b) Associated element Cu map of alloy A; (c) Associated element Al map of alloy D; (d) Associated element Cu map of alloy D

图3所示为不含Sc的合金A铸态组织的SEM像与能谱分析结果。由图可见,晶界处存在较为粗大的骨骼状析出相,能谱分析该相的主要成分为Al、Zn、Mg和Cu。图4所示为含0.60%Sc的合金D铸态组织的SEM像和能谱分析结果。由图可见,图中方块相经能谱分析可知其主要成分为Al、Sc和Zr,根据文献[12?14]可知该相为合金凝固过程中产生的一次Al3(Sc,Zr)相。

图3 合金A铸态组织的SEM像与能谱分析结果

Fig.3 SEM image of alloy A in castings and EDS pattern: (a) SEM image of alloy A; (b) EDS pattern of phase in grain boundary; (c) Chemical compositions of phase in grain boundary

图4 合金D铸态组织的SEM像与能谱分析结果

Fig.4 SEM image of alloy D in castings and EDS pattern: (a) SEM image of alloy D; (b) EDS pattern of phase in grain boundary; (c) Chemical compositions of phase in grain boundary

2.2 合金的力学性能

表2所列为4种合金在峰值时效状态下的力学性能。可以看出,合金A的抗拉强度最低,随着Sc含量的提高,合金的抗拉强度和伸长率都得到提高,合金D的抗拉强度最高,达到783.9 MPa,伸长率为8.5%。

表2 T6态合金的拉伸性能

Table 2 Tensile properties of alloys in T6 state

2.3 合金经热处理后的显微组织

图5所示为合金A与合金C经固溶及峰值时效后的显微组织。从图中可知,合金A经固溶及T6时效后已明显发生再结晶,合金C经固溶及T6时效后仍为纤维状变形组织,没有发生再结晶,说明添加微量Sc可提高合金的再结晶温度,抑制合金的再结晶过程。

图5 合金T6态的显微组织

Fig.5 Microstructures of alloys in T6 state: (a) Alloy A; (b) Alloy C

图6所示为合金C固溶态和T6态显微组织的透射电镜像。从图6(a)中可以看到,呈豆瓣状的Al3(Sc,Zr)粒子[5?7, 12?15] 与基体共格,钉扎位错,对位错运动产生牵制与阻碍。图6(b)所示为合金T6态下晶内的显微组织,可以看到晶内析出大量细小弥散的η′相[2?3, 16]和呈豆瓣状的Al3(Sc, Zr)粒子。

图6 合金C的透射电镜像

Fig.6 TEM images of alloy C: (a) In solution; (b) In T6 state

3 分析与讨论

根据非均匀形核理论,铸态晶粒的细化程度取决于添加剂的两种作用——单位熔体中形核粒子数和粒子的有效形核作用。而粒子的有效形核作用依赖形核粒子与α(Al)基体的晶格常数和晶格类型,晶体结构相类似是引起晶粒细化的主要原因。

文献[12?14]指出,Al-Sc系富铝端存在L→α(Al)+Al3Sc共晶反应,共晶温度655 ℃,共晶成分为0.52%的Sc,Sc在铝中的最大固溶度为0.38%Sc。化合物Al3Sc为L12型面心立方晶格(AuCu3结构),a=0.410 3 nm,与α(Al)基体的晶格常数a=0.404 88 nm非常接近[10],符合晶格相似点阵匹配原理,因此在铝合金凝固过程中可以起到非均质形核核心的作用,从而大幅度细化合金铸态晶粒尺寸。文献[11?15]指出,在Al-Sc-Zr系统中存在有Al3(Sc1?xZrx) 或Al3(Sc,Zr)相,它是在Al3Sc相基础上的置换固溶体,Sc被性质接近的Zr置换,最多可置换到50%Sc(摩尔分数)。L12型的Al3Zr与α(Al)的错配度约为0.5%,而L12型Al3Sc与α(Al)的错配度约为1.5%,Zr置换Al3Sc中Sc,使得含Zr的Al3Sc与基体的错配度减小,晶格常数的差异率降低,非均匀形核效率增高,晶粒细化效果增强[13]。从图1和4可见,合金凝固时从熔体中析出Al3(Sc,Zr)一次粒子,该粒子呈方块或多边形,它在合金凝固时优先析出,具有熔点高,稳定性好,分布均匀的特点,是理想的非均质晶核,能大大细化铸态晶粒组织,提高合金强度。Sc含量(在0~0.60%之间)越高,在合金凝固过程中析出的Al3(Sc,Zr)粒子就越多,即单位熔体中形核粒子数越多,越有利于细化合金铸态晶粒组织。

Sc的加入使得合金在凝固过程中的偏聚程度降低。由图1~3可知,合金A铸态组织中晶粒大小不一,且存在网络状树枝晶,晶界粗而厚,说明合金在凝固过程是非平衡凝固,形成的非平衡组织在三叉晶界处聚集, 形成偏析。添加Sc后,合金晶界明显变得细小、窄而薄,偏析程度大幅度降低。一方面, 晶粒细化, 使偏析距离缩短,易于扩散均匀化,使晶内偏析程度降低[17];另一方面,由于晶粒细小,凝固过程中固/液界面的移动速度受到限制,在晶粒碰撞前溶质来不及充分扩散,使成分反而均匀[10]。

含钪铝合金强度的增加是由Al3(Sc,Zr)粒子引起的。Al3(Sc,Zr)粒子的显微硬度高达2 250 MPa[18],均匀化过程中析出的二次Al3(Sc,Zr)对合金产生直接析出强化作用[6, 18?19];与基体共格的二次Al3(Sc, Zr)粒子较小, 约为20 nm, Orowan强化机制起作用,因此,细小的Al3(Sc,Zr)沉淀析出相钉扎位错、将阻碍位错的运动和亚晶界迁移[7, 11],提高合金的再结晶温度,产生亚结构强化。随着Sc含量的增加,合金的晶粒更加细化,降低了铸态组织中低熔点相的含量,使合金在抗拉强度提高的同时,伸长率也得到提高[4]。

4 结论

1) 含Sc的Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr合金凝固时,从熔体中析出的Al3(Sc,Zr)一次粒子可有效地细化α(Al)基体晶粒。

2) 当Sc含量在0~0.60%之间时,Sc含量越高,越有利于细化合金的铸态组织,含0.60%Sc的合金的铸态晶粒最细小。

3) 在Al-9.0Zn-2.5Mg-2.5Cu-0.15Zr合金添加Sc有利于减少合金元素的偏聚,尤其可以减少Cu元素的偏聚。

4) 当Sc含量在0~0.60%之间时,Sc含量越高,越有利于提高合金的抗拉强度和伸长率,含0.60%Sc的合金的抗拉强度和伸长率分别为:783.9 MPa和8.5%。

5) 合金强度提高主要是Al3(Sc,Zr)引起的细晶强化、亚结构强化和沉淀强化。

REFERENCES

[1] 贺永东, 张新明. 微量Cr、Mn、Ti、Zr细化7A55铝合金铸锭组织的效果与机理[J]. 中国有色金属学报, 2005, 15(10): 1594?1601.

HE Yong-dong, ZHANG Xin-ming. Refinement mechanism of trace Cr, Mn, Ti and Zr as cast 7A55 alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(10): 1594?1601.

[2] 赵中魁, 周铁涛, 刘培英, 陈昌麒. Al-Zn-Mg-Cu-Li-Er合金时效组织中Er相的TEM观察[J]. 稀有金属材料与工程, 2004, 33(10): 1108?1111.

ZHAO Zhong-kui, ZHOU Tie-tao, LIU Pei-ying, CHEN Chang-qi. Observation of formed Er phase in Al-Zn-Mg-Cu-Li alloys by TEM[J]. Rare Metal Materials and Engineering, 2004, 33(10): 1108?1111.

[3] 张 坤, 刘志义, 冯 春. 添加微量Ag对高Zn超高强铝合金微观组织和力学性能的影响[J]. 中国有色金属学报, 2005, 15(1): 116?122.

ZHANG Kun , LIU Zhi-yi , FENG Chun. Effect of small addition of silver on microstructure and mechanical properties of high-zinc super-high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 116?122.

[4] Norman A F, Hyde K, Costello F, Thompson S, Birley S, Prangnell P B. Examination of the effect of Sc on 2000 and 7000 series aluminum alloy castings: For improvements in fusion welding[J]. Mater Sci Eng A, 2003, A354: 188?198.

[5] Senkov O N, Miracle D B, Milman Y V, Scott J M, Lotsko D V, Sirko A. Low temperature mechanical properties of scandium-modified Al-Zn-Mg-Cu alloys[J]. Mater Science Forum, 2002, 396/402: 664?670.

[6] Milman Y V, Sirko A I, Lotsko D V, Senkov O N, Miracle D B. Microstructure and mechanical properties of cast and wrought Al-Zn-Mg-Cu alloys modified with Zr and Sc[J]. Mater Science Forum, 2002, 396/402: 1127?1132.

[7] YIN Zhi-min, JIANG Feng, PAN Qing-lin, GUO Fei-yue, ZHU Da-peng, SONG Lian-peng, ZEN Yu, WANG Tao. Microstructures and mechanical properties of Al-Mg and Al-Zn-Mg based alloys containing minor scandium and zirconium[J]. Trans Nonferrous Met Soc China, 2003, 13(3): 515?520.

[8] YU Kun, LI Wen-xian, LI Song-rui, ZHAO Jun. Mechanical properties and microstructure of aluminum alloy 2618 with Al3(Sc, Zr) phases[J]. Mater Sci Eng A, 2004, A368: 88?93.

[9] Ocenasek V, Slamova M. Resistance to recrystallization due to Sc and Zr addition to Al-Mg alloys[J]. Materials Characterization, 2001, 47: 157?162.

[10] Norman A F, Prangnell P B, Mcewen R S. The solidification behavior of dilute aluminium-scandium alloys[J]. Acta Materialia, 1998, 46(16): 5715?5732.

[11] Miura Y, Shioyama T, Hare D. Recrystallization of Al-3Mg and Al-3Mg-0.2Sc alloys[J]. Mater Science Forum, 1996, 217/222: 505?510.

[12] XIA Chang-qing, ZENG Fan-hao, GU Yi. Phase relations of Al-4Mg-Sc-Zr quaternary system in Al-rich range at 430 ℃[J]. Trans Nonferrous Met Soc China, 2003, 13(3): 546?552.

[13] Rokhlin L L, Dobatkina T V, Bochvar N R, Lysova E V. Investigation of phase equilibria in alloys of the Al-Zn-Mg-Cu-Zr-Sc system[J]. Journal of Alloys and Compounds, 2004, 367: 10?16.

[14] ZENG Fan-hao, XIA Chang-qing, GU Yi. The isothermal section of the Al-4Mg-Sc-Zr quaternary system in Al-rich range[J]. Journal of Alloys and Compounds, 2004, 363: 175?181.

[15] Royset J, Ryum N. Scandium in aluminium alloys[J]. International Materials Reviews, 2005, 50(1): 19?44.

[16] 李 海, 杨迎新, 郑子樵, 王芝秀. 少量Sc对7055铝合金组织与性能的影响[J]. 材料科学与工艺, 2006, 14(1): 46?49.

LI Hai, YANG Ying-xin, ZHENG Zi-qiao, WANG Zhi-xiu. Effect of minor addition of scandium on microstructures and mechanical properties of 7055 aluminum alloy[J]. Materials Science and Technology, 2006, 14(1): 46?49.

[17] 曹明盛, 物理冶金基础[M]. 北京, 冶金工业出版社, 1985: 52?111.

CAO Ming-sheng. Basis of physical metallurgy[M]. Beijing: Metallurgical Industry Press, 1985: 52?111.

[18] 戴晓元, 夏长清, 刘昌斌. 加钪对Al-Zn-Mg-Cu-Zr合金组织性能的影响[J]. 稀有金属材料及工程, 2006, 35(6): 913?915.

DAI Xiao-yuan, XIA Chang-qing, LIU Chang-bin. Effect of Sc addition on microstructures and mechanical properties of Al-Zn-Mg-Cu-Zr alloys[J]. Rare Metal Materials and Engineering, 2006, 35(6): 913?915.

[19] 王祝堂, 张 燕, 江 斌. 钪—铝合金的新型微合金元素[J]. 轻合金加工技术, 2000, 8(1): 23?31.

WANG Zhu-tang, ZHANG Yan, JIANG Bing. Scandium—a new trace alloying element for aluminium alloy[J]. Light Alloy Fabrication Technology, 2000, 8(1): 23?31.

基金项目: 湖南省自然科学基金资助项目(06JJ4111); 国家重点基础研究发展规划资助项目(2005CB623706)

收稿日期: 2006-12-15;修订日期: 2007-04-11

通讯作者: 戴晓元,讲师;电话: 0731-8830267;E-mail: dxy0124@126.com

(编辑 陈爱华)