Al-Mg系铝合金超塑性薄壁管材

刘黎明1, 陶 华1 , 肖于德2

(1. 西北工业大学 机电学院,陕西 西安,710072;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:采用熔铸—均匀化退火—挤压工艺研制Al-5.60Mg-0.30Zr-0.07Cr-0.16Mn(质量分数,%)合金管材。对该合金管材进行析出退火处理后,采用热旋—退火—冷旋工艺制备薄壁旋压管。采用金相显微镜、扫描电镜、拉伸性能测试等手段研究该铝合金旋压管冷变形态与完全再结晶退火态的组织与性能,测试其超塑性能,讨论其超塑性变形与断裂行为。研究结果表明,在Al-Mg铝合金中加入微量锆、铬、锰,可以促使试验合金中第二相颗粒弥散分布,减小后续加工的变形不均匀性;Al-5.6Mg-0.30Zr合金经析出退火—旋压变形后,于500 ℃退火1 h的再结晶退火组织晶粒平均粒径小于10 μm。

关键词:Al-Mg合金;超塑性;再结晶

中图分类号:TG111.7;TG146.2+1;TG316 文献标识码:A 文章编号:1672-7207(2007)04-0608-04

Superplasticity of Al-Mg aluminum alloys tube

LIU Li-ming1, TAO Hua1, XIAO Yu-de2

(1. College of Mechanical Engineering, Northwestern Polytechnical University, Xi’an 710072, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The extruded tube of Al-5.6Mg-0.30Zr-0.07Cr-0.16Mn (mass fraction, %) alloy was prepared in a smelting-casting-homogenizing-extruding process. The tube samples were spun into thin tube via combination of warm-spinning-annealing-cold-spinning process. Microstructures and tensile properties of the cold-spun pipes and their fully recrystallization annealed alloys were characterized by means of optical microscopy, scanning electron microscopy and tensile test. Superplastic tensile test was carried out to study superplastic deforming and fracturing behaviour of the cold-rolled sheets and cold-spun pipes. The results show that precipitating annealing treatment can improve distributing uniformity of the second phase particles in the testing alloy, minish plastically deforming heterogeneity of the sequential cold-rolling or cold-spinning process, and so the ultra-fine equiaxed grain structure with uniform distribution state can be obtained via a combination of warm-deforming-annealing-cold-deforming process, which can meet the microstructural request for high temperature superplastic deformation.

Key words: Al-Mg alloy; superplasticity; recrystallization

金属超塑性现象自被发现以来[1],超塑性研究已经成为材料科学的一个重要研究方向[2-5]。一般认为,材料在一定条件下,其流变应力的应变速率敏感性指数m>0.3,显示特大延伸率的能力,这种性能称为超塑性。金属超塑性的宏观变形特点是大延伸、无颈缩、流变应力低以及易成形,与一般的塑性变形相比,在外观特征、金相组织以及变形机制等方面都有很大区别。超塑性变形后工件表面平滑,没有起皱、凹陷、微裂及滑移痕迹等现象,因此,被广泛应用于复杂形状零件的成形。在已发现的超塑材料中,铝合金含量高于33.3%。铝合金超塑性的研究在超塑性研究领域中具有极其重要的地位。铝合金超塑性属于细晶超塑性,为了细化铝合金晶粒,一般在合金中添加稀土元素或者过渡族元素如锆,可以明显细化铸造晶粒,也可以细化后续加工和热处理组织[6-7]。另一方面,结合合金材料制备过程中变形(如轧制、挤压)与再结晶退火工艺可以进一步细化材料晶粒,使铝合金材料具有良好的细晶超塑性[8-10]。Al-Mg系铝合金具有良好的力学性能、抗腐蚀性和焊接成形性,在航天航空工业领域应用广泛。在此,本文作者在Al-Mg系铝合金中添加微量锆、铬、锰等,并在材料加工过程中采用挤压、旋压变形与再结晶退火工艺,研制Al-Mg系铝合金薄壁管材。

1 试验方法

采用纯Al,纯Mg,Al-5Zr,Al-10Cr和Al-10Mn等配制试验合金,合金名义化学成分(质量分数,%)为:Al-5.60Mg-0.30Zr-0.07Cr-0.16Mn。合金锭经均匀化退火((450~490) ℃×24 h)后,挤压成直径为200 mm、壁厚为16 mm的管材,挤压比为5?1,制备流程如图1所示。

图1 试验合金样品制备工艺流程

Fig.1 Processing scheme of two specimens of testing alloy

从挤压管上截取试样,观察挤压管材的组织,同时将挤压管车削加工成旋压毛坯(内径为180 mm、厚度为12 mm),经过析出退火(490 ℃×24 h固溶+ 300 ℃×8 h过时效)处理后,采用热旋—中间退火—冷旋工艺,经过多道次反旋制成内径为180 mm、厚度为2.4 mm冷旋管,冷旋壁厚减少约50%。

采用机械研磨、抛光、浸蚀法制备金相试样,浸蚀剂选用Keller(HF+HCl+HNO3+H2O)试剂。采用电解抛光—阳极覆膜方法制样进行晶粒粒径与分布分析,抛光剂为CrO3+H2SO4+H3PO4 +H2O混合液,阳极覆膜剂为H3BO3+HF+H2O混合液。样品观察均在POLYVAR-MET立式显微镜下进行。

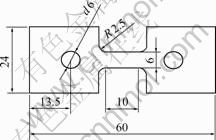

从冷轧板和冷旋管截取标准拉伸长试样和超塑性拉伸短试样(超塑性拉伸短试样尺寸见图2),拉伸试验在配有均热炉的CSS-44100电子万能拉伸机上完成,超塑性拉伸试验温度为500~520 ℃,应变速率为8×10-4 s-1。室温常规拉伸断口和超塑性高温拉伸断口形貌均在KYKY-2800B扫描电镜下观察。

单位:mm

图2 超塑性拉伸短试样尺寸

Fig.2 Dimensions of short specimen for superplastic tensile test

2 试验结果与讨论

2.1 挤压管材的析出退火组织

高镁含量的Al-Mg合金中主要的析出相是Al8Mg5平衡相。通常,Al8Mg5相多分布于晶界上,且易长大为粗大的不规则颗粒。挤压变形可以强烈破碎块状相,再经析出退火处理后,Al8Mg5则多为细小粒子弥散分布在合金中,如图3所示。

图3 析出退火后试验合金的金相显微组织

Fig.3 Microstructure of testing alloy after precipitation annealing treatment

此外,试验合金是在Al-Mg合金中加入微量Zr,Cr和Mn合金化,这些微量元素在Al-Mg合金中可以形成Al3Zr,Al7Cr和Al6Mn等难溶相,通过挤压变形和析出退火处理也可以改变这些难溶相,尤其是Al3Zr颗粒的形状,并促使其分布更加均匀地弥散。

经挤压—析出退火处理后加压管的组织均匀性好,这可提高大变形量冷加工后的形变均匀性,也有利于提高再结晶形核率,提高形核均匀性。

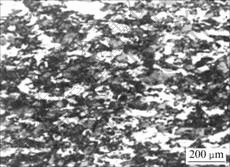

2.2 旋压管冷变形组织与再结晶退火组织

经490 ℃×24 h固溶+300 ℃×8 h过时效处理后,采用多道次反旋工艺将试验合金挤压管旋压成薄壁管。冷变形减薄率ε≈50%的旋压管金相显微组织如图4所示。在强烈的剪切变形作用下,旋压变形组织大致平行于旋压主变形方向(轴向),呈现出较强的方向性。晶粒被压扁,并沿变形方向延展,破碎比较充分。

图4 冷旋管的金相显微组织

Fig.4 OM microstructure of cold spun pipe(ε ≈50%)

但是,在强力旋压减薄过程中,变形集中于与旋轮接触的微小变形区内,通过连续加载、逐点累积而导致径向压缩、周向切变和轴向延伸,而受到极限减薄率的限制,试验合金管材累积减薄率为50%。这种加载会引起强烈的局部剪切形变,而易导致旋压变形不均匀。

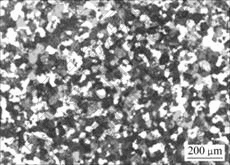

图5所示为旋压管材经500 ℃保温1 h再结晶 退火后的金相显微组织,再结晶晶粒平均粒径小 于10 μm,而且表现出细小、均匀且呈等轴状的特点。在再结晶和晶粒长大过程中,弥散颗粒强烈钉扎位错和晶界,稳定亚结构,强烈阻碍再结晶形核与长大过程。虽然高温加热导致Al8Mg5溶解,但是Al3Zr等颗粒仍然存在,可阻碍晶粒长大。

图5 冷旋管的再结晶退火组织

Fig.5 Microstructure of cold spun pipe after recrystallization annealing

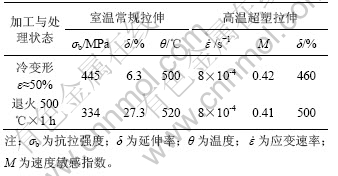

2.3 冷旋管的拉伸性能与超塑性变形行为

试验合金冷旋管的拉伸力学性能如表1所示。由于冷作硬化效应,旋压管材在冷变形状态具有较高的强度和较低的伸长率。经退火处理后,室温强度降低,但是伸长率显著提高,有利于后续加工成形。在温度为500~520 ℃,应变速率为8×10-4 s-1的条件下旋压薄壁管材具有良好的高温超塑拉伸性能,如图6所示。

表1 冷旋管的室温拉伸性能与高温超塑拉伸性能

Table 1 Room temperature tensile properties and high temperature superplastic tensile properties of cold-spun pipe

(a) 原始试样;(b) 冷变形后于520 ℃超塑性拉伸;

(c) 热处理后于520 ℃超塑性拉伸

图6 试验合金超塑拉伸照片

Fig.6 Superplastic tensile photographs of original specimen at 520 ℃

在扫描电镜下观察冷旋管试样室温常规拉伸和高温(520 ℃)超塑性拉伸的断口表面形貌,结果如图7所示。可以看到,室温常规拉伸断口上存在大量带有细小第二相颗粒的韧窝,呈现出典型的穿晶断裂的 特点,裂纹多萌生于第二相颗粒处,而后以微孔聚集、长大、联接的模式扩展,最终导致韧性断裂;而在高温(520 ℃)超塑性拉伸断口上观察不到大量的韧窝,呈现出典型的沿晶界断裂的特点,存在大量的深坑,深坑内可看到多个晶粒的晶界,晶粒呈现出剥离状。

Al-Mg系合金是以位错运动或扩散蠕变协调的晶界滑移机制来实现其细晶超塑性变形。在高温超塑性变形过程中,晶界滑动于三叉晶界、晶界台阶和第二相粒子等处受阻,并产生应力集中,这时,启动位错滑移和扩散蠕变协调机制,晶粒发生转动,变形得以继续。然而,随着变形量增大,晶界滑移受阻严重,于受阻处萌生空洞,经历一个形核长大的过程,空洞数量增加,尺寸增大,最终聚集、扩展而导致沿晶破断。显然,在高温超塑性变形过程中晶粒细小、均匀,且呈等轴状,有利于实现晶界滑移和晶粒转动而超塑性变形,也有利于阻滞空洞形核长大而推迟破裂。

(a) 室温常规拉伸;(b) 高温超塑性拉伸

图7 冷旋管试样在不同温度的拉伸断口SEM形貌

Fig.7 SEM graphs of tensile samples of cold-spun pipe at different temperatures

3 结 论

a. 在Al-Mg合金中加入微量元素锆,可以明显细化挤压管组织晶粒,也可以细化后续加工和热处理组织。引入析出退火处理,可以促使Al-5.6Mg-0.30Zr试验合金中第二相颗粒均匀弥散分布,从而减小后续加工的变形不均匀性,有利于获得均匀细小的再结晶组织。

b. Al-5.60Mg-0.30Zr合金经析出退火—旋压变形后,于500 ℃退火1 h的再结晶退火组织的晶粒平均粒径小于10 μm,多呈等轴状,且分布均匀,达到材料超塑性所需的组织要求。

c. Al-5.60Mg-0.30Zr合金旋压薄壁管材表现出良好的室温常规拉伸性能和高温超塑拉伸性能。

参考文献:

[1] 马图哈K H. 非铁合金的结构和性能[M]. 丁道云, 译. 北京: 科学出版社, 1999: 190-245.

Matuha K H. The construction and property of nonferrous alloy[M]. DING Dao-yun, trans. Beijing: Science Press, 1999: 190-245.

[2] 黄世民. 铝合金超塑成形的研究和进展[J]. 铝加工技术, 1994(4): 1-6.

HUANG Shi-min. The investigation and development of aluminum alloy superplastic forming[J]. Aluminum Processing Technology, 1994(4): 1-6.

[3] 黄晓旭, 刘 庆, 姚 枚. 温轧Al-8Mg-0.2Zr合金的超塑性[J]. 金属学报, 1992, 28(5): 233-234.

HUANG Xiao-xu, LIU Qing, YAO Mei. The superplasticity of Al-8Mg-0.2Zr alloy after warm-rolling[J]. Metal Transaction, 1992, 28(5): 233-234.

[4] Verma R, Ghosh A K, Kim S. Grain refinement and superplasticity in 5083 Al[J]. Materials Science and Engineering, 1995, A191(1): 143-150.

[5] Hsiao I C, Huang J C. Development of low temperature superplasticity in commercial 5083 Al-Mg alloys[J]. Scripta Materialia, 1999, 40(6): 697-703.

[6] 尹志明, 高拥政. Sc和Zr对铸态Al-Mg合金晶粒细化的影响[J]. 中国有色金属学报, 1997, 7(4): 75-80.

YING Zhi-ming, GAO Yong-zheng. The influence of Sc and Zr to the grain refinement of casting Al-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 75-80.

[7] Ocenasek V, Slamova M. Resistance to recrystallization due to Sc and Zr addition to Al-Mg alloys[J]. Materials Characterization, 2001, 47(1): 157-162.

[8] 刘 腾, 刘 冰, 雷 毅. Al-Mg合金动态再结晶诱发超塑性时的空洞行为[J]. 中国有色金属学报, 2000, 10(6): 853-859.

LIU Teng, LIU Bin, LEI Yi. The cavity behavior of Al-Mg alloy while dynamic recrystallization duing superplasticity[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 853-859.

[9] Chen C L, Tan M J. Cavity growth and filament formation of superplastically deformed Al 7475 alloy[J]. Materials Science and Engineering, 2001, A298 (2): 235-244.

[10] Bae D H, Ghosh A K. Cavity growth in a superplastic Al-Mg alloy: Ⅱ An improved plasticity based model [J]. Acta Materalia, 2002, 50(8): 1011-1029.

收稿日期:2007-03-09

基金项目:“十五”国防基础科研项目(K0400020201)

作者简介:刘黎明(1968-),男,湖南武冈人,博士研究生,高级工程师,从事金属材料精密塑性成形研究

通讯作者:刘黎明,男,博士研究生,高级工程师;电话:010-68376720; E-mail: liuzhyuru@tom.com