用循环热处理细化铸造TiAl基合金的显微组织

来源期刊:中南大学学报(自然科学版)1999年第1期

论文作者:彭超群 黄伯云 贺跃辉 刘咏 孟力平

文章页码:52 - 54

关键词:TiAl基合金;循环热处理;显微组织;显微硬度

Key words:TiAl-based alloy; cyclic heat treatments; microstructures; microhardness

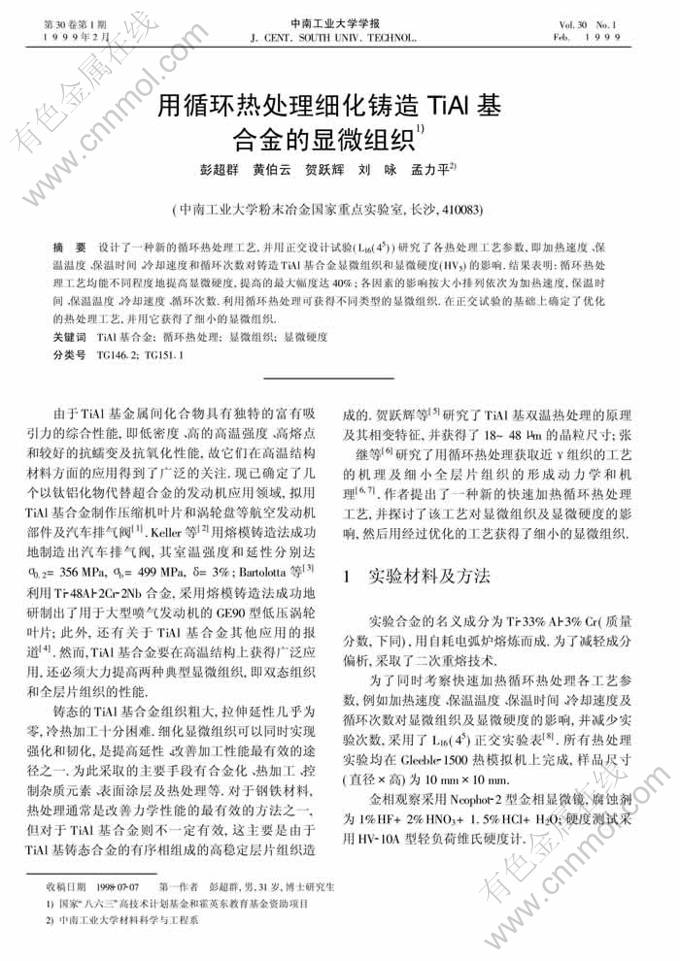

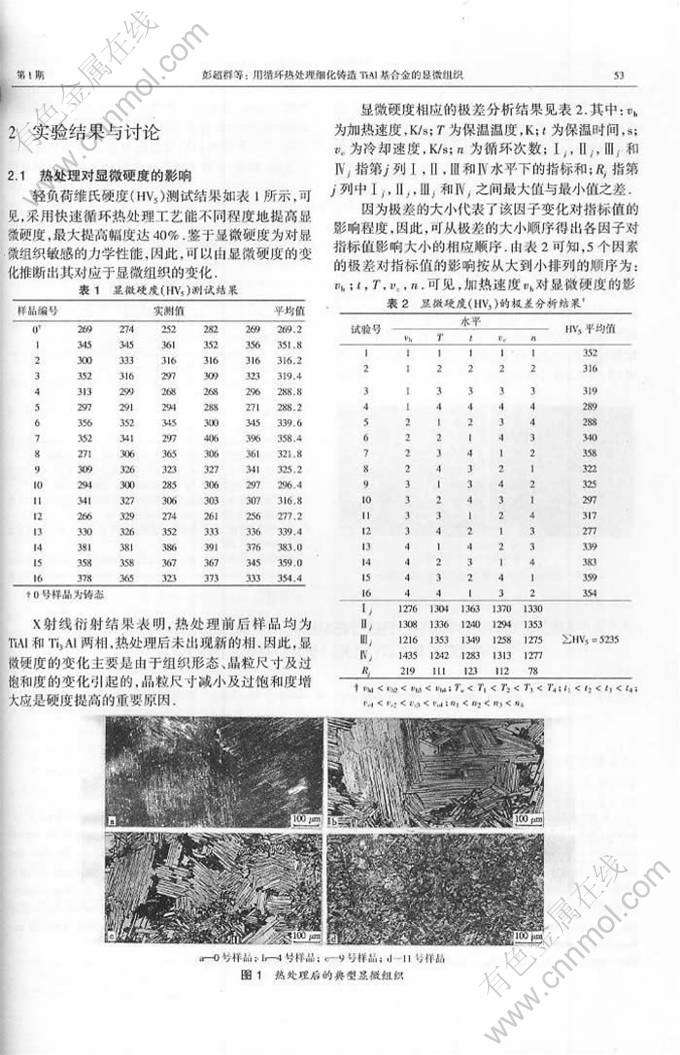

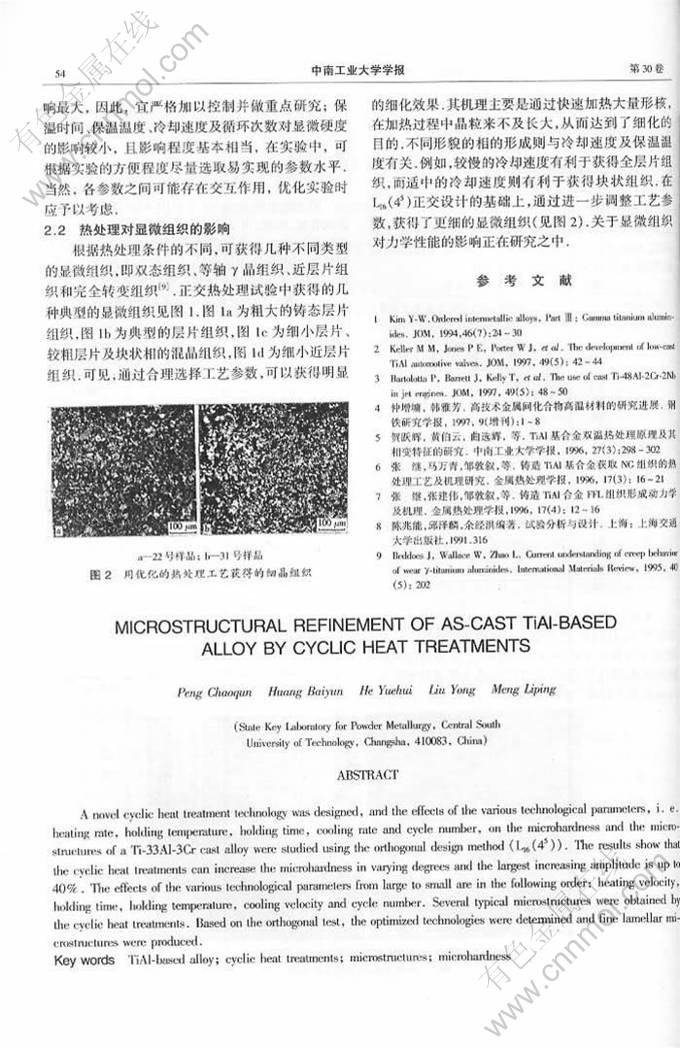

摘 要:设计了一种新的循环热处理工艺,并用 正交设计试验(L16(45))研究了各热处理工艺参数,即加热速度、保温温度、保温时间、冷却速度和循环次数对铸造TiAl基合金显微组织和显微硬度 (HV5)的影响.结果表明:循环热处理工艺均能不同程度地提高显微硬度,提高的最大幅度达40%;各因素的影响按大小排列依次为加热速度,保温时间、保 温温度、冷却速度、循环次数.利用循环热处理可获得不同类型的显微组织.在正交试验的基础上确定了优化的热处理工艺,并用它获得了细小的显微组织.

Abstract: A novel cyclic heat treatment technology was designed, and the effects of the various technological parameters, i. e. heating rate, holding temperature, holding time, cooling rate and cycle number, on the microhardness and the microstructures of a Ti-33Al-3Cr cast alloy were studied using the orthogonal design method (L 16 (4 5)). The results show that the cyclic heat treatments can increase the microhardness in varying degrees and the largest increasing amplitude is up to 40%. The effects of the various technological parameters from large to small are in the following order: heating velocity, holding time, holding temperature, cooling velocity and cycle number. Several typical microstructures were obtained by the cyclic heat treatments. Based on the orthogonal test, the optimized technologies were determined and fine lamellar microstructures were produced.