Microstructure and mechanical properties of

2D woven Grf/Al composite

ZHANG Yun-he(张云鹤)1,2, WU Gao-hui(武高辉)1, CHEN Guo-qin(陈国钦)1,

XIU Zi-yang(修子扬)1, ZHANG Qiang(张 强)1, WANG Chun-yu(王春雨)1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. School of Electromechanical Engineering, Northeast Forestry University, Harbin 150040, China

Received 28 July 2006; accepted 15 September 2006

Abstract: A 2D woven graphite fibers reinforced aluminum matrix composite with 50%Grf (volume fraction) was fabricated by the squeeze-casting technology, and its microstructure and mechanical properties were investigated. The results show that the composite is dense, the graphite fibers are distributed uniformly in the composite. TEM observation indicates the bonding between fiber and matrix is good and little interfacial reaction is found in the Grf/Al composite. This is attributed to the better stability of graphite fiber and the fabrication process minimizing the contact time between fiber with matrix at high temperatures. The 2D woven Grf/Al composite exhibites better mechanical properties with tensile strength, bending strength and elastic modulus of 366.2, 519.7 and 110.7 GPa, respectively. SEM images suggeste that the fracture is irregular and some pulled-out fibers are found, which indicats that the high strength of fiber is not degraded.

Key words: 2D woven composites; graphite fiber; aluminum matrix composites; mechanical property

1 Introduction

Graphite fiber reinforced aluminum composite has many advantages, such as high specific strength, high specific stiffness, low coefficient of thermal expansion and high thermal conductivity, and it is always one type of metal matrix composites(MMCs) that have attracted interest to composite researchers. Many investigations [1-8] on microstructures and properties of unidirectional graphite fiber reinforced aluminum composites were carried out, but the research on two dimensional woven fiber reinforced metal composite was hardly found. A 2D woven fabric as reinforcement MMCs provided many advantages: the increased transverse strength and stiffness, low manufacturing costs, easy forming of complex geometry and high damage tolerance[9-10]. Squeeze casting technology is an effective technique because of the advantages of higher production rates, elimination of expensive equipments, feasibility of mass production and near-net products[11-14]. In order to fully realize the potential of woven fabric reinforced aluminum matrix composite, it is necessary to understand the mechanical properties as well as manufacturing process of the composites. In this study, a two dimensional woven graphite fiber reinforced aluminum composite (2D Grf/Al) was fabricated by squeeze casting technology, and its microstructures and mechanical properties were investigated.

2 Experimental

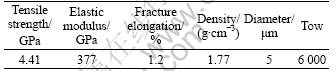

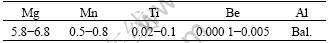

A plain woven fabric of M40 graphite fibers, whose warp and weft yarn density was 60/60/100 mm, was used as the reinforcement. The basic properties of M40 are shown in Table 1. The nominal compositions Al-Mg alloy matrix are shown in Table 2. The 2D Grf/Al com- posite with 50% Grf (volume fraction) was fabricated by squeeze casting technology. The fabrics were arranged at right angles. The composite was annealed at 330 ℃ for 0.5 h.

Tensile tests and three-point bending tests were conducted at ambient temperature using INSTRON 5569 universal test machine with loading rate of 0.5 mm/min. The test specimens were cut along orientation of fiber. The results of each tensile strength, the elastic modulus and bending strength are the average values of three measurements. The fractured surfaces of the tensile specimens were examined using a S-570 scanning electron microscopy(SEM), and the microstructure feature of the composite was examined using a Zeiss optical microscope. The interfacial microstructure in the composite was observed by a Philips T20 transmission electron microscopy with accelerating voltage of 200 kV, the specimens for TEM were thinned by a Gattan-600 ion beam thinner.

Table 1 Basic properties of M40 graphite fiber

Table 2 Nominal composition of matrix(mass fraction, %)

3 Results and discussion

3.1 Microstructure examination

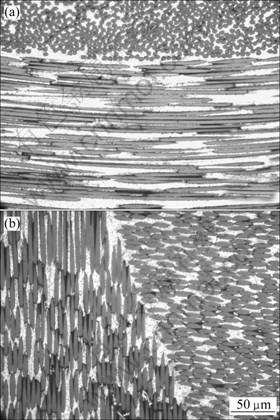

Fig.1 shows the optical micrographs of as-cast 2D Grf/Al composite. From Fig.1, the composite is free from common cast defects, such as porosity and shrinking cavities, and the molten aluminum infiltrates into the preform fully including gap between warp and weft yarn. The graphite fiber distributes homogeneously in the composite, which indicates that the composite is dense and macroscopically homogeneous. It is beneficial to improve the mechanical strength. The graphite fiber can be wetted by aluminum only at above 1 000 ℃, but higher fabrication temperature will accelerate the kinetics of reaction between graphite fiber and aluminum and results in decreased property. In this study, squeeze casting technology can make aluminum infiltrate into preform of fiber fully under the pressure through overcoming the viscous resistance and capillary pipe resistance. As a result, the composite is dense and homogeneous.

Fig.1 Optical micrographs of as-cast 2D Grf/Al composite: (a) Transverse; (b) Longitudinal

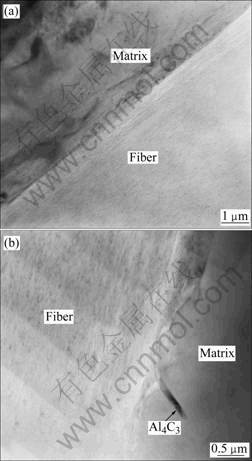

Fig.2 shows TEM images of 2D Grf/Al composite. Little reaction products of needle shaped aluminum carbide(Al4C3) are found at the interface of Grf/Al (Fig.2(b)), while the most interface of Grf/Al are planar and smooth without Al4C3 (Fig.2(a)). The TEM observation suggests very little reaction occurs along the interface of the composite under the present fabrication condition. The fabrication process can force molten aluminum to infiltrate into the preform rapidly and minimize the contact time between fiber with matrix at high temperatures[15]. In addition, graphite fiber as a reinforcement with much better stability than carbon fiber is not easy to react with aluminum[16]. Therefore, little reaction appears along the interface of the composite. Low amount of aluminum carbide does not provide the main influence on Gr/Al composite strength[5].

Fig.2 TEM images of interface in 2D Grf/Al composite: (a) No reactions; (b) Interfacial reaction products of aluminum carbide (Al4C3)

3.2 Mechanical properties

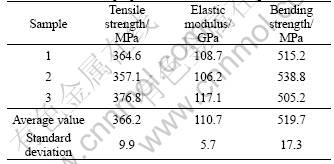

Table 3 shows mechanical properties of as-annealed 2D Grf/Al composite. The mechanical properties, the tensile strength, bending strength and elastic modulus of 2D Grf/Al composite are 366.2, 519.7 and 110.7 GPa, respectively. Furthermore, lots of data indicate that the fluctuation of measuring results is smaller while the distribution of strength values of unidirectional fiber reinforced composites is random commonly[17]. This can be attributed to homogeneity of the 2D Grf/Al composite.

Table 3 Mechanical properties of 2D Grf/Al composite

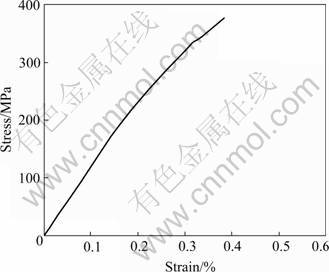

Fig.3 Stress—strain curve of 2D Grf/Al composite

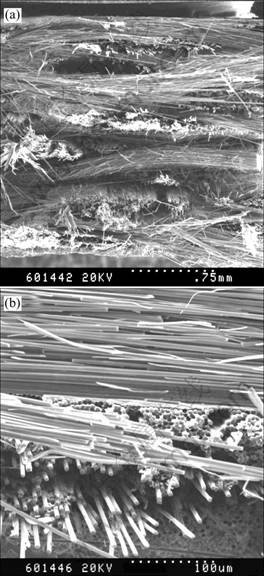

Fig.4 gives the tensile fracture surfaces of 2D Grf/Al composite. Macrofractography (in Fig.4(a)) shows that the tensile fracture surface is quite irregular and some pulled-out fibers are found, which suggests a weak interfacial bonding of Grf/Al, and it is beneficial to the enhancement of tensile strength. No ruptures occurred on fiber of weft yarn and the Grf/Al interface of weft yarn is separated (in Fig.4(b)), which indicates that the bonding of interface is weak. The weak bonding of interface is attributed to little reaction in the interface.

Fig.4 Tensile fractographs of 2D Grf/Al composite

Therefore, both little interfacial reaction and homogeneity of the composite cause better mechanical properties of the composite.

4 Conclusions

1) A 2D Grf/Al composite is fabricated by squeeze casting technology successfully. The composite is dense and homogeneous, and the graphite fibers are distributed uniformly in the composite.

2) The bonding between fiber and matrix is weak and little interfacial reaction is found in the Grf/Al composite.

3) The 2D Grf/Al composite exhibits better mechanical properties, the tensile strength, bending strength and elastic modulus are 366.2, 519.7 and 110.7 GPa, respectively.

4) Some pulled-out fibers on the fracture of the composite indicate that the high strength of fiber is not degraded.

References

[1] CHU Shuang-jie, WU Ren-jie. Relations between interface of Cf/Al-4.5Cu composite and solidification processing [J]. Trans Nonferrous Met Soc China, 1997, 7(2): 132-136.

[2] DAOUD A. Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration [J]. Materials Science and Engineering A, 2005, 391: 114-120.

[3] GU Ming-yuan, QI Ming. Effects of dendrite interphase on the strength of continuous fiber-reinforced metal matrix composites [J]. Materials Letters, 2003, 57: 1385-1390.

[4] WANG Hao-wei, SHANG Bao-lu, ZHOU Yao-he. Liquid fabricating C/Al composites [J]. Acta Aeronautica Et Astronautica Sinica, 1993, 14(8): 435-438.

[5] LANCIN M, MARHIC C. TEM study of carbon fibre reinforced aluminium matrix composites: influence of brittle phases and interface on mechanical properties [J]. J of the European Ceramic Society, 2000, 20: 1493-1503.

[6] RAWAL S P. Interface structure in graphite-fiber-reinforced metal- matrix composites [J]. Surface and Interface Analysis, 2001, 31: 692-700.

[7] WANG Yu-qing, ZHOU Ben-liam. Effect of a fiber coating on the fabrication of fiber reinforced metal-matrix composites [J]. J of Materials Processing Technology, 1998, 73: 78-81.

[8] ZHOU Yuan-xin, YANG Wang, XIA Yuan-min, MALLIK P K. An experimental study on the tensile behavior of a unidirectional carbon fiber reinforced aluminum composite at different strain rates [J]. Materials Science and Engineering A, 2003, 362: 112-117.

[9] LEE S K, BYUN L H, HONG S H. Effect of fiber geometry on the elastic constants of the plain woven fabric reinforced aluminum matrix composites [J]. Materials Science and Engineering A, 2003, 347: 346-358.

[10] LI Chao, QIU Zhe-ming, LIU Jian-chao. Study on the mechanical properties of carbon fabric composites [J]. Fiber Composites, 2003, 4: 23-24.

[11] ZHANg Qiang, WU Gao-hui, CHEN Guo-qin, JIANG Long-tao, LUAN Bo-feng. The thermal expansion and mechanical properties of high reinforcement content SiCp/Al composites fabricated by squeeze casting technology [J]. Composites: Part A, 2003, 34: 1023-1027.

[12] ZHAO Min, WU Gao-hui, DOU Zuo-yong, JIANG Long-tao. TiB2P/Al composite fabricated by squeeze casting technology [J]. Materials Science and Engineering A, 2004, 374: 303-306.

[13] ZHANG Qiang, CHEN Guo-qin, WU Gao-hui, XIU Zi-yang, LUAN Bo-feng. Property characteristics of a AlNp/Al composite fabricated by squeeze casting technology [J]. Materials Letter, 2003, 57: 1453-1458.

[14] ZHANG Si-qi, HUANG Jin-song, SHEN Jian, LU Bin, XU Guo-fu, Solidifying structures of Al2O3 short fiber/Al-Si alloy matrix composite prepared by squeeze casting [J]. Trans Nonferrous Met Soc China, 1995, 5(3): 133-135.

[15] WANG Yu-qing, ZHENG Jiu-hong, WANG Zuo-ming, ZHOU Ben-lian, ZHOU Long-jiang, ZHANG Fen-qiu. SiC coated carbon fibres by solution coating and their application to preparing Cf/Al composite [J]. Acta Metallurgia Sinica, 1994, 30(4): 194-197.

[16] ZHAO Chang-zheng. Correlation between interface reaction and properties of carbon and graphite fibre reinforced aluminum composites [J]. Acta Aeronautica Et Astronautica Sinica, 1985, 6(3): 267-271.

[17] LU Yun, ZHU Shi-jie, MA Ming-tu, PAN Fu-sheng. Advanced Composite Materials [M]. Beijing: China Machine Press, 2004. (in Chinese)

(Edited by LI Yan-hong)

Corresponding author: ZHANG Yun-he; Tel: +86-451-96402374; E-mail: zhangyh@hit.edu.cn