作为可生物降解植入体替代材料的热轧AZ31B镁合金的磨损行为

来源期刊:中国有色金属学报(英文版)2017年第12期

论文作者:Faruk MERT

文章页码:2598 - 2606

关键词:干滑动磨损;生物材料;AZ31B镁合金;磨损机制;磨损图

Key words:dry sliding wear; biomaterial; AZ31B magnesium alloy; wear mechanism; wear map

摘 要:植入体材料的表面完整性和摩擦学行为对其在人体内的性能有着至关重要的影响。热轧AZ31B镁合金是一种可生物降解的优良植入体材料,本文对其摩擦磨损行为进行研究。在干滑动条件下,采用热处理高碳钢盘作为对偶材料,固定滑动距离为5000 m,测量滑动速率分别为0.25、0.5、1和2 m/s以及载荷分别为10、20、40和80 N的材料磨损率。采用SEM/EDS表征材料的微观磨损表面,并绘制材料的磨损机制图。根据实验结果,在载荷20 N和滑动速率0.25 m/s时发生磨粒磨损,而在载荷80 N和滑动速率2 m时熔化磨损占主导地位。结果表明,在高载荷和高滑动速率情况下,超严重的塑性变形是主要的磨损机制。因此,热轧AZ31B镁合金由于具有细小的显微组织和高的硬度而表现出良好的耐磨性。

Abstract: Surface integrity and tribological behaviour of implant materials have a critical impact on their performance in the body. To understand wear behaviour well, the present article focuses on the sliding wear behavior of hot rolled AZ31B magnesium alloy which is a good candidate for biodegradable implant material. Dry-sliding conditions which include pin-on disc method with heat-treated high-carbon steel disc as counterface were used. Wear rates at a fixed sliding distance of 5000 m were measured at sliding velocities of 0.25, 0.5, 1 and 2 m/s, and loads of 10, 20, 40 and 80 N. Microstructure of worn surfaces of pins was characterized using SEM/EDS. Wear mechanism maps of the investigated materials were composed to understand comprehensively. According to test results, abrasive wear occurred at load of 20 N and sliding speed of 0.25 m/s while melting wear was predominant at load of 80 N and sliding speed of 2 m/s. Results show that ultra-severe plastic deformation is the main wear mechanism at the highest applied load and sliding velocity speed for the investigated alloy. Consequently, hot rolled AZ31B magnesium alloy exhibited a good wear resistance due to fine microstructure and high hardness.

Trans. Nonferrous Met. Soc. China 27(2017) 2598-2606

Faruk MERT1,2

1. Department of Manufacturing Engineering, Faculty of Technology, Gazi University, TR-06500 Ankara, Turkey;

2. Magnum Engineering Medical R&D Company, TR-06830 Ankara, Turkey

Received 7 February 2017; accepted 13 September 2017

Abstract: Surface integrity and tribological behaviour of implant materials have a critical impact on their performance in the body. To understand wear behaviour well, the present article focuses on the sliding wear behavior of hot rolled AZ31B magnesium alloy which is a good candidate for biodegradable implant material. Dry-sliding conditions which include pin-on disc method with heat-treated high-carbon steel disc as counterface were used. Wear rates at a fixed sliding distance of 5000 m were measured at sliding velocities of 0.25, 0.5, 1 and 2 m/s, and loads of 10, 20, 40 and 80 N. Microstructure of worn surfaces of pins was characterized using SEM/EDS. Wear mechanism maps of the investigated materials were composed to understand comprehensively. According to test results, abrasive wear occurred at load of 20 N and sliding speed of 0.25 m/s while melting wear was predominant at load of 80 N and sliding speed of 2 m/s. Results show that ultra-severe plastic deformation is the main wear mechanism at the highest applied load and sliding velocity speed for the investigated alloy. Consequently, hot rolled AZ31B magnesium alloy exhibited a good wear resistance due to fine microstructure and high hardness.

Key words: dry sliding wear; biomaterial; AZ31B magnesium alloy; wear mechanism; wear map

1 Introduction

Magnesium alloys are promising candidates as temporary implant materials for orthopedic implant surgery due to its close properties to bone [1]. The mechanical properties, biocompatibility and biodegradability are significant advantages and attracting interesting of the scientists. A number of animal tests have shown the in-vivo degradation property, bio-safety and positive bone tissue response to the magnesium alloys [2-4]. In recent years, clinical trials demonstrated that the repair outcome of magnesium screw in hallux valgus surgery can almost equal to titanium screw [5]. However, their too fast initial degradation rate and wear properties are the drawback of the magnesium alloys. The fast degradation of magnesium alloys may lead to an early loss of the mechanical strength of the implant, a massive generation of gas and an intense alkalization of the surrounding tissues [6]. As-cast magnesium alloys are not enough to meet most of the requirements, so wrought magnesium alloys have great application field by replacing other metal parts such as titanium or stainless steel. In order to develop hardness and strength, severe plastic deformation processes such as rolling and forging are used [6]. Increasing in mechanical properties of magnesium alloys enable to use in appropriate friction and wear applications [7,8].

The Mg-based bone implants must keep their mechanical strength until 12 weeks to allow sufficient healing time for the fractured bone while premature failures of these implants often occurred [9]. The early failures were mainly attributed to low mechanical properties and fast corrosion rate. Therefore, grain refinement was proved to be an effective way to improve the corrosion and wear resistance of magnesium alloys [10]. The improved corrosion resistance of AZ31B magnesium alloy was attributed to the ultrafine grains about 523 nm in size produced on the surface by cryogenic burnishing [11]. In addition to the corrosion performance, grain refinement of magnesium alloys may also improve their wear resistance. It was reported that nanocrystalline grains about 30 nm on the surface improved the wear resistance of AZ91D magnesium alloy [12].

Tribological behaviour mainly depends on test materials, counterface materials and their surface finish as well as testing conditions including sliding speed, applied load and test environments. Even though wear behaviour of other implant materials such as stainless steel, titanium alloys, Co-Cr-Mo alloys. have been mostly studied, tribological investigation of biodegradable magnesium alloys in the literature is extremely rare. AZ series alloys (aluminum and zinc) are well-known in magnesium alloy system and commonly used in many applications [13]. Magnesium alloy with 3% Al and 1% Zn (AZ31) is one of the most widely investigated compositions among the other AZ series magnesium alloys, such as AZ61, AZ80, AZ91 for biomedical applications because of less aluminum content, good mechanical properties and corrosion resistance, thus, it is better suitable for biomedical implant applications [14]. Aluminum element is known as toxic to human body. However, if aluminum content is less than 3% and degradation rate is lower than 0.1 g/(cm-2·d-1), the toxic effect can be less harmful [15]. According to our literature survey, AZ91D magnesium alloy has been the most commonly used and the most investigated alloy in terms of wear behavior until now [16-18]. The AZ91D magnesium alloy showed higher wear resistance than AS21 alloy against sintered iron alloy [16] and it resists to wear than AM60B alloy under the same material combinations [19]. AN et al [20] studied the friction and wear properties of as-cast Mg-1%Zn-2%Y and AZ91 magnesium alloys under dry sliding conditions using pin-on disc configuration. The results showed that Mg-1%Zn-2%Y exhibited better wear resistance compared with AZ91 for applied loads excess of 80 N. ZHANG et al [21] reported wear behaviour of as-cast Mg-Zn-Y magnesium alloy against steel with 65 RC hardness as counterface using block-on wheel test system. Test results exhibited that Mg-25Zn-2Y quasicrystal metal had better wear performance at all applied loads. ABDEL-WAHAB [22] studied the wear behaviour of extruded Mg-6Al-1Zn magnesium alloy under dry sliding conditions using pin-on ring type test apparatus. The results showed that sliding wear behaviour could be classified as two main wear regimes, mild wear and sever wear regime. CHEN et al [23] studied the friction properties and wear behaviours of thixoformed and permanent mold cast AZ91 magnesium alloy under reciprocating sliding conditions using ball-on disk configuration. They revealed that wear resistance of thixoformed AZ91 alloy was notably excellent than permanent mold cast AZ91 alloy due to finer microstructure. HABIBNEJAD- KORAYEM et al [24] investigated the wear behavior of pure magnesium, AZ31 magnesium alloy and their composites reinforced with 2% Al2O3 nano-particles using pin-on disc test setup. The results indicated that the composites showed better wear resistance than pure magnesium and its alloy because of grain refinement, higher hardness and load bearing capacity. DING et al [25] investigated the wear properties of AZ31 magnesium alloy and its composites with SiC particles. They also revealed that the microhardness and wear resistance of composites were superior to those of as-received AZ31 magnesium alloy. In recent years, some serious studies have been done on dry sliding behaviour of ZE41A magnesium alloy in the as-cast, hot extruded and heat treated conditions [26-28]. The wear tests were made under the different conditions using the pin-on disc configuration. According to investigations presented above, mild, severe and ultra-severe wear regimes were found and wear mechanisms such as abrasion, adhesion, oxidation, delamination, thermal softening, melting, plastic deformation, and severe plastic deformation were observed under different wear conditions.

Although AZ31B magnesium alloy is a good candidate for biomedical applications, little effort has been made to study on the wear behavior. Therefore, it is valuable and necessary to investigate wear behaviors of AZ31B magnesium alloy at various loads and speeds, so that the results can provide more useful information for the future development of the magnesium alloys. In this study, dry sliding wear behaviours of hot rolled AZ31B magnesium alloy were studied using a pin-on-disc type wear apparatus against an EN42 steel with heat treatment as counterface. A wear mapping approach has been undertaken to represent the wear regime and the main mechanism of wear in each regime.

2 Experimental

A commercial AZ31B magnesium alloy as hot rolled plate form (Mg-3%Al-1%Zn) used in this work was supplied by Xi’an Yuechen Metal Products Co., Ltd, China. The chemical composition of the studied alloy is given in Table 1. The rolled material was supplied as plate of 12 mm in thickness and HV 68 hardness.

Table 1 Chemical composition of hot rolled AZ31B magnesium alloy (mass fraction, %)

The microstructure of the as-received alloy and the pin worn surfaces were examined by Leica DMI 5000 optical microscopy and scanning electron microscopy (SEM) (JEOL JSM-6060 LW) equipped with an energy dispersive X-ray spectrometer (EDS). Metallographic samples were cut using a fine saw without heating and mounted in hardened epoxy resin. Then, the samples were ground with emery paper up to 2000 grade and polished with diamond paste of 3 μm in particle size. The polished surfaces were cleaned ultrasonically in a methanol solution before etching. AZ31B specimens were etched using a mixture of acetic acid (7 mL), picric acid (25 g), ethanol (140 mL), and purified water (40 mL) for 20 s to reveal the microstructure.

The wear tests were accomplished under dry sliding condition in accordance with the ASTM G99-95a standard [29] using a pin-on disc wear testing machine. In the present study, pins of AZ31B magnesium alloy were machined to 6 mm in diameter and 10 mm in length. The surface preparation procedure of the wear test samples consisted of grinding surfaces manually up to 1200 grit SiC emery papers. Specimen surfaces were cleaned with acetone to avoid the presence of humidity and non-desirable deposits, dried by warm air. The counterface was EN42 steel disc (in HRC 55 hardness) of 150 mm in diameter and 18 mm in width having surface roughness 0.15 μm (Ra) on which the test specimen slide. The steel disc was cleaned in an ethanol solution before each wear test.

The wear tests were performed under sliding velocities of 0.25, 0.5, 1 and 2 m/s and loads of 10, 20, 40 and 80 N with a constant sliding distance of 5000 m. The mass losses were calculated from the differences in mass of specimens measured before and after the sliding test (after removing any loose debris) using a precision balance (0.1 mg). Each test was repeated three times in order to check the reproducibility and average of three tests was considered to determine the wear rate. Because the hardness of the steel disc face was far higher than that of the specimens and its wear volume was too small, so the wear properties of the steel disc are not considered in the present work.

Volume lost during the wear test was determined from the mass lost using the alloy density to determine the wear rate. To evaluate the wear response of the material under different conditions, the Archard’s law was applied [30]:

V/L=K(F/H)=kF (1)

where V is the wear volume, L is the sliding distance, the coefficient V/L is the wear rate, F is the applied load, H is the hardness of the sample, K is the Archard’s constant and k is the specific wear rate. Hardness measurements of the hot rolled pin were measured using an EMCO TEST Duravision 200 machine with a 10 N load using ISO 6507-1standard [31]. Each hardness value was the average of at least three test results.

3 Results and discussion

3.1 Microstructure characterization

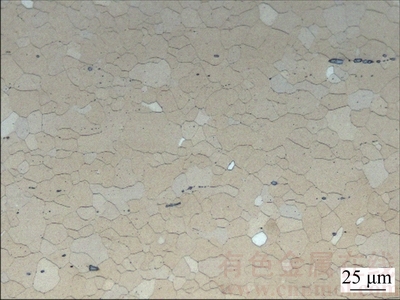

The microstructure of hot rolled AZ31B magnesium alloy was observed by optical microscopy, as shown in Fig. 1. According to Fig. 1, the microstructure of alloy mainly includes α-Mg phase as matrix and β-Mg17Al12 along the grain boundaries as the second phase precipitate. The grain size is heterogeneously distributed in microstructure and measured as approximately 18 μm. According to the Hall-Petch equation, grain size is directly related to mechanical strength, thus also influences the hardness. Furthermore, refined grains increase the hardness, hence elevating the wear resistance [32-34].

Fig. 1 Microstructure of hot rolled AZ31B magnesium alloy

3.2 Wear behaviour

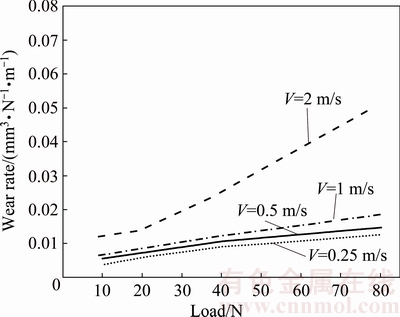

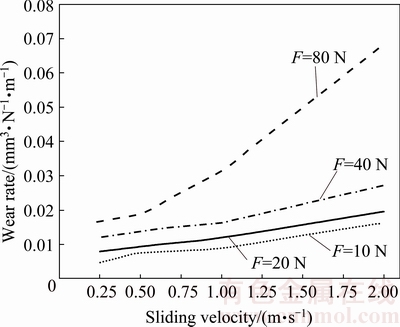

The volumetric wear rates of hot rolled AZ31B magnesium alloy are represented versus applied loads for the tests controlled at a constant sliding speed of 0.25, 0.5, 1.0 and 2.0 m/s in Fig. 2. The wear rate is enhanced with increasing applied load at whole sliding speeds. Great difference in slope of wear rates was obtained at 80 N for hot rolled alloy. The slope changes concurred with the transition from mild wear regime to severe wear regime [19]. Results show that mild wear keeps up to 40 N for hot rolled alloy. The effect of sliding velocity on the volumetric wear rates at constant applied loads of 10, 20, 40 and 80 N for hot rolled alloy is presented in Fig. 3. The wear rate is increased with enhancing sliding velocity at entire applied loads. Great difference in slope of wear rates occurred at 1.0 m/s for hot rolled alloy. This indicates that mild wear regime keeps up to 1.0 m/s under the present conditions.

According to Figs. 3 and 4, it is observed that the hot rolled AZ31B magnesium alloy has low wear rate at whole applied load and sliding velocity states. This is accomplished by grain refinement, less porosity, strengthening and hardening of the material by hot rolling. This is good agreement with the results by ABDEL-WAHAB [22], SELVAN and RAMANATHAN [35] and LIN et al [36]. From the well-known Hall–Petch relationship, the grain refinement will be resulted in the hardening or strengthening of the metallic materials, so it is observed that the wear volume decreases with an increase in pin hardness. In conclusion, the wear resistance of hot rolled AZ31B magnesium alloy is developed owing to the increase in strength, fine grain and hardness. Similar results were found in other reports about the extrusion of magnesium alloys [24,37,38].

Fig. 2 Effect of applied load on wear rate of hot rolled AZ31B magnesium alloy at different sliding velocities

Fig. 3 Effect of sliding velocity on wear rate of hot rolled AZ31B magnesium alloy at different applied loads

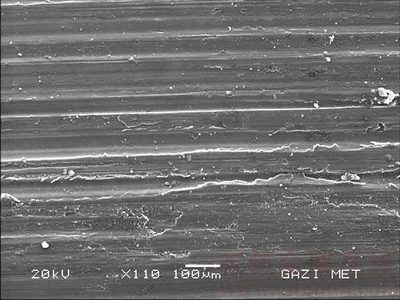

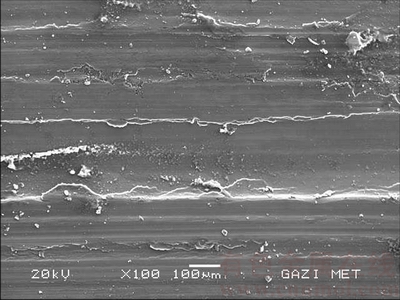

Fig. 4 SEM image of grooves and scratches on pin surfaces, showing abrasion of hot rolled AZ31B magnesium alloy at load of 20 N and velocity of 0.25 m/s

3.3 Wear mechanism

The worn surfaces of the tested pins were observed by SEM and EDS in order to identify the main wear mechanisms that took place in the different wear conditions for this study. In most of the wear tested conditions several wear mechanisms occurred, but a definition of the dominant wear mechanism for each wear test has been developed. The main wear mechanisms were observed as abrasion, oxidation, delamination, plastic deformation and melting, which are explained below.

3.3.1 Abrasion

Figure 4 shows surface morphology of hot rolled AZ31B magnesium alloy after dry sliding wear tests. Abrasion wear took place in the hot rolled worn surfaces at 20 N and 0.25 m/s. It can be observed on the wear surface the presence of numerous grooves aligned, mostly parallel to the sliding direction are evident of abrasion on all the worn pins. This wear mechanism dominates in the medium regimes of load and speed, but it is also available in nearly all the conditions tested mixed with other wear mechanisms. This result is good agreement with previous studies [36,39].

3.3.2 Oxidation

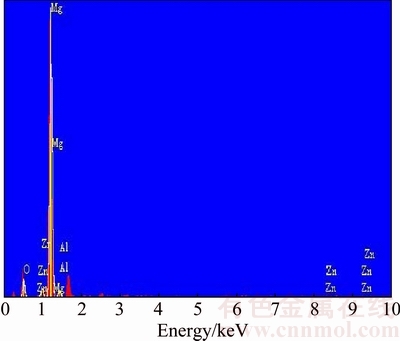

Magnesium alloys are known as strong tendency to oxidation, so oxidation of the worn surface plays a significant role in the wear behaviour. To determine the rate of oxidation under the different testing conditions, the amount of oxygen on the surface of the samples was evaluated by EDS. Oxidation wear occurred in the hot rolled worn surfaces at 40 N and 0.5 m/s as shown in Fig. 5. According to SEM images, the dark surfaces are found to be covered broadly by a thin layer of fine particles. The EDS analysis indicated the presence of a strong oxygen peak in the debris in addition to the magnesium peak, as shown in Fig. 6. This wear mechanism is referred as the oxidational wear, frictional heating during sliding leads to the surface oxidation, with wear occurring through the removal of oxide fragments [40]. Due to repeated sliding, oxide wear debris fills out the valleys on the pin surface, and becomes compacted into a protective layer. Thus, metallic contact between disc and pin is prevented and minimum absolute wear rates took placed. SELVAN and RAMANATHAN [35] reported that the thick oxide layer effectively protected the sliding surface resulting in a mild wear condition with accompanying low wear rate.

Fig. 5 SEM image showing oxidation of hot rolled pin surfaces at load of 40 N and velocity of 0.5 m/s

Fig. 6 EDS analysis exhibiting strong oxygen peaks, indicating oxidation of worn surfaces of hot rolled AZ31B magnesium alloy at load of 40 N and velocity of 0.5 m/s

3.3.3 Delamination

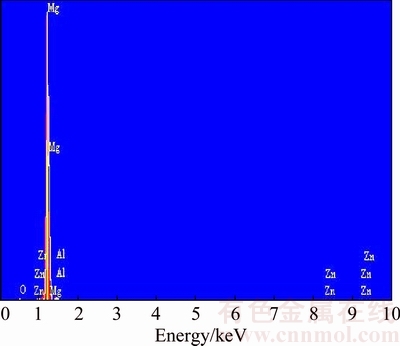

Delamination is a wear mechanism that was characterized by the detachment of material due to formation of cracks perpendicular to the sliding direction during the wear process. Most of magnesium alloys have low cold ductility, so there is a significant hardening of the worn surface even using lower loads [41]. Figure 7 shows the SEM image of delamination wear for hot rolled samples at 40 N and 1 m/s. When the applied load is increased in the mild wear regime, a systematic transition in the wear behavior of the alloy occurred from an oxidational wear to a delamination wear [20]. The existence of an oxygen peak of low intensity in the EDS spectrum of Fig. 8 indicated that the surface is slightly oxidized when the new produced surfaces of the detached particles became in contact with the air. In delamination wear, short cracks occur coarsely perpendicular to the sliding direction. The intersection of these cracks results in the detachment of sheet-like wear particles and the sizes of crack voids were 20-70 μm in length and 15-30 μm in depth, depends on material. In delamination wear the subsurface cracks, which may either exist earlier or get nucleated due to the stress, propagate during the course of wear. When such subsurface cracks combine the wear surface, delamination is the main wear mechanism [42]. These findings are good agreement with similar observations, which were made by earlier researchers [28,39,43].

Fig. 7 SEM image showing cracks of pin surfaces, indicating delamination of hot rolled AZ31B magnesium alloy at load of 40 N and velocity of 1 m/s

Fig. 8 EDS analysis exhibiting low intensity oxygen peaks, indicating delamination with oxide on worn surfaces of hot rolled AZ31B magnesium alloy at load of 40 N and velocity of 1 m/s

3.3.4 Plastic deformation

Plastic deformation is a serious wear mechanism that was characterized by large surface deformation on the worn surface without cracks. This wear mechanism introduces extensive surface damage, thus, it leads to higher wear rate with increase in load and speed. Figure 9 shows the SEM image of plastic deformation for hot rolled samples at 40 N and 2 m/s. VENKATARAMAN and SUNDARARAJAN [44] offered that the transition from delamination to plastic deformation happened when higher loads and speeds are issue. It was reported that increase in applied load and sliding velocity concluded rose in plastic deformation, which resulted in high level of structural corruption and large damage for the surface [45]. The deformed surface layers extended along the sliding direction and out of the contact surface of the sample. It is known that the temperature on the contact surface between steel counterface and test specimen during heavy conditions could reach higher temperatures. The transition from mild to severe wear was accompanied by an important enhancing in the roughness of worn surface of the samples [46]. The increment in applied load and sliding velocity resulted in a raise in plastic deformation, which resulted in high level of structural disruption and extensive damage for the material. As the temperature increases, the strength of both as-cast and hot rolled alloy decreases proportionately and makes softened. Consequently, they become prone to easy plastic deformation and spread out of the contact surface in the direction of sliding as well as by moving sideways [45].

Fig. 9 SEM image showing cracks of pin surfaces, indicating plastic deformation of hot rolled AZ31B magnesium alloy at load of 40 N and velocity of 2 m/s

3.3.5 Melting

Melting in the wear process occurs when applied load and sliding velocity lead to high friction. Figure 10 exhibits the SEM image of surface melting on the worn surface of hot rolled samples tested at 80 N and 2.0 m/s. As the applied load and sliding speed increase to crucial threshold limit value, instant temperatures on contacting surfaces could exceed the melting point of the alloy, hence enhancing pin temperature and leading regular softening of both as-cast and hot rolled alloy. Maintaining sliding or raising applied load and speed will increase temperatures further, causing melting and fast increase in wear rate [47]. According to the reports [42,48], during the wear tests at the highest applied loads, i.e. above 40 N and 50 N respectively, the local temperature of the contact surfaces, depending on the test temperature, exceeded the melting temperature of the alloy results friction-induced surface melting. The molten material spread out of the contact surface in the sliding direction as well as by moving sideways. During the sliding wear, the solidified material formed thin layers. The new layers were continuously generated over the previously formed layers.

Fig. 10 SEM image showing cracks of pin surfaces, indicating melting of hot rolled AZ31B magnesium alloy at load of 80 N and velocity of 2 m/s

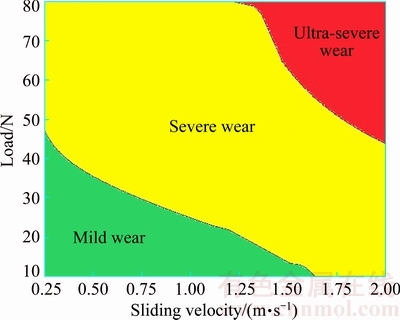

3.4 Construction of wear maps

Wear rate maps are required to completely understand the wear behaviour of the studied materials under a range of testing conditions. Firstly, the maps are generated and then they allow subsequent analysis in terms of wear mechanism maps and wear transition maps [49]. Figure 11 shows the wear rate map of hot rolled AZ31B magnesium alloy under different dry sliding conditions. These contour wear rate maps have been built on sliding velocity versus applied load axis operating Origin software and wear rate data. Each contour shows the wear rate under different sliding velocity and applied load conditions. The wear rate is maximum at higher applied load and sliding velocity, whereas it is minimum at lower applied load and sliding velocity for hot rolled alloy.

Fig. 11 Wear rate maps of hot rolled AZ31B magnesium alloy

The wear mechanism maps are useful to describe material behavior under tribological conditions. These maps are separated to regions by a transition line which is a function of two or more process parameters. As the contour maps are analyzed, lines of equal spacing and lack of curvature usually mean the same dominant mechanism. Recesses and ledges on the map generally recommend some change in the wear type. Hence, regions with potentially different wear mechanism can be defined. Wear mechanism maps can also help as a guide line to select wear resistant materials and suitable counterfaces for them. Wear mechanism maps could be a helpful instrument to forecast the wear conditions [40]. Figure 12 exhibits the wear mechanism for hot rolled AZ31B magnesium alloy. Wear transitions could be described as the rapid increasing in wear rate over a small change in conditions such as load, speed, temperature or time. Wear transition plots provide opportunity to examine the different wear mechanisms in each region for investigated materials under various wear parameters. Three wear regimes are obtained as mild wear, severe wear and ultra-severe wear for hot rolled alloy. In the mild wear regime, the wear takes place by abrasion, oxidation and delamination of the bulk material. These wear mechanisms are dominant in the mild wear regime. For industrial applications, the mild wear regime could be considered as safe operation regime because the wear rates are typically low and wear proceeds under steady-state condition [40]. Plastic deformation based wear is the dominant wear mechanism in the severe wear regime. Increasing in sliding velocity and applied load leading to rise local temperature on contact surfaces of the alloy concludes great plastic deformation. The transition from mild to severe wear is checked by sliding velocity and applied load. Surface melting is the dominant wear mechanism in the ultra-severe wear regime. Further increasing sliding velocity and applied load leads higher contact temperatures between specimen and steel disc and also raising frictional heat concludes surface melting. The transition from severe wear to ultra-severe wear is also checked by sliding velocity and applied load.

Fig. 12 Wear mechanism map of hot rolled AZ31B magnesium alloy

4 Conclusions

1) The wear rate increases with increasing in sliding velocity and applied load for hot rolled AZ31B magnesium alloy.

2) The main wear mechanisms were abrasion, oxidation, delamination, plastic deformation and melting.

3) Wear surfaces uncovered that the sliding wear behavior of hot rolled AZ31B magnesium alloy can be classified into three wear regimes, mild wear, severe wear and ultra-severe wear.

4) The dominant wear mechanisms in each regime were identified and summarized in the wear mechanism map.

5) Abrasion, delamination and oxidation wear are predominant wear mechanisms in the mild wear regime, while plastic deformation wear is the dominant wear mechanism in the severe wear regime.

6) Melting wear is the dominant wear mechanism in the ultra-severe wear regime.

7) The wear rate of the hot rolled AZ31B magnesium alloy depends on the applied load and sliding velocity.

8) The better wear resistance property is succeeded in hot rolled AZ31B magnesium alloy due to finer grains, decreasing in porosity, hardening and strengthening of the material.

Acknowledgements

The author would wish to thank Magnum Engineering R&D Company Ankara-TURKEY for providing material and technical assistance. The invaluable contribution of Dr. Onur  , in making the wear test is gratefully acknowledged.

, in making the wear test is gratefully acknowledged.

References

[1] STAIGER M, PIETAK A, HUADMAI J, DIAS G. Magnesium and its alloys as orthopedic biomaterials: A review [J]. Biomaterials, 2006, 27: 1728-1734.

[2] QI Z R, ZHANG Q, TAN L L, LIN X, YIN Y, WANG X L, YANG K, WANG Y. Comparison of degradation behavior and the associated bone response of ZK60 and PLLA in vivo [J]. Journal of Biomedical Material Research A, 2013, 102: 1255-1263.

[3] WILLBOLD E, KALLA K, BARTSCH I, BOBE K, BRAUNEIS M, REMENNIK S, SHECHTMAN D, NELLESEN J, TILLMANN W, VOGT C, WITTE F. Biocompatibility of rapid-solidified magnesium alloy RS66 as a temporary biodegradable metal [J]. Acta Biomaterialia, 2013, 9: 8509-8517.

[4] KRAUS T, FISCHERAUER S F, HANZI A C, UGGOWITZER P J,  J F, WEINBERG A M. Magnesium alloys for temporary implants in osteosynthesis: in vivo studies of their degradation and interaction with bone [J]. Acta Biomaterialia, 2012, 8: 1230-1238.

J F, WEINBERG A M. Magnesium alloys for temporary implants in osteosynthesis: in vivo studies of their degradation and interaction with bone [J]. Acta Biomaterialia, 2012, 8: 1230-1238.

[5] CASTELLANI C, LINDTNER R A, HAUSBRANDT P, TSCHEGG E, STANZL-TSCHEGG S E, ZANONI G, BECK S, WEINBERG A. Bone-implant interface strength and osseointegration: Biodegradable magnesium alloy versus standard titanium control [J]. Acta Biomaterialia, 2011, 7: 432-440.

[6] WINDHAGEN H, RADTKE K, WEIZBAUER A, DIEKMANN J, NOLL Y, KREIMEYER U, SCHAVAN R, STUKENBORG C, WAIZY H. Biodegradable magnesium-based screw clinically equivalent to titanium screw in hallux valgus surgery: Short term results of the first prospective, randomized, controlled clinical pilot study [J]. BioMedical Engineering Online, 2013, 12-62: 3-10.

[7] WU G, IBRAHIM J M, CHU P K. Surface design of biodegradable magnesium alloys—A review [J]. Surface and Coatings Technology, 2013, 233: 2-12.

[8] SHANTHI M, LIM C Y H, LU L. Effects of grain size on the wear of recycled AZ91 Mg [J]. Tribology International, 2007, 40: 335-338.

[9] PIETAK A M, STAIGER M P, HUADMAI J, DIAS G. Magnesium and its alloys as orthopedic biomaterials: A review [J]. Biomaterials, 2006, 27: 1728-1734.

[10] WANG H, ESTRIN Y, FU H, SONG G, ZUBEROVA Z. The effect of pre-processing and grain structure on the bio-corrosion and fatigue resistance of magnesium alloy AZ31 [J]. Advanced Engineering Materials, 2007, 9: 967-972.

[11] PU Z, YANG S, SONG G L, DILLON O W, PULEO, D A, JAWAHIR I S. Ultra fine grained surface layer on Mg-Al-Zn alloy produced by cryogenic burnishing for enhanced corrosion resistance [J]. Scripta Materialia, 2011, 65: 520-523.

[12] SHI Y N, SUN H Q, ZHANG M X. Wear behaviour of AZ91D magnesium alloy with a nanocrystalline surface layer [J]. Surface and Coatings Technology, 2008, 202: 2859-2864.

[13] ADEKANMBI I, MOSHER C Z, LU H H, RIEHLE M, KUBBA H, TANNER K E. Mechanical behaviour of biodegradable AZ31 magnesium alloy after long term in vitro degradation [J]. Materials Science and Engineering C, 2017, 7: 1135-1144.

[14] SONG Y, SHAN D, CHEN R, ZHANG F, HAN E H. Biodegradable behaviors of AZ31 magnesium alloy in simulated body fluid [J]. Materials Science and Engineering C, 2008, 29: 1039-1045.

[15] ZHENG Y F, GU X N, WITTE F. Biodegradable metals [J]. Materials Science and Engineering R, 2014, 77: 1-34.

[16] MEHTA D S, MASOODAND S H, SONG W Q. Investigation of wear properties of magnesium and aluminum alloys for automotive applications [J]. Journal of Materials Processing Technology, 2004, 155-156: 1526-1531.

[17] HUANG W, HOU B, PANG Y, ZHOU Z. Fretting wear behaviour of AZ91D and AM60B magnesium alloys [J]. Wear, 2006, 260: 1173-1178.

[18] BLAU P J, WALUKAS M. Sliding friction and wear of magnesium alloy AZ91D produced by two different methods [J]. Tribology International, 2000, 33: 573-579.

[19] CHEN H, ALPAS A T. Sliding wear map for the magnesium alloy Mg-9Al-0.9Zn (AZ91) [J]. Wear, 2000, 246: 106-116.

[20] AN J, LI R G, LU Y, CHEN C M, XU Y, CHEN X, WANG L M. Dry sliding wear behavior of magnesium alloys [J]. Wear, 2008, 265: 97-104.

[21] ZHANG Y, YU S, LUO Y, HU H. Friction and wear behavior of as-cast Mg-Zn-Y quasicrystal materials [J]. Materials Science and Engineering A, 2008, 472: 59-65.

[22] ABDEL-WAHAB E. Dry sliding wear behavior of hot deformed magnesium AZ61 alloy as influenced by the sliding condition [J]. Materials Science and Engineering A, 2008, 473: 330-335.

[23] CHEN T J, MA Y, LI B, LI, Y D, HAO Y. Wear behavior of thixoformed AZ91D magnesium alloy: A comparison with permanent mould cast alloy [J]. Materials Science and Engineering A, 2007, 445: 477-485.

[24] HABIBNEJAD-KORAYEM M, MAHMUDI R, GHASEMI H M, POOLE W J. Tribological behavior of pure Mg and AZ31 magnesium alloy strengthened by Al2O3 nano-particles [J]. Wear, 2010, 268: 405-412.

[25] DING W, JIANG H, ZENG X, LI D, YAO S. Microstructure and mechanical properties of GTA surface modified composite layer on magnesium alloy AZ31 with SiCp [J]. Journal of Alloys and Compounds, 2007, 429: 233-241.

[26] SELVAN S A, RAMANATHAN S. Dry sliding wear behavior of hot extruded ZE41A magnesium alloy [J]. Materials Science and Engineering A, 2010, 527: 1815-1820.

[27] SELVAN S A, RAMANATHAN S. A comparative study of the wear behavior of as-cast and hot extruded ZE41A magnesium alloy [J]. Journal of Alloys and Compounds, 2010, 502: 495-502.

[28]  A J, RODRIGO P, TORRES B, RAMS J. Dry sliding wear behaviour of ZE41A magnesium alloy [J]. Wear, 2011, 271: 2836-2844.

A J, RODRIGO P, TORRES B, RAMS J. Dry sliding wear behaviour of ZE41A magnesium alloy [J]. Wear, 2011, 271: 2836-2844.

[29] ASTM G99-05. Standard test method for wear testing with a pin-on-disk apparatus [S]. 2004.

[30] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics, 1953, 24: 981-988.

[31] ISO 6507-1. Metallic materials—Vickers hardness test Part1: Test method [S]. 2005.

[32] MAO X Y, LI D Y, FANG F, TAN R S, JIANG J Q. A simple technique of nanocrystallizing metallic surfaces for enhanced resistances to mechanical and electrochemical attacks [J]. Materials Science and Engineering A, 2010, 527: 2875-2880.

[33] MAO X Y, LI D Y, FANG F, TAN R S, JIANG J Q. Application of a simple surface nanocrystallization process to a Cu-30Ni alloy for enhanced resistances to wear and corrosive wear [J]. Wear, 2011, 271: 1224-30.

[34] CHEN C, LI D Y, SHANG C J. Nanocrystallization of aluminized surface of carbon steel for enhanced resistances to corrosion and corrosive wear [J]. Electrochimica Acta, 2009, 55: 118-24.

[35] SELVAN S A, RAMANATHAN S. Dry sliding wear behavior of as-cast ZE41A magnesium alloy [J]. Materials and Design, 2010, 31: 1930-1936.

[36] QU Xuan-hui, DUAN Bo-hua, HE Xin-bo, QIN Ming-li. Effect of porosity on wear resistance of SiCp/Cu composites prepared by pressureless infiltration [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 1076-1082.

[37] CHENA Y J, WANG Q D, ROVEN H J, KARLSEN M, YU Y D, LIU M P, HJELEN J. Microstructure evolution in magnesium alloy AZ31 during cyclic extrusion compression [J]. Journal of Alloys and Compounds, 2008, 462: 192-200.

[38] DING H, LIU L, KAMADO S, DING W, KOJIMA Y. Microstructure evolution in magnesium alloy AZ31 during cyclic extrusion compression [J]. Journal of Alloys and Compounds, 2008, 456: 400-406.

[39] TALTAVULL C, RODRIGO P, TORRES B, LOPEZ A J, RAMS J. Dry sliding wear behavior of AM50B magnesium alloy [J]. Materials and Design, 2014, 56: 549-556.

[40] AUNG N N, ZHOU W, LIM L E N. Wear behaviour of AZ91D alloy at low sliding speeds [J]. Wear, 2008, 265: 780-786.

[41] TALTAVULL C, TORRES B, LOPEZ A J, RAMS J. Dry sliding wear behavior of AM60B magnesium alloy [J]. Wear, 2013, 301: 615-625.

[42] ZAFARI A, GHASEMI H M, MAHMUDI R. Tribological behavior of AZ91D magnesium alloy at elevated temperatures [J]. Wear, 2012, 292-293: 33-40.

[43] LIM S C. The relevance of wear-mechanism maps to mild-oxidational wear [J]. Tribology International, 2002, 35: 717-723.

[44] VENKATARAMAN B, SUNDARARAJAN G. The sliding wear behaviour of Al-SiC particulate composites- I. Macrobehaviour [J]. Acta Materialia, 1996, 44: 451-460.

[45] MONDAL A K, CHANDRA RAO B S S, KUMAR S. Wear behavior of AE42+20% saffil Mg-MMC [J]. Tribology International, 2007, 40: 290-296.

[46] ZHANG J, ALPAS A T. Transition between mild and severe wear in aluminium alloys [J]. Acta Materialia, 1997, 45: 513-528.

[47] LIM C Y H, LIM S C, GUPTA M. Wear behaviour of SiCp-reinforced magnesium matrix composites [J]. Wear, 2003, 255: 629-637.

[48] HUANG W, LIN Q, LIU C. Tribological behaviour of AZ71E alloy at high temperatures [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2057-2065.

[49] HSU S M, SHAN M C. Ceramic wear maps [J]. Wear, 1996, 200: 154-175.

Faruk MERT1,2

1. Department of Manufacturing Engineering, Faculty of Technology, Gazi University, TR-06500 Ankara, Turkey;

2. Magnum Engineering Medical R&D Company, TR-06830 Ankara, Turkey

摘 要:植入体材料的表面完整性和摩擦学行为对其在人体内的性能有着至关重要的影响。热轧AZ31B镁合金是一种可生物降解的优良植入体材料,本文对其摩擦磨损行为进行研究。在干滑动条件下,采用热处理高碳钢盘作为对偶材料,固定滑动距离为5000 m,测量滑动速率分别为0.25、0.5、1和2 m/s以及载荷分别为10、20、40和80 N的材料磨损率。采用SEM/EDS表征材料的微观磨损表面,并绘制材料的磨损机制图。根据实验结果,在载荷20 N和滑动速率0.25 m/s时发生磨粒磨损,而在载荷80 N和滑动速率2 m时熔化磨损占主导地位。结果表明,在高载荷和高滑动速率情况下,超严重的塑性变形是主要的磨损机制。因此,热轧AZ31B镁合金由于具有细小的显微组织和高的硬度而表现出良好的耐磨性。

关键词:干滑动磨损;生物材料;AZ31B镁合金;磨损机制;磨损图

(Edited by Xiang-qun LI)

Corresponding author: Faruk MERT; E-mail: 36faruk@gmail.com

DOI: 10.1016/S1003-6326(17)60287-5