淬火转移时间对1933铝合金拉伸性能、腐蚀性能及微观组织的影响

刘文军1, 2,刘胜胆1, 2,张新明1, 2,陈慧1, 2,钟奇鸣1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 教育部有色金属重点实验室,湖南 长沙,410083)

摘要:通过常温拉伸性能测试、晶间和剥落腐蚀试验、光学显微镜及透射电子显微镜研究淬火转移时间(5~90 s)对1933铝合金锻件拉伸性能、腐蚀性能及微观组织的影响。研究结果表明:随着淬火转移时间延长,合金的拉伸性能和耐腐蚀性能均降低;当转移时间增加至90 s时,抗拉强度下降7.5%,屈服强度下降9%,伸长率下降约20%,腐蚀深度增加400%。淬火转移时间过长导致晶粒内部析出粗大的平衡η相,降低了时效强化效果;晶界无沉淀析出带宽化,降低了伸长率和耐腐蚀性能。为获得良好的综合性能,转移时应使该合金产品淬火时的温度不低于约366 ℃。

关键词:1933铝合金;淬火转移时间;拉伸性能;腐蚀性能;微观组织

中图分类号:T146.2 文献标志码:A 文章编号:1672-7207(2012)04-1276-05

Influence of quench transfer time on tensile properties, corrosion properties and microstructure of 1933 aluminum alloy

LIU Wen-jun1, 2, LIU Sheng-dan1, 2, ZHANG Xin-ming1, 2, CHEN Hui1, 2, ZHONG Qi-ming1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key laboratory of Nonferrous Materials, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The influence of quench transfer time(5~90s) on the tensile properties, corrosion properties and microstructure of 1933 aluminum alloy forging was investigated by ambient tensile testing, intergranular and exfoliation corrosion exposure test, optical microscopy and transmission electron microscopy. The results show that the tensile properties and corrosion resistance decrease with the increase of quench transfer time. At 90 s, the drop percentages of ultimate strength, yield strength and elongation are about 7.5%, 9% and 20%, respectively, and the corrosion depth increases by 400%. Prolonged transfer time results in coarse η equilibrium phase in the grains, which causes the strengthening effect decrease after aging, and wider precipitates free zone, which makes elongation and corrosion resistance decrease. In order to obtain high properties, the transfer time for the alloy products should be controlled to keep the temperature just before quenching no lower than about 366 ℃.

Key words: aluminum alloy 1933; quench transfer time; tensile properties; corrosion resistance; microstructure

飞机上大型整体结构件的制备需要高强Al-Zn-Mg-Cu合金的(超)厚板和大锻件。由于截面面积大,这些(超)厚板和大锻件固溶后淬火时往往较难获得足够快的冷却速率[1];而为了控制残余应力,需适当降低冷却速率[2]。因此,用于生产大截面产品的Al-Zn-Mg-Cu合金的淬火敏感性要低,需要的临界淬火速率可较小[3-4]。1933铝合金是俄罗斯开发的低淬火敏感合金,适用于生产厚截面的锻件[5],但在实际生产过程中,该合金的工艺参数仍需严格控制才能保证得到较好的力学和腐蚀等性能以及低的残余应 力[6]。锻件在固溶后,通常需要从炉子中转移到淬火槽中进行淬火,从炉子中取出到淬入冷却介质之间的时间称为淬火转移时间。对于Al-Zn-Mg-Cu合金,淬火转移时间是必须控制的1个关键工艺参数,因为当该时间超过某一临界值时,时效后的性能会有显著降低[7-8]。在转移过程中,合金温度降低,固溶体发生分解在基体及晶界等处析出第二相,从而影响强度、伸长率及电导率等性能[7-8]。当材料的成分不同时,固溶体分解的速度也不同[3],因此,对于不同的合金,淬火转移时要控制的临界时间也不同。另外,以往研究获得的结果往往对某一厚度的产品有参考意义。本文作者研究淬火转移时间对1933铝合金锻件时效后拉伸性能和腐蚀性能的影响规律,并结合微观组织观察对其原因进行分析,测定其水淬时对应的温度,以便为该合金大截面产品淬火转移时间的控制提供参考。

1 实验

1.1 材料及热处理

实验采用1933铝合金锻件,其中各元素的质量分数分别为:Zn,6.80%,Mg,1.90%;Cu,1.00%;Zr,0.12%; Fe+Si,<0.15%,余量为Al。从锻件上切取厚度为2.5 mm的样品,将其在盐浴炉中进行470 ℃/100 min固溶处理,然后取出在空气中分别停留5,20,40,60和90 s后淬入室温水中,该停留的时间即为淬火转移时间。样品在淬火后进行110 ℃/12 h+180 ℃/6 h(T73)的双级人工时效。另取,样品在中间部分焊上热电偶,测定经不同转移时间后淬火时样品所对应的温度。

1.2 性能测试

拉伸性能样品按国标GB/6497-14进行加工,拉伸实验在CSS-44100电子万能试验机上进行,测得屈服强度σ0.2、抗拉强度σb和伸长率δ5,每个状态取3个平行样品。

晶间腐蚀实验按照国标GB/T 7998—2005进行。腐蚀溶液配比为:57 g NaCl+10 mL H2O2+1 L蒸馏水,面容比为15 mm2/L,采用水浴将温度保持在(35±2) ℃,每种状态取平行试样3块。实验结束后制备金相观察腐蚀情况,并进行腐蚀等级评定。

剥落腐蚀实验按照ASTM G34—79标准进行。腐蚀液配比为:234 g NaCl+50 g KNO3+6.3 mL HNO3+ 1 L蒸馏水,容面比为25 mL/cm2,采用水浴将温度保持在(25±3) ℃,每种状态取平行试样3个。腐蚀实验结束后取出样品,采用数码相机记录表面形貌,按照标准评定剥蚀等级,然后水洗,并用30% HNO3去除腐蚀产物。

1.3 微观组织观察

金相样品经水磨砂纸粗磨后,依次采用400号,800号和1 200号金相砂纸细磨,最后用绒布抛光,在XJP-6A型金相显微镜下观察腐蚀情况。

透射电镜样品先预磨至厚约0.1 mm,冲成直径为3 mm的圆片,然后在MTP-1A型双喷仪上减薄,电解液为90% CH3OH+10% HNO3,电压约为15 V,采用液氮进行冷却。样品观察在TECNAI G2 20型透射电镜上进行,加速电压为200 kV。

2 结果与分析

2.1 转移时间-温度曲线

图1所示为样品在转移过程中的温度变化曲线。由图1可见:随着转移时间的增加,样品的温度不断下降,其下降的速率随着时间的延长而减小;在5 s时,样品的温度约435 ℃;至20 s时,温度下降至约366 ℃;至40 s时,温度约为330 ℃;至60 s时,温度降至约280 ℃;至90 s时,温度约为225 ℃。

图1 样品在转移过程中的温度变化曲线

Fig.1 Temperature curve of sample during transfer process

2.2 拉伸性能

图2所示为淬火转移时间对1933铝合金时效后拉伸性能的影响。由图2可见:随着淬火转移时间的延长,合金的拉伸性能下降。屈服强度σ0.2在转移时间小于20 s时基本没有变化,大于20 s时呈单调下降,至90 s时,下降至约为360 MPa,与转移时间为5 s时相比下降程度约为9%。随着转移时间延长,抗拉强度σb不断下降,至90 s约为410 MPa,下降程度约为7.5%。伸长率在转移时间5 s时最高,约13%,至20 s时明显下降,之后随着时间延长变化不大,在11%左右。

图2 淬火转移时间对1933铝合金拉伸性能的影响

Fig.2 Effect of quench transfer time on tensile properties of 1933 aluminum alloy

2.3 晶间和剥落腐蚀性能

所有的样品均未观察到晶间腐蚀迹象,但表面可观察到大量的点蚀坑,只发生了点腐蚀,典型的结果如图3所示。随着淬火转移时间的延长,点蚀坑的深度增加,最大腐蚀深度在5 s时约为10 μm;20 s时约为13 μm;40 s时约为25 μm;60 s时约为36 μm;至90 s时,增加至约为50 μm。和5 s时的相比,增加幅度为400%。但对照国标GB/T 7998—2005可知,这些样品均具有良好的抗晶间腐蚀性能。

样品经剥落腐蚀浸泡后的表面形貌如图4所示。样品表面均未观察到分层、剥落的迹象,只观察到一些点蚀,但随着淬火转移时间的延长点蚀变得更严重,出现了一些爆皮的迹象,如图4(b)所示。因此,样品的腐蚀等级都为P级,都具有良好的抗剥落腐蚀性能。

由此可知,淬火转移时间延长略降低了1933铝合金的抗腐蚀性能。

2.4 微观组织

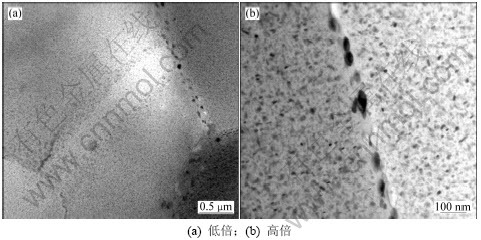

图5所示为淬火转移时间为5 s时,合金时效后的透射电镜照片。由图5可见:经过双级时效(T73)处理后合金基体中析出了大量的η′+η沉淀强化相;大部分晶界上的第二相较粗大,呈断续分布状态,如图5(b)所示,而且晶界无沉淀析出带很窄,约50 nm。

图3 晶间腐蚀浸泡后样品截面的金相照片

Fig.3 Metallographs of samples after intergranular corrosion exposure

图4 剥落腐蚀浸泡48 h后样品表面形貌

Fig.4 Surface morphology of samples after exfoliation corrosion exposure for 48 h

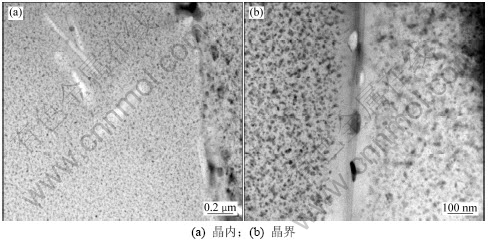

图6所示为淬火转移时间为90 s时,合金时效后的透射电镜照片。由图6可知:合金基体中除了大量的沉淀强化相(η′+η)外,还可观察到一些尺寸较大的条状η平衡相,如图6(a)所示。在样品制备过程中这些η平衡相被腐蚀掉,所以呈白色。这些相长度为几百纳米,长的达约0.6 μm,其周围可观察到无沉淀析出带的存在。合金中大部分晶界上的第二相更粗大,分布更加不连续,如图6(b)所示,而且晶界无沉淀析出带的宽度明显增加,约达150 nm。

图5 淬火转移时间为5 s时样品时效后的TEM照片

Fig.5 TEM images of aged sample with quench transfer time of 5 s

图6 淬火转移时间为90 s时样品时效后的TEM照片

Fig.6 TEM images of aged sample with quench transfer time of 90 s

3 分析与讨论

淬火转移时间延长降低了1933铝合金锻件时效后的强度,据TEM观察认为,主要是因为晶粒内部析出了一些粗大的η平衡相(见图6(a))。合金锻件淬火前在空气中转移时,温度不断下降(见图1),合金元素的溶解度必然减小,固溶体发生分解,在晶内弥散粒子或大角度晶界上非均匀形核析出平衡相[9-11]。这种平衡相基本没有强化作用,反而消耗了溶质原子,减少后续时效生成的沉淀强化相,降低强化效果。转移时间越长,平衡相数量越多,直径越大,因此时效后获得强化效果越小,强度越低,如图2所示。第二相在晶界的优先析出导致晶界附近溶质原子浓度的降低;另外,晶界是空位阱,合金缓冷时空位向晶界扩散而造成晶界附近空位浓度的降低[12],因此时效后晶界上第二相分布更加不连续,无沉淀析出带宽化,如图5和6所示。晶界无沉淀析出带更软,变形时在其中易产生应变和应力集中,增加沿晶断裂的比例,降低伸长率[7, 13]。

1933铝合金锻件淬火后经过了T73双级时效处理,晶界的第二相呈不连续分布状态(见图5),因此,具有良好的耐腐蚀性能,均未发生晶间腐蚀和剥落腐蚀(见图3和4)。但淬火转移时间延长仍然增加了腐蚀深度,降低了合金的耐腐蚀性能。据组织观察结果认为(见图5和6),这主要是晶界无沉淀析出带宽化所导致的。当淬火转移时间延长至90 s时,晶界的第二相更加粗大,分布更加离散,通常可提高耐蚀性能,因为晶界析出相的这种分布状态有利于阻断沿晶界的阳极溶解通道[14-17]。但其效果可能为晶界无沉淀析出带宽化带来的不利影响所抵消甚至超过,因为晶界无沉淀析出带在一定条件下即可充当阳极,加快腐蚀的发展[18],所以,降低合金的耐腐蚀性能。

从淬火转移时间对合金时效后性能的影响也可反映其淬火敏感性。以往有研究发现淬火转移时间为 40 s时,7075铝合金的强度下降程度约为10% [8],7055铝合金的约为9% [7],而对于1933铝合金只有约4%,这说明1933铝合金具有更弱的淬火敏感性。这与采用时间-温度-性能曲线研究Al-Zn-Mg-Cu铝合金淬火敏感性得到的结果一致[3]。对于本研究的1933铝合金样品,综合考虑其拉伸性能和腐蚀性能,淬火转移时间控制在20 s以内较好;但当产品的尺寸不同时,在转移过程中温度的下降速率也不同。据图1中样品水淬时对应的温度,该合金产品在淬火时的温度需高于约366 ℃,据此在实际生产过程中可视不同尺寸产品转移过程的降温情况来控制淬火转移时间,从而为获得良好的综合性能奠定基础。

4 结论

(1) 随着淬火转移时间增加,1933铝合金时效后的拉伸性能和耐蚀性能降低。为获得良好的综合性能,淬火转移时间应小于20 s。

(2) 淬火转移时间过长导致晶粒内部析出粗大的平衡η相,晶界无沉淀析出带宽化,是拉伸性能和耐蚀下降的主要原因。

(3) 为保证时效后良好的综合性能,转移时间的控制应使该合金产品淬火时的温度不低于366 ℃。

参考文献:

[1] Robinson J S, Cudd R L, Tanner D A. Quench sensitivity and tensile property inhomogeneity in 7010 forgings[J]. Journal of Materials Processing Technology, 2001, 119 (1/2/3): 261-267.

[2] Dolan G P, Robinson J S. Residual stress reduction in 7175-T73,6061-T6 and 2017A-T4 aluminium alloys using quench factor analysis[J]. Journal of Materials Processing Technology, 2004, 153/154(1/2/3): 346-351.

[3] Liu S D, Zhong Q M, Zhang Y. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams[J]. Materials & Design, 2010, 31(6): 3116-3120.

[4] Chakrabarti D J, Liu J, Sawteli R R. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity[J]. Materials Forum, 2004, 28: 969-974.

[5] Ekachenko E A, Valkov V J, Baratov V I, et al. The properties and structure of high-strength aluminum 1933 alloy forgings[J]. Materials Science Forum, 1996, 217/222: 1819-1822.

[6] Firdlyander I N, Tkachenko E A, Galliot A, et al. Structure and properties of 1933 circiform large fitting blanks[J]. Materials Science Forum, 2000, 331/337: 1365-1368.

[7] You J H, Liu S D, Zhang X M, et al. Influence of quench transfer time on microstructure and mechanical properties of 7055 aluminum alloy[J]. J Central South University Technology, 2008, 15(2): 153-158.

[8] 张华, 谢延翠, 于洪伟. 7075-T7651铝合金厚板热处理工艺研究[J]. 轻合金加工技术, 2002, 30 (3): 12-14.

ZHANG Hua, XIE Yan-cui, YU Hong-wei. Study of heat treatment process of 7075-T7651 aluminium alloy plate[J]. Light Alloy Fabrication Technology, 2002, 30 (3): 12-14.

[9] Deschamps A, Bréchet Y. Nature and distribution of quench-induced precipitation in an Al-Zn-Mg-Cu alloy[J]. Scripta Materialia, 1998, 39 (11): 1517-1522.

[10] Dumont D, Deschamps A, Bréchet Y. Characterization of precipitation microstructures in aluminium alloys 7040 and 7050 and their relationship to mechanical behavior[J]. Materials Science and Technology, 2004, 20 (5): 567-576.

[11] Godard D, Archambault P, Aeby-Gautier E. Precipitation sequences during quenching of the AA7010 alloy[J]. Acta Materialia, 2002, 50 (9): 2319-2329.

[12] Porter D A, Easterling K E. Phase transformation in metals and alloys[M]. Britain, Oxford: Alden Press, 1981: 264-265.

[13] 刘胜胆, 张新明, 游江海, 等. 淬火速率对AlZnMgCu(Zr)合金断裂行为的影响[J]. 材料热处理学报, 2007, 28 (6): 45-49.

LIU Sheng-dan, ZHANG Xing-ming, YOU Jiang-hai, et al. Quench rates effect on the fracture behavior of AlZnMgCu(Zr) alloy[J]. Transactions of Materials and Heat Treatment. 2007, 28 (6): 45-49.

[14] Ramgopal T, Gouma P I, Frankel G S. Role of grain boundary precipitates and solute-depleted zone on the intergranular corrosion of aluminum alloy 7150[J]. Corrosion, 2002, 58 (8): 687-697.

[15] Tsai T C, Chuang T H. Role of grain size in the stress corrosion cracking of 7475 aluminum alloy[J]. Materials Science and Engineering A, 1997, 225(1/2): 135-144.

[16] Robinson M J, Jackson N C. The influence of grain structure and intergranular corrosion rate on exfoliation and stress corrosion cracking of high strength Al-Cu-Mg alloys[J]. Corrosion Science, 1999, 41(5): 1013-1028.

[17] Sinyavskii V S,Ulanova V V, Kalinin V D. On the mechanism of intergranular corrosion of aluminum alloys[J]. Protection of Metals, 2004, 40(5): 537-546.

[18] 张琦, 李荻, 丁学谊. LC4铝合金晶间腐蚀电化学机理[J]. 材料保护, 1996, 29 (8): 6-8.

ZHANG Qi, LI Di, DING Xue-yi. Electro-chemical mechanism of intergranular corrosion of LC4 aluminum alloy[J]. Materials Protection, 1996, 29 (8): 6-8.

(编辑 邓履翔)

收稿日期:2011-03-05;修回日期:2011-06-02

基金项目:湖南省科技厅计划项目(2010GK3116);中南大学自由探索计划资助(201012200238)

通信作者:刘胜胆(1980-),江西吉水人,博士,副教授,从事高强铝合金制备、组织及性能方面的研究;电话:0731-88830265;E-mail:csuliusd@163.com