文章编号:1004-0609(2014)03-0584-09

变形Al-Si-Cu-Mg合金热处理强化及其组织特征

林高用1,雷玉霞1,郭道强2,许秀芝1,张宗鹏1

(1. 中南大学 材料科学与工程学院 有色金属材料科学与工程教育部重点实验,长沙 410083;

2. 郴州强旺新金属材料有限公司,郴州 423000)

摘 要:采用正交实验法和金相、力学性能、扫描电镜、能谱等测试手段对自主研发的变形Al-Si-Cu-Mg合金进行固溶和时效强化研究,并探究热处理过程中其组织特征的变化规律。结果表明:通过固溶(495 ℃,90 min,水冷)和时效(170 ℃,4 h,空冷)处理后,合金的硬度提高31.3%,强度提高3.3倍。固溶过程中,大量Si、Cu和Mg原子固溶于基体中,起到强烈的固溶强化作用;过剩的共晶Si逐渐发生明显粒状化;剩余的大块θ相和Q相发生球化。时效过程中,细小针状强化相θ″和细小板条状Q′相在基体的(100)面上大量析出,分布均匀,对合金起到强烈的沉淀强化效果;过剩Si主要通过扩散附着于共晶Si表面析出。

关键词:变形铝合金;固溶;时效;正交实验;力学性能

中图分类号:TG166.2 文献标志码:A

Heat treatment strengthening and microstructure characteristics of wrought Al-Si-Cu-Mg alloy

LIN Gao-yong1, LEI Yu-xia1, GUO Dao-qiang2, XU Xiu-zhi1, ZHANG Zong-peng1

(1. Key Laboratory of Non-ferrous Materials Science and Engineering, Ministry of Education,

School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Chenzhou Qiangwang New Metal Materials Co., Ltd., Chenzhou 423000, China)

Abstract: Solid solution and aging treatments of a novel wrought Al-Si-Cu-Mg alloy were investigated with orthogonal experiment and several other test methods, including OM, mechanical test, SEM and energy spectrum analysis, etc. Meanwhile, the variation regularities of the microstructure characteristics during this process were explored. The results show that, by solution (495 ℃, 90 min, water-quenching) and aging (170 ℃, 4 h, air-cooling) treatment, the hardness and the tensile strength of the alloys are improved by 31.3% and 3.3 times, respectively. During the solid solution, a large number of Si, Cu and Mg atoms dissolve into the matrix, resulting in a strong solid solution strengthening. The excessive eutectoid Si develops into granule, as well as the remanent big bulks of θ and Q phases. Moreover, during the aging, fine needle-shaped θ″ phase and fine lath-shaped Q′ phase precipitate from the (100) plane of the matrix uniformly and dispersively, leading to an enormous precipitation strengthening effect. Additionally, the excessive Si atoms precipitate primarily on the surfaces of the eutectoid Si by diffusion.

Key words: wrought aluminum alloy; solid solution; aging; orthogonal experiment; mechanical properties

高强轻质的特点使铝合金广泛应用于汽车行业、航空航天及军工领域。许多重要领域如特种重载荷负荷重轮、航空用铝合金等多采用变形铝合金。变形铝合金通过挤压、轧制、锻造等手段减少材料内部缺陷,细化晶粒,提高致密性,因而具有较高的强度、优良的韧性以及良好的综合使用性能。铸造铝合金因强韧性稍逊色使其应用范围受到较大限制。但部分铸造合金,特别是铸造Al-Si合金,仍拥有其无可取代的独特优点,如优良的铸造性能、良好的耐磨性能及低热膨胀系数[1-3]。如何结合变形铝合金和铸造铝合金的优点成为目前研究的一大亮点。因此,铸造铝合金的变形处理应运而生。

提高铸造铝合金的变形性能显得尤为重要。已有研究多采用添加多种合金元素,如Cu、Ni、Zn和Mg等。一方面,通过调整合金成分,在各元素的交互作用下,结合一定的热处理工艺,并采用合理的变形工艺,实现铸造合金的变形化。另一方面,多种合金元素的加入必然导致合金组织的变化,在某种程度上提高了合金的可变性,通过固溶和时效处理可有效地控制合金中组织的变化,从而提高合金的强度等综合性能,使不可热处理强化的Al-Si合金成为可热处理强化合金。在此过程中,化学成分、熔炼工艺、浇注条件和热处理工艺等因素共同决定着铸造Al-Si合金的力学性能。其中,针对合金的化学成分和铸造工艺参数、合金元素与杂质元素、精炼与变质、熔炼和浇注、铝合金宏观与微观组织形成机理、晶粒细化机理与晶粒细化剂等方面的研究均取得了重要的进展[4-7]。相对而言,针对热处理工艺理论方面的研究工作尚显得很薄弱。

国内外许多学者已经取得一定的研究进展,李润霞[3]针对Al-10Si-1.5Cu-0.5Mg亚共晶类铸造合金的热处理强化过程和时效强化机理进行了较为详细的研究;土耳其的ZEREN等[8]对砂型铸造的Al-10.6Si-5Cu-0.1Mg-0.6Fe合金硬度及微观组织特征进行了研究;加拿大的TAVITAS等[9]研究了铸造Al-6.17Si-3.57Cu-0.43Mg-0.09Fe合金热处理析出强化时各个强化相的形貌和析出位置等组织特征。但此类研究多以合金化程度小于15%的Al-Si系合金为对象,且基本针对铸态试样,鲜有合金化程度更高的Al-Si合金的研究成果,而针对变形态下高合金化Al-Si合金的热处理及其热处理过程组织演变规律的研究则未见公开报道。

本文作者以连续挤压后变形态下合金化高达20%的Al-Si-Cu-Mg合金为研究对象,通过热处理提高该合金的硬度、强度和耐磨性等综合性能。采用正交实验及单因素实验验证法确定其固溶和时效的最佳工艺。并对其热处理过程中合金性能和组织的变化进行进一步研究,旨在为其热处理工艺的制定提供理论和实验依据。

1 实验

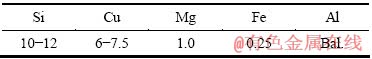

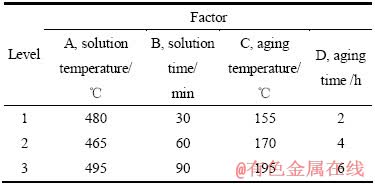

以自主研制的Al-Si-Cu-Mg合金为研究对象,在美国IRIS 1000 ICP-AES等离子发射光谱仪上对实验合金进行化学成分分析,结果见表1。采用水平连铸方式制备合金杆料并通过Conform连续挤压进行合金的挤制成型。对挤压态下的合金进行固溶和时效处理,参考相关相图及文献[3, 10-13],结合合金的实际成分,确定热处理工艺中固溶温度、固溶时间、时效温度和时效时间4个因素的3个水平,并设计L9(34)正交实验如表2所列。其中,固溶处理后冷却方式采用水冷,时效后采用空冷,固溶后试样在室温下停放的时间不超过10 min,以避免自然时效。此外,在正交实验结果的基础上进行进一步的验证性实验,最终确定较佳的热处理工艺。热处理实验设备为箱式电阻炉,加热速度约为40~50 ℃/min。

对热处理过程中典型的状态进行性能及组织的进一步分析。室温拉伸实验在美国Instron3369力学实验机上进行,拉伸速率为2 mm/min;宏观硬度测试实验载荷F选用2450 N,压头选用直径D为5 mm的钢球,载荷持续时间为30 s;金相侵蚀剂采用凯勒试剂(2 mL HF+3 mL HCl+5 mL HNO3+90 mL H2O);并利用POLYVAR-MET光学显微镜、配备GENESIS60S能谱仪的Quanta-200环境扫描电镜及Tecnai G2 20透射电镜对合金的微观组织进行观察及分析。

表1 合金的化学成分

Table 1 Chemistry composition of investigated alloy (mass fraction, %)

表2 正交实验因素水平

Table 2 Levels and factors of orthogonal experiment

2 结果与讨论

2.1 热处理工艺

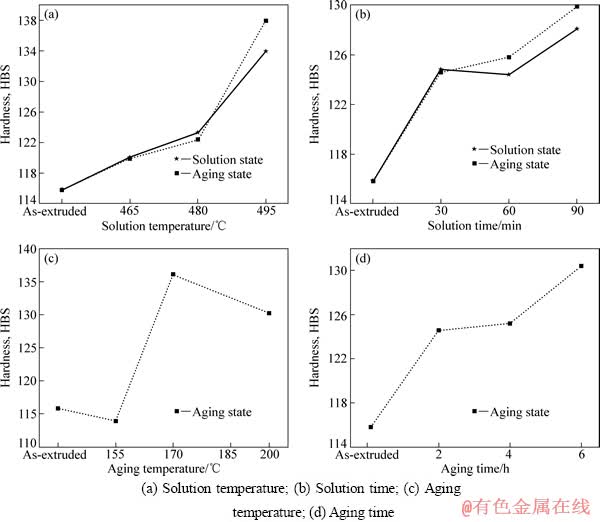

正交实验结果见表3,正交实验中相关因素对合金固溶态硬度和时效态硬度的影响见图1。由于该合金主要应用于高速运转工况下的发动机活塞、空气压缩机转子滑片等服役条件,该类核心材料硬度及其耐磨性要求较高,因此,本次正交实验的结果以合金的硬度为主要评判指标。通过计算极差可知,时效温度及固溶温度对合金硬度的影响最为显著,且时效温度为主要影响因素;而固溶时间和时效时间极差相近,两者均为次要因素,对合金硬度的影响不大。显然,各因素作用的由强到弱顺序为时效温度、固溶温度、固溶时间、时效时间。从表3中可知,第9组实验所获布氏硬度最大为148.3HBS,因此,A3B3C2D1为该实验中的较佳工艺,即固溶(495 ℃,90 min,水冷)和时效(170 ℃,2 h,空冷)处理。

此外,表3中给出了固溶态(固溶淬火)及时效态(时效空冷)两种状态下的合金硬度,经固溶处理后合金硬度较挤压态(115.8HBS)均有一定程度的提高。在同一固溶温度下,即使固溶时间有所差别,合金硬化程度却是相似的,可认为在465、480和495 ℃下合金硬度较挤压态的分别提高了3.71%、6.51%和15.60%,该合金具有较为明显的固溶强化效果。且其强化效果随着固溶温度的升高和固溶时间的延长而不断的提高,见图1(a)和(b)。

各因素对合金最终硬化程度均表现为正影响,且固溶温度和时效温度的影响程度明显较其他两因素显著。在固溶处理的基础上,通过时效处理,利用析出强化可进一步提高该合金的硬化程度,其中以时效温度为170 ℃效果最为显著,其次为195 ℃。当时效温度为155 ℃时固溶处理强化的合金再次软化,硬度降低7.1%,这是由于在过低的时效温度下,强化相未能析出,而初生相则发生偏聚,降低其弥散度,合金强硬化效果降低,致使合金的硬度大幅度下降。

表3 正交实验设计及硬度测试结果

Table 3 Arrangement of orthogonal design and hardness test result

图1 热处理制度对合金硬化程度的影响

Fig. 1 Influences of different factors on hardness of investigated samples

图2 495 ℃固溶、170 ℃时效下合金的硬化曲线

Fig. 2 Hardness curves of samples with 495 ℃ solid solution and 170 ℃ aging

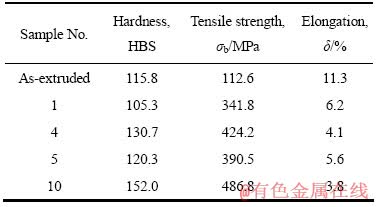

对正交实验进行单因素实验验证,确定最佳固溶温度及时效温度分别为495和170 ℃,分别设定固溶时间为30、60、90 min及时效时间为2、4、6、8、12、16、20和24 h,实验结果见图2。硬化曲线中最高时效峰值为152.0HBS,出现在固溶(495 ℃,90 min,水冷)和时效(170 ℃,4 h,空冷)条件下。每一曲线在12 h处均出现次峰,显示出θ(Al2Cu)脱溶序列明显的双峰时效现象,这与文献[3]的研究结果是一致的。对比不同固溶时间下硬化曲线可知,主峰值的大小随着固溶时间的增加而增加,最大值在固溶时间为90 min时。合金在4 h时效后均出现一定程度的软化,处于过时效阶段;且固溶时间为90 min的曲线后续的硬化效果小于其他两组实验的。这是由于在过时效阶段,第二相粒子发生了粗化及偏聚,大大降低了合金后续沉淀强化效果。因此,该合金的最佳热处理工艺为固溶(495 ℃,90 min,水冷)后,再时效(170 ℃,4 h,空冷)处理,将其命名为第10组。

2.2 热处理前后合金性能变化

取正交实验中硬度值分别为105.3HBS、130.7HBS、120.3HBS和150.0HBS的第1、4、5和10组合金作为典型状态。表4所列为各典型状态合金的力学性能测试结果。随着合金硬度的升高,合金的强度不断的上升,但塑性却逐渐降低。经过最佳的热处理后合金的抗拉强度为486.8 MPa,较挤压态的112.6 MPa提高了3.3倍。

表4 典型状态下合金力学性能

Table 4 Mechanical properties of alloys in typical state

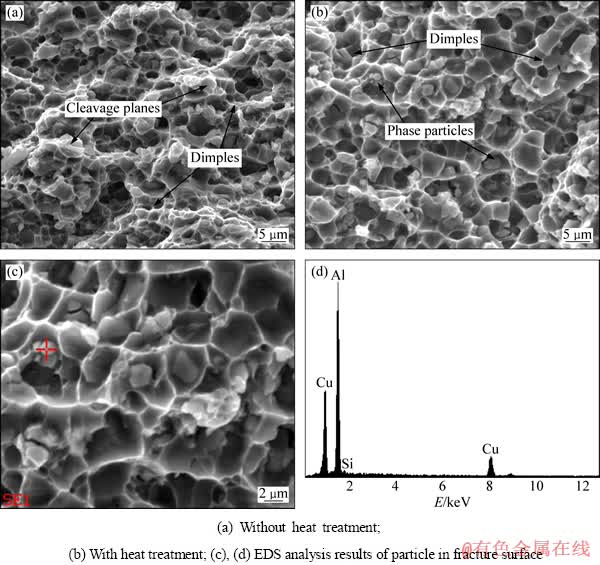

对挤压态样品及第10组合金进行拉伸断口扫描,并对热处理后断口中所观察到的残余第二相粒子进行能谱分析,结果如图3所示。热处理前合金拉伸断口形貌中存在较深的韧窝,但同时存在少量大块解理面,大大降低了合金的强度,呈现出韧性断裂和脆性断裂相结合的典型断口形貌。经热处理后合金的拉伸断口呈现典型的韧性断裂形貌,均匀分布着大小相近的韧窝,且韧窝中心残留着大量第二相粒子。从能谱分析结果可知,该粒子为θ(Al2Cu)相。该类粒子多为初生第二相,但也含有时效析出时长大的第二相,它们通过阻碍位错的运动提高合金的强度,同时由于与基体相的物化性能差异,易成为微裂纹源,而均匀分布的第二相粒子将使断口中的韧窝数量增加,均匀分布,提高合金的强度及韧性。

2.3 合金组织变化规律

针对Al-Si-Mg和Al-Si-Cu-Mg合金的相组成,国内外已有相关研究。李润霞[3]认为该类合金中主要时效相为θ(CuAl2)和/或β(Mg2Si)序列脱溶相;BASSAI等[14]提出在含Cu量较高的Al-Si合金中,只有当n(Mg)/n(Si)大于1时,合金中才能观察到β(Mg2Si)析出相;CHAKRABARTI等[15]提出Q(Al5Cu2Mg8Si6)相和S相的析出根据Si含量不同而不同,当Si含量较低的时候,S相的析出概率大于Q相的,当Si含量较高时则相反。此外,对于Q相中各元素的比例目前仍无定论,分别被描述为Al4Cu2Mg8Si7、Al5Cu2Mg8Si6和Al4CuMg5Si4等[3,16]。图4所示为本实验合金挤压态、固溶态(495 ℃,90 min,水冷)及时效态(170 ℃,4 h,空冷)扫描电镜下微观组织形貌特征。结合相关相图、文献[12-15]及能谱分析结果,确定该合金以α(Al)为基体,在基体上分布着多种合金相及组织:亮白色为θ(Al2Cu);灰色为α(Al)+Si共晶体;而介于前两者忖度之间的是Q相,这3种主要相组织的析出数量、形貌和分布变化对合金性能起着决定性的作用。

图3 热处理前后合金的拉伸断口形貌及EDS能谱分析结果

Fig. 3 Morphologies and EDS analysis of tensile fracture surface of alloys under different states

图4 合金在不同状态下的微观组织及其各相组织的EDS能谱分析结果

Fig. 4 Microstructures of alloys under different states ((a), (b), (c)) and EDS analysis of various phases ((d), (e), (f))

由图4(a)可知,在经过Conform连续挤压大剪切变形后,合金组织致密,存在部分微裂纹,在受拉应力时裂纹将很快扩展,使材料断裂,导致挤压态下的合金拉伸强度较低。由于连续挤压是利用坯料与旋转挤压轮之间的强摩擦所产生足够的挤压力和温度,将杆料、颗粒料或熔融金属以连续大剪切变形方式直接挤压成制品。在变形过程中合金受到作用力及热的双重作用,最终显示的组织不再存在铸态下的枝晶;且共晶组织等多种相组织发生了部分溶解,并在特定的位置再次析出,各个相有明显的取向。然而,由于变形过程较为迅速,相变未完全,最终多种相组织均未形成规整的形状,并随变形方向呈流线分布。

经过固溶处理(见图4(b)),合金中各相分布、形貌及数量均发生了明显的变化。首先,大量的共晶Si、θ相和Q相溶于基体中,且由于淬火时冷却速度较大,各合金元素来不及扩散、重新分配和生成平衡态组织,最终形成过饱和固溶体,产生强烈的“淬火效应”。由于Si、Cu及Mg原子尺寸与Al原子尺寸存在较大的差异,在过饱和的固溶体中,固溶原子(特别是大颗粒的Si原子)在基体中引起严重的晶格畸变,与位错场发生弹性交互作用,加大位错周围柯垂尔气团(Cottrell atmosphere)的形成趋势,对位错产生强烈的钉扎作用,产生固溶强化效果。此外,在固溶处理过程中,过剩的共晶Si逐渐发生钝化和粒状化,最终形成近球形的颗粒状共晶Si组织;剩余的大块θ相和Q相亦发生了球化,形状较挤压态更为规整,第二相与基体分界更为明显。

从图4(c)中可看出,时效为溶质原子的二次析出及扩散提供了足够的能量。李润霞[3]提出,此类合金在时效过程中大量过剩Si将以单质Si的形式析出或通过扩散附着到共晶Si表面析出,且以前种方式析出的几率更大。然而,对本文所研究合金固溶态和时效态α(Al)基体和共晶组织的进行了能谱分析,结果如表5所列。显然,在固溶态下,Si原子大量溶于基体中,使得基体中Si含量高达13.87%(质量分数),经过时效后,基体中的Si含量降至0.43%,与之相反,共晶组织中的Si含量则在时效态下大大提高。因此,可以认为,在时效过程中大量过剩的Si主要通过扩散附着于剩余的共晶Si表面析出。此外,在时效过程中,对合金起到强化作用的还有θ相和Q相两种第二相粒子。由图4(c)可见,经过时效处理合金基体上析出了大量弥散分布的θ相和Q相,然而扫描电镜倍数下所能看到的θ相和Q相多为初生第二相,而对合金起到强烈沉淀强化效果是时效过程中析出的纳米级上述两种相的脱溶产物(过渡相),因此要进一步探究其时效强化机理,必须对合金进行透射电镜观察。

表5 固溶态和时效态基体α(Al)及共晶组织α(Al)+Si的EDS能谱分析结果

Table 5 EDS analysis results of matrix α(Al) and eutectoid α(Al)+Si under solution state and aging state

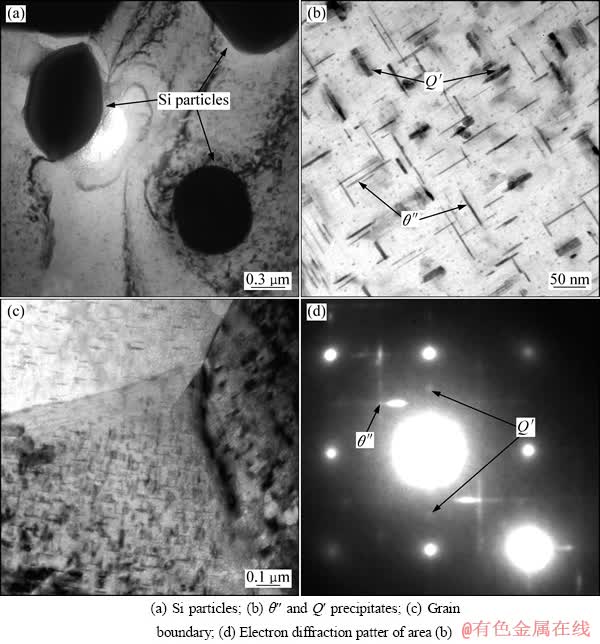

图5所示为峰时效状态下合金[100]方向透射电镜的明场相及选区电子衍射花样。图5(a)中黑色的圆球为Si颗粒,该粒子经过固溶和时效处理后由不规则形状逐渐形成了稳态的椭球形及球形,Si相粒子尺寸为60~120 nm。结合图5(b)和图5(d)的选区衍射花样,峰时效状态下在基体(100)面上析出了大量弥散分布的片状θ″相和板条状Q′相。其中,θ″相沿基体的[010]和[100]两个方向析出,尺寸为50~100 nm;板条状Q′相厚度方向尺寸大于θ″相的,一般长度在40 nm左右,厚度为10 nm左右;基体中还存在少量的圆片状Q′相。θ″相和板条状Q′相是θ相和Q相脱溶序列 和

和 中强化效果最为显著的两种过渡相[3, 16-19]。此类过渡相与基体保持完全或者部分共格,晶格畸变较为严重,阻碍位错运动,从而产生显著的强化效果。欠时效至峰时效之间,合金中的主要强化相为过渡相粒子,过渡相自身强度不大,当位错运动到此类质点处时,位错应变场与过渡相粒子应变场发生交互作用,过渡相粒子并不能完全钉扎位错,只是对其运动造成一定程度上的阻碍,位错在外力的作用下,完全可以切过该类粒子,此时切割机制占主导地位。尺寸细小的过渡相析出得越多、分散越弥散时,将不断提高强化效果,使合金不断逼近峰时效状态。随着过渡相的不断长大及稳定相的析出,最终的第二相粒子与母相脱离共格关系,无晶格畸变产生,此时,第二相粒子本身强度较高,位错难以直接切过粒子,只能绕过质点继续前进,此阶段Orowan机制将占主导地位。合金强度降低,处于过时效状态。选区衍射花样中θ″相呈现出明显的“十”字光斑,主要产生于θ″相的多种变体衍射效应多重叠加而成。此外,θ″和Q′两相的析出分布于整个晶粒内,如图5(c)所示,晶界处未见明显的无沉淀析出带,对合金的强化效果最佳。合金中多种相的存在及多种相变的发生是实现Al-Si合金热处理强化的关键所在,掌握新型Al-Si合金相变规律是调控其性能的必然途径。

中强化效果最为显著的两种过渡相[3, 16-19]。此类过渡相与基体保持完全或者部分共格,晶格畸变较为严重,阻碍位错运动,从而产生显著的强化效果。欠时效至峰时效之间,合金中的主要强化相为过渡相粒子,过渡相自身强度不大,当位错运动到此类质点处时,位错应变场与过渡相粒子应变场发生交互作用,过渡相粒子并不能完全钉扎位错,只是对其运动造成一定程度上的阻碍,位错在外力的作用下,完全可以切过该类粒子,此时切割机制占主导地位。尺寸细小的过渡相析出得越多、分散越弥散时,将不断提高强化效果,使合金不断逼近峰时效状态。随着过渡相的不断长大及稳定相的析出,最终的第二相粒子与母相脱离共格关系,无晶格畸变产生,此时,第二相粒子本身强度较高,位错难以直接切过粒子,只能绕过质点继续前进,此阶段Orowan机制将占主导地位。合金强度降低,处于过时效状态。选区衍射花样中θ″相呈现出明显的“十”字光斑,主要产生于θ″相的多种变体衍射效应多重叠加而成。此外,θ″和Q′两相的析出分布于整个晶粒内,如图5(c)所示,晶界处未见明显的无沉淀析出带,对合金的强化效果最佳。合金中多种相的存在及多种相变的发生是实现Al-Si合金热处理强化的关键所在,掌握新型Al-Si合金相变规律是调控其性能的必然途径。

图5 峰时效态合金的TEM像及选区电子衍射花样

Fig. 5 TEM micrographs and electron diffraction patter of peak-aged alloy

3 结论

1) 实验合金最佳固溶时效工艺为固溶(495 ℃,90 min,水冷)后再进行时效(170 ℃,4 h,空冷);通过该制度热处理后,合金的硬度较挤压态的提高了31.3%,强度提高了3.3倍。

2) 通过Conform连续挤压后,铸态合金显微组织得到明显改善,大量疏松和缩孔等缺陷得以修复,枝晶完全消除,共晶组织及第二相呈不规则形状,并随变形方向呈流线分布。

3) 固溶过程中,大量Si、Cu和Mg原子固溶于基体中,引起强烈的固溶强化;过剩的共晶Si逐渐发生钝化、粒状化,最终形成近球形的颗粒状共晶Si组织;剩余的大块θ相和Q相亦发生了球化,形状较挤压态更为规整,第二相与基体分界更为明显。

4) 时效过程中,细小针状强化相θ″和细小板条状Q′相在基体的(100)面上大量析出,分布均匀,对合金起到强烈的沉淀强化效果;过剩Si主要通过扩散附着到共晶Si表面析出。

REFERENCES

[1] MONAHANED A M A, SAMUEL F H, SAMUEL A M, DOTY H W. Influence of additives on the impact toughness of Al-10.8%Si near-eutectic cast alloys[J]. Materials and Design, 2009, 30(10): 4218-4229.

[2] XU F T, XIA Y, LI G. The mechanism of PEO process on Al-Si alloys with the bulk primary silicon[J]. Applied Surface Science, 2009, 255(23): 9531-9538.

[3] 李润霞. 高强度铸造Al-Si-Cu-Mg合金固态相变研究[D]. 沈阳: 沈阳工业大学, 2004.

LI Run-xia. Research of phase transformation of high strength Al-Si-Cu-Mg casting alloy[D]. Shenyang: Shenyang University of Technology, 2004.

[4] 祖方遒. 变质元素对铸造Al-Si合金共晶结晶的作用及机制[J]. 铸造, 2011, 60(11): 1073-1079.

ZU Fang-qiu. Function of modification element on eutectic solidification of Al-Si alloy and its mechanism[J]. Foundry, 2011, 60(11): 1073-1079.

[5] 王明杰. 铝-硅合金砂型铸件改为压铸生产的工艺改进[J]. 轻合金加工技术, 2006, 34(11): 9-12.

WANG Ming-jie. Process improvements on Al-Si alloy casting produced by die-casting instead of sand mold casting[J]. Light Alloy Fabrication Technology, 2006, 34(11): 9-12.

[6] 黄正军. 铸造AlSi7Cu2Mg合金成分优化及组织、性能研究[D]. 太原: 中北大学, 2009.

HUANG Zheng-jun. The optimization of constituent of casting AlSi7Cu2Mg alloying and studies on organization, performance[D]. Taiyuan: North University of China, 2009.

[7] 姚书芳, 毛卫民, 赵爱民, 钟雪友. 铸造铝硅合金细化变质处理的研究进展[J]. 铸造, 2009, 49(9): 512-515.

YAO Shu-fang, MAO Wei-min, ZHAO Ai-min, ZHONG Xue-you. The development of refining and modification of cast Al-Si alloy[J]. Foundry, 2009, 49(9): 512-515.

[8] ZEREN M, KARAKULAK E. Study on hardness and microstructure characteristics of sand cast Al-Si-Cu alloys[J]. Bulletin of Materials Science, 2009, 32(6): 617-620.

[9] TAVITAS M F J, MOHAMED A M A, GRUZLESKI J E, SAMUEL F H, DOTY H W. Precipitation-hardening in cast Al-Si-Cu-Mg alloys[J]. Journal of Material Science, 2010, 45(3): 641-651.

[10] CHAUDHURY S K, APELIAN D. Fluidized bed heat treatment of cast Al-Si-Cu-Mg alloys[J]. Metallurgical and Materials Transactions A, 2006, 37(7): 2295-2311.

[11] SAMUEL F H. Incipient melting of Al5Mg8Si6Cu2 and Al2Cu intermetallics in unmodified and strontium-modified Al-Si-Cu-Mg (319) alloys during solution heat treatment[J]. Journal of Material Science, 1998, 33(9): 2283-2297.

[12] 杨明波, 代 兵, 钱翰城. 高强韧铸造铝硅合金Al-7%Si-1.5%Cu-Mg-Ti-Mn最佳热处理工艺的研究[J]. 铸造, 2002, 51(8): 470-473.

YANG Ming-bo, DAI Bing, QIAN Han-cheng. Research on the optimized heat treatment process of the high strength and toughness cast Al-Si alloy Al-7%Si-1.5%Cu-Mg-Ti-Mn[J]. Foundry, 2002, 51(8): 470-473.

[13] OTT R D, BLUE C A, SANTELLA M L, BLAU P J. The influence of a heat treatment on the tribological performance of a high wear resistant high Si Al-Si alloy weld overlay[J]. Wear, 2001, 251(1/12): 868-874.

[14] BASSAI P, GARIBOLDI E, VINERCATI G. Calorimetric analysis on aged Al-4.4Cu-0.5Mg-0.9Si-0.8Mn alloy[J]. Journal of Thermal Analysis and Calorimetry, 2007, 87(1): 247-253.

[15] CHAKRABARTI D J, LAUGHLIN D E. Phase relations and precipitation in Al-Mg-Si alloys with Cu additions[J]. Progress in Materials Science, 2004, 49(3/4): 389-410.

[16] ARNBERG L, AURIVILLIUS B. The crystal structure of AlxCu2Mg12-xSi7, (h-AlCuMgSi)[J]. Acta Chemica Scandinavica, 1980, 34: 1-5.

[17] RAVI C, WOLVERTON C. First-principle study of crystal structure and stability of Al-Mg-Si-(Cu) precipitates[J]. Acta Materialia, 2004, 52: 4213-4227.

[18] LI R X, LI R D, ZHAO Y H, HE L Z, LI C X, GUAN H R, HU Z Q. Age-hardening behavior of cast Al-Si base alloy[J]. Material letters, 2004, 58(12): 2096-2101.

[19] WEATHERLY G C, PEROVIC A, PEROVIC D D, MUKHOPADHYAY N K, LIOYD D J. The precipitation of the Q phase in an AA6111 alloy[J]. Metallurgical and Materials Transaction A, 2001, 32(2): 213-218.

(编辑 陈卫萍)

基金项目:国家“十一五”科技支撑计划资助项目(2009BAE71B01)

收稿日期:2013-04-02;修订日期:2013-11-05

通信作者:林高用,教授,博士;电话:13507422779;E-mail:mater218@163.com