Article ID: 1003-6326(2005)03-0524-05

Aluminum ion beam surface modification of

elastic metallic-plastic pads for improving

tribological properties

SHAO Jun-peng(邵俊鹏)1, JIA Hui-juan(贾会娟)2, TANG Hui(汤 卉)1

(1. Department of Mechanical Engineering,

Harbin University of Science and Technology, Harbin 150080, China;

2. College of Pharmaceutics and Biotechnology, Tianjin University, Tianjin 300072, China)

Abstract: Elastic metallic-plastic pads(EMP) were irradiated by low energy aluminum ion in a metal vapor vacuum arc(MEVVA) 80-10 implantation system. The samples were irradiated with 20keV Al ion with the influx from 1×1015 to 1×1016Al/cm2. Then the as-irradiated samples were measured by ESCA, XRD, AFM/FFM and a nano-probe. It is found that the hardness of as-irradiated samples is 5-6 times as that of the pristine ones. The worn depth of sample implanted at ion influx of 1×1016 Al/cm2 is about one eighth of that of the pristine sample at the same load. The XRD results show that there are some Al2O3 and AlF3 intermingled with the phase of polytetrafluoroethylene(PTFE). The experimental results reveal that the tribological properties of EMP can be significantly improved by the ion beam surface modification.

Key words: elastic metallic-plastic pads; ion beam implantation; tribological property; Al CLC

number: TB383 Document code: A

1 INTRODUCTION

The elastic metallic-plastic pads(EMP) are widely used in vertical electric machines of hydropower plants. The surface material of EMP is PTFE. The PTFE has low friction coefficient and excellent insulativity, but the strength, hardness and wear-resistant properties are not satisfactory[1]. In order to improve the strength, hardness and wear-resistant character of PTFE, some physical commingling methods are used[2-4].

In recent years, there has been ever-increasing interest in the surface modification of polymers to improve their chemical, physical, mechanical and tribological properties. Many techniques have been applied to produce the desired surface modifications, ranging from conventional flame treatment, and electrical treatments, to modern plasma treatments and particle beam irradiation(ions, neutrons and photons) techniques[5-8]. Among them, particle beam techniques are particularly attractive owing to their flexibility, validity, and no environmental pollution compared with conventional techniques. Moreover, in the domain of particle beam techniques, the ion beam has been proven more effective in modifying polymer surfaces than UV-light, γ-ray, X-ray and electron beams. This is because that energetic ion has a higher cross-section for ionization[9] and larger linear energy transfer than those conventional radiation types of comparable energy owing to their deeper range[10]. Whilst it is widely recognized that cross-linking plays an important role in increasing surface mechanical properties of ion beam modified polymers, it is noticeable that, although PTFE is a typical chain scission polymer, electron beam and irradiated γ-ray show a significantly enhanced wear resistance. It is supposed that PTFEs wear resistance induced by radiation is closely related to the chain scission, the reduction of relative molecular mass, and the loss of long-range molecular interactions[1]. But, the thin film formed in this method is not strong enough to bear heavy load. So, we have studied another method to improve the tribological properties of EMP by means of aluminum ion beam irradiation. It is proved to be feasible to improve the behavior of chain scission polymers.

In the present work, EMP was irradiated with Al ion beam of 20keV with different ion influxes. The aim of this work is to investigate the tribological properties, surface hardness, chemical bonds, surface toughness and micro-wear characteristic of EMP.

2 EXPERIMENTAL

The EMP samples, which were provided by Harbin Electrical Machine Company, were rinsed with alcohol, and cleaned ultrasonically in acetone. All samples were finally dried in an oven at 100℃ for 1.5h. Al ion irradiation was carried out in a vacuum chamber of a metal vapor vacuum arc(MEVVA) source implanter with extraction voltage of 40kV. The irradiation energy of the Al ion was 20keV. Three ion influx were selected, i.e. 1×1015, 5×1015 and 1×1016 /cm2. The samples were irradiated with an ion current density of 10μA/cm2. The low ion doses and irradiation energy of the Al ions were employed in order to prevent the surface from the heavier erosion[11, 12]. The low beam current density was employed in order to lower the temperature of the samples resulting from ion beam heating. The samples were not cooled during ion irradiation. The base pressure of the vacuum chamber was 2×10-4Pa, and the ion irradiation was accomplished at a gas pressure of 3 ×10-3Pa.

[BJ(,,,][BJ)] Vol.15 №.3 Aluminum ion beam surface modification of elastic metallic-plastic pads After ion irradiation, the samples were taken out from the vacuum chamber, and then examined by ESCA(PHI-5300). The AlKα irradiation source was used in ESCA analysis. The chemical bonding and phase composition were analyzed with PHI 5300 and X-ray diffractometer. The micro-hardness and elastic modulus of the samples were measured by a nano-probe. The use of nano-probe makes it possible to estimate surface mechanical properties such as hardness, elastic modulus and creep resistance[13]. The micro wearing behavior was observed in a CSPM-930a atomic force and friction force microscope (AFM/FFM). And the micro friction force signal and wear were measured at a given load. The friction coefficients were investigated on a CJS111A friction machine.

3 RESULTS AND DISCUSSION

3.1 ESCA surface toughness analysis

The surface toughness of the as-irradiated samples was measured with AFM. There was no significant damage to the surface of the as-irradiated samples.

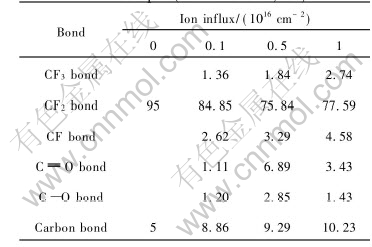

The C1s core-level spectra of the as-irradiated samples were obtained by ESCA. The observed C1s peaks can be distributed to CF3 bond at 293.1-294.0eV, CF2 bond at 292.2-292.5eV, CF bond at 289.8-290.4eV, C-O bond at 288.1-288.9eV, C—O bond at 285.9-286.6eV, and carbon bond at 284.6-284.8eV. The surface composition of the as-irradiated samples is shown in Table 1.

The C1s components at 292.2eV for the CF2 bond and at 284.8eV for the adsorbed carbon bond are found on the surface of the control sample. Six chemical bonds, i.e. CF3, CF2, CF, C-O,

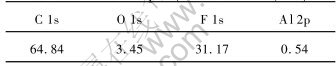

Table 1 Surface composition of as-irradiated samples(mole fraction, %)

C—O and C—C, were observed on the surface of all as-irradiated samples. It can be found that all the chemical bond data of the as-irradiated samples have changed with the increasing of ion influx. The values of CF3 bond, CF bond, C—O and C-O bond have increased with the given ion influx, while the ones of CF2 bond have decreased with the ion influx, as shown in Table 2.

Table 2 Surface compositions of EMP samples(mole fraction, %)

The force caused by Al ion irradiation is high enough to break the PTFE bonds. The formation of CF3 and CF bonds is due to chain scission, defluorination, and reaction. So the formation of the C-O and C—O bonds can be explained as follows. Some free radicals, such as alkyl and end-methyl type radicals, are produced in PTFE during Al ion irradiation. After irradiation, the PTFE samples are taken out from the vacuum chamber, and the free radicals react with oxygen in air.

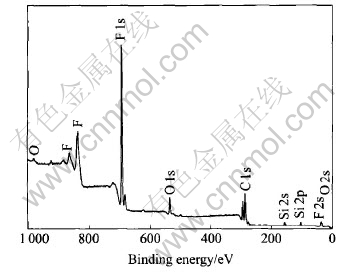

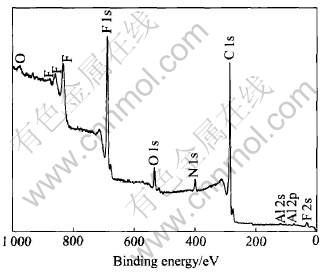

Fig.1 shows the XPS spectrum of the control sample and Fig.2 shows the XPS spectrum of the as-irradiated sample. In Fig.2, there are two obvious peaks—Al2s and Al2p, which are from Al2O3 and AlF3 respectively.

Fig.1 XPS spectrum of pristine samples

Fig.2 XPS spectrum of as-irradiated sample

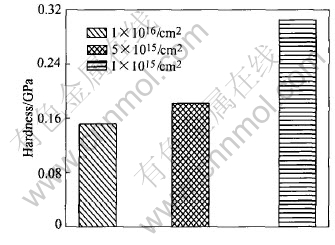

Fig.3 Hardness of as-irradiated samples

3.2 Hardness and elastic modulus

The hardness and elastic modulus of as-irradiated samples and the pristine samples were tested by the nano-probe. The results are shown in Fig.3. It is found that their surface hardness increases with the increasing of ion influx, the as-irradiated samples being observed are 5-6 times as hard as the pristine ones. The modulus of as-irradiated sample is degraded at the ion influx of 1×1015 and 5×1015 /cm2, while the modulus is enhanced at the ion influx of 1×1016. The as-irradiated samples exhibit a lower E/H ratio than that of the pristine samples, which limits the plastic deformation and promotes the elastic deformation, thus the adhesive wear resistant character of the ion beam modified polymeric surface is better[14, 15].

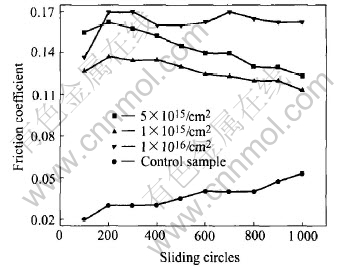

3.3 Micro tribological properties

The friction coefficients of the as-irradiated samples were measured under the unlubricated conditions using CJS111A sphere-disk tribometer. The upper sample was a sphere, which was made of GCr15, and its diameter was 7mm. The one under the sphere sample was the as-irradiated sample, which were cut into 20mm×20mm. The load was 1.47N and the rotate speed was 3000r/min. It is found that the friction coefficients of all the as-irradiated samples are higher than that of the pristine sample, as shown in Fig.4.

Fig.4 Friction coefficients of as-irradiated and control samples

After the micro-wear tests, the depth of the worn marks were measured by AFM. It is revealed that under the same testing conditions, the depth of the pristine sample is much deeper than that of the as-irradiated samples. And the worn depth of the as ingratiated sample at ion influx of 1×1016/cm2 is about one eighth of the pristine sample under the same load.

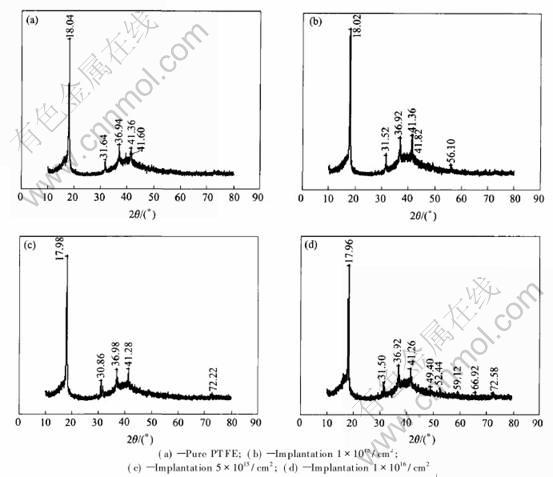

3.4 X-ray diffraction pattern

Fig.5 shows the phase compositions of the pristine samples and the as-irradiated samples. It is found that: 1) the diffraction angle decreases with the increasing of the ion influx, the main diffraction angles are 18.04°, 18.02°, 17.98° and 17.96°, which are in its turn with the ion influx, caused by the increasing of some complex effects, indicating that the properties of the material have been improved by Al ion implantation; 2) the phases increase with the increasing of the ion influx, and when the ion influx is 1×1016Al/cm2 there are 10 phases.

The X-ray diffraction patterns of the as-irradiated and pristine samples are shown in Fig.5. It is found that there are some Al2O3 peaks(72.22°- 72.58°), apart from some PTFE peaks. Because

Fig.5 XRD spectra of controlled and as-irradiated samples

low ion influx is employed in this experiment, the peaks of Al2O3 are rather weak. It is known that Al2O3 is a hard material, which is used to reduce the attrition wear. Thus, the Al2O3 phase can intensify the PTFE.

3.5 Discussion

In general, Al ion irradiation significantly induces the change of PTFE tribological properties. The hardness and elastic modulus of as irradiated samples are improved. The hardness is closely related to the Al ion influx. The desired elastic modulus can be obtained at 1×1016 /cm2. Although the friction coefficients of as-irradiated samples are higher than that of the pristine samples, it is insignificant under the oil lubricated conditions.

4 CONCLUSIONS

1) The wear resistant character of the as-irradiated EMP is much better than that of the pristine ones.

2) The Al2O3 produced by irradiation is a hard material, which is used to reduce the attrition wear.

REFERENCES

[1]TANG Hui, JIA Hui-juan, SHAO Jun-peng. Structure and micro-tribological properties of PTFE/Al2O3 micro-assembling film [J]. Trans Nonferrous Met Soc China, 2003, 13(6): 1381-1384.

[2]DAI Ha-li. The development and application of plastic pad in Japan [J]. News of Great Electric Machines, 2002, 3: 9-10.

[3]ZHANG Ji-zhong, ZHANG Xiao-ji, ZHOU Hong-yu. Effect of aging on surface chemical bonds of PTFE irradiated by low energy Ti ion [J]. Applied Surface Science, 2003, 205: 343-352.

[4]Nakao A, Kobayashi T, Iwaki M. Surface modification of polystyrene by K ion implantation [J]. Nuclear Instruments and Methods in Physics Research B, 2002, 191: 685-689.

[5]Feast W J, Munro H S, Richards R W. Polymer Surfaces and Interfaces(Ⅱ) [M]. Chichester, UK: Wiley, 1993. 220-225.

[6]Chan C M. Polymer Surface Modification and Characterization [M]. Carl Hanser, Munich, 1994. 117-253.

[7]Colwell J M, Wentrup-Byrne E, Bell J M, et al. A study of the chemical and physical effects of ion implantation of micro-porous and nonporous PTFE [J]. Surface and Coating Technology, 2003, 168: 216-222.

[8]Turos A, Jagieski J, Piatkowska A, et al. Ion beam modification of surface properties of polyethylene [J]. Vaccum, 2003, 70: 201-206.

[9]Chan C M, Ko T M, Hiraoka H, Polymer surface modification by plasmas and photons [J]. Surface Science Reports, 1996, 24: 1-9.

[10]Calcagno L, Foti G, Licciardello A, et al. Ion beam effects on optical and rheological properties of polystyrens [J]. Appl Phys Lett, 1988, 53: 1495-1501.

[11]ZHANG Ji-zhong, YU Xiao-jun, LI Heng-de, et al. Surface modification of polytetrafluoroethylene by nitrogen ion implantation [J]. Applied Surface Science, 2002, 185: 255-261.

[12]SAN Jin-fu, LIU Jia-jun, ZHU Bao-liang, et al. Metal-ion implantation effects on nano-hardness and tribological properties of Nylon6 [J]. Surface and Coatings Technology, 2002, 161: 1-10.

[13]Deaenley P A, Panagopoulos K, Kern E, et al. Sliding abrasion wear assessment of Al2-SiC nanocomposite coatings [J]. Surface Engineering, 2003, 19(5): 373-379.

[14]Wang A, Essner A, Polineni V K, et al. New Directions in Tribology [M]. London: Mechanical Engineering Publications, 1997. 443-458.

[15]Schiller T L, Sheeja D, McKenzie D R, et al. Plasma immersion ion implantation of poly(tetrafluoroethylene) [J]. Surface and Coating Technology, 2004, 177-178: 483-488.

(Edited by YUAN Sai-qian)

Foundation item: Project(2003AFXXJ005) supported by Harbin Science and Technology Committee, China

Received date: 2004-10-18; Accepted date: 2005-01-17

Correspondence: SHAO Jun-peng, Professor, PhD; Tel: +86-451-86612537; E-mail: sjp566@sina.com