TC6合金等温锻造过程中晶粒尺寸的数值模拟

李晓丽1, 李淼泉1, 李 锋2, 熊爱明1

(1. 西北工业大学 材料学院, 西安 710072;

2. 中国人民解放军驻沈阳飞机工业(集团)有限公司, 沈阳 100034)

摘 要: 通过引入一个与微观组织相关的函数对稳态流动应力模型进行修正, 建立了金属材料高温变形时的稳态流动应力模型。 并将该耦合微观组织参数的流动应力模型写入有限元程序中, 模拟了TC6合金叶片在等温锻造过程中初生α相晶粒尺寸的变化。 研究了变形工艺参数(压下量, 变形温度, 变形速度和摩擦因子)对零件内部初生α相晶粒尺寸的影响。

关键词: 叶片; 等温锻造; 晶粒尺寸; 数值模拟 中图分类号: TG319

文献标识码: A

Numerical simulation of grain size during isothermal forging of TC6 alloy

LI Xiao-li1, LI Miao-quan1, LI Feng2, XIONG Ai-ming1

(1. School of Materials Science and Engineering,Northwestern Polytechnical University, Xian 710072,China;

2. Shenyang Aircraft Industries (Group) Co., Ltd., Shenyang 100034, China)

Abstract: A constitutive equation to describe a correlation of the deformation behavior with the microstructure evolution of the TC6 alloy during high temperature deformation was proposed, through introducing a function related to the microstructure variables. Combining FEM and the present equation and model for microstructure evolution, the grain size of prior α phase was simulated during the isothermal forging of TC6 alloy airfoil blade using commercial FE software. The present results illustrate the α phase grain size during the forging of TC6 alloy airfoil blade in detail. The simulated results show that the height reduction, deformation temperature and strain rate have more significant effects on the grain size of prior α phase than the friction factor between the billet and the die.

Key words: airfoil blade; isothermal forging; grain size; numerical simulation

在金属高温变形过程中, 材料微观组织的变化, 如晶粒尺寸、 晶粒形态、 相组成等在很大程度上决定了产品的机械性能。 因此, 微观组织模拟技术已经成为国内外学者研究的热点。

20世纪70年代, Sellars[1]应用半经验的微观组织模型研究了C-Mn钢和钢带的热轧过程。 Kopp等[2]将微观组织模拟技术与FEM结合研究了碳钢轧制过程的微观组织演化。 Ding等[3]将经典冶金学原理与Cellular Automaton技术结合, 研究了高温塑性变形过程中不同阶段的微观组织演变。 Brand等[4]利用有限元法对IN718合金涡轮盘锻造过程中的晶粒尺寸变化及动态再结晶体积分数进行了数值模拟研究。 Dean等[5]对Ti-6Al-4V合金航空叶片截面的晶粒尺寸和体积分数进行了二维有限元模拟。 李等[6]建立了钛合金微观组织演化的模糊数学(FS)模型和人工神经网络[7](ANN)模型, 与FEM结合后实现了圆柱体镦粗过程中微观组织演变的计算[8]。 虽然以上模型均能达到足够的精度, 但是大多不能反映材料的内在塑性变形机理。 近年来, 应用内变量法(Internal state variable method)建立微观组织模型的方法受到了特别关注。 基于内变量法的微观组织模型从微观角度考虑微观组织的演变过程, 揭示了一定的微观塑性变形机理, 目前已经用于钢、 铸铁、 铝合金等金属与合金在高温变形过程中微观组织模型的建立[9-11]。

本文作者探索将刚塑性有限元法与材料的微观组织模型结合, 以TC6合金叶片的等温锻造过程为研究对象, 对航空发动机叶片在等温锻造过程中的晶粒尺寸演化进行数值模拟, 并研究不同工艺参数对锻件内的晶粒尺寸及其分布的影响。

1 微观组织演变模型

在塑性变形过程中, 位错结构与位错密度的变化是微观组织演变的驱动力。 由于TC6合金的层错能较高, 动态回复是高温变形的主要软化机制。 加工硬化与流动软化是由于位错的聚集与回复引起的。

在变形过程中, 位错密度的变化为[12]

式中 α1 和α2为材料常数; ρ为位错密度, mm-2; R为摩尔气体常数(8.314J/(mol·K)); Qd为位错运动(如位错攀移、 交滑移)的激活能, kJ/mol; ε[DD(-*2]·[DD)]为变形速率, s-1; T为绝对变形温度, K。 等号右边的第一项代表由于应变的增加导致位错密度增加, 第二项则代表由于动态回复导致位错密度降低。

TC6合金在两相温度区间是(α+β)型两相组织, 微观组织由初生α相、 细小的次生α相以及β相组成。 初生α相的多少、 形状和大小决定了(α+β)型钛合金的性能。 因此本文主要研究初生α相晶粒尺寸的变化。 TC6合金在两相温度区间变形时晶粒尺寸的变化是由晶粒的静态长大、 动态长大以及由于位错密度变化而引起的晶粒长大这三种长大机制同时发生作用并且相互竞争的结果。 同时考虑三种长大机制, 以位错密度变化率ρ[DD(-*2]·[DD)]为内变量, 则初生α相晶粒尺寸的演变可用下式表示[12]:

式中 β0、 β1、 β2、 γ0、 γ1、 γ2、 γ3均为材料常数。 材料常数的计算方法及实验验证见文献[12]。

2 本构关系模型

通过对TC6合金的高温压缩实验和定量金相实验[13-15]的结果分析, 本文提出一种新的建立流动应力模型的方法。 在建立流动应力模型时, 首先建立描述材料塑性变形的稳态流动应力模型, 然后引入一个与微观组织参数相关的函数, 反映材料的高温塑性变形历史, 从而实现对材料整个高温变形过程的描述。

本文提出的耦合材料微观组织参数的流动应力模型形式为

σ=FsFg(3)

式中 σ为材料在高温变形过程中的流动应力, MPa; Fs为稳态应力模型, 它反映了材料在高温塑性变形过程中加工硬化和动态软化达到平衡时的流动应力; Fg为微观组织参数函数, 反映了材料在高温塑性变形过程中初始微观组织状态逐步演化为当前状态时对流动应力的累积影响。

稳态流动应力Fs的大小与变形温度和变形速度有关, 而与塑性变形过程无关。 稳态应力模型为

Fs∶σs=f1(x)(4)

式中 σs为稳态流动应力, MPa; f1为模型函数, 可按下式计算:

f1(x)=A0+A1x+A2x2+A3x3(5)

变量x为lnZ, Z为应变速率温度补偿因子(Zener-Hollomon参数),

式中 A0、 A1、 A2和A3为材料常数; Q为变形激活能, kJ/mol; R为摩尔气体常数, 8.314J/(mol·K);  为变形速率, s-1; T为绝对变形温度, K。

为变形速率, s-1; T为绝对变形温度, K。

从塑性变形的物理本质来说, 材料内部微观组织的演化过程是整个宏观变形过程在微观尺度上的信息积累和反映。 本文考虑引入微观组织参数对稳态流动应力模型进行修正, 微观组织参数修正模型形式如下所示:

Fg∶f2(d)=B0+B1(d/d0)+B2(d/d0)2(7)

式中 d0为初始平均晶粒尺寸, μm; d为当前变形阶段平均晶粒尺寸, μm。 晶粒尺寸可按式(2)进行计算。

为了使得流动应力模型能够适应整个变形工艺范围, 本文中构造系数B0、 B1和B2为lnz的函数, 其具体形式如式(8)所示。 这里变量x为lnZ。

f3(x)=C0+C1x+C2x2+C3x3(8)

式中 C0、 C1、 C2、 C3为材料常数。

根据前述流动应力模型的建立方法和TC6合金高温变形力学实验结果以及定量金相结果, 采用数值拟合的办法确定出新型流动应力模型中的材料常数。

3 晶粒尺寸的数值模拟

3.1 有限元模型

3.1.1 力学模型

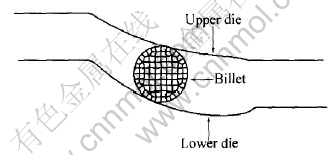

TC6合金叶片锻造过程的二维有限元力学模型见图1。 坯料直径为22mm, 初始网格采用四节点四边形等参单元。 采用的模拟软件是MSC公司的专用锻造成型仿真软件SUPERFORM。 将微观组织演变模型和本构关系模型写入用户子程序, 已知初始速度场和初始晶粒尺寸, 根据微观组织演变模型计算出初始增量步的晶粒尺寸, 将其代入本构关系模型, 刷新速度场, 计算下一增量步的晶粒尺寸, 实现变形与微观组织的耦合模拟。 模拟过程中的变形温度范围是860~950℃, 上模速度范围是0.3~300mm/s, 剪切摩擦因子范围是0.1~0.4。

图1 数值模拟的有限元力学模型及坯料的初始网格划分

Fig.1 Model for simulation and initial meshes of billet

3.1.2 特征点的选取

图2所示为工件内选定的三个特征点的分布示意图。 用于研究变形工艺参数对特征点处晶粒尺寸的影响。

图2 工件内部特征点的分布

Fig.2 Distribution of characteristic points in workpiece

3.2 模拟结果及讨论

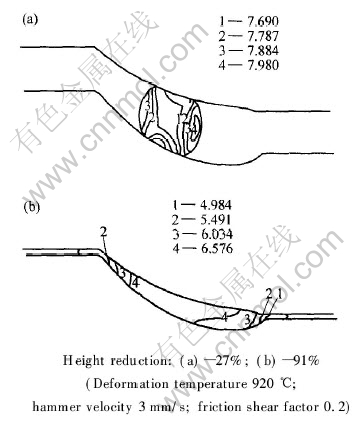

3.2.1 压下量的影响

变形开始时, 变形体的中部区域变形较大, 晶粒尺寸最小, 而其它部分区域如自由流动区域和靠近下模附近区域晶粒尺寸较大。 随着压下量的增加, 较小晶粒尺寸区域逐渐增大, 较大晶粒尺寸区域逐渐减小。 对上下模附近的变形体对比分析可知, 在上模附近的晶粒先进入小晶粒尺寸区域。 随着变形的深入, 晶粒尺寸趋于均匀化。 到最后压靠时, 最小晶粒尺寸出现在毛边与模具之间的拐角区域, 这主要是因为此处的流动速度比较大, 而且拐角对晶界有破碎作用。 上下模之间靠近毛边的区域以及毛边处晶粒尺寸较小, 而其它区域如变形体中部的大部分难变形区域晶粒尺寸最大。 图3给出了不同压下量时晶粒尺寸的分布情况。

图3 压下量对晶粒尺寸的影响

Fig.3 Effects of height reduction on grain size

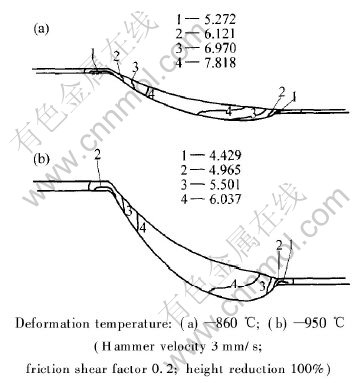

3.2.2 变形温度的影响

钛合金在热变形过程中, 动态回复是内部组织结构的主要演化形式, 而这一过程的发生和发展对温度有较大的依赖性。 变形温度不同时变形过程中存在不同的显微组织演化方式, 因而变形温度对钛合金晶粒的生长方式具有决定性作用。 图4所示为不同变形温度下α相晶粒尺寸的分布情况。 结果表明, 随着变形温度的升高, 整个变形体内的α相晶粒尺寸减小。 这主要是由于随着温度的升高, 发生了相转变, α相的体积分数逐渐减小, β相体积分数逐渐增大, α相部分晶粒转变成为β相晶粒, 导致α相晶粒尺寸减小。 在不同的变形温度下, α相晶粒尺寸在工件内的分布基本相同。 图5所示为在变形速度为3mm/s、 摩擦因子为0.2条件下变形温度对工件内不同特征点处晶粒尺寸的影响。 由图5可知, 位于工件毛边部的特征点3由于承受较大的变形和具有较高的温升, 因而该点处的晶粒尺寸比其它特征点处的晶粒尺寸要小。

图4 变形温度对晶粒尺寸的影响

Fig.4 Effects of deformation temperature on grain size of α phase

图5 变形温度对特征点处晶粒尺寸的影响

Fig.5 Effects of deformation temperature on grain size of α phase at characteristic points

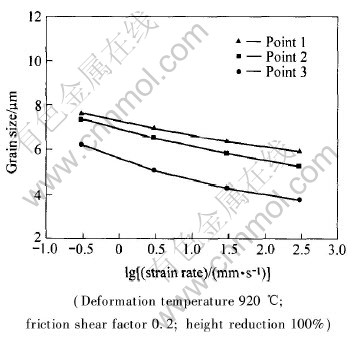

3.2.3 变形速度的影响

变形速度对工件内微观组织分布的影响较大。 图6所示为变形温度为920℃, 摩擦因子为0.2时变形速度对晶粒尺寸的影响情况。 从图中可以看出, 随着变形速度的升高, 工件内小晶粒区域增大了。

图7所示为变形温度为920℃, 摩擦因子为0.2条件下变形速度对工件内不同特征点处晶粒尺寸的影响。 从图中可以看出, 当变形速度为0.3mm/s时, 工件内所有特征点处的微观组织分布比

图6 变形速度对晶粒尺寸的影响

Fig.6 Effects of hammer velocity on α phase grain size

图7 变形速度对特征点处晶粒尺寸的影响

Fig.7 Effects of hammer velocity on grain size of α phase at characteristic points

较均匀。 随着变形速度的增加, 工件内的微观组织分布的不均匀性加剧。 这主要是由于不同变形速度下给予变形体回复的时间不同导致位错密度不同所致。 因而, 等温锻造时需要适当地控制变形速度, 以获得理想的微观组织分布。

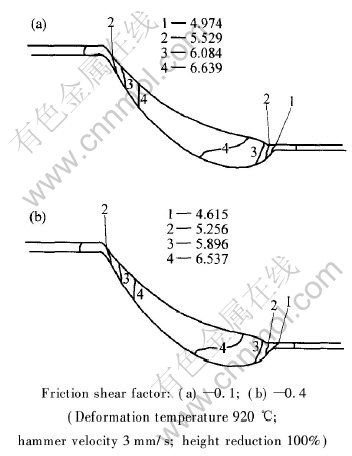

3.2.4 摩擦的影响

图8所示为不同摩擦因子下晶粒尺寸的分布。 无论是从α相的晶粒尺寸大小来看, 还是从在工件内的分布规律来看, 边界摩擦条件对微观组织参数

图8 摩擦因子对晶粒尺寸的影响

Fig.8 Effects of friction shear factor on grain size of α phase

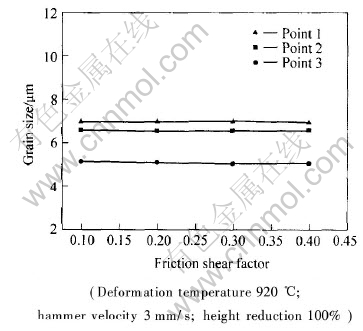

的影响均不显著。 图9所示为在变形温度为920℃、 变形速度为3mm/s的条件下摩擦因子对工件内不同特征点处晶粒尺寸的影响。 三个特征点处的晶粒尺寸基本保持不变, 这也说明边界摩擦条件对微观组织的影响不显著。

图9 摩擦因子对特征点处晶粒尺寸的影响

Fig.9 Effects of friction shear factor on grain size of α phase at characteristic points

4 结论

1) 压下量、 变形温度、 变形速度对晶粒尺寸的影响较显著, 而摩擦对晶粒尺寸的影响则不显著。

2) 压下量增加, 晶粒尺寸趋均匀。 在变形的最后阶段, 晶粒尺寸的最小值出现在毛边处。

3) 初生α相晶粒尺寸随着变形温度的升高而减小。

4) 变形速度的增大使晶粒尺寸分布的不均匀性增加。 变形速度较小时, 晶粒尺寸在整个变形体内分布较均匀; 变形速度较大时, 晶粒尺寸相应减小, 较小晶粒尺寸区域逐渐增大。

REFERENCES

[1]Sellars C M. Modeling microstructural development during hot rolling[J]. Mater Sci Technol, 1990, 6: 1072-1081.

[2]Kopp R, Karnhausen R, Souza M M. Numerical simulation method for designing thermomechanical treatment illustrated by bar rolling[J]. Journal of Metallurgy, 1991, 20: 351-360.

[3]Ding R, Guo Z X. Microstructural modelling of dynamic recrystallisation using an extended cellular automation approach[J]. Computational Materials Science, 2002, 23: 209-218.

[4]Brand A J, Karhausen K, Kopp R. Microstructural simulation of nickel base alloy Inconel 718 in production of turbine discs[J]. Mater Sci Technol, 1996, 12: 963-969.

[5]Hu Z M, Brooks J W, Dean T A. Experimental and theoretical analysis of deformation and microstructural evolution in the hot-die forging of titanium alloy aerofoil sections[J]. Journal of Materials Processing Technology, 1999, 88: 251-265.

[6]LI Miao-quan, XIONG Ai-ming. New model of microstructure evolution during isothermal forging of the Ti-6Al-4V titanium alloy[J]. Mater Sci Technol, 2002, 18(2): 212-214.

[7]熊爱明, 薛善坤, 李淼泉. TC4钛合金高温变形时微观组织变化的计算[J]. 塑性工程学报, 2002, 19(1): 14-16.

XIONG Ai-ming, XUE Shan-kun, LI Miao-quan. Microstructure evolution and modeling during isothermal deformation of TC4 titanium alloy[J]. Journal of Plasticity Engineering, 2002,9(1): 14-16.

[8]LI Miao-quan, LIU Xue-mei, XIONG Ai-ming, et al. Microstructure modelling and FE simulation of a titanium alloy during isothermal forging[A]. Proceedings of 4th ICFG Workshop on Process Simulation in Metal Forming Industry[C]. Shanghai, 2004. 108-120.

[9]Grong , Shercliff H R. Microstructural modelling in metals processing[J]. Progress in Materials Science, 2002, 47: 163-282.

[10]Onsien M I, Grong , Gundersen , et al. A process model for the microstructure evolution in ductile, cast iron (part Ⅰ): the model[J]. Metallurgical and Materials Transactions A, 1999, 30A: 1053-1068.

[11]Hemmer H, Grong . A Process Model for the Heat-Affected Zone Microstructure Evolution in Duplex Stainless Steel Weldments (Part Ⅰ): the model[J]. Metallurgical and Materials Transactions A, 1999, 30A: 2915-2929.

[12]LI Xiao-li, LI Miao-quan. Microstructure evolution model based on deformation mechanism of titanium alloy in hot forming[J]. Trans Nonferrous Met Soc China, 2005, 15(4): 749-753.

[13]熊爱明, 林海, 李淼泉. TC6钛合金高温变形力学行为的实验研究[J]. 材料科学与工艺, 2001, 9: 105-107.

XIONG Ai-ming, LIN Hai, LI Miao-quan. Investigation of thermal deformation performance of the TC6 titanium alloy[J]. Mater Sci Techonol, 2001, 9: 105-107.

[14]熊爱明, 黄维超, 陈胜晖, 等. 高温变形参数对TC6钛合金微观组织的影响研究[J]. 航空材料学报, 2003, 23(1): 11-15.

XIONG Ai-ming, HUANG Wei-chao, CHEN Sheng-hui, et al. Effects of hot forming parameters on microstructure of TC6 titanium alloy[J]. Journal of Aeronautical Materials, 2003, 23(1): 11-15.

[15]熊爱明, 黄维超, 陈胜晖, 等. 热处理制度对TC6钛合金显微组织的影响[J]. 中国有色金属学报, 2002, 12(1): 206-209.

XIONG Ai-ming, HUANG Wei-chao, CHEN Sheng-hui, et al. Effects of heat treatment on microstructure of TC6 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(1): 206-209.

(编辑陈爱华)

基金项目: 国家重点基础研究发展规划资助项目(G2000067206); 国家自然科学基金资助项目(50475144); 首届青年教师奖励基金资助项目; 西北工业大学博士论文创新基金资助项目

收稿日期: 2005-03-07; 修订日期: 2005-05-27

作者简介: 李晓丽(1977-), 女, 博士研究生.

通讯作者: 李晓丽, 电话: 029-88460465; 传真: 029-88491619; E-mail: ustblxl@163.com