DOI: 10.11817/j.issn.1672-7207.2015.05.002

以钢渣为原料的SiO2-CaO-Al2O3系陶瓷烧结机理

艾仙斌1, 2,李宇1, 2,郭大龙1, 2,赵立华1, 2,苍大强1, 2

(1. 北京科技大学 钢铁冶金新技术国家重点实验室,北京,100083;

2. 北京科技大学 冶金与生态工程学院,北京,100083)

摘要:以主要化学成分为CaO和SiO2的钢渣为原料,制备SiO2-CaO-Al2O3系钢渣陶瓷,采用差分扫描量热仪(DSC)、X线衍射仪(XRD)、扫描电子显微镜(SEM)与热力学计算研究钢渣陶瓷烧结过程及反应机理。研究结果表明:在以钢渣-黏土-长石-石英为主要原料的SiO2-CaO-Al2O3体系中,钢渣陶瓷晶相以钙长石相为主;钢渣陶瓷烧结初期以扩散传质反应为主,之后形成高温液相,促进反应进行和晶体长大,并完成坯体致密化;经过湿磨的钢渣中存在大量的氢氧化钙等矿相,这些矿相在钢渣陶瓷烧结过程中能够分解产生具有很强反应活性的氧化钙,因而促进了原料间的反应和陶瓷致密化过程。

关键词:钢渣;陶瓷;烧结机理;SiO2-CaO-Al2O3系

中图分类号:TF09 文献标志码:A 文章编号:1672-7207(2015)05-1583-05

Sintering mechanism of SiO2-CaO-Al2O3 ceramic from steel slag

AI Xianbin1, 2, LI Yu1, 2, GUO Dalong1, 2, ZHAO Lihua1, 2, CANG Daqiang1, 2

(1. State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing,

Beijing 100083, China;

2. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing,

Beijing 100083, China)

Abstract: The SiO2-CaO-Al2O3 system ceramic was prepared using the steel slag mainly composed of CaO and SiO2. Thermodynamic calculation, differential scanning calorimetry (DSC), X-ray diffraction (XRD) and scanning electron microscopy (SEM) were introduced to analyze the sintering reaction and sintering mechanism. The results indicate that anorthite is the main crystal phase in the slag-clay-feldspar-quartz system. Sintering of ceramic based on steel slag is controlled by mass transfer reaction at initial step, and then liquid phase is formed, which promotes reaction, crystal growth and further densification. A large amount of calcium hydroxide in steel slag forms after wet milling. Calcium oxide transformed from calcium hydroxide during sintering process has a strong reactivity and promote the reaction among ingredients of ceramic.

Key words: steel slag; ceramic; sintering mechanism; SiO2-CaO-Al2O3 system

钢铁行业在冶炼过程中产生大量固体副产物,其中,钢渣年产生量为粗钢产量的10%~15%,国内目前粗钢年产量超8亿t,但钢渣的利用率约为30%[1],钢渣堆放不仅占用大量土地,而且造成大气、水体等环境污染,已成为限制钢铁行业健康发展的瓶颈之一。由于陶瓷行业存在原料紧缺问题,近年来开展了陶瓷行业利用不同工业废弃物的研究[2-4],废弃物包括钢铁行业产生的铁尾矿[5-6]、高炉渣[7-8]、钢渣[9-11]等。由于高炉渣、钢渣等固体废弃物主要成分以SiO2和CaO为主,因此,掺入大量固体废弃物的陶瓷不同于传统以SiO2和Al2O3为主要原料的石英-黏土-长石三元系陶瓷[12-13]。然而,目前这些研究主要侧重于基础配方的试制以及试样后续性能的检测等,对固体废弃物在烧结过程的作用及新构成的SiO2-CaO-Al2O3系陶瓷烧结机理的研究还非常少,因此,开展以固体废弃物为主要原料的SiO2-CaO-Al2O3系陶瓷烧结过程及烧结机理的研究对这类非传统陶瓷原料的资源化利用和新型陶瓷制备具有重要意义。本文作者以钢渣为典型固体废弃物,制备钢渣陶瓷,并通过热力学计算探讨钢渣在陶瓷烧结过程中的反应,结合差分扫描量热仪(DSC)、X线衍射仪(XRD)及扫描电子显微镜(SEM)分析钢渣陶瓷的烧结反应及烧结机理。

1 试验原料和试验方法

试验选用钢渣为山东钢铁集团湿磨磁选处理转炉钢渣,其他原料为黏土、长石、石英等矿物原料。所有原料的主要化学成分见表1。由表1可见:钢渣的主要成分为氧化钙、铁氧化物和二氧化硅,不同于传统陶瓷原料的K2O(Na2O)-Al2O3-SiO2系统。添加黏土可以保证坯体的可塑性,而长石类原料是坯体中碱金属的来源,是坯体的主要助熔剂,石英原料则补充坯体的二氧化硅含量[14]。

将钢渣与其他矿物原料按照一定比例混合球磨,其中钢渣质量分数为40%。所有混合料在转速150 r/min的球磨机中球磨至过孔径为63 μm的筛,筛余小于1%。混合料在含水量约6%时,通过850 μm筛造粒,并在单轴压力30 MPa下成型。成型样品在110 ℃下烘干24 h后,在硅碳棒电阻炉中进行烧结实验,设定升温速率为10 ℃/min,保温时间为20 min。试样坯体粉料利用NETZSCH STA 449C进行差分扫描量热(DSC)分析。试样经烧结后,利用M21X型X线衍射仪进行物相分析(XRD)和EVO18型扫描电子显微镜(SEM)观察表观形貌。

2 结果与分析

2.1 烧结过程反应

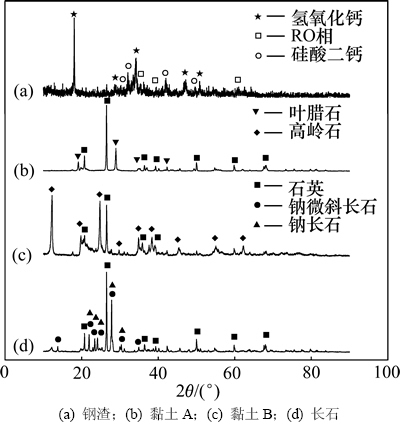

研究坯体烧结过程中的反应,首先需要了解原料的矿物相。图1所示为所选用原料XRD分析的物相图谱。一般钢渣矿物相包括硅酸二钙、硅酸三钙、铁酸钙、镁铁相和游离氧化钙等[15],而经过湿磨破碎过程的钢渣主要物相为氢氧化钙、硅酸三钙和固溶氧化亚铁等的RO相,这是因为钢渣在湿磨粉碎过程中发生了如下反应[16]:

CaO+H2O→Ca(OH)2 (1)

2Ca2SiO4+4H2O→3CaO·2SiO2·3H2O+Ca(OH)2 (2)

图1 原料矿物相XRD衍射图谱

Fig. 1 XRD spectra of steel slag and other raw materials

表1 钢渣及矿物原料的主要化学成分(质量分数)

Table 1 Main chemical composition of steel slag and other raw materials %

2Ca3SiO5+6H2O→3CaO·2SiO2·3H2O+3Ca(OH)2 (3)

在湿磨破碎过程中,游离氧化钙与水接触后迅速反应。随球磨进行,钢渣的颗粒度减小,钢渣表面能增加,反应(2)和(3)可较快进行,从而产生大量的氢氧化钙。

通常钢渣在高温下冷却速率较快,晶体形成和发育的时间较短,使得钢渣中晶体结晶不完整或呈不规则状,且存在少量玻璃相,从而导致钢渣矿物相的X线衍射峰偏弱。黏土A的主要矿物相是石英和叶腊石;黏土B的主要矿物相是高岭土和石英;长石的主要矿物相包括钠长石、钠微斜长石和石英。三者属于常用的传统陶瓷原料[17]。

钢渣陶瓷混合料的DSC-TG曲线如图2所示。由图2可见混合料的质量损失可分为2个阶段:

1) 700 ℃之前,混合料质量损失明显,约为6%。在该阶段,混合料中的质量损失主要是吸附水、结合水和结构水的脱除;DSC曲线上有3个较明显吸热峰,其中573.4 ℃为石英的晶型转变吸热,其他2个峰为结构水脱除作用所致。

2) 700 ℃之后,混合料的质量损失随温度变化平缓,约为0.8%,可能是少量结构水持续脱除,以及钢渣中氢氧化钙与空气中二氧化碳反应生成碳酸钙的分解作用。700~1 100 ℃时,DSC曲线显示缓慢吸热趋势,但没有明显的吸热峰,直到1 160 ℃形成大的吸热峰,此时坯体混合料中产生大量液相,试样开始熔化。在此过程混合料伴随有约0.3%的质量损失,这可能是 钢渣中高价铁氧化物在高温下分解产生氧气所致[10]。

根据原料矿物相以及DSC-TG曲线推测,在烧结过程中,钢渣陶瓷坯体可能发生的主要反应为

图2 钢渣陶瓷混合料DSC-TG曲线

Fig. 2 DSC-TG curve of mixture based on steel slag

Ca(OH)2→CaO+H2O (4)

3CaO·2SiO2·3H2O→3CaO·2SiO2+3H2O (5)

Al2O3·2SiO2·2H2O(高岭石)→Al2O3·2SiO2(变高岭石)+2H2O (6)

CaO+Al2O3·2SiO2(变高岭石)→CaO· Al2O3·2SiO2(钙长石) (7)

Ca2SiO4+2(Al2O3·2SiO2)(变高岭石)→2(CaO· Al2O3·2SiO2)(钙长石)+SiO2(非晶) (8)

Ca3SiO5+3(Al2O3·2SiO2)(变高岭石)→3(CaO· Al2O3·2SiO2)(钙长石)+3SiO2(非晶) (9)

3CaO·2SiO2+3(Al2O3·2SiO2)(变高岭石)→3(CaO· Al2O3·2SiO2)(钙长石)+2SiO2(非晶) (10)

CaO+2SiO2+MgxFe1-xO→CaO·MgxFe1-xO·2SiO2 (11)

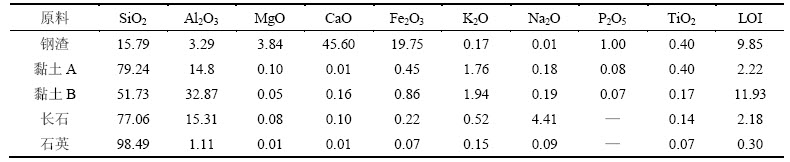

计算上述各反应式的反应吉布斯自由能变化与温度的关系,如图3所示。反应(4)~(6)为原料自身的脱水作用,反应(7)~(11)主要为钢渣矿物相与黏土中矿物相的反应。

图3 烧结过程中各反应△G-T关系

Fig. 3 Relationship between △G and T of reactions during sintering process

由图3可见,反应(4)~(6)在达到一定温度后,反应△G<0,对应DSC曲线较明显的脱水反应峰。反应(7)~(11)具有很强的不可逆自发反应趋势,在满足反应动力学条件后,反应将彻底进行。钢渣中大量的氢氧化钙在烧结过程中分解产生的氧化钙具有很强反应活性,可促进陶瓷原料间的反应[16]。钢渣湿法球磨过程生成的水化硅酸钙脱水后形成的3CaO·2SiO2等组分也有利于与黏土矿物间的反应进行。

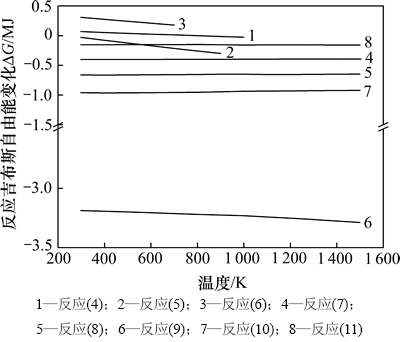

由上述可能反应可知,在钢渣-黏土-长石-石英体系中,钢渣陶瓷坯体烧结后晶相主要包括钙长石相和石英相。对1 120 ℃烧结后试样进行X线衍射分析,得到其XRD图谱如图4所示。

图4 钢渣陶瓷烧结试样XRD衍射图谱(烧结温度为1 120 ℃)

Fig. 4 XRD spectra of ceramic body based on steel slag (sintered at 1 120 ℃)

由图4可见:钢渣陶瓷坯体经烧结后,主要的矿物相为石英和钙长石相,并且有象征玻璃相的非晶峰出现,这表明烧结过程中出现了液相。

钢渣陶瓷坯体在烧结后无原料原始矿物相,说明原料矿物相在烧结过程中反应彻底,且在试样中没有检测到CaO·MgxFe1-xO·2SiO2相,这主要是因为钢渣中镁氧化物含量较少,且未添加含镁原料[18]。钢渣陶瓷烧结后最终生成了钙长石和石英相等,与推测的反应吻合,且钙长石相有利于提高坯体机械性能[7]。

2.2 烧结机理

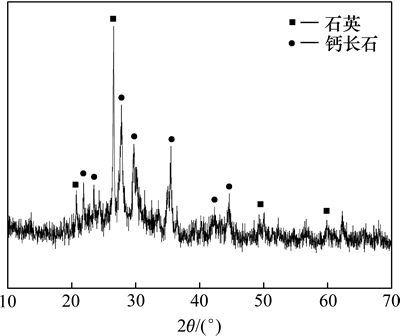

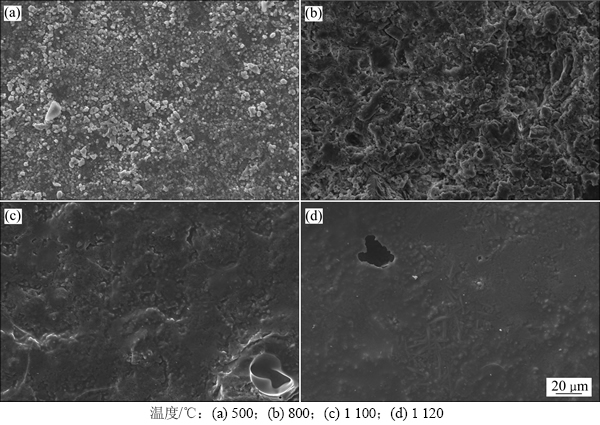

用扫描电子显微镜观察在不同烧结温度下获得试样的表观形貌,如图5所示。在500 ℃时烧结,坯体中颗粒棱角清晰,大量颗粒粒径为4~6 μm之间,少数石英颗粒粒径超过10 μm。颗粒间松散接触,保持原料颗粒形态。随烧结温度升高,在扩散作用下,坯体中颗粒形状开始变化,颗粒间接触紧密,并且开始产生粘结,形成接触颈,如图5(b)所示。在这一阶段,坯体中的反应主要是各组分自身的加热变化,如钢渣中氢氧化钙分解与黏土矿物结晶水的脱除等。钢渣中的少量玻璃相对颗粒间的黏结有促进作用,但在烧结温度达到1 100 ℃之前,坯体中以扩散传质为主。

在烧结温度达到1 100 ℃时,试样表面如图5(c)所示。坯体中长石组分开始熔融,产生少量高温液相,颗粒间粘结加剧,填充部分空隙,坯体致密度提高,固相反应得到增强,可观察到针状晶体包裹在玻璃相中。此时,分解产生的氧化钙开始与黏土矿物相硅铝酸盐反应生成钙长石相,并且产生无定形的二氧化硅。液相的产生促进了颗粒接触,有利于扩散进行。在烧结温度达到1 120 ℃时,坯体内部形成大量液相,这些液相在毛细管力的作用下迁移,填充晶体颗粒间隙,隔断原始连通孔隙,开始形成封闭圆形气孔,并促进坯体中扩散作用,增大固相反应强度,促使晶体长大,而部分液相迁移至坯体表面,降低坯体的显气孔率和吸水率,完成坯体的致密化。如图5(d)所示,在玻璃相的覆盖下,可观察到长大的针状晶体。且气孔聚集成大孔并且趋于圆形。此时,大量液相的形成主要是钢渣中钙、铁氧化物等与反应产生的无定形二氧化硅形成低共熔物导致。大量的晶体有利于提高陶瓷坯体的机械强度。烧结温度如果进一步升高,坯体将会由于液相量过多而发生变形。

图5 不同温度烧结的钢渣陶瓷坯体表观形貌

Fig. 5 Microstructures of ceramic based on steel slag at different sintering temperatures

3 结论

1) 掺入钢渣的陶瓷属于SiO2-CaO-Al2O3体系,其坯体的烧结反应与传统陶瓷明显不同,钢渣中各矿物相均参与烧结反应,并促进了原料间反应和坯体的致密化。

2) 湿磨后的钢渣存在大量的氢氧化钙,其在烧结过程中分解产生的氧化钙具有很强的反应活性,可促进烧结过程反应。

3) 钢渣-黏土-长石-石英的SiO2-CaO-Al2O3体系中,钢渣陶瓷的主晶相为钙长石相和石英相。钙长石相有利于提高陶瓷坯体的机械强度。

4) 钢渣陶瓷烧结初期以扩散传质反应为主,随温度升高,在钙、铁、硅氧化物作用下,形成低共熔物,产生大量高温液相,促进反应进一步进行和晶体长大,并完成坯体致密化。

参考文献:

[1] 王纯, 杨景玲, 朱桂林, 等. 钢铁渣高价值利用技术发展和现状[J]. 中国废钢铁, 2012(1): 42-53.

WANG Chun, YANG Jingling, ZHU Guilin, et al. Development of technology for value-added utilization of blast furnace slag and steel slag[J]. Iron and Steel Scrap of China, 2012(1): 42-53.

[2] Amritphale S S, Avneesh A, Chandra N, et al. A novel process for making radiopaque materials using bauxite-Red mud[J]. Journal of the European Ceramic Society, 2007, 27(4): 1945-1951.

[3] Zimmer A, Bergmann C P. Fly ash of mineral coal as ceramic tiles raw material[J]. Waste Management, 2007, 27(1): 59-68.

[4] 陆占清, 夏举佩, 张召述, 等. 铝土矿选尾矿制备低温陶瓷泡沫材料工艺研究[J]. 硅酸盐通报, 2010, 29(5): 1133-1138.

LU Zhanqing, XIA Jupei, ZHANG Zhaoshu, et al. Technological study of producing low temperature ceramic and foam material with tailing of flotation bauxite[J]. Bulletin of Chinese Ceramic Society, 2010, 29(5): 1133-1138.

[5] 吴建锋, 丁培, 徐晓虹, 等. 富赤泥陶瓷清水砖的研制[J]. 武汉理工大学学报, 2007, 29(7): 22-25.

WU Jianfeng, DING Pei, XU Xiaohong, et al. Preparation of rich-red mud ceramic simple brick[J]. Journal of Wuhan University of Technology, 2007, 29(7): 22-25.

[6] LIU Chengjun, SHI Peiyang, ZHANG Dayong, et al. Development of glass ceramics made from ferrous tailings and slag in China[J]. Journal of Iron and Steel Research, 2007, 14(2): 73-78.

[7] Karamanova E, Avdeev G, Karamanov A. Ceramics from blast furnace slag, kaolin and quartz[J]. Journal of the European Ceramic Society, 2011, 31: 989-998.

[8] Ozdemir I, Yilmaz S. Processing of unglazed ceramic tiles from blast furnace slag[J]. Journal of Materials Processing Technology, 2007, 183: 13-17.

[9] Favoni C, Minichelli D, Tubaro F, et al. Ceramic processing of municipal sewage sludge (MSS) and steelworks slag (SS)[J]. Ceramics International, 2005, 31: 697-702.

[10] Badiee H, Maghsoudipour A, Raissi Dehkordi B. Use of Iranian steel slag for production of ceramic floor tiles[J]. Advances in Applied Ceramics, 2008, 107: 111-115.

[11] Furlani E, Tonello G, Maschio S. Recycling of steel slag and glass cullet from energy saving lamps by fast firing production of ceramics[J]. Waste Management, 2010, 30: 1714-1719.

[12] ZHAO Lihua, LI Yu, ZHOU Yuanyuan, et al. Preparation of novel ceramics with high CaO content from steel slag[J]. Materials and Design, 2014, 64: 608-613

[13] AI Xianbin, LI Yu, GU Xiaomeng, et al. Development of ceramic based on steel slag with different magnesium content[J]. Advances in Applied Ceramics, 2013, 112(4): 213-218.

[14] Chen C Y, Lan G S, Tuan W H. Microstructural evolution of mullite during the sintering of kaolin powder compacts[J]. Ceramics International, 2000, 26: 715-720.

[15] 侯贵华, 李伟峰, 郭伟, 等. 转炉钢渣的显微形貌及矿物相[J]. 硅酸盐学报, 2008, 36(4): 436-443.

HOU Guihua, LI Weifeng, GUO Wei, et al. Microstructure and mineral phase of converter slag[J]. Journal of Chinese Ceramic Society, 2008, 36(4): 436-443.

[16] Yan J Y, Moreno L, Neretnieks I. The long-term acid neutralizing capacity of steel slag[J]. Waste Management, 2000, 20: 217-223.

[17] Chen Y F, Wang M C, Hon M H. Phase transformation and growth of mullite in kaolin ceramics[J]. Journal of the European Ceramic Society, 2004, 24(8): 2389-2397.

[18] AI Xianbin, BAI Hao, ZHAO Lihua, et al. Thermodynamic analysis and formula optimization of steel slag-based ceramic materials by FACTsage software[J]. International Journal of Minerals, Metallurgy and Materials, 2013, 20(4): 379-385.

(编辑 赵俊)

收稿日期:2014-05-20;修回日期:2014-07-16

基金项目(Foundation item):国家自然科学基金资助项目(51474027);中央高校基本科研业务费专项基金资助项目(FRF-TP-14-106A2) (Project(51474027) supported by the Key Program of the National Natural Science Foundation of China; Project(FRF-TP-14-106A2) supported by the Fundamental Research Funds for the Central Universities of China)

通信作者:李宇,副教授,从事二次资源循环利用和无机非金属材料制备研究;E-mail: leeuu00@sina.com