文章编号:1004-0609(2015)11-3067-10

钛/铝异种合金电弧熔钎焊接接头的组织与断裂行为

马志鹏1, 2,于心泷1,孟庆武1

(1. 东北石油大学 材料科学与工程系,大庆 163318;

2. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050)

摘 要:采用Al-Si共晶钎料对TC4钛合金与2A12铝合金异种合金进行钨极氩弧焊接,研究焊接电流对焊接接头显微组织和力学性能的影响。结果表明:当焊接电流为110~120 A时,焊接接头的抗拉强度最高可达158 MPa,此时焊接接头上部断裂在焊缝中,下部断裂在钛合金与焊缝的界面上。焊缝组织主要由α(A1)基体和在晶界析出的A1-Si共晶相组成,而钛合金与液态钎料在接头界面上部化学反应形成3种不同形态的TiAl3金属间化合物,而在接头界面下部只形成针状的τ1金属间化合物。当焊接电流达到并超过140 A时,接头界面化合物厚度显著增至300 μm左右,导致抗拉强度急剧下降。

关键词:钛/铝异种合金;钨极氩弧焊;界面组织;断裂行为

中图分类号:TG454 文献标志码:A

Microstructure and fracture behavior of arc welding-brazing joints between titanium and aluminum dissimilar alloys

Ma Zhi-peng1, 2, YU Xin-long1, MENG Qing-wu1

(1. Department of Materials Science and Engineering, Northeast Petroleum University, Daqing 163318, China;

2. State Kay Laboratory of Advanced Processing and Recycling of Nonferrous Metals,

Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The butt joining of TC4 titanium alloy to 2A12 aluminum alloy was conducted by gas tungsten arc welding using Al-Si eutectic filler wire, and the effects of the welding current on the microstructure and mechanical properties of the weld joint were analyzed. The results show that the maximum tensile strength of 158 MPa is achieved, the top joint fractures in the seam, and the bottom joint fractures at the interface between the titanium alloy and seam at welding current of 110–120 A. The seam consists of α(Al) and Al-Si eutectic phase precipitated at the grain boundary. The reaction layer consists of the continuous layer TiAl3 phases, the block-like and the long rod-like TiAl3 phase at the top part of the interfacial area of the weld joint. At the bottom part of the interfacial area, the reaction layer includes only the needle-like τ1 phase. The joint strength abruptly decreases with increasing the interfacial layer thickness up to approximately 300 μm as the welding current increases to 140 A.

Key words: Ti/Al dissimilar alloy; gas tungsten arc welding; interfacial reaction; fracture behavior

随着我国航空和航天等行业的快速发展,钛合金和铝合金等轻质高强材料所构成的异种金属复合构件具有着巨大的潜在应用前景,但钛/铝复合构件的应用面临着钛合金与铝合金异种金属能否可靠焊接的技术瓶颈。在高温作用下,钛与铝会发生化学反应而生成大量的脆性金属间化合物,包括Ti3Al[1]、TiAl[2]、TiAl2[3]和TiAl3[4-5]等。这些化合物会快速生长并以杆状等形态分布在整个接头中,严重降低焊接接头的力学性能。这种现象会使得钛/铝异种金属的复合构件在现代工业的应用中受到极大的限制,从而影响了钛/铝复合构件的使用。

近年来,国内外的学者对钛合金与铝合金的连接进行了广泛研究,主要集中在焊接工艺[6-9]、焊接接头性能[10-12]、焊接界面显微组织[13-14]及界面化合物的形成原因[15-16]等方面。结果表明,抑制金属间化合物的形成与长大才能提高钛合金与铝合金焊接接头的力学性能。陈彦宾等[8-9]出于控制金属间化合物的目的,以CO2激光为热源,在焊接过程中使用Nocolok钎剂,对1.5 mm厚的Ti-6Al-4V钛合金板和5056铝合金板进行了激光熔钎焊研究。结果表明:所得接头具有熔焊和钎焊双重性质,接头表面覆盖残渣;钛合金与焊缝界面会形成大量的金属间化合物,其种类与厚度直接决定焊接接头的抗拉强度,导致抗拉强度稳定性较差。吕世雄等[10-11]采用交流TIG电弧对2 mm厚TC4钛合金板和6056铝合金板进行电弧熔钎焊连接。在 不同焊接电流条件下,钛合金与焊缝界面主要形成不同形状的TiAl3化合物,焊接接头抗拉强度仅为103 MPa。从以上的研究可以看出,在焊接过程中,使用焊剂会导致焊接后形成熔渣且难于清理;采用钨极氩弧(TIG)电弧进行焊接时,其接头抗拉强度较低。而不使用任何焊剂,以TIG电弧熔钎焊方法控制焊接热输入,用于焊接钛合金与铝合金且得到较理想焊接力学性能的研究在国内外还未见报道。本文作者采用TIG的方法,在不使用任何焊剂的情况下,以Al-12Si焊丝为填充材料,针对3 mm厚TC4钛合金与2A12铝合金异种金属进行焊接,并对其界面组织及断裂行为进行了研究。

1 实验

钛合金基体材料为TC4,铝合金基体材料为2A12,板厚均为3.0 mm。TC4钛合金的化学成分(质量分数,%)如下,Fe≤0.30;C≤0.10;N≤0.05;H≤0.015;O≤0.20;Al 5.5~6.8;V 3.5~4.5;Ti为余量。2A12铝合金的化学成分(质量分数,%)如下,Si≤0.50;Fe≤0.50;Cu 3.8~4.9;Mn 0.3~1.0;Mg 1.2~1.8;Cr 0.10;Zn 0.25;Al为余量。实验用钎料是Al-Si共晶焊丝,直径均为2.0 mm。A1-Si焊丝成分(质量分数,%)如下,Si 11.0~13.0;Fe≤0.80;Cu 0.30;Mn 0.15;Mg≤0.10;Zn≤0.20;Al为余量。试验中没有使用任何焊剂或钎剂。

焊接之前,将两种母材对接端面开Y形坡口,钛侧和铝侧坡口角度为30°左右,用钢丝刷、粗砂纸去除焊件表面及坡口端面的油污和氧化膜,直至露出新鲜金属表面。再依次用无水乙醇和丙酮进行清洗。在焊件下面放置Cu垫板,并使用钢夹具固定,Cu垫板上开8 mm×0.5 mm规格的凹槽,焊件对接间隙为1.0~2.0 mm左右。采用交流TIG电源焊接,氩气对焊缝表面进行保护。焊接工艺参数如下:焊接电流70~150 A,电弧长度3.0~4.0 mm,焊接速度70~80 mm/min,送丝速度500~700 mm/min,氩气流量10~12 L/min。钛/铝焊接过程示意图如图1所示。

图1 钛/铝焊接过程示意图

Fig. 1 Schematic diagram of Ti/Al dissimilar alloy welding process

焊接之后,对焊接获得的接头经过线切割取样和镶嵌作成金相试样。试样采用水砂纸和金相砂纸按顺序打磨,然后用2.5 μm和1 μm的金刚石抛光剂抛光。抛光后接头试样采用日本Olympus公司生产的PM-20型万能金相显微镜观察宏观形貌组织。采用美国FEI公司生产的Quanta 200F型扫描电子显微镜(SEM)观察显微组织形貌,并利用自带能谱仪(EDS)分析焊缝各区域化学成分及元素分布。透射电镜试样的制取分为切割、研磨和减薄3个过程:首先采用线切割方法切取焊接接头界面区域试样大小为8 mm×8 mm,厚度约为500 μm的薄片;其次将切取好的试样薄片依次用粗砂纸、细砂纸打磨抛光,直至厚度为40~60 μm为止,用酒精清洗后吹干,冲制成直径d 3 mm的薄片;最后采用Gatan 691型离子减薄仪将d 3 mm薄片进行减薄,至获得可供观察的薄区。采用Tecnai G2 F30型透射电子显微镜(TEM)对焊接接头的界面反应物进行分析,并对不同相进行选区电子衍射花样(SADP)分析,加速电压设为300 kV。抗拉强度测试试样在测试前将接头余高铣平,并打磨去除试样侧面的加工痕迹,然后利用Instron 5569型万能试验机上进行拉伸测试,加载速率为1 mm/min。

2 结果与分析

2.1 接头的宏观组织分析

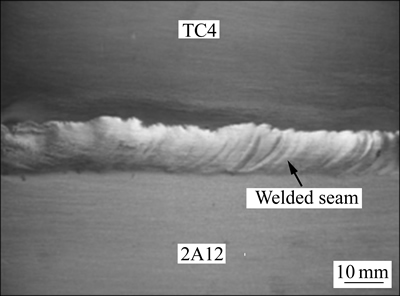

图2所示为焊接电流110 A时钛/铝熔钎焊试样表面形貌。从图2可以看出,采用Al-Si共晶焊丝但不使用任何焊剂进行焊接时,能够实现焊接,且接头表面光滑,无表面裂纹和未熔合的现象。

图2 焊接电流为110 A时钛/铝焊接接头典型试样外观形貌

Fig. 2 Typical weld appearances of Ti/Al dissimilar alloy welding joint at welding current of 110 A

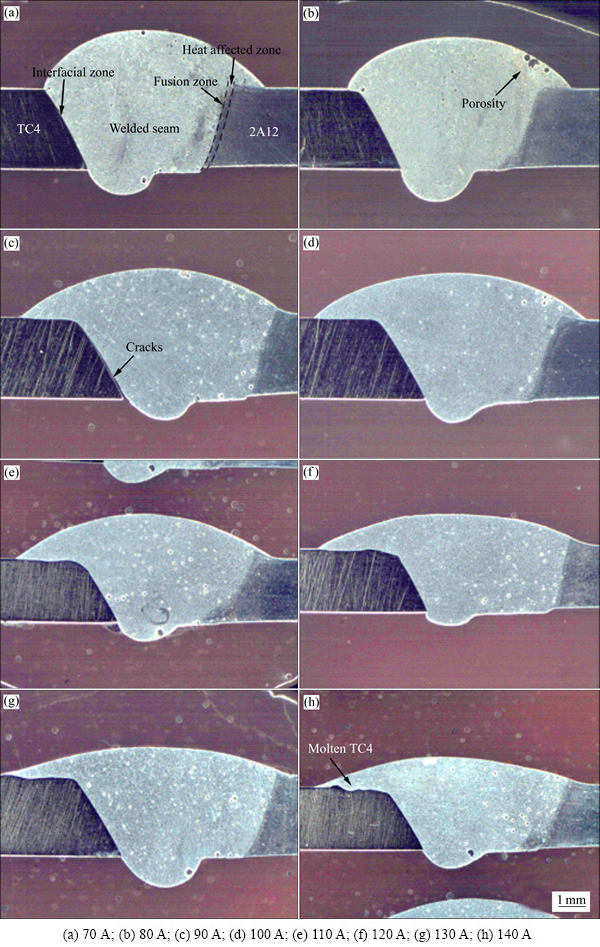

在整个焊接过程中,不同焊接电流电弧产生的热效应并不相同,而焊接材料在不同热效应作用下会产生不同程度熔化现象及冶金反应,所以,可以通过调整焊接电流来控制焊接热输入的大小。图3所示为不同焊接电流下钛/铝接头的横截面组织。由图3可以看出,焊接接头上存在6个不同的区域,分别包括铝母材和钛母材区、铝铡热影响区、铝侧熔合区、焊缝区以及钛侧界面化合物区。当焊接电流为70 A时,液态Al-Si钎料与部分熔化铝合金形成熔化接头,但是在钛合金表面上的铺展并不充分,导致钛合金与焊缝非圆滑过渡(见图3(a));当焊接电流升高到90 A时,可以观察到液态钎料在钛合金坡口内润湿铺展,但是部分区域没有发生结合,能够观察到焊缝区与钛合金母材界面出现裂纹;当焊接电流达到100 A时,钛合金没有发生熔化,与焊缝结合较好(见图3(d));当焊接电流达到120 A以上时,钛合金表面开始出现微熔现象(见图3(h))。从图3可以看出,随着焊接电流的变化,液态Al-Si钎料与铝合金母材和钛合金母材的结合会发生明显变化。当电流合适时,不借助外来钎剂的辅助,焊接接头中铝合金侧母材均发生熔化,与钎料混合在一起形成了熔焊接头;而钛合金与钎料发生了反应,从而实现了连接,钛合金侧为钎焊结合。

2.2 接头的显微组织与物相分析

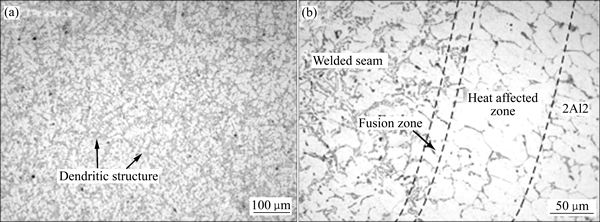

图4所示为焊接电流为110 A时焊接接头的显微组织。接头上的焊缝金属中存在着大量的枝晶状组织,这些组织主要由局部铝合金母材和A1-Si钎料在电弧热作用下熔化混合后凝固所形成(见图4(a))。所以,可以推测焊缝组织主要是α(A1)基体,其枝晶状组织主要是A1-Si共晶和化合物构成。在凝固过程中,Al-Si共晶组织在α(A1)晶界处析出,同时形成较多的细长板条状组织及不规则状的化合物。铝合金侧熔合区由于紧邻焊缝的母材,受高温液态熔池的传热而发生局部熔化,同时焊缝中的元素向铝母材晶界扩散渗透,最后在晶界处生成枝晶状及网状组织。铝合金侧热影响区的组织沿最大冷却速度方向迅速长大,形成沿垂直于熔合区方向生长的粗大晶粒组织(见图4(b))。

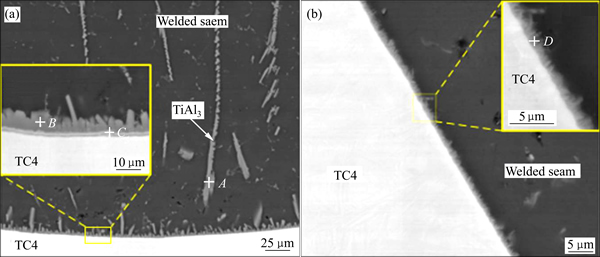

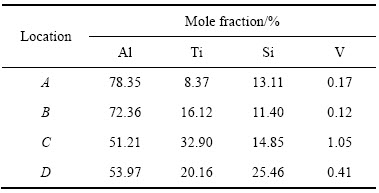

图5所示分别为钛/铝焊接接头中钛合金侧界面层的显微组织。从图5可以看出,接头上部的界面反应层由3种形态的化合物组成。其中,靠近钛侧的连续反应层呈亮白色,厚度在2 μm以内,在连续反应层的上面分布着由块状化合物所构成反应层,平均厚度约为15 μm(见图5(b))。另一种断续的长杆状化合物分布于焊缝内部,其长度可达100 μm以上。表1所列为图5中各点处的EDS分析结果。由表1中各点处元素摩尔比可以看出,长杆状和块状化合物中主要由Ti、Al和Si这3种元素构成,并且A点与B点处含Ti、Al和Si含量都比较接近。块状化合物上B点由于靠近钛合金母材,Ti元素的测量值略高一点,因此,可以推测块状化合物和长杆状化合物应为同一种化合物。这种化合物的Ti与Al、Si含量之和的摩尔比基本为1:3,Si原子的原子半径与Al原子的原子半径非常接近,因而在TiAl3结晶的过程中,界面残留的Si原子很有可能取代Al原子在晶格上的位置,形成TiAl3的置换固溶体,可以确定此化合物应为TiAl3,并固溶了Si元素,这种化合物也可以表达为Ti(Al,Si)3。亮白色化合物较薄且靠近钛合金母材,导致C点Ti元素测量值偏高,但Si含量只有14.85%(摩尔分数),与相邻的块状化合物接近。根据文献[17]中的研究可知,TiAl3中可以固溶Si量达到15%(摩尔分数)。由此可以推测,亮白色化合物也应为TiAl3,只是形成的机制不同而导致最后形态不同。

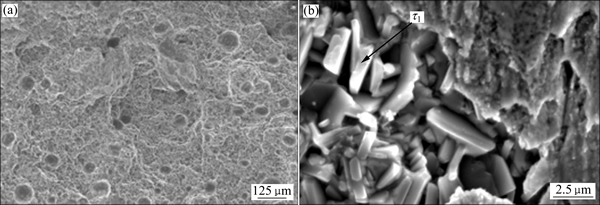

接头下部的界面反应层只由一种针状的化合物组成,其平均厚度约为2 μm。通过表1可以看出,D点Si含量可达到25.46%,远超出Si元素在TiAl3中的最大固溶度,这说明针状化合物应是一种Ti-Al-Si三元化合物。

图3 不同焊接电流下钛/铝焊接接头宏观组织

Fig. 3 Macroscopic cross-section morphologies of Ti/Al dissimilar alloy welding joints made at different welding currents

图4 焊接电流为110 A时钛/铝焊接接头中焊缝及铝侧界面的显微组织

Fig. 4 Microstructures of Ti/Al dissimilar alloy welding joint at welded seam(a) and interfacial zone close to Al alloy(b) at welding current of 110 A

图5 焊接电流为110 A时钛/铝焊接接头钛侧上部和下部界面组织

Fig. 5 Microstructures of Ti/Al dissimilar alloy welding joint at top part(a) and bottom part(b) of interfacial zone close to Ti alloy at welding current of 110 A

表1 图5中界面反应层的能谱元素分析结果

Table 1 EDS analysis results of interfacial reaction layer shown in Fig. 5

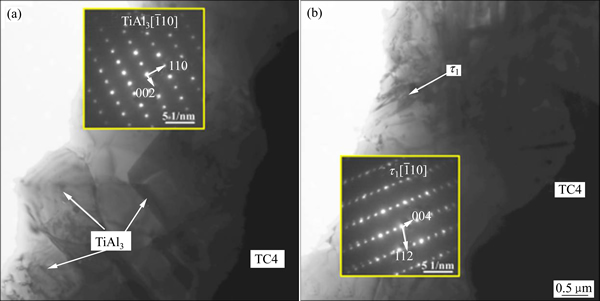

为了进一步研究焊接接头钛合金与焊缝界面的金属间化合物的成分和结构,对其进行透射电镜观察分析,界面化合物的TEM像及选区电子衍射花样如图6所示。图6中呈块状形貌的组织应为图5中的块状化合物。将表1中B点的EDS结果与衍射花样的标定结合起来,与PDF卡片对比发现,此种化合物是以 为晶带轴的四方晶系,(002)晶面和(110)晶面夹角为90°,TiAl3这两种晶面夹角为90.01°,可以证实块状化合物就是TiAl3。图5中所示的亮白色连续化合物层在图6(a)中呈黑色,也证实为TiAl3。接头下部的须状化合物在TEM形貌中呈针状,将表1中D点的EDS结果与衍射花样的标定结合起来,与PDF卡片对比,可发现此种化合物是以

为晶带轴的四方晶系,(002)晶面和(110)晶面夹角为90°,TiAl3这两种晶面夹角为90.01°,可以证实块状化合物就是TiAl3。图5中所示的亮白色连续化合物层在图6(a)中呈黑色,也证实为TiAl3。接头下部的须状化合物在TEM形貌中呈针状,将表1中D点的EDS结果与衍射花样的标定结合起来,与PDF卡片对比,可发现此种化合物是以 为晶带轴的四方晶系,(004)晶面和(112)晶面夹角为80.01°,这两种晶面夹角为79.4658°,可以确认须状化合物为τ1。

为晶带轴的四方晶系,(004)晶面和(112)晶面夹角为80.01°,这两种晶面夹角为79.4658°,可以确认须状化合物为τ1。

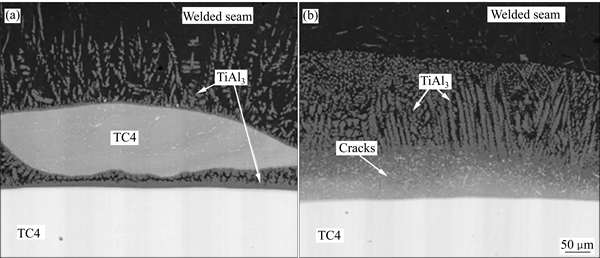

图7所示为焊接电流140 A时钛/铝接头上部和下部钛侧的界面组织。从图7可以看出,接头上部一整块钛合金从母材上溶解并进入到焊缝中,在这块钛合金周围分布大量长杆状化合物TiAl3。同样在接头下 部也形成了大约300 μm厚的TiAl3等化合物,并且在化合物内部出现了裂纹。这说明随着焊接电流的增大,温度随之升高,热效应也明显增强,固态钛合金开始发生溶解,溶解的钛原子将进一步向焊缝中扩散,致使在钛合金界面前沿附近汇集了一定含量的钛原子,随着温度的升高与时间的延长,界面前沿钛原子的含量不断上升。当钛合金界面前沿的浓度达到饱和溶解度时,大块的固态钛合金就会进入到焊缝中,出现如图7(a)中所观察到的现象。由于钛合金界面处钛原子浓度较高,且依附于界面进行非均匀形核时需要的能量起伏较少,化合物TiAl3优先在界面处形核。随着温度的快速下降,TiAl3将依附于界面渐渐长大。焊缝金属在电弧作用下发生剧烈流动,在界面上形成的长杆状化合物TiAl3在流动金属的冲击下发生折断,形成最终断续的化合物。随着温度降低到一定值,焊缝开始凝固,残余应力导致靠近钛合金界面的化合物出现裂纹(见图7(b))。

图6 焊接电流为110 A时钛/铝焊接接头钛侧上部和下部界面区的TEM明场形貌及衍射花样

Fig. 6 Bright-field TEM images and diffraction patterns of Ti/Al dissimilar alloy welding joint at top part(a) and bottom part(b) of interfacial zone close to Ti alloy at welding current of 110 A

图7 在140 A焊接电流下钛/铝焊接接头钛侧上部和下部界面组织

Fig. 7 Microstructures of Ti/Al dissimilar alloy welding joint at top part(b) and bottom part(b) of interfacial zone close to Ti alloy at welding current of 140 A

当焊接电流为110 A时,电弧熔钎焊过程中电弧通过加热钎料使其熔化,并促使钎料流动把热量传递给钛合金,液态钎料流动的同时伴随内部元素的扩散。当热量传递不均匀的液态钎料与钛合金相接触后,一方面会导致钛合金部分区域发生微溶解,这样溶解的钛元素通过扩散及随着钎料流动进入焊缝区;另一方面液态钎料会在其钛合金界面发生化学反应生成化合物。化合物的形成与长大一般分为两种机制:第一阶段为界面反应控制,在时间非常短的情况下,化合物只在平行于界面的方向上非均匀形核,形成一层连续的反应层;第二阶段为扩散控制,随着保温时间的延长,化合物层的厚度增加,开始在垂直于界面的方向上通过扩散开始生长[18-19]。电弧熔钎焊过程中电弧加热时间短,温度适合时会导致界面反应控制的金属间化合物层厚度较薄,应为图5中最靠近钛合金的呈亮白色连续化合物。紧挨着亮白色化合物层是由大量块状化合物所构成的反应层,其厚度并不一致且存在择优生长。这种形态的化合物是由扩散机制所控制,即钛元素通过扩散与焊缝中的铝元素反应所得到块状的化合物。当焊接电流为110 A时,电弧热量较适中,生成的这种块状的化合物层的厚度表达式为[20]

(1)

(1)

式中:L为界面反应层总的厚度;k为与扩散系数及热力学性能有关的生长系数;t为保温时间;b为初始时刻下界面反应层的原始厚度。

方程中的k遵循Arrhenius关系:

(2)

(2)

式中:A为指数系数;Q为生长激活能;R为摩尔气体常数(8.31462 J/K);T为反应温度。从式(1)和(2)可以看出,块状化合物层厚度由反应时间和反应温度所决定。最外层的长杆状化合物可能是由微溶解的钛元素与焊缝中的铝元素反应生成,且与钛合金溶解量成正比关系。这些长杆状金属间化合物垂直于界面方向生长,高温液态钎料流动过程中对金属间化合物产生冲击,使一些长杆状金属间化合物在焊缝中断裂。这些断裂的化合物之间为塑性较好的焊缝金属,通过这样犬牙交错的形式与焊缝金属牢固地结合在一起。

在相同焊接电流情况下,处于焊接接头下部的钛合金界面也会在第一时间生成化合物TiAl3,但钛合金通过电弧所获得的热量明显下降,降低了钛元素的扩散和钛合金的溶解,同时界面化学反应速率变慢,这些都为焊缝中Si元素扩散到钛合金侧界面提供了时间。由文献[21]可知,钛合金会吸引Si在其表面集聚,同时Si在化合物TiAl3中可以大量固溶,当Si的含量超过TiAl3固溶度时,Si元素会与化合物TiAl3发生反应生成τ1。因此,处于钛合金界面的TiAl3会不断与从 焊缝扩散过来的Si元素发生反应,消耗完所有的TiAl3,直至反应结束。

当焊接电流升高时,电弧热量增加,钛合金侧表面的温度升高,同时钛合金的溶解量增大,各种元素的扩散速率相应加快,液态钎料与钛合金的界面反应会更加剧烈,形成了较厚的金属间化合物反应层。

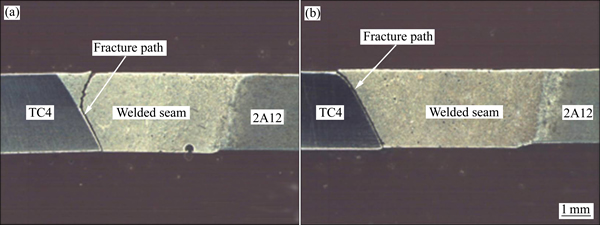

2.3 接头的力学性能与断裂分析

对所有钛/铝异种合金焊接接头的试样进行抗拉强度的测试,可以发现接头的断裂类型分为两种情况:一种是部分断裂于焊缝中,部分断裂于钛合金界面处;另一种是完全断裂于钛合金界面处。其中当焊接电流为70~90 A时,焊接接头完全断裂于钛合金界面处。在这种情况下焊接热输入较少,接头下部的界面温度低,钛合金与液态钎料作用时间短,界面铺展和界面反应不够充分,会出现非冶金结合区,致使界面处的连接可能仅仅为机械结合,在焊接接头受到载荷时,有可能萌生裂纹,并沿界面扩展,所以导致接头强度不高(小于82 MPa)。当焊接电流达到110~120 A时,焊接接头部分断裂于焊缝处,部分断裂于钛合金界面处(见图8(a))。断裂路径呈现裂纹在接头上部焊缝内部扩展,到接头下部时转向沿着钛合金界面扩展。在这种情况下,随着电流的增加,热输入量随之增加,接头下部的界面温度与焊接电流较小时有所升高,钛合金与液态钎料进行反应,生成了化合物τ1。且焊接接头上部所形成的参差不齐的杆状化合物TiAl3与拉伸方向成一定角度,这样的结构有利于阻止裂纹的扩展,起到了“钉扎”裂纹的作用[22-23]。因此,当焊接电流达到110~120 A时,界面金属间化合物能阻止裂纹扩展,大幅提高了钛与焊缝的结合强度,故焊接接头的抗拉强度最高可达到158 MPa。当焊接电流超过130 A时,焊接接头完全断裂于钛合金界面处(见图8(b))。这时的焊接热输入进一步加大,根据上面的分析可知,钛合金表面出现了局部微熔,界面化合物层急剧增厚(超过200 μm),而且在化合物层内部出现了微裂纹,拉伸时,裂纹完全在界面化合物层中产生和扩展,最后破坏整个焊接接头,所以接头的抗拉强度急剧降低(小于58 MPa)。

图9所示为焊接电流为110 A钛/铝焊接接头钛合金侧的断口形貌。接头上部和下部钛合金侧断口形貌表现了两种完全不同形式,接头上部断口中存在大量的韧窝,同时在韧窝中还存在一些气孔,应为韧窝状塑性断裂(见图9(a))。但从图9(b)中可以观察到在接头下部区域存在着一些片层状物质,根据上面的分析可知,此处应为界面的化合物τ1。焊接过程中电弧加热使得试件的上下两面存在明显的温度梯度,接头上部的温度较高,界面反应非常剧烈,形成了垂直于界面的块状化合物TiAl3。在拉伸过程时,这些化合物阻止了裂纹的扩展,故裂纹会优先萌生于焊缝内部,所以上部焊缝区域通常会成为焊接接头的薄弱环节。

图8 焊接电流为110 A和140 A时钛/铝焊接接头拉伸试验的断裂路径

Fig. 8 Cracks path of Ti/Al dissimilar alloy welding joint obtained from tensile tests at welding current of 110 A(a) and 140A(b)

图9 焊接电流为110 A时钛/铝焊接接头拉伸试验的断口形貌

Fig. 9 Fracture surface morphologies of Ti/Al dissimilar alloy welding joint at top part(a) and bottom part(b) of zone obtained from tensile tests at welding current of 110 A

焊接接头下部区域由于电弧熔钎焊的固-液相互作用时间比较短,温度较上部区域低,界面反应还没有完全进行时焊缝已经开始凝固,形成了不完全冶金反应的连接区域。并且在钛合金表面不可避免地存在着一定厚度的氧化膜和杂质,在焊接过程中溶解这些氧化膜与杂质需要一定的时间,氧化膜的存在阻碍了冶金反应的进行,导致固-液界面刚刚相互接触时不可能立刻发生冶金反应,使得界面处V形破口的尖端容易形成不完全冶金结合。化合物τ1与焊缝组织可以完整分开,由此可以确定断裂发生在化合物τ1与焊缝之间。

3 结论

1) 当焊接电流达到110~120 A时,焊接接头部分断裂于焊缝处,部分断裂于钛合金界面处,焊接接头的抗拉强度最高可达到158 MPa。钛合金/焊缝界面上部金属间化合物为3种形态的TiAl3,分别呈现靠近界面的连续状、块状及在焊缝内部的长杆状。钛合金/焊缝界面下部金属间化合物τ1呈针状,平均厚度仅为 2 μm。

2) 当焊接电流小于100 A时,接头界面处温度较低,界面铺展和界面反应不够充分,会出现非冶金结合区,拉伸试验时完全断裂于界面处,导致接头强度小于82 MPa。

3) 当焊接电流大于130 A时,钛合金会从母材上溶解进入到焊缝中,接头界面化合物显著增厚,可达300 μm以上,并会在其内部出现微裂纹,导致抗拉强度小于58 MPa。

REFERENCES

[1] MAJUMDAR B, GALUN R, WEISHEIT A, MORDIKE B L. Formation of a crack-free joint between Ti alloy and Al alloy by using a high-power CO2 laser[J]. Journal of Materials Science, 1997, 32(23): 6191-6200.

[2] CHEN S H, LI L Q, CHEN Y B. Interfacial reaction mode and its influence on tensile strength of the joint in laser joining Al alloy to Ti alloy[J]. Materials Science and Technology, 2010, 26(2): 230-235.

[3] SUN Y B, ZHAO Y Q, ZHANG D, LIU C Y, DIAO H Y, MA C L. Multilayered Ti-Al intermetallic sheets fabricated by cold rolling and annealing of titanium and aluminum foils[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(8): 1722-1727.

[4] LIANG C, LI F, GENG L, HUANG L J. Fabrication of Ti-Al complex with superior deformation capability by pressure infiltration[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S2): s358-s361.

[5] LIU J P, LUO L S, SU Y Q, XU Y J, LI X Z, CHEN R R, GUO J J, FU H Z. Numerical simulation of intermediate phase growth in Ti/Al alternate foils[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 598-603.

[6] 孙军浩, 曹 睿, 黄 倩, 陈剑虹. Al6061/TA2异种金属冷金属过渡焊接性分析[J]. 焊接学报, 2013, 34(9): 25-28.

SUN Jun-hao, CAO Rui, HUANG Qian, CHEN Jian-hong. Cold metal transfer welding of dissimilar metals between6061 aluminum alloy and TA2[J]. Transactions of the China Welding Institution, 2013, 34(9): 25-28.

[7] 王亚荣, 滕文华, 余 洋, 樊亚丽. 铝/钛异种金属的电子束熔钎焊[J]. 机械工程学报, 2012, 48(20): 88-92.

WANG Ya-rong, TENG Wen-hua, YU Yang, FAN Ya-li. Electron beam welding-brazing of Al/Ti dissimilar alloys[J]. Journal of Mechanical Engineering, 2012, 48(20): 88-92.

[8] 陈树海, 李俐群, 陶 汪, 陈彦宾, 刁旺战. 电流辅助钛/铝异种合金激光熔钎焊的特性[J]. 中国有色金属学报, 2009, 19(11): 1942-1947.

CHEN Shu-hai, LI Li-qun, TAO wang, CHEN Yan-bin, DIAO Wang-zhan. Laser welding-brazing characteristics of Ti/Al dissimilar alloy with assistant current[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1942-1947.

[9] 陈树海, 李俐群, 陈彦宾. 铝/钛异种合金激光熔钎焊接头界面特性[J]. 中国有色金属学报, 2008, 18(6): 991-996.

CHEN Shu-hai, LI Li-qun, CHEN Yan-bin. Interface characteristic and property of Ti/Al dissimilar alloys joint with laser welding-brazing[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 991-996.

[10] 吕世雄, 杨 涛, 黄永宪, 石经纬, 敬小军, 曲 杰. Ti/Al TIG微熔钎焊界面行为及接头断裂行为[J]. 稀有金属材料与工程, 2013, 42(3): 478-482.

Shi-xiong, YANG Tao, HUANG Yong-xian, SHI Jing-wei, JING Xiao-jun, QU Jie. Interface characteristics and facture behavior of TIG arc welding-brazed Ti/Al dissimilar alloys[J]. Rare Metal Materials and Engineering, 2013, 42(3): 478-482.

Shi-xiong, YANG Tao, HUANG Yong-xian, SHI Jing-wei, JING Xiao-jun, QU Jie. Interface characteristics and facture behavior of TIG arc welding-brazed Ti/Al dissimilar alloys[J]. Rare Metal Materials and Engineering, 2013, 42(3): 478-482.

[11] 吕世雄, 崔庆龙, 黄永宪, 敬小军. Ti/Al 异种合金电弧熔钎焊接头界面断裂行为分析[J]. 焊接学报, 2013, 34(6): 33-36.

Shi-xiong, CUI Qing-long, HUANG Yong-xian, JING Xiao-jun. Analysis of interface fracture behavior of arc fusion-brazed joint between titanium and aluminum dissimilar alloys[J]. Transactions of the China Welding Institution, 2013, 34(6): 33-36.

Shi-xiong, CUI Qing-long, HUANG Yong-xian, JING Xiao-jun. Analysis of interface fracture behavior of arc fusion-brazed joint between titanium and aluminum dissimilar alloys[J]. Transactions of the China Welding Institution, 2013, 34(6): 33-36.

[12] 马志鹏, 闫久春. TC4 钛合金与 2A12 铝合金超声钎焊接头组织及性能研究[J]. 焊接, 2010(1): 33-35.

MA Zhi-peng, YAN Jiu-chun. Microstructure and mechanical properties of ultrasonic assisted brazed joints between dissimilar alloys of TC4 titanium and 2A12 aluminum[J]. Welding & Joining, 2010(1): 33-35.

[13] 宋玉强, 马圣东, 李世春. Al/Ti扩散层形成的扩散溶解机制[J]. 焊接学报, 2014, 35(6): 49-52, 89.

SONG Yu-qiang, MA Sheng-dong, LI Shi-chun. Diffusion and dissolve mechanism of Al/Ti diffusion layer formation[J]. Transactions of the China Welding Institution, 2014, 35(6): 49-52, 89.

[14] CHEN Y H, NI Q, KE L M. Interface characteristic of friction stir welding lap joints of Ti/Al dissimilar alloys[J]. Transactions of Nonferrous Metals Society of China. 2012, 22(2): 299-304.

[15] CHEN S H, LI L Q, CHEN Y B, HUANG J H. Joining mechanism of Ti/Al dissimilar alloys during laser welding- brazing process[J]. Journal of Alloys and Compounds, 2011, 509(3): 891-898.

[16] SOHN W H, BONG H H, HONG S H. Microstructure and bonding mechanism of Al/Ti bonded joint using Al-10Si-1Mg filler metal[J]. Materials Science and Engineering A, 2003, 355(1): 231-240.

[17] GUPTA S P. Intermetallic compounds in diffusion couples of Ti with an Al-Si eutectic alloy[J]. Materials Characterization, 2002, 49(4): 321-330.

[18] YANG D K, HODGSON P, WEN C E. The kinetics of two-stage formation of TiAl3 in multilayered Ti/Al foils prepared by accumulative roll bonding[J]. Intermetallics, 2009, 17(9): 727-732.

[19] ZHU G L, DAI Y B, SHU D, WANG J, SUN B. Substitution behavior of Si in Al3Ti (D022): A first-principles study[J]. Journal of Physics (Condensed Matter), 2009, 21(41): 415503-415509.

[20] YAO W, WU A P, ZOU G S, REN J L. Formation process of the bonding joint in Ti/Al diffusion bonding[J]. Materials Science and Engineering A, 2008, 480(1/2): 456-463.

[21] MA Z P, ZHAO W W, YAN J C, LI D C. Interfacial reaction of intermetallic compounds of ultrasonic-assisted brazed joints between dissimilar alloys of Ti-6Al-4V and Al-4Cu-1Mg[J]. Ultrasonics Sonochemistry, 2011, 18(5): 1062-1067.

[22] PENG L M, WANG J H, LI H, ZHAO J H, He L H. Synthesis and microstructural characterization of Ti-Al3Ti metal- intermetallic laminate (MIL) composites[J]. Scripta Materialia, 2005, 52(3): 243-248.

[23] QIN Q D, ZHAO Y G, LIU C, ZHOU W, JIANG Q C. Development of aluminium composites with in situ formed AlTiSi reinforcements through infiltration[J]. Materials Science and Engineering A, 2007, 460/461(7): 604-610.

(编辑 龙怀中)

基金项目:省部共建有色金属先进加工与再利用国家重点实验室开放基金项目(skl1309)

收稿日期:2015-02-09;修订日期:2015-05-22

通信作者:马志鹏,副教授,博士;电话:18846282641;E-mail: mazhipeng77@163.com