文章编号:1004-0609(2016)-01-0007-09

新型Al-Cu-Li-X合金热处理强化及组织特征

李树飞1, 2,尹登峰1, 2, 3,余鑫祥1, 2,潘康观1, 2,袁新雄1, 2,房洪杰3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属先进结构材料与制造协同创新中心,长沙 410083;

3. 烟台南山学院 工学院,烟台 265713)

摘 要:采用正交试验及其方差分析、最小显著差数(LSD)法研究新型Al-Cu-Li-Ag-Mg-Zr-Ce合金的固溶和时效热处理工艺,并采用电导率、SEM、EDX、TEM等测试手段对合金热处理过程中组织结构和性能进行分析。结果表明:该合金在固溶(520 ℃,1.5 h,水冷)和时效(180 ℃,18 h,空冷)处理后,T6态显微硬度比轧制态的提高100.8%,T87态强度值达到623 MPa。固溶过程中,大量Ce、Cu、Mg、Zr溶于基体起到固溶强化作用;时效时细小片状强化相T1和薄盘状θ′相均匀弥散在基体中析出,具有强烈沉淀强化效果。

关键词:Al-Cu-Li合金;热处理;正交实验;力学性能

中图分类号:TG146 文献标志码:A

铝锂合金属可热处理强化型合金,因其具有低密度、高弹性模量、高比强度和比刚度、疲劳裂纹扩展率低等优势,被广泛认为是21世纪航空航天及军工领域最理想的轻质高强结构材料之一[1]。近年来,国内外专家学者在研究Al-Cu-Li系合金热处理强化及其组织与性能的关系方面做了大量工作,认为Al-Cu-Li系合金沉淀特征取决于(Cu+Li)总量、w(Cu)/w(Li)比和合金化元素含量,强化相包括GP区、θ″/θ′、T1和δ′相等,它们之间的竞争析出动力学及强化受固溶时效机制、变形工艺等影响,其具备超高强度是因时效处理析出的主要强化相δ′、T1和θ′所致[2-5]。其中,第三代新型铝锂合金2195、2099、2199、2397等研究开发均是以高强可焊性Al-Cu-Li-Ag-Mg系Weldalite 049合金为基础,侧重于改变w(Cu)/w(Li)、w(Cu)/w(Mg)比以及调整优化合金元素成分与时效处理工艺;特别是稀土元素的加入,有效减小晶粒尺寸、促进析出相θ′和T1弥散分布,显著改善合金强度、塑韧性以及降低铝锂合金板材各向异性[6-8]。但由于多种合金化元素的加入提高了各组元间交互作用的复杂性和多层次结构与合金性能的可变性[9-10],而关于Al-Cu-Li-X合金显微组织结构及其性能在整个固溶淬火和时效热处理工艺过程中的演变规律方面鲜有研究报道。因此,本文作者采用多重观测值的L9(34)正交试验方法,结合直观与方差法分析固溶温度、固溶时间、时效温度、时效时间对Al-Cu-Li-X合金硬度和强韧性等综合性能的影响,旨在通过合理的固溶、时效热处理精准地控制合金中的组织变化从而提高其综合性能,确定一种新型Al-Cu-Li-Ag-Mg- Zr-Ce合金的最佳热处理工艺,并对热处理过程中合金组织和性能进行研究,为合金最佳热处理工艺的制定提供理论基础和实验依据。

049合金为基础,侧重于改变w(Cu)/w(Li)、w(Cu)/w(Mg)比以及调整优化合金元素成分与时效处理工艺;特别是稀土元素的加入,有效减小晶粒尺寸、促进析出相θ′和T1弥散分布,显著改善合金强度、塑韧性以及降低铝锂合金板材各向异性[6-8]。但由于多种合金化元素的加入提高了各组元间交互作用的复杂性和多层次结构与合金性能的可变性[9-10],而关于Al-Cu-Li-X合金显微组织结构及其性能在整个固溶淬火和时效热处理工艺过程中的演变规律方面鲜有研究报道。因此,本文作者采用多重观测值的L9(34)正交试验方法,结合直观与方差法分析固溶温度、固溶时间、时效温度、时效时间对Al-Cu-Li-X合金硬度和强韧性等综合性能的影响,旨在通过合理的固溶、时效热处理精准地控制合金中的组织变化从而提高其综合性能,确定一种新型Al-Cu-Li-Ag-Mg- Zr-Ce合金的最佳热处理工艺,并对热处理过程中合金组织和性能进行研究,为合金最佳热处理工艺的制定提供理论基础和实验依据。

1 实验

以高纯铝、纯锂、纯镁、纯银和中间合金Al-Cu、Al-Zr、Al-Ce为原料,在低频电阻丝石墨坩埚炉中用LiF和LiCl按质量比1:2混合的精炼剂进行熔炼,用六氯乙烷除气,熔液浇注时通氩气保护,制备了成分为Al-5.8Cu-1.3Li-0.4Ag-0.4Mg-0.14Zr-0.11Ce的合金铸锭。铸锭在盐浴炉中进行((470 ℃,8 h)+(500 ℃,8 h)+(510 ℃,8 h))三级均匀化处理,经切头、铣面后(450 ℃,3 h)预热,热轧至厚度为6 mm的板材,经(450 ℃,2.5 h)中间退火后冷轧至2 mm薄板,随后进行固溶处理,立即水淬,时效(冷轧预变形量7%)后采用空冷。确定热处理工艺中固溶温度、固溶时间、时效温度、时效时间4个因素3个水平,设计L9(34)正交实验如表1所列。

采用HV-10B型小负荷维氏显微硬度计进行硬度测试,负荷4.9 N,加载时间30 s。采用D60K型数字金属测量仪测固溶处理时合金电导率值,取3次测量结果的平均值。室温拉伸实验在美国Instron3369型力学试验机上进行,拉伸速度2 mm/min。在配有GENESIS60S型能谱仪的KYKY-1000型扫描电镜上进行SEM和EDX分析。透射试样经人工减薄至0.1~0.08 mm后冲裁成直径3 mm的薄片,用液氮冷却至-20~-35 ℃,在MTP~I型双喷电解减薄仪上减薄,电解液采用25%硝酸和75%甲醇(体积分数)混合溶液,在TECNAIG220型透射电镜上观察显微组织。

2 实验结果

2.1 正交试验分析

硬度可理解为材料抵抗变形或破坏的能力,是材料弹性、塑性、强度和韧性等力学性能的综合指标,因此本次多重观测值的正交试验结果以硬度值作为评判指标,设计正交实验如表2所列。

表1 热处理工艺的正交实验因素水平

Table 1 Levels and factors of orthogonal experiment of heat treatment

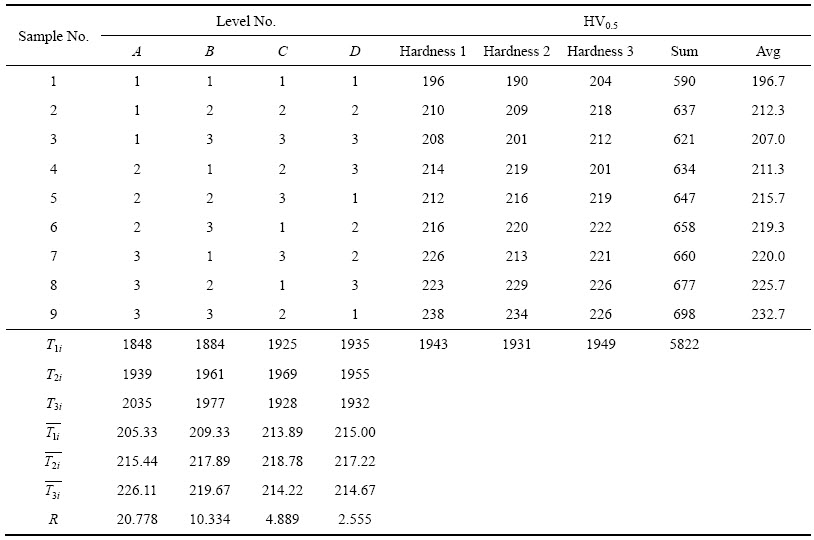

表2 L9(34)正交实验设计及硬度测试值

Table 2 Values of orthogonal design and hardness test result

通过对极差R的直观分析可知,A(固溶温度)及B(固溶时间)对硬度值影响较大,且固溶温度为主要影响因素;C(时效温度)和D(时效时间)均为次要因素,对合金硬度指标影响不大,即各因素对硬度指标影响作用强弱顺序为A>B>D>C,初步得到较好的热处理工艺A3B3C2D2,将其命名为试验10,即固溶(520 ℃,1.5 h,水冷)和时效(180 ℃,16 h,空冷),按此热处理工艺所得硬度值为243HV0.5。由于正交实验的直观分析不能给出误差估计,将直接影响结果分析的准确性,尤其针对有重复且采取随机区组设计的正交实验,误差估计至关重要,因此,通过多因素方差分析将各因子对硬度的显著性影响进行分析计算,如表3所列(检验水平α=0.05)。

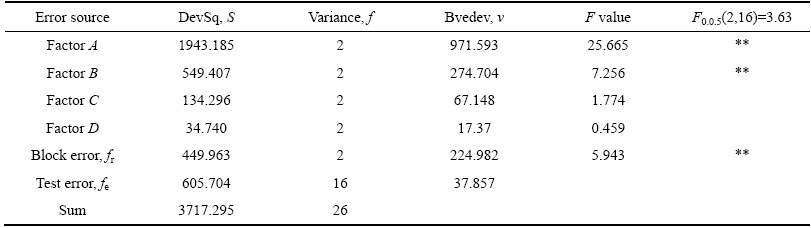

根据表3中F值与临界值比较可知,固溶温度及固溶时间对实验结果影响是极其显著的,与极差R分析结果一致,但得出区组误差对实验结果显著性影响是直观分析不能得到的,突出方差分析的准确性,说明试验各因素间存在交互作用,各因素所在列将出现交互作用的混杂,此时各因素水平间的差异不能真正反映因素的主效,需进行试验处理间的多重比较(LSD法)如表4所列,以期得到最优水平组合。

其中,最小显著差数标准值LSD0.05=t0.05(16)× =10.65,LSD0.01=t0.01(16)×

=10.65,LSD0.01=t0.01(16)× =14.68。

=14.68。

如表4所列可知,样品9除与样品8平均硬度值间差异不显著外,与其余样品平均硬度值间差异极显著或显著(与试验7、6号)。因此,该实验最优水平组合为第9号试验处理A3B3C2D1,即固溶(520 ℃,1.5 h,水冷)和时效(180 ℃,12 h,空冷),按此热处理工艺所得合金硬度值为233HV0.5。

2.2 合金组织与性能变化规律

2.2.1 固溶处理组织与性能分析

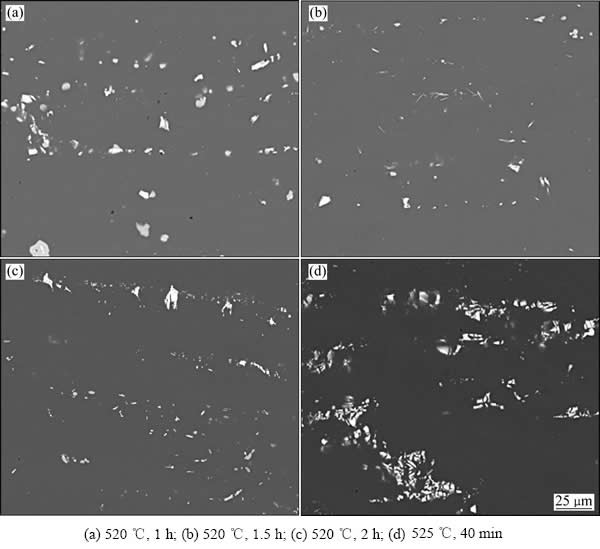

对正交试验结果进行单因素实验验证,为合金最佳热处理工艺制定提供实验依据。合金在不同温度下进行固溶处理得到的SEM像如图1所示。

表3 有重复观测值正交试验方差分析表

Table 3 Variance analysis results of repeated observations orthogonal experiment

表4 各试验处理平均数间的多重比较(LSD法)

Table 4 Test processing multiple comparisons between average(LSD)

图1 合金试样经不同固溶热处理工艺后的背散射SEM像

Fig. 1 Backscattered SEM images of alloy after different solution treatments

在520 ℃下固溶1.5 h后,大部分过剩相粒子溶入到α(Al)基体中,尺寸和数量明显减少,另有少许小尺寸残留相;延长固溶时间,溶入基体的第二相粒子较少,且残留相的尺寸和数量没有明显改变;而(525 ℃,40 min)固溶后合金基体中未溶第二相粒子偏聚长大,固溶效果下降。对(520 ℃,2 h)固溶后基体中未溶残留第二相进行EDX谱分析如图2所示,表明合金在α(Al)基体上分布着多种合金相及组织,其中残留难溶第二相主要是三类粒子,即分布较多富铜相Al2Cu(箭头1)、形状规则富铁相Al7Cu2Fe(箭头2)、粒子偏聚最多含铈相Al8Cu4Ce(箭头3),这3种粒子的形貌和分布对合金固溶态性能有一定影响。另外还存在少量亮白色衬度为ZrAl3(箭头4)、易与Al2Cu相邻的灰色衬度为Al2CuMg(箭头5)。

试样合金经520 ℃固溶处理不同时间所得硬度值及电导率变化如图3所示。固溶体中溶质原子浓度越高表示溶质原子溶入溶剂晶格的数量越多,固溶强化效果越好,而其引起溶剂晶格畸变区越大,电子的散射能力也就变强,导致电阻率增大,即电导率就越小。由图3可知,合金在520 ℃固溶1.5 h后,硬度值达到最大值,电导率变化亦很小,趋于平缓,从而得出合金固溶处理最佳工艺为(520 ℃,1.5 h)。

2.2.2 时效处理组织与性能分析

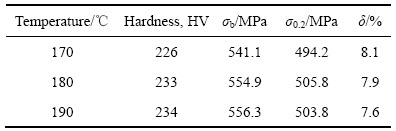

将试样在相同固溶(520 ℃,1.5 h,水冷)处理后进行不同温度下时效12 h得合金T6态力学性能如表5所列。对于时效(170 ℃,12 h)处理所得力学性能明显较低,而较高温度的时效(190 ℃,12 h)所得硬度和抗拉强度值虽稍高于180 ℃时效处理的,但高温时效加快过饱和空位扩散速率,使其快速移动到位错等缺陷处湮灭导致晶内缺陷密度降低,易使强化相T1在晶界或亚晶界析出,降低晶内强化作用,亦会使强化相分布不均匀[11],影响合金性能。试验9和10的区别在于时效时间不同而导致硬度值指标有差异,为确定合金最佳热处理工艺,在180 ℃时效不同时间得出合金力学测试结果,如表6所列。

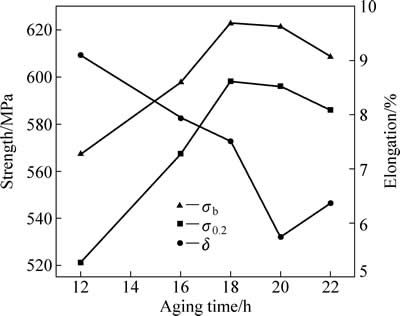

相比而言,经时效处理(180 ℃,18 h)所得合金力学性能具有最好的强韧性配合,虽然硬度指标与样品10的相同,伸长率相差不大,均大于7%,但抗拉强度和屈服强度分别高6.7、15.5 MPa,继续延长时效时间,硬度、强度值均明显降低,仅伸长率升高,故而得出合金T6态的最佳热处理工艺(520 ℃,1.5 h+180 ℃,18 h)。合金经固溶(520 ℃,1.5 h)处理后将T87 态试样于180 ℃时效不同时间得室温拉伸强度曲线如图4所示。

图2 合金基体中(520 ℃,2 h)固溶后残留第二相EDX分析

Fig. 2 EDX analysis of residual phase of alloy after solid solution at (520 ℃, 2 h)

图3 合金经520 ℃固溶处理不同时间的硬度及电导率曲线

Fig. 3 Hardness and electrical conductivity curves of alloy after solution treatment at 520 ℃ for different times

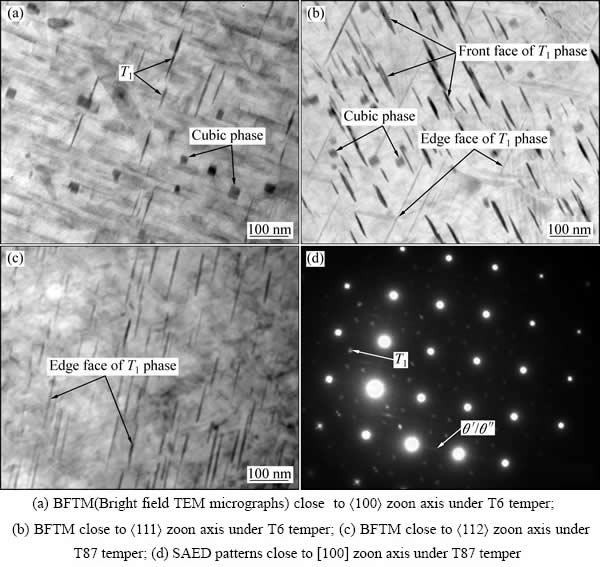

图5所示为合金按最佳热处理工艺得到样品T6、T87态TEM像,结合试样T87态电子衍射斑点分析,在铝基体衍射斑周围形成“十字花”的典型结构,基体对角线1/3处斑点表示T1相,过基体斑点而平行于<100>方向的白色亮线代表θ′/θ″相。由此可知,新型Al-Cu-Li-Ag-Mg-Zr-Ce合金时效析出沉淀强化相主要为T1(Al2CuLi)、θ′(Al2Cu),存在少量立方相(Al5Cu6Li2)粒子[12-13],稀土Ce的添加对Al-Cu-Li-X合金主要强化相种类的析出影响不大,且T87状态下T1、θ′相更加细小弥散地在基体中均匀析出。

表5 合金试样在不同温度下时效12 h的力学性能 (T6)

Table 5 Mechanical properties of alloy aged at different temperatures for 12 h (T6)

表6 合金试样在180 ℃时效不同时间的力学性能(T6)

Table 6 Mechanical properties of the alloy aged at 180 ℃ for different times (T6)

图4 合金在T87态180 ℃时效不同时间的室温力学性能

Fig. 4 Mechanical properties of alloy aged at 180 ℃ for different time (T87)

3 分析和讨论

Al-Cu-Li-X合金系脱溶强化型铝合金,合理的热处理工艺将显著提高其综合性能,特别是稀土元素Ce的加入,在基体中与其他合金化元素间的交互作用影响合金析出相数量、尺寸大小以及分布情况。其中Ce与主元素间交互作用强度W[14]表示为 ,εr为原子尺寸因素,Nr为电负性因素,W越大则元素间形成化合物趋势越强,即固溶度越低。Ce与Al之间的交互作用强度W为3.55,Ce与Cu之间的W为11.7,即Ce除少量固溶于Al基体中,多数以化合物Al8Cu4Ce存在;Al与Cu之间的W为1.13,Al与Mg之间的W为1.07,Ce与Mg之间的W仅为0.98。另外,Li在Ce周围偏聚的弹性势能低于Cu在Ce周围偏聚的,Cu与Ce间存在弹性交互势能[15],结合考虑在铝锂合金中高铜、锂含量比几乎不出现强化相δ′,故而推断在Al-Cu-Li-Ag-Mg-Zr-Ce合金中,主要的析出强化相为θ′和T1。

,εr为原子尺寸因素,Nr为电负性因素,W越大则元素间形成化合物趋势越强,即固溶度越低。Ce与Al之间的交互作用强度W为3.55,Ce与Cu之间的W为11.7,即Ce除少量固溶于Al基体中,多数以化合物Al8Cu4Ce存在;Al与Cu之间的W为1.13,Al与Mg之间的W为1.07,Ce与Mg之间的W仅为0.98。另外,Li在Ce周围偏聚的弹性势能低于Cu在Ce周围偏聚的,Cu与Ce间存在弹性交互势能[15],结合考虑在铝锂合金中高铜、锂含量比几乎不出现强化相δ′,故而推断在Al-Cu-Li-Ag-Mg-Zr-Ce合金中,主要的析出强化相为θ′和T1。

图5 T6、T87态合金试样峰时效TEM像和SAED谱

Fig. 5 TEM images and SAED patterns of samples under T6 and T87 conditions

固溶处理时,溶质原子溶入基体产生的位错运动阻力对屈服强度的贡献 [16]可表示为

[16]可表示为 。其中,k为与原子尺寸、错配度及弹性模量有关的常数;C为固溶体中溶质原子的平均浓度,在合金组织不过烧前提下固溶温度越高C值越大,强化效果相对越好。当合金固溶(520 ℃,1.5 h)处理后,残余过剩相在基体中溶解充分,使基体中Cu、Li等溶质原子平均浓度上升,不仅引起溶剂晶格畸变区变大,电子散射能力增强,降低电导率,也增大固溶体的过饱和度,加速时效脱溶速率,增强固溶强化效果(见图3)。过饱和固溶体中被“冻结”在晶格内的部分空位优先沿着{111}面偏聚成空位盘崩塌为位错环,为时效初期GP区的形成提供溶质原子扩散和富集的条件,而多余空位与Cu、Li等溶质原子的结合对θ′和T1相形核生长有支配作用;同时与位错的弹性交互作用及与Mg、Ag等微量元素的综合影响,也降低了θ′、T1 相的析出激活能。稀土元素Ce原子半径(0.183 nm)大于Al原子半径(0.143 nm),由交互作用强度W可知其固溶度较低,固溶时除占据正常晶体空间点阵位置外,还要占据部分空位,降低了基体空位浓度,限制了Cu、Li原子偏聚区(GP区、θ′)的形成,对随后时效处理时θ′、T1相的生长至关重要[17-18]。再者,溶质原子偏聚形成的科垂尔气团对位错的钉扎作用产生固溶强化效应,提高基体强度和硬度。但固溶温度过高及保温时间较长时,溶质原子偏聚区域过大,合金再结晶程度增加导致平均晶粒尺寸增大、基体强度下降、硬度降低。

。其中,k为与原子尺寸、错配度及弹性模量有关的常数;C为固溶体中溶质原子的平均浓度,在合金组织不过烧前提下固溶温度越高C值越大,强化效果相对越好。当合金固溶(520 ℃,1.5 h)处理后,残余过剩相在基体中溶解充分,使基体中Cu、Li等溶质原子平均浓度上升,不仅引起溶剂晶格畸变区变大,电子散射能力增强,降低电导率,也增大固溶体的过饱和度,加速时效脱溶速率,增强固溶强化效果(见图3)。过饱和固溶体中被“冻结”在晶格内的部分空位优先沿着{111}面偏聚成空位盘崩塌为位错环,为时效初期GP区的形成提供溶质原子扩散和富集的条件,而多余空位与Cu、Li等溶质原子的结合对θ′和T1相形核生长有支配作用;同时与位错的弹性交互作用及与Mg、Ag等微量元素的综合影响,也降低了θ′、T1 相的析出激活能。稀土元素Ce原子半径(0.183 nm)大于Al原子半径(0.143 nm),由交互作用强度W可知其固溶度较低,固溶时除占据正常晶体空间点阵位置外,还要占据部分空位,降低了基体空位浓度,限制了Cu、Li原子偏聚区(GP区、θ′)的形成,对随后时效处理时θ′、T1相的生长至关重要[17-18]。再者,溶质原子偏聚形成的科垂尔气团对位错的钉扎作用产生固溶强化效应,提高基体强度和硬度。但固溶温度过高及保温时间较长时,溶质原子偏聚区域过大,合金再结晶程度增加导致平均晶粒尺寸增大、基体强度下降、硬度降低。

时效前7%预变形增加基体中位错密度,易使位错在滑移面上形成与{100}面具有相同伯格斯矢量和一定间距的割界,减小晶格畸变能,低界面提供T1相非均匀形核的位置场所,T1相的大量沉淀析出又抑制其自身粗化,致使其尺寸细小而均匀分布。时效时脱溶相的析出依靠溶质原子扩散,其脱溶序列符合固态相变的阶次规则,而温度是决定原子扩散速率的重要因素。在同等时间下,高温190 ℃(>180 ℃)时效会降低固溶体的过饱和度,减少强化相θ′、T1析出率,却提高θ′、T1相的生长速率,导致其粗化并分布不均,降低合金性能;低温170 ℃(<180 ℃)时效原子扩散速率缓慢,相变驱动力增大,形核率提高而强化相长大受抑制,沉淀析出程度不够充分,降低合金性能。比较而言,180 ℃时效时固溶体过饱和度相对较高,相变驱动率较大,析出相生长速率相对较慢,相对不易粗化且更均匀弥散析出。延长时效时间,脱溶相尺寸以奥斯瓦尔德熟化规律增大,质点向半共格或非共格质点转变,尺寸达一定值时经运动的位错通过后将增加质点周围位错密度,因奥罗万机制作用而改善合金性能(见图4)。当Ce在淬火后以固溶态分布于基体{100}面和{111}面时,将会在{100}面和{111}面产生晶格畸变区,过饱和空位将集聚在Ce原子周围以减小晶格畸变能和空位的形成能;除此之外,在T1/α宽界面上Mg、Ag原子的偏聚有效降低了T1/α界面的共格应变,可显著增加{111}面GP区的数量。时效时若Cu,Li原子的溶质团被偏聚在Ce原子周围的空位对或空位簇等缺陷俘获,必将增加θ′、T1相形核的GP区,有利于在{100}α面析出立方相和θ′相,{111}α面析出T1相[19-20]。另外,微量Ce能够提高Cu原子在基体中的结合能,时效时基体中Ce含量将降低溶质原子Cu、Li的扩散速率,有利于T1、θ′相弥散细化地析出,抑制共面滑移,提高合金塑韧性[21-23]。当时效时间超过22 h后,时效过程形成的脱溶相聚集粗化,溶质间距增大,粗大的晶界析出相和PFZ消弱了晶粒间的结合强度,使合金强度降低。

4 结论

1) 新型Al-Cu-Li-Ag-Mg-Zr-Ce合金最佳热处理工艺为固溶(520 ℃,1.5 h,水冷)和时效(180 ℃,18 h,空冷)。通过该热处理工艺,合金T6态显微硬度值达243HV0.5,比轧制态(121HV0.5)提高100.8%,抗拉强度、屈服强度分别为571、525 MPa,伸长率为7.1%;T87态抗拉强度、屈服强度分别为623 MPa、598 MPa,伸长率为7.6%。

2) 对重复且采取随机区组设计的正交实验,用方差分析表将各因子对指标影响的显著性进行分析,得出实验各因素之间存在交互作用,从而进行试验处理间LSD法得到最优水平组合。

3) 稀土Ce与其他合金化元素间的交互作用影响析出相数量、大小及分布情况。固溶处理时,大量Cu、Zr、Mg、Ce原子固溶于基体中形成第二相引起固溶强化效应;时效过程中,在α(Al)基体{111}面上析出细小片状强化相T1和{100}面析出立方相Al5Cu6Li2以及薄片状θ′相,均匀弥散分布,具有强烈的沉淀强化效果。

REFERENCES

[1] GUPTA R K,NIRAJ Nayan,NAGASIREESHA G,SHARMA S C . Development and characterization of Al-Li alloys[J].Materials Science and Engineering, 2006, 420: 228-234.

[2] 余鑫祥, 余志明, 尹登峰, 王 华, 何岸青, 崔 凡. 稀土Ce对新型Al-Cu-Li合金力学性能与组织的影响[J]. 稀有金属材料与工程, 2014, 43(2): 495-500.

YU Xin-xiang, YU Zhi-ming, YIN Deng-feng, WANG Hua, HE An-qing, CUI Fan. Effects of trace addition of cerium on microstructure and mechanical properties of novel Al-Cu-Li alloy[J]. Rare Metal Materials and Engineering, 2014, 43(2): 495-500.

[3] YU Cheng, YIN Deng-Feng, ZHENG Feng, YU Xin-Xiang. Effects of solution treatment on mechanical properties and microstructures of Al-Li-Cu-Mg-Ag alloy[J]. J Cent South Univ, 2013, 20: 2083-2089.

[4] KUMAR K S, BROWN S A, PICKENS J R. Microstructural evolution during aging of an Al-Cu-Li-Ag-Mg-Zr alloy[J]. Acta Materialia, 1996, 44(5): 1899-1996.

[5] KUMAR K S, HEUBAUM F H . The effect of li content on the natural aging response of Al-Cu-Li-Mg-Ag-Zr alloys[J]. Acta Materialia, 1997, 45(6): 2317-2327.

[6] 郑子樵, 李劲风, 陈志国, 李红英, 李世晨, 谭澄宇. 铝锂合金的合金化与微观组织演变[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

ZHENG Zi-qiao, LI Jing-feng, CHEN Zhi-guo, LI Hong-ying, LI Shi-chen, TAN Cheng-yu. Alloying and microstructural evolution of Al-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2337-2351.

[7] 程 彬, 郑子樵, 范春平, 钟继发, 韩 烨, 孙景峰. 时效制度对新型Al-Cu-Li合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(4): 926-933.

CHENG Bin, ZHENG Zi-qiao, FAN Chun-ping, ZHONG Ji-fa, HAN Ye, SUN Jing-feng. Effect of aging treatments on microstructures and properties of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 926-933.

[8] 高文理, 闫 豪, 冯朝辉, 陆 政. 时效制度对2A97铝锂合金组织和力学性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1206-1211.

GAO Wen-li, YAN Hao, FENG Zhao-hui, LU Zheng. Effect of aging treatment on microstructure and mechanical properties of 2A97 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1206-1211.

[9] 林高用, 雷玉霞, 郭道强, 许秀芝, 张宗鹏. 变形Al-Si-Cu-Mg合金热处理强化及其组织特征[J]. 中国有色金属学报, 2014, 24(3): 584-592.

LIN Gao-yong, LEI Yu-xia, GUO Dao-qiang, XU Xiu-zhi, ZHANG Zong-peng. Heat treatment strengthening and microstructure characteristics of wrought AI-Si-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 584-592.

[10] 罗先甫, 郑子樵, 钟继发, 张海峰, 钟 警, 李世晨, 李劲风. Mg、Ag、Zn多元微合金化对新型Al-Cu-Li合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

LUO Xian-fu, ZHENG Zi-qiao, ZHONG Ji-fa, ZHANG Hai-feng, ZHONG Jing, LI Shi-chen, LI Jing-Feng. Effects of Mg, Ag and Zn multi-alloying on aging behavior of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1833-1842.

[11] 李红英, 张建飞, 欧 玲, 郑子樵. 时效处理对新型Al-Cu-Li合金组织与性能的影响[J]. 金属热处理, 2007, 32(3): 48-52.

LI Hong-ying, ZHAN Jian-fei, OU Ling, ZHENG Zi-qiao. Effect of aging process on microstructures and mechanical properties of a new A l-Cu-Li alloy[J]. Heat Treatment of Metals, 2007, 32 (3): 48-52.

[12] PAN Zheng-rong, ZHENG Zi-qiao, LIAO Zhong-quan. New cubic precipitate in Al-3.5Cu-1.0Li-0.5In (wt.%) alloy[J]. Materials Letters, 2010, 64: 942-944.

[13] LI Hong-Ying, TANG Yi, ZENG Zai-de, ZHENG Zi-qiao, ZHENG Feng. Effect of ageing time on strength and microstructures of an Al-Cu-Li-Zn-Mg-Mn-Zr alloy[J]. Materials Science and Engineering A, 2008, 314-320.

[14] 余 琨. 稀土变形镁合金组织性能及加工工艺研究[D]. 长沙: 中南大学, 2002.

YU Kun. Study on the microstructure, properties and deformation techniques of rare earth wrought magnesium alloys[D]. Changsha: Central South University, 2002.

[15] 赵志龙, 张海南, 刘 林, 陈 铮. 2090铝锂合金中稀土铈微合金化作用分析[J]. 稀有金属材料与工程, 2000, 29(5): 305-307.

ZHAO Zhi-long, ZHANG Hai-nan, LIU Lin, CHEN Zheng. Analysis of the micro-alloying effect of Cerium additions to the Al-Li alloy 2090[J]. Rare Metal Materials and Engineering, 2000, 29(5): 305-307.

[16] SHERCLIFF H R, ASHBY M F. A process model for age hardening of aluminum alloy-I. The model[J]. Acta Metallurgy, 1990, 38(10): 1789-1802.

[17] CHEN Zheng, WANG Yong-xin, LIU Bing, ZHAO Zhi-long, LI Xiao-ling. Strength-ductility combination in aluminum-lithium alloy 2090 containing rare earth element[J]. Acta Materialia, 2000, 19(1): 27-33.

[18] HUANG B P, ZHENG Z Q. Independent and combined roles of trace Mg and Ag additions in properties precipitation process and precipitation kinetics of Al-Cu-Li-(Mg)-(Ag)-Zr-Ti alloys[J]. Acta Materialia, 1998, 46(12): 4381-4393.

[19] XIAO D H, WANG J N, DING D Y, YANG H L. Effect of rare earth Ce addition on the microstructure and mechanical properties of an Al-Cu-Mg-Ag alloy[J]. Journal of Alloys and Compounds, 2003, 352: 84-88.

[20] LAI Jian-ping, JIANG Rong-piao, LIU Hua-shan, DUN Xiao-long, LI Yan-fen, LI Xiao-qian. Influence of cerium on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys[J]. J. Cent. South Univ, 2012, 19: 869-874.

[21] YU Xin-xiang, YIN Deng-feng, YU Zhi-ming, WANG Jing, CUI Fan. Mechanism of enhanced fracture toughness in a novel Al-Cu-Li-Ce alloy[J]. Rare Metal Materials and Engineering, 2014, 43(5): 1061-1066.

[22] ZHANG Min-gang, CHANG Zhi-liang, YAN Jun-min, JIN Zhi-hao. Investigation of the behaviour of rare earth element cerium in aluminium-lithium alloys by the method of internal friction[J]. Journal of Materials Processing Technology, 2001, 115: 294-297.

[23] GAO Z, LIU J Z, CHEN J Z, DUAN S Y, LIU Z R, MING W Q, WU C L. Formation mechanism of precipitate T1 in Al-Cu-Li alloys[J]. Journal of Alloys and Compounds, 2015, 624: 22-26.

Heat treatment strengthening and microstructure characteristics of novel Al-Cu-Li-X alloy

LI Shu-fei1, 2, YIN Deng-feng1, 2, 3, YU Xin-xiang1, 2, PAN Kang-guan1, 2, YUAN Xin-xiong1, 2, FANG Hong-jie3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation

Center Central South University, Changsha 410083, China;

3. School of Engineering, Yantai Nanshan University, Yantai 265713, China)

Abstract: Solid solution and aging treatment of novel Al-Cu-Li-Ag-Mg-Zr-Ce alloy was investigated by orthogonal experiment variance analysis and least significant difference (LSD) methods. Meanwhile, the microstructure characteristics and mechanical properties were explored by electrical conductivity (EC) test, scanning electron microscopy (SEM), energy dispersive X-ray spectrum (EDX) and transition electron microscopy (TEM). The results show that the micro-hardness of alloy under T6 condition are improved by 100.8% compared to that of rolling one, and the strength for alloy under T87 condition also reaches to 623 MPa after solid solution (520 ℃, 1.5 h, water quenched) and aging treatment (180 ℃, 18 h, air quenched). During solid solution, a lager amount of Ce、Cu、Mg and Zr atoms dissolve into the matrix, resulting in a strong solid solution strengthening. During the aging treatment, many fine needle-shaped T1 phase and plate-shaped θ′ phase precipitate in the matrix uniformly and dispersively, leading to an enormous precipitation strengthening.

Key words: Al-Cu-Li alloy; heat treatment; orthogonal experiment; mechanical property

Foundation item: Project (6140506) supported by the General Armament Department, China; Project (2014GGX102006) supported by the Science and Technology Development of Sandong, China

Received date: 2015-06-29; Accepted data: 2015-10-26

Corresponding author: YIN Deng-feng; Tel: +86-731-88879341; E-mail: dfyin@126.com

(编辑 王 超)

基金项目:总装备部重点基金资助项目(6140506);山东省科技发展计划项目(2014GGX102006)

收稿日期:2015-06-29;修订日期:2015-10-26

通信作者:尹登峰,副教授,博士;电话:13873136610;E-mail:dfyin@126.com