TiC颗粒增强钛基复合材料的热变形行为及加工图

胡加瑞1,肖来荣1,蔡一湘2,李威1,罗锴2,刘彦1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 广州有色金属研究院,广东 广州,510650)

摘要:在Gleeble-1500热模拟实验机上对原位生成TiC颗粒增强钛基复合材料进行热压缩实验,研究变形温度为700~950 ℃,应变速率为0.001~1 s-1时的热变形行为。研究结果表明:变形温度和应变速率对流变应力有显著影响,流变应力随变形温度的升高而降低,随应变速率的增加而升高。原位生成钛基复合材料在(α+β)相区激活能为357.09 kJ/mol,β相区激活能为227.18 kJ/mol,采用Zener-Hollomon 参数法构建其高温塑性变形的本构关系。根据动态材料模型,建立原位生成钛基复合材料的加工图,并确定热变形的流变失稳区域。

关键词:流变应力;加工图;原位生成复合材料;钛基复合材料;热变形

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2012)05-1672-06

Hot deformation and processing map of titanium matrix composites reinforced by TiC particulates

HU Jia-rui1, XIAO Lai-rong1, CAI Yi-xiang2, LI Wei1, LUO Kai2, LIU Yan1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Guangzhou Research Institute of Non-ferrous Metals, Guangzhou 510600, China)

Abstract: The deformation behaviour of in-situ synthesized titanium matrix composites reinforced by TiC particulates was investigated by compression tests on Gleeble-1500 thermal simulator machine. The tests were performed in the temperature range from 700 to 950 ℃ and strain rate range from 0.001 to 1 s-1. The results show that the flow stress is controlled by strain rate and deformation temperature. The flow stress increases with the increase of strain rate and decreases with the increase of deformation temperature. The deformation activation energy is 357.09 kJ/mol in (α+β) phase region and 227.18 kJ/mol in β phase region. The constitutive equation of the plastic deformation is obtained by introducing Zener-Hollomon parameter. The processing maps of in-situ synthesized titanium matrix composites are also established based on the dynamic material model and the flow instability region is noted.

Key words: flow stress; processing map; in-situ synthesized composite; titanium matrix composites; hot deformation

颗粒增强钛基复合材料具有高比强度、高比模量、高耐蚀性、高耐磨性,极佳的抗疲劳性能和抗蠕变性能及优异的高温性能,在航空、航天、电子及汽车制造等工业领域有广阔的应用前景[1-2]。利用原位生成方法制备的颗粒增强钛基复合材料避免了外加增强体颗粒的界面污染问题,并且工艺简单,得到广泛研究[3-5]。熔炼法和粉末冶金等方法已用于原位合成颗粒增强钛基复合材料[6-9]。但是随着增强体的加入,由于在相对较软的基体上分布了很多硬度很高的增强体颗粒,钛基复合材料的加工性能变差,在较大程度上加大了钛基复合材料的工程化应用难度。因此,为了选择合适的热加工工艺路线,避免热变形开裂等失稳现象的产生,必须深入研究合金在不同变形条件下的高温变形行为。目前国内外对原位生成钛基复合材料的研究大多数集中在制备和微观结构方面,对热变形行为的研究则鲜有报道。本研究以热模拟压缩实验结果为基础,研究变形工艺参数对原位生成TiC颗粒增强钛基复合材料的流变应力的影响,建立高温变形加工图,为原位生成TiC颗粒增强钛基复合材料加工工艺的制定与优化提供理论依据。

1 实验

本研究采用的原位生成TiC颗粒增强钛基复合材料由广州有色金属研究院提供。采用粉末冶金法制 备,将Ti-2Mo-Ni合金配制成混合粉,在其中添加5%(体积分数)的Cr3C2粉末,配制好的粉末在Ar气氛保护下混合,经冷等静压后真空烧结。烧结过程中发生反应(1),生成的TiC为颗粒增强相。经实验测定,该原位生成钛基复合材料的α/β同素异晶转变温度为798 ℃。

2Ti+Cr3C2→2TiC+3Cr (1)

将烧结后所得复合材料坯料加工成直径×高为10 mm×15 mm的小圆柱试样,两端面加工出0.2 mm深的凹槽,热变形在Gleeble-1500热模拟试验机上进行,压缩时在试样两端填充75%石墨+20%机油+5%硝酸三甲苯脂作为润滑剂,以减少摩擦力的影响。变形温度分别为700,750,800,850,900和950 ℃,应变速率为0.001,0.01,0.1和1 s-1。试样压缩前升温速度为5 ℃/s,到温后保温5 min,变形程度为50%,卸载后立即将变形试样水冷保留其高温变形组织。

2 实验结果

2.1 真应力-真应变曲线

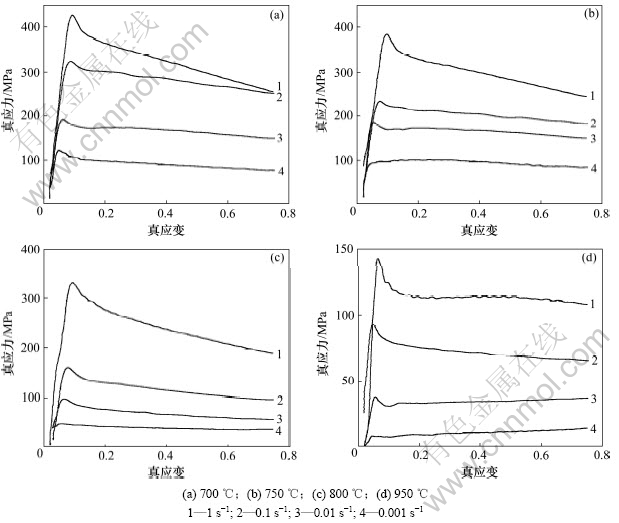

钛基复合材料高温压缩变形时的真应力-真应变曲线如图1所示。从图1可以看出:钛基复合材料在热压缩变形时,流变应力的变化规律表现为:随着变的进行,高应变速率下应力迅速升高并出现峰值,低应变速率下峰值并不明显。钛基复合材料热变形时发生动态回复和动态再结晶,由流变应力曲线可以看出,出现峰值应力后,应力开始逐渐下降并趋于稳定。

图1 材料在不同温度压缩变形时的真应力-应变曲线

Fig.1 Compressive true stress-true strain curves at different temperatures

在同一应变速率下,随温度升高流变应力明显降低;在变形温度保持不变时,流变应力随着应变速率的提高而增大。这可能由以下原因造成:一方面,随着变形温度的升高,金属原子动能增加,原子热震动的振幅增大,使位错活动性提高,可开动滑移系增多,从而改善晶粒间的变形协调性,同时扩散蠕变和晶粒方向的改变都对流变应力的降低产生一定的影响;随着温度升高,动态回复和动态再结晶也容易进行,使得位错密度下降,从而使流变应力减小;另一方面,应变速率的增加使得位错增殖率显著增大,这也使得材料的流变应力增大。可见,原位生成钛基复合材料属于热敏感性和应变速率敏感性材料。

2.2 本构方程模型

材料在高温塑性变形时,在所有应力条件下稳定流变应力 和应变速率

和应变速率 服从Arrhenius关系[10]:

服从Arrhenius关系[10]:

(2)

(2)

低应力水平条件下( <0.8),式(2)可表达为:

<0.8),式(2)可表达为:

(3)

(3)

高应力水平条件下( >1.2),式(2)可表达为:

>1.2),式(2)可表达为:

(4)

(4)

其中:n和A为常数;Q为变形激活能;R为气体常数; 为应变速率;T为热力学温度;

为应变速率;T为热力学温度; 。

。

假设原位生成钛基复合材料在高温(700~950 ℃)压缩变形时的峰值应力 和应变速率

和应变速率 之间满足式(3)和式(4) 2种关系,则对式(3)和式(4)两边分别取自然对数,可以得到:

之间满足式(3)和式(4) 2种关系,则对式(3)和式(4)两边分别取自然对数,可以得到:

(5)

(5)

(6)

(6)

将不同变形条件的峰值应力随应力速率变化的值代入式(5)和(6),利用 和

和 曲线的线性关系(如图2(a)和(b)所示),线性回归求出(α+β)相区和β相区的n1和β,并确定α。然后,由式(2)转化成如下线性关系:

曲线的线性关系(如图2(a)和(b)所示),线性回归求出(α+β)相区和β相区的n1和β,并确定α。然后,由式(2)转化成如下线性关系:

(7)

(7)

对式(7)进行偏微分可求出变形激活能Q为:

(8)

(8)

通过图2(c)及2(d)中的 直线斜率可分别求出材料在(α+β)相区和β相区的应力指数n,由图2可以看到两者呈较好的线性关系,但在不同的温度下,直线的斜率稍有不同,说明变形激活能随温度的变化有一定的变化。可由

直线斜率可分别求出材料在(α+β)相区和β相区的应力指数n,由图2可以看到两者呈较好的线性关系,但在不同的温度下,直线的斜率稍有不同,说明变形激活能随温度的变化有一定的变化。可由 直

直

线斜率确定不同温度区间的 ,同样由

,同样由

图2(d)可以看出两者有很好的线性关系,但在不同的应变速率下直线的斜率也稍有不同,说明变形激活能随应变速率的改变也有变化。(α+β)相区和β相区的各参数如表1所示。

表1 高温变形原位生成钛基复合材料的材料常数

Table 1 Material constants of in-situ synthesized titanium matrix composites in high temperature deformation

根据表1变形激活能Q的计算结果可知:原位生成钛基复合材料在(α+β)相区的变形激活能为357.09 kJ/mol,而在β相区的变形激活能为227.18 kJ/mol。不同温度区间得到不同的变形激活能,表明在不同的温度区间有不同的热变形机制。β相区变形激活能较低,推测变形由自扩散控制,(α+β)相区变形激活能较高,变形机制可能为动态再结晶。

结合式(2)引入温度补偿应变速率即Zener- Hollomon 参数Z [11],则有如下关系:

(9)

(9)

(10)

(10)

可以得到合金在(α+β)相区和β相区下用Z参数表示的峰值流变应力σ、应变速率 和变形温度T之间的关系本构方程。

和变形温度T之间的关系本构方程。

在(α+β)相区为:

(11)

(11)

图2 原位生成钛基复合材料高温塑性变形峰值应力σ与应变速率 及温度T的关系

及温度T的关系

Fig.2 Relationship between strain rate  and temperature T and peak stress σ of high temperature plastic deformation

and temperature T and peak stress σ of high temperature plastic deformation

在β相区为:

(12)

(12)

式中:

2.3 热加工图的构建与分析

按照动态材料模型的观点,材料在热加工过程中单位体积内所吸收的功率P可以分为2部分[12-13],即:

(13)

(13)

式中:总的功率P(恒等于 )可以表示为2个互补函数G (耗散量)和J (耗散协量),G代表由于塑性变形引起的功率消耗,其大多数转化成黏塑性热,另外很小的部分以晶格缺陷的形式保留下来。耗散协变量J是材料变形过程中与组织变化有关的功率消耗。在变形过程中,G变量是做功函数,而J协变量是补充函数,物理冶金的变化过程是由于耗散协变量J的变化所引起的。

)可以表示为2个互补函数G (耗散量)和J (耗散协量),G代表由于塑性变形引起的功率消耗,其大多数转化成黏塑性热,另外很小的部分以晶格缺陷的形式保留下来。耗散协变量J是材料变形过程中与组织变化有关的功率消耗。在变形过程中,G变量是做功函数,而J协变量是补充函数,物理冶金的变化过程是由于耗散协变量J的变化所引起的。

J与G的变化率就构成了应变速率敏感指数m的

定义式,即: ,对理想线性耗散

,对理想线性耗散

而言,当m=1时,J达到了最大值Jmax,这就意味着: 。

。

Prasad等通过引入1个与尺寸无关的功率耗散效率的参变量η同ε, 和T一起构成了功率耗散图[14],其定义为

和T一起构成了功率耗散图[14],其定义为 。它是ε,

。它是ε, 和T的函数,通常是在由应变速率

和T的函数,通常是在由应变速率 和变形温度T所构成的二维平面上绘出由等功率耗散效率的轮廓曲线构成,它反映了材料在热加工过程中的功率消耗特征,其不同的区域体现着不同的显微组织的变化机制。可以得到由应变速率敏感指数m所表示的功率耗散效率的计算式:η=2m/(m+1)。根据大应变塑性变形的极大值原理,当dD/d

和变形温度T所构成的二维平面上绘出由等功率耗散效率的轮廓曲线构成,它反映了材料在热加工过程中的功率消耗特征,其不同的区域体现着不同的显微组织的变化机制。可以得到由应变速率敏感指数m所表示的功率耗散效率的计算式:η=2m/(m+1)。根据大应变塑性变形的极大值原理,当dD/d <D/

<D/ 时,会出现失稳。按照动态材料模型原理,D等于耗散协量J,因此可以得出流变失稳的判据为[15]:

时,会出现失稳。按照动态材料模型原理,D等于耗散协量J,因此可以得出流变失稳的判据为[15]:

(14)

(14)

把参数 作为变形温度和应变速率的函数,计算出各变形温度和应变速率对应的

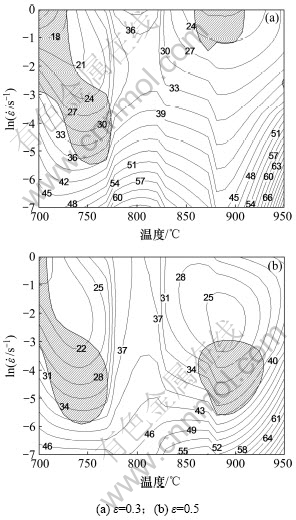

作为变形温度和应变速率的函数,计算出各变形温度和应变速率对应的 ,即构成流变失稳图。将功率耗散图和流动失稳图叠加就构成加工图。图3所示为原位生成钛基复合材料在真应变ε=0.3和ε=0.5时的热加工图。

,即构成流变失稳图。将功率耗散图和流动失稳图叠加就构成加工图。图3所示为原位生成钛基复合材料在真应变ε=0.3和ε=0.5时的热加工图。

图3所示的等值线是功率耗散效率,从图3可以看出:功率耗散效率轮廓曲线在大约800 ℃时出现明显拐点,接近原位生成钛基复合材料的α/β相变温度。如图3(a)所示:真应变为0.3时包含2个功率耗散效率较大的区域。区域一温度为775~875 ℃,应变速率为0.001~0.01 s-1,峰值效率为66%;区域二变形温度为900~950 ℃,应变速率为0.001~0.1 s-1,峰值效率为85%。如图3(b)所示:当真应变为0.5时,功率耗散效率的较大区域为变形温度为900~950 ℃,应变速率为0.001~0.1 s-1,峰值效率为90%。据文献[16]报道,在加工图中当功率耗散效率值大于60%,而应变速率小于0.01 s-1时,容易发生超塑性变形,同时动态再结晶一般发生在功率耗散效率为40%~50%的区域,因此,上述区域已经具备了发生动态再结晶和超塑性变形的条件。

图3 不同真应变下原位生成钛基复合材料的热加工图

Fig.3 Processing Map at different true strains of in-situ synthesized titanium matrix

图3所示阴影部分表示失稳区域,如果原位生成钛基复合材料在失稳区域内对应的工艺参数下进行塑性变形,可能会出现对微观组织不利的各种缺陷。图3(a)中存在2个失稳区域,第1个区域是变形温度为700~775 ℃,应变速率为0.004~1 s-1;第2个区域变形温度为850~900 ℃,应变速率为0.2~1 s-1。图3(b)中存在2个失稳区域,第1个区域是变形温度为700~775 ℃,应变速率为0.003~1 s-1;第2个区域是变形温度为860~920 ℃,应变速率为0.003~0.05 s-1。同时,对比图3(a)与图3(b)可知:随着变形量的增加,(α+β)相区的失稳区域变化不大,而β相区的失稳区域由高应变速率区域向低应变速率区域移动。综上所述,原位生成钛基复合材料在温度为700~775 ℃,应变速率为0.003~1 s-1以及温度为850~920 ℃,应变速率为0.004~1 s-1范围内存在失稳区域,制定热加工工艺时应避开这些区域。除上述区域外,原位生成钛基复合材料高温塑性变形时最高的功率耗散率对应最佳的变形工艺参数。

3 结论

(1) 在温度为700~950 ℃和应变速率为0.001~ 1 s-1时,流变应力随变形温度的升高而降低,随应变速率的增加而升高。

(2) 原位生成钛基复合材料在(α+β)相区激活能为357.09 kJ/mol,β相区激活能为227.18 kJ/mol。

(3) 原位生成钛基复合材料在温度为700~775 ℃、应变速率为0.003~1 s-1和850~920 ℃、应变速率为0.004~1 s-1范围内存在失稳区域,制定热加工工艺时应避开这些区域。

参考文献:

[1] 罗国珍. 钛基复合材料的研究与发展[J]. 稀有金属材料与工程, 1997, 26(2): 1-7.

LUO Guo-zhen. Recent development of titanium metallic matrix composites[J]. Rare Metal Materials and Engineering, 1997, 26(2): 1-7.

[2] Ranganath S. Review on particulate-reinforced titanium matrix composites[J]. J Mater Sci, 1997, 32(1): 1-16.

[3] 毛小南, 周廉, 周义刚, 等. TP-650颗粒增强钛基复合材料的性能与组织特征[J]. 稀有金属材料与工程, 2004, 33(6): 620-623.

MAO Xiao-nan, ZHOU Lian, ZHOU Yi-gang, et al. Characteristic of principle properties and microstructure of TP-650 particles reinforced titanium matrix composites[J]. Rare Metal Materials and Engineering, 2004, 33(6): 620-623.

[4] 耿珂, 吕维洁, 张荻, 等. 原位合成TiB和Nd2O3增强钛基复合材料[J]. 上海交通大学学报, 2004, 38(2): 300-303.

GENG Ke, LU Wei-jie, ZHANG Di, et al. In situ synthesized (TiB+Nd2O3)/Ti composites[J]. Journal of Shanghai Jiao Tong University, 2004, 38(2): 300-303.

[5] 张二林, 金云学, 曾松岩, 等. 自生TiC增强钛基复合材料的微观组织[J]. 材料研究学报, 2000, 14(5): 524-530.

ZHANG Er-lin, JIN Yun-xue, ZENG Song-yan, et al. Microstructure of in situ TiC reinforced titanium alloy matrix composites[J]. Chinese Journal of Material research, 2000, 14(5): 524-530.

[6] Tsang H T, Chao C G, Ma C R. Effects of volume fraction of reinforcement on tensile and creep properties of in situ TiB/Ti MMC[J]. Scripta Mater, 1997, 37(9): 1359-1365.

[7] Dubey S, Lederich R J, Soboyejo W O. Fatigue and fracture of damage tolerant in situ titanium matrix composites[J]. Metall Trans, 1997, 28A(10): 2037-2047.

[8] Takahashi T. In-situ synthesis of TiB whisker-reinforced titanium by mechanical alloying[J]. Japan Inst Metals, 1995, 59(3): 244-250.

[9] Hu D, Johnson T P, Loretto M H. Titanium precipitation in substoichiometric TiC particles[J]. Scripta Mater, 1994, 30(8): 1015-1020.

[10] Poirier J P. 晶体的高温塑性变形[M]. 关得林, 译. 大连: 大连理工大学出版社, 1989: 72-75.

Poirier J P. High temperature plastic deformation[M] GUAN De-lin, Trans. Dalian: Dalian University of Technology Press,1989: 72-75.

[11] Medina S F, Hemaderz C A. General expression of Zener-Hollomon parameter as a function of chemical composition of low alloy and microalloyed steels[J]. Acta Mater, 1996, 44(1): 137-146.

[12] Prasad Y V R K, Gegel H L, Doraivelu S. Metal. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15(10): 1883-1891.

[13] Prasad Y V R K, Sasidhara S. Hot working guide: A compendium of processing maps[M]. ASM International, Materials Park, OH, 1997: 451-493.

[14] Prasad Y V R K, Seshacharyulu T. Modelling of hot deformation for microstructural control[J]. International Materials Reviews, 1998, 43(6): 243-258.

[15] Seghacharyulu T, Medeiros S C, Frazier W G, et al. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Mater Sci Eng A, 2002, 325(1/2): 112-125.

[16] Prasad Y V R K, Seghacharyulu T. Processing maps for hot working of titanium alloys[J]. Materials Science and Engineering, 1998, 243(1): 82-88.

(编辑 何运斌)

收稿日期:2011-06-23;修回日期:2011-09-27

基金项目:国家支撑计划资助项目(2009BAE71B0)

通信作者:肖来荣(1968-),男,湖南邵阳人,教授,从事钛合金及高温涂层研究;电话:0731-88830137;E-mail: xiaolr368@sina.com