DOI: 10.11817/j.issn.1672-7207.2020.11.028

基于精轧平坦度优先的凸度分配策略

刘东冶1, 2,何安瑞1,邵健1,陈超超1, 2

(1. 北京科技大学 高效轧制国家工程研究中心,北京,100083;

2. 北京科技大学 设计研究院有限公司,北京,100083)

摘要:为了得到较高的平坦度,在板带不发生曲屈失稳的前提下,通过由精轧入口机架向出口机架以及出口机架向入口机架递推得到合理凸度控制范围。通过优化函数得出各个机架出口的凸度,在合理的凸度控制范围内对优化函数的凸度分配结果进行修正,得出基于平坦度优先的凸度分配模型。研究结果表明:现场实验成品凸度与平坦度目标值分别为50 μm和0 μm/m,模型计算凸度与平坦度分别为47.2 μm和0 μm/m,成品头部实际凸度与平坦度平均值分别为48.7 μm和43 μm/m;该策略在保证精轧出口平坦度的前提下,能保证凸度与目标凸度偏差最小。

关键词:凸度;平坦度;热轧;板形

中图分类号:TG335.5+6 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3253-07

Strategy of crown distribution based on flatness priority in finishing rolling

LIU Dongye1, 2, HE Anrui1, SHAO Jian1, CHEN Chaochao1, 2

(1. National Engineering Research Center for Advanced Rolling, University of Science & Technology Beijing, Beijing 100083, China;

2. Design and Research Institute Co. Ltd., University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In order to get a higher flatness, on the premise of no buckling, the reasonable control range of crown was obtained by recursion from finishing mill entrance stand to exit stand and from exit stand to entrance stand. Through the optimization function, the crown of each stand exit was obtained, and the crown distribution result of the optimization function was modified within the reasonable range of crown. The crown distribution model based on the priority flatness was obtained. The results show that the target values of crown and flatness are 50 μm and 0 μm/m, the crown and flatness calculated by the model are 47.2 μm and 0 μm/m, and the average value of actual crown and flatness of finished product head are 48.7 μm and 43 μm/m, respectively. The strategy ensures the minimum deviation between crown and target crown on the premise of ensuring the finish rolling exit flatness.

Key words: crown; flatness; hot rolling; buckling

热轧板带在轧制前后具有良好的断面形状和较高的平坦度是板形系统控制的目标。热连轧板形设定的第一步是各机架出口凸度的确定,其目的有:1) 在板带屈曲失稳极限允许范围内,充分发挥设备的调控能力,完成板带在精轧机组内的凸度分配,以获得指定目标凸度的产品;2) 考虑凸度与平坦度之间的耦合关系,将比例凸度变化量控制在合理范围内,以保证每个机架间的带钢平坦度。当前国内热连轧生产线板形控制系统主要由西马克、西门子、TMEIC等外企公司提供[1]。各公司的板形控制模型凸度分配策略都主要以凸度简单分配作为基础,基于板带在“平坦度死区”不会产生表观浪形为目标。TMEIC公司通过板带凸度包络线,考虑机械执行机构和板带约束的凸度和平坦度控制范围,并根据Shohet临界条件确定每个机架在满足平坦度要求的前提下的凸度控制范围,再与机械约束凸度控制范围取交集,确定每个机架的凸度控制范围[2]。西马克公司的板形凸度模型将来料比例凸度与精轧出口比例凸度变化量的比例加权分配到各个机架完成凸度分配控制[3]。西门子公司板形模型根据粗轧带钢入口比例凸度、成品带钢目标比例凸度、各机架比例凸度减少率及各机架出口带钢厚度完成凸度分配[4]。丁敬国等[5]提出了轧辊凸度协同负荷分配方法。马会文[6]建立了考虑板带横向流动凸度分配模型。刘立忠等[7]提出了按各机架压下率占整个机组总压下率的比例,将总比例凸度变化值分配给各机架,进而计算出各机架轧后板凸度的分配策略。王涛[8]从金属塑性变形方面和辊系弹性变形方面对板凸度和板形理论进行了研究。李波[9]采用动态规划法建立了凸度分配模型。陈超超[10]对板带曲屈进行了研究,并通过板带曲屈临界条件建立了凸度分配模型。郝建伟等[11]对支持辊辊形进行了研究,采用CVR辊形,凸度控制能力较强。曹建国等[12]通过数据挖掘的方法对现场数据进行分析,提出了相应的调整策略,可以有效提高板凸度控制能力。梁冰等[13]基于支持向量机方法,针对热轧工艺生产过程中的板带凸度定位出关键因素。孔繁甫等[14]通过混合变凸度工作辊辊形,增强了工作辊在带钢宽度发生变化后的控制能力。在现有的凸度分配模型中,凸度分配的思路基本一致,即首先通过Shohet判别式计算起浪边界条件的范围,然后,在此范围内按照比例凸度相等或带有凸度修正系数对凸度进行重新分配。但Shohet判别式实验材料主要为不锈钢和铝[15],其起浪边界条件的范围不完全适用于板带生产。为了得到更好的精轧出口板形以及机架间板形,本文作者通过对上下游机架凸度范围反复递推,在曲屈失稳判别[10]基础上,采用优化函数建立以平坦度优先的凸度分配模型,并进行工业应用。

1 凸度控制范围的确定

机械比例凸度Cm的范围与当前机架的轧制力P、弯辊力F、综合辊形凸度Cc、工作辊直径Dw、支持辊直径Db、窜辊量S、横向流动凸度修正系数Cf相关的函数以及凸度常修正系数Ccon有关。其中,综合辊形凸度Cc包含工作辊的初始辊形、磨损辊形、热辊形共3部分,凸度常修正系数Ccon主要用于模型自学习时的偏差量修正。机械比例凸度计算具体表达式如下:

(1)

(1)

横向流动凸度修正系数计算式为

(2)

(2)

板形遗传系数计算式如下:

(3)

(3)

(4)

(4)

(5)

(5)

式中: 为当前机架入口比例凸度;

为当前机架入口比例凸度; 为当前机架出口比例凸度;

为当前机架出口比例凸度; 为板形遗传系数;k为板形遗传系数中间系数;H为带钢厚度;B为带钢宽度[9];

为板形遗传系数;k为板形遗传系数中间系数;H为带钢厚度;B为带钢宽度[9]; 为机架入口厚度;

为机架入口厚度; 为机架出口厚度。

为机架出口厚度。

上述计算模型表明出口比例凸度由机械比例凸度与入口比例凸度共同决定,通过板形遗传系数计算出相应结果。

文献[10]板带轧制中曲屈的临界条件为

(6)

(6)

式中: 与

与 分别为通过曲屈失稳计算得到的边浪与中浪临界阈值。其中,文献[10]中曲屈临界阈值考虑了带钢横向温差、金属塑性变形对曲屈失稳条件的影响。

分别为通过曲屈失稳计算得到的边浪与中浪临界阈值。其中,文献[10]中曲屈临界阈值考虑了带钢横向温差、金属塑性变形对曲屈失稳条件的影响。

根据式(1),采用极限的弯辊力与窜辊位置求得各个机架机械比例凸度的上、下限。机械比例凸度上限 为

为

(7)

(7)

机械比例凸度下限 为

为

(8)

(8)

其中: 和

和 分别为机架i弯辊力最小值和最大值。

分别为机架i弯辊力最小值和最大值。

1.1 下一机架不起浪的比例凸度计算

计算当前机架下保证下一机架在机械比例凸度上下限时不会产生浪形的阈值范围,在该阈值范围内,1台机架不会因为弯辊力和窜辊发生改变而出现曲屈失稳现象。当前机架的出口凸度Ci为下一机架的入凸度,联立式(3),(6),(7)和(8)可得

(9)

(9)

经整理可得下一机架不起浪的凸度上限 为

为

(10)

(10)

同理, 下极限求解式为

下极限求解式为

(11)

(11)

下一机架不起浪的凸度下限 为

为

(12)

(12)

若末机架采用微中浪轧制,则末机架的比例凸度范围为

(13)

(13)

(14)

(14)

其中:faim为目标平坦度,根据式(9)~(14)可以得出保证下一机架不产生浪形的比例凸度控制区域为( ,

, )。

)。

1.2 当前机架出口凸度范围的计算

当弯辊力与窜辊位置采用极限值时,机架出口的凸度范围可根据式(3)得出。首机架的入口凸度为Cent,首机架出口比例凸度上下限 和

和 分别为:

分别为:

(15)

(15)

(16)

(16)

其余机架出口比例凸度上、下限 和

和 分别为

分别为

(17)

(17)

(18)

(18)

根据式(17)和(18)可得各个机架出口比例凸度的范围为( ,

, )。

)。

1.3 当前架不起浪的比例凸度计算

计算当前机架在机械比例凸度上下限时也不会产生浪形的出口比例凸度阈值范围。

(19)

(19)

经整理,可得当前机架不起浪的凸度上限 为

为

(20)

(20)

同理可得 下极限求解式为

下极限求解式为

(21)

(21)

当前机架不起浪的凸度下限 为

为

(22)

(22)

若末机架采用微中浪轧制,则末机架的比例凸度范围为

(23)

(23)

(24)

(24)

根据式(23)和(24)可得出各个机架出口比例凸度的范围为( ,

, )。

)。

通过上述求解得出3个比例凸度区间,将3个区间取交集,得最终的比例凸度控制区间为( ,

, ),其中,

),其中, 和

和 分别为最终凸度控制范围的下限和上限。

分别为最终凸度控制范围的下限和上限。

(25)

(25)

式(25)主要确定当前机架的下一机架不出现板形缺陷的范围、当前机架的凸度控制范围以及当前机架不出现板形缺陷的范围之间的交集。例如,当辊形选取不同时,若当前机架板形调节极限范围小于当前机架不出现板形缺陷的范围,则按机械极限控制,以保证当前机架板形缺陷影响最小。

2 凸度分配

式(25)表征了凸度分配选取路径的区间范围,根据凸度分配控制范围,需要判断各个机架出口目标凸度 是否在此范围内:若

是否在此范围内:若 ∈(

∈( ,

, ),则可以按照目标凸度进行凸度分配计算;若目标凸度

),则可以按照目标凸度进行凸度分配计算;若目标凸度

(

( ,

, ),则需要按这个范围的极限值处理,以优先保证机架间不出现板形缺陷以及精轧出口平坦度较高。初始计算时,设各个机架需要完成的比例凸度与精轧出口比例凸度相等,即

),则需要按这个范围的极限值处理,以优先保证机架间不出现板形缺陷以及精轧出口平坦度较高。初始计算时,设各个机架需要完成的比例凸度与精轧出口比例凸度相等,即

(26)

(26)

若各个机架比例凸度相等,则各个机架不会产生平坦度缺陷。构造凸度分配函数为

(27)

(27)

式中:Cout为机架当前机架出口比例凸度;CMid为当前机架凸度调节域的中间值,各个机架的凸度调节与可由式(15)~(18)得出;CMax与CMin分别为当前机架机械极限时的比例凸度最大值和最小值;Cin为当前机架入口比例凸度;flmt为平坦度死区的范围,可由式(6)得出; 为下一机架的平坦度死区范围;a1,a2和a3为常数。为了求Cout的最小值,需要对式(27)求导,经整理可得

为下一机架的平坦度死区范围;a1,a2和a3为常数。为了求Cout的最小值,需要对式(27)求导,经整理可得

(28)

(28)

式中:

;

; ;

; 。

。

通过调节b1,b2和b3可对系数a1,a2和a3进行修正。对于下游机架,当b3越大时,Cout更接近于Caim,以保证下一机架平坦度较高;上游机架平坦度死区较宽,其相应的b1较大,b2和b3较小。弯窜辊设定会在一定程度上向中间值修正,避免出现大的波动或者轻易达到极限。普通热连轧一般选用7机架精轧,机架F1,F2,F3和F4一般完成入口凸度向目标凸度逼近的过程,机架F5,F6和F7一般按目标凸度比例凸度轧制。故采用式(27)计算机架F1,F2,F3和F4的出口比例凸度,完成凸度分配过程。根据式(26)和(27)可以得出各个机架出口凸度,即

(29)

(29)

根据式(29)判断各个机架的出口比例凸度是否在式(25)所示的( ,

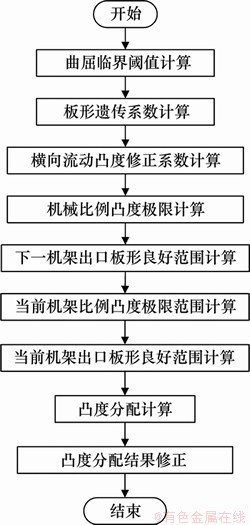

, )范围内:若在此范围内,则采用当前机架出口的凸度分配计算值;若超出式(25)范围,则采用式(25)的极限值。图1所示为凸度分配计算过程程序流程图。

)范围内:若在此范围内,则采用当前机架出口的凸度分配计算值;若超出式(25)范围,则采用式(25)的极限值。图1所示为凸度分配计算过程程序流程图。

图1 凸度分配计算流程

Fig. 1 Crown distribution calculation processes

3 实践应用

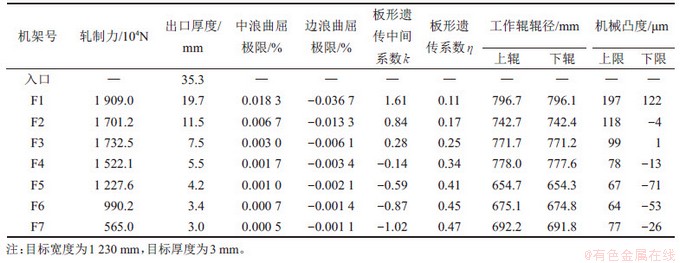

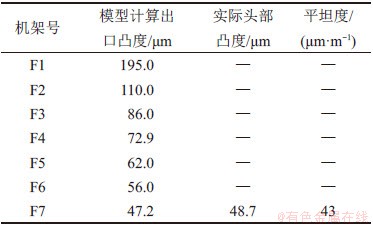

本模型在某1 780 mm热连轧厂(即精轧支持辊为1 780 mm长的热连轧生产线)投入使用。该生产线工作辊长度为2 080 mm,支持辊长度为1 780 mm,F1,F2,F3和F4机架最大轧制力为40 000 kN,F5,F6和F7机架最大轧制力为38 000 kN,窜辊行程为±150 mm,机架F1,F2,F3和F4的弯辊力范围为200~1 500 kN,F5,F6和F7机架弯辊力范围为200~1 200 kN。该生产线轧制钢种Q235B在厚度为3.0 mm、宽度为1 220 mm、目标凸度为50 μm,目标平坦度为0 μm/m、中间坯厚度为35.32 mm时的模型计算参数见表1。

表1 凸度分配计算参数与结果

Table 1 Calculation parameters and results of crown distribution

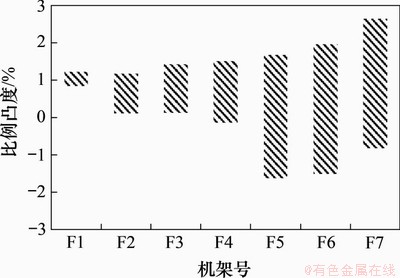

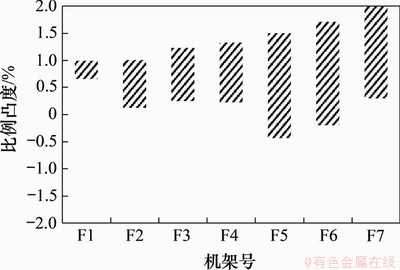

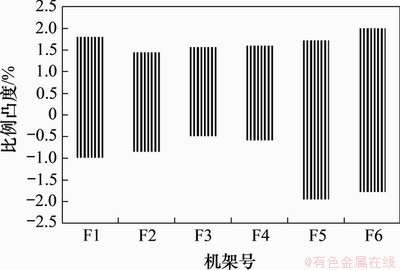

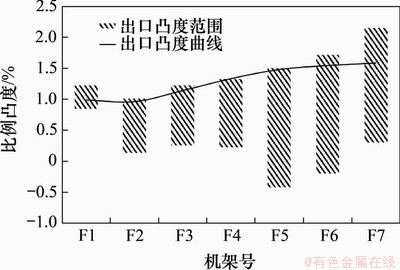

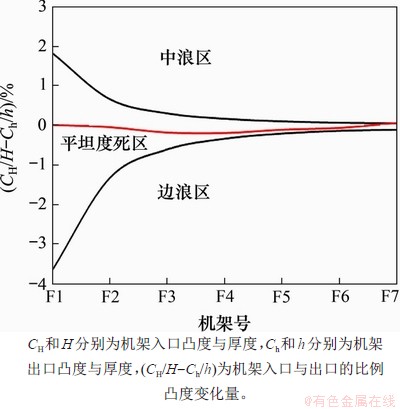

根据上述计算公式可以得出弯窜辊极限位置时的比例凸度范围如图2所示,保证当前机架不起浪的比例凸度范围如图3所示,保证下一机架不起浪的凸度范围如图4所示(由于计算下一机架不起浪的比例凸度范围时,F7机架为末机架,故计算结果只考虑到机架F6机架、机架F7执行当前机架不起浪的计算结果),最终比例凸度范围如图5所示。

图2 极限比例凸度范围

Fig. 2 Range of limit ratio crown

图3 出口不起浪比例凸度范围

Fig. 3 No waves range of ratio crown at finishing mill exit

图4 下一机架不起浪比例凸度控制范围

Fig. 4 No waves range of ratio crown at the next finishing mill exit

按照曲屈范围得到凸度控制范围见图6。从图6可以看出:各个机架入口与出口比例凸度差值在曲屈范围内,证明按照当前凸度分配策略可以保证各个机架间均无浪且精轧出口无浪。

由模型计算各个机架出口凸度以及精轧出口仪表采集的头部凸度、平坦度见表2。从表2可看出模型计算的精轧出口凸度为47.2 μm,实际头部采集凸度为48.7 μm,计算结果与实际结果偏差较小,头部带有平坦度为43 μm/m的中浪,模型计算精度满足实际生产需求。

图5 最终比例凸度控制范围

Fig. 5 Final range of ratio crown

图6 比例凸度曲线

Fig. 6 Ratio crown curves

表2 计算结果与实际值

Table 2 Calculation results and actual values

4 结论

1) 以保证各个机架出口平坦度为目标,建立了优先考虑平坦度的凸度分配计算模型。

2) 经过推导得出各个机架出口不起浪的比例凸度控制范围,在此范围内认为凸度无论如何变化都可以保证轧机出口平坦度较高。

3) 建立了凸度分配过程优化函数,根据优化函数结果,计算得到各个机架出口比例凸度,根据各个机架不起浪的凸度范围对凸度分配结果进行修正,最终得到合理的凸度分配结果,实际应用效果良好。

参考文献:

[1] 刘文仲. 国外公司带钢热连轧数学模型的比较与分析[J]. 冶金自动化, 2013, 37(5): 5-11.

LIU Wenzhong. Comparison and analysis of the foreign companies' mathematical model for HSM[J]. Metallurgical Industry Automation, 2013, 37(5): 5-11.

[2] 夏晓明, 张永雪, 曹伟文. GE板形模型的功能及应用[J]. 宝钢技术, 2006(2): 11-13.

XIA Xiaoming, ZHANG Yongxue, CAO Weiwen. Function and application of the GE shape model[J]. Baosteel Technology, 2006(2): 11-13.

[3] 夏小明. 热轧宽带钢连轧机组辊型配置研究与应用[D]. 沈阳: 东北大学材料与冶金学院, 2011:14-15.

XIA Xiaoming. Research and application of roll profile configuration in hot strip CVC mill[D]. Shengyang: Northeastern University. School of Materials and Metallurgy, 2011: 14-15.

[4] 孔祥伟, 徐建忠, 史静, 等. 热轧带钢板形(PFC)控制系统[J]. 东北大学学报(自然科学版), 2002, 23(7): 684-686.

KONG Xiangwei, XU Jianzhong, SHI Jing, et al. Profile and flat control system of hot rolled strip[J]. Journal of Northeastern University(Natural Science), 2002, 23(7): 684-686.

[5] 丁敬国, 曾庆亮, 胡贤磊, 等.中厚板规程负荷分配中轧辊凸度协调分配方法[J]. 钢铁, 2009, 44(6): 48-50.

DING Jingguo, ZENG Qingliang, HU Xianlei, et al. Coordination distribution method of roll crown to medium plate rolling schedule[J]. Iron & Steel, 2009, 44(6): 48-50.

[6] 马会文. 考虑横向流动系数的热轧带钢比例凸度分配模型[J]. 轧钢, 2009, 26(3): 13-14, 17.

MA Huiwen. Calculation of unit crown distribution of hot rolled strip considering transverse flow coefficient[J]. Steel Rolling, 2009, 26(3): 13-14, 17.

[7] 刘立忠, 吕程, 刘相华等. CVC热连轧机的板凸度计算模型[J]. 东北大学学报, 2001, 22(1): 95-98.

LIU Lizhong, LU Cheng, LIU Xianghua, et al. New crown setup model of CVC hot strip mill[J]. Journal of Northeastern University, 2001, 22(1): 95-98.

[8] 王涛. 热轧带钢板凸度和板形计算及预设定建模理论研究[D].秦皇岛: 燕山大学机械工程学院. 2012: 59-82.

WANG Tao. Theory research on strip crown and shape calculation and pre-set modeling in hot rolling[D]. Qinhuangdao: Yanshan University. School of Mechanical Engineering, 2012: 59-82.

[9] 李波. 热连轧带钢板形分配策略的研究[D]. 北京: 北京科技大学工程技术研究院, 2015: 64-71.

LI Bo. Research on shape allocation strategy among hot strip mills[D]. Beijing: University of Science and Technology Beijing. Institute of Engineering Technology, 2015: 64-71.

[10] 陈超超. 热轧带钢精轧过程屈曲行为的研究[D]. 北京: 北京科技大学冶金工程研究院, 2015: 116-122.

CHEN Chaochao. Research on buckling behavior of hot rolled strip in finishing mills[D]. Beijing: University of Science and Technology Beijing. Institute of Metallurgical Engineering, 2015: 116-122.

[11] 郝建伟, 曹建国, 张杰, 等. 2250CVC热连轧机支持辊辊形研究[J]. 中南大学学报(自然科学版), 2007, 38(4): 734-738.

HAO Jianwei, CAO Jianguo, ZHANG Jie, et al. Backup roll contour of 2250 CVC hot strip mill[J]. Journal of Central South University(Science and Technology), 2007, 38(4): 734-738.

[12] 曹建国, 江军, 赵秋芳, 等. 基于数据挖掘的宽厚板板凸度控制[J]. 中南大学学报(自然科学版), 2019, 50(11): 2743-2752.

CAO Jinaguo, JIANG Jun, ZAHO Qiufang, et al. Wide and heavy plate crown control based on data mining[J]. Journal of Central South University(Science and Technology), 2019, 50(11): 2743-2752.

[13] 梁冰, 何飞, 杨德斌, 等. 热轧板带凸度影响因素的敏感性分析[J]. 中南大学学报(自然科学版), 2018, 49(2): 353-358.

LIANG Bing, HE Fei, YANG Debin, et al. Sensitivity analysis on influencing factor of strip crown in hot rolling[J]. Journal of Central South University(Science and Technology), 2018, 49(2): 353-358.

[14] 孔繁甫, 何安瑞, 邵健, 等. 板带轧机工作辊混合变凸度辊形研究[J]. 机械工程学报, 2012, 48(22): 87-92.

KONG Fanfu, HE Anrui, SHAO Jian, et al. Research on mixed variable crown contour for work roll of strip mill[J]. Chinese Journal of Mechanical Engineering, 2012, 48(22): 87-92.

[15] SHOHET K N, TOWNSEND N A. Roll bending methods of crown control in 4-high plate mills[J]. Journal of the Iron and Steel Institute, 1968, 11: 5-12.

(编辑 陈灿华)

收稿日期: 2020 -07 -03; 修回日期: 2020 -09 -11

基金项目(Foundation item):国家自然科学基金资助项目(51674028);广西创新驱动发展专项资金资助项目(桂科AA17202008) (Project(51674028) supported by the National Natural Science Fundation of China; Project(GK AA17202008) supported by the Guangxi Special Funding Program for Innovation-Driven Development)

通信作者:邵健,博士,副研究员,从事热连轧板形研究;E-mail:ustbshao@163.com