Effect of sintering temperature and composition on microstructure and properties of PMS-PZT ceramics

DU Hong-liang(杜红亮)1, PEI Zhi-bin(裴志斌)2, LI Zhi-min(李智敏)1, LUO Fa(罗 发)1,

ZHU Dong-mei(朱冬梅)1, ZHOU Wan-cheng(周万城)1, QU Shao-bo(屈绍波)3

1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. College of Science, Air Force Engineering University, Xi’an 710051, China;

3. Key Laboratory of Electronic Materials Research, Ministry of Education, Xi’an Jiaotong University, Xi’an 710049, China

Received 10 April 2006; accepted 25 April 2006

Abstract: The piezoelectric ceramics xPb(Mn1/3Sb2/3)O3-(1-x)Pb(Zr1/2Ti1/2)O3 (abbreviated as PMS-PZT) were synthesized by traditional ceramics process. The effect of sintering temperature and the amount of Pb(Mn1/3Sb2/3)O3 (abbreviated as PMS) on phase structure, microstructure, piezoelectric and dielectric properties of PMS-PZT ceramics was investigated. The results show that the pure perovskite phase is in all ceramics specimens, the phase structure of PMS-PZT ceramics changes from tetragonal phase to single rhombohedral phase with the increasing amount of PMS. The dielectric constant εr, Curie temperature TC, electromechanical coupling factor kp and piezoelectric constant d33 decrease, whereas the mechanical quality factor Qm and dielectric loss tanδ increase with the increasing amount of PMS in system. The optimum sintering temperature is 1 200-1 250 ℃. It is concluded that the PMS-PZT (x=0.07) ceramics sintered at 1 250 ℃ is suitable for high-power piezoelectric transformer. These properties include εr=674.8, tanδ=0.005 25, kp=0.658, Qm=1 520, d33=230 pC/N, Tc=275 ℃.

Key words: PMS-PZT piezoelectric ceramics; piezoelectric properties; dielectric properties; perovskite

1 Introduction

Recently, piezoelectric ceramics used for high- power devices such as transformers, actuators and ultrasonic motors have been extensively studied [1-4]. For these piezoelectric ceramics, it is desirable to combine high mechanical quality factor (Qm) with large planar electromechanical coupling factor (kp) and low dielectric loss (tanδ), as well as high mechanical strength, because these high-power devices usually operate at their resonant frequency in transformation between electrical and mechanical energy[5-7]. Pb(Mn1/3Sb2/3)O3-PbZrO3- PbTiO3 (abbreviated as PMS-PZT) have received special attention as high-power materials applying for transformers and ultrasonic motors because of their excellent physical properties such as high Qm, large kp and high maximum vibration velocity [8-10]. GAO et al [8] reported that PMS-PZT ceramics doped with Eu3+ and Yb3+ introduce combinatory “hard” and “soft” piezoelectric characteristics, which result in significant increases in Qm, d31, and k31. They also found that PMS-PZT modified with 2% Yb (mole fraction) has superior characteristics under high power conditions which suit for acting as a new high-power material.

LONG et al [10] reported that the compositions of 0.05Pb(Mn1/3Sb2/3)O3-0.95Pb(Zr1/2Ti1/2)O3+0.1% Nb2O5 have superior piezoelectric properties (d33=450 pC/N, kp=0.65, Qm=1 210), and are practically suitable for ultrasonic motor applications. However, to the best of our knowledge, the effect of sintering temperature and compositions on phase structure, microstructure and properties of PMS–PZT ceramics was reported very seldom. In this study, PMS–PZT ceramics with different contents of Pb(Mn1/3Sb2/3)O3 (abbreviated as PMS) were prepared by traditional ceramics process. The effect of sintering temperature and the content of PMS on phase structure, microstructure, piezoelectric and dielectric properties was investigated. The results show that 0.07PMS–0.93PZT piezoelectric ceramics is a promising candidate for high-power piezoelectric transformer.

2 Experimental

The specimens in this study were fabricated according to formula: xPb(Mn1/3Sb2/3)O3-(1-x)Pb- (Zr1/2Ti1/2)O3, x=0.06, 0.07, 0.08, 0.09, (respectively abbreviated as PMSZT1, PMSZT2, PMSZT3, PMSZT4). The specimens were prepared by traditional ceramics process. The reagent-grade Pb3O4, ZrO2, TiO2, MnO2 and Sb2O3 powders were acetone-milled for 12h in a zirconia ball mill and then calcined at 850 ℃ for 2 h. The calcined powders were ground, ball-milled again and pressed into disks using PVA as a binder. After burning off PVA, the pellets were sintered in a sealed alumina crucible at different soaking temperature (from 1 100 ℃ to 1 300 ℃) for 2 h. In order to compensate for PbO loss from the pellets, a PbO-rich atmosphere was maintained by placing an equi-molar mixture of PbO and ZrO2 inside the covered alumina crucible.

The bulk density was measured using the Archimedes method. The phase structure of the sintered ceramics was analyzed by using a Rigaku D/Max-2400 diffractometer using Cu Kα radiation. The fractured surfaces were examined by scanning electron microscopy (HITACHI S-2700). The average grain size (diameter) was determined from the number of grains in the fixed area, on the supposition of the grain sphere. The specimens were polished for the dielectric and piezoelectric studies. Silver paste was fired on both sides of the samples at 560 ℃ for 10 min as the electrodes for the dielectric and piezoelectric measurements. The dielectric response was measured at the frequency of 1 kHz using an automatic LCR meter (WK4225) at a temperature range from 50 ℃ to 450 ℃. The samples were poled in 120 ℃ silicon oil bath by applying a DC electric field of 3 kV/mm for 30 min. The piezoelectric constant d33 was measured using a quasi-static d33 meter (Model ZJ-3, Institute of Acoustics Academic Sinica). The specimens were aged for 24 h prior to testing. The piezoelectric properties were measured by the resonance-antiresonance method on the basis of IEEE standards using an impedance analyzer (HP4294A).

3 Results and discussion

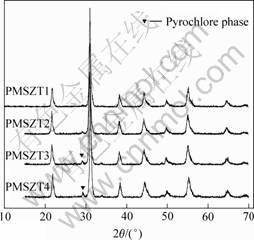

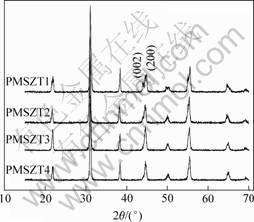

Fig.1 shows the X-ray diffraction patterns of specimens calcined at 850 ℃. When the content of PMS is less than 0.08 mol, only pure perovskite phase exists and no detectable trace of the pyrochlore structure can be found. When the content of PMS is more than 0.08 mol, some pyrochlore phase is found, at the same time, the content of pyrochlore phase increases with the concentration of PMS increasing. This is because PMS can not exit as a stable single phase [8]. Fig.2 shows the XRD patterns of the specimens sintered at 1 250 ℃. The phase structure in all samples sintered at 1 250 ℃ is pure perovskite phase, which shows that the increase of the sintering temperature can eliminate pyrochlore phase. Moreover, it is noted that the peak splitting at (2 0 0) plane position weakens gradually with the concentration of PMS increasing. It is reported that tetragonal and rhombohedral phases are identified by an analysis of the peaks (002) and (200) in the 2θ≈45?. The splitting of (002) and (200) peaks indicates that they are the ferroelectric tetragonal phase (FT), while the single (200) peak shows the ferroelectric rhombohedral phase (FR)[11,12]. Therefore, the phase structure of PMS-PZT ceramics changes from tetragonal phase to single rhombohedral phase with the amount of PMS increasing. There are two possible reasons for weakening of splitting at (200) plane position. Firstly, the incorporation of Mn2+

Fig.1 XRD patterns of powders calcined at 850℃

Fig.2 XRD patterns of ceramics sintered at 1 250 ℃

into B-site of perovskite-structured morphotropic phase boundary (MPB) composition stabilizes the rhombo- hedral phase against tetragonal one [13]. Secondly, the increase of PMS shifts the MPB region towards PbZrO3-rich side at room temperature.

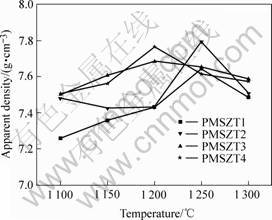

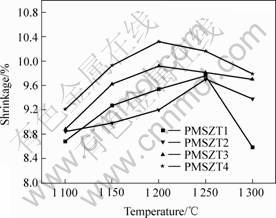

Fig.3 shows the variation of apparent density of PMS-PZT ceramics with the content of PMS and sintering temperature. It can be seen that the apparent density of specimens increases with increasing sintering temperature over the range between 1 100 and 1 200 ℃. The sintering temperature with the maximum density of each specimen is different between 1 200 and 1 250 ℃, the higher the content of PMS is, the lower the sintering temperature is. However, further increasing the sintering temperature above 1 250 ℃ causes a slightly fall in density, which is most likely due to poor densification and an increasing mass loss of PbO (melting point 890 ℃). Fig.4 shows the variation of shrinkage of PMS-PZT ceramics with the content of PMS and sintering

Fig.3 Apparent density of PMS-PZT ceramic as function of sintering temperature

Fig.4 Shrinkage of PMS-PZT ceramic as function of sintering temperature

temperature. The variation of shrinkage is in accordance with the result of apparent density.

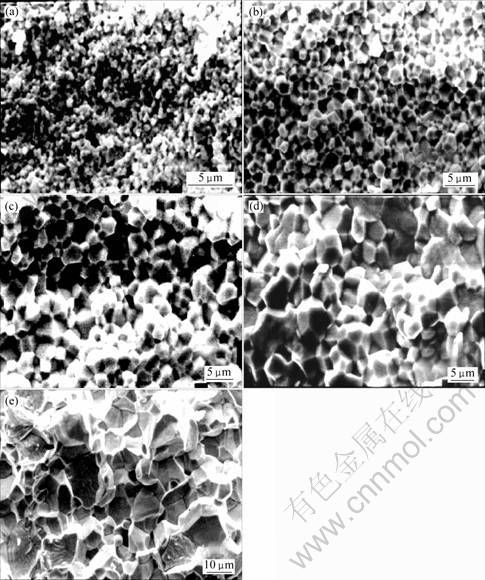

Fig.5 shows the SEM micrographs of the fractured surface of the PMSZT2 specimen with 0.07 mol PMS sintered at 1 100-1 300 ℃ for 2 h. When the sintering temperature increases, the grain size and densification are increased simultaneously. At 1 250 ℃ (Fig.5(d)), a very homogeneous and pore-free structure can be seen. The grain size is about 3.4 μm for PMS-PZT ceramics sintered at 1 250 ℃. However, above sintering temperature of 1 250 ℃, the microstructures become inhomogeneous due to oversize grains appearing, as shown in Fig.5(e). The variation of SEM photographs is in accordance with the result of apparent density and shrinkage. According to above results, it is expected that the optimum sintering temperature of PMS-PZT ceramics is 1 200-1 250 ℃.

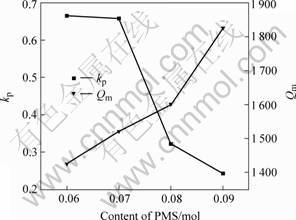

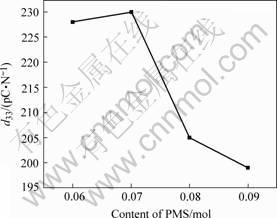

Figs.6 and 7 show respectively kp, Qm and d33 as a function of the content of PMS. With the content of PMS increasing, kp, d33 decrease and Qm increase. There are likely two reasons. First, the previous investigations have demonstrated that PMS ceramics have “hard” piezoelectric characteristics [8]. It is well known that the addition of acceptor dopants improves Qm, while d33 and kp decrease. More and more oxygen vacancies are introduced into PMS-PZT ceramics owing to the increase of the content of PMS, the introduction of oxygen vacancies inhibits the domain wall mobility, which subsequently decreases kp and d33, increases Qm. Second, the phase structure of PMS-PZT ceramics changes from the tetragonal phase to single rhombohedral, with the amount of PMS increasing.

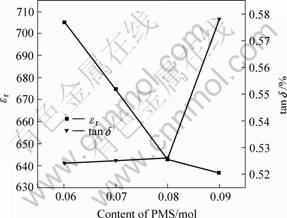

The dielectric properties as a function of PMS content measured at room temperature are plotted in Fig.8. With the content of PMS increasing, εr decreases and tan δ increases gradually, because more oxygen vacancies will be generated to balance the charge, when more Mn2+ are incorporated into B-site of perovskite structure. It is well known that these oxygen vacancies can inhibit the domain or microdomain wall move, therefore, εr decreases and tan δ increase gradually with the content of PMS increasing.

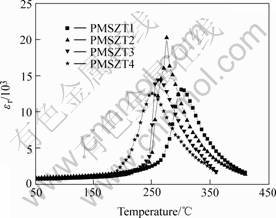

Fig.9 shows Tc as a function of the content of PMS. Pb(Mn1/3Sb2/3)O3 has a low Curie temperature. With increasing of Pb(Mn1/3Sb2/3)O3 addition, the Curie temperature of PMS–PZT ceramics becomes lower and consequently the peak of dielectric spectrum corresponding to the Curie temperature moves toward room temperature as shown in Fig.9.

Fig.5 SEM photographs of fractured surface of PMSZT2 specimen sintered at different temperatures: (a) 1 100 ℃; (b) 1 150 ℃; (c) 1 200 ℃; (d) 1 250 ℃; (e) 1 300 ℃

Fig.6 Variation of kp and Qm of PMS-PZT ceramics with content of PMS

Fig.7 Variation of d33 of PMS-PZT ceramics with content of PMS

Fig.8 Variation of εr and tan δ of PMS-PZT ceramics with content of PMS

Fig.9 Variation of Tc of PMS-PZT ceramics with content of PMS

4 Conclusions

1) PMS-PZT piezoelectric ceramics with pure perovskite phase were synthesized by traditional ceramics process. With the amount of PMS increasing, the phase structure of PMS-PZT ceramics changes from tetragonal phase to rhombohedral phase. The optimum sintering temperature of PMS-PZT ceramics is 1 200 ℃-1 250 ℃.

2) With the increasing amount of PMS in the system, the dielectric constant εr, Curie temperature TC, electro- mechanical coupling factor kp and piezoelectric constant d33 decrease, whereas the mechanical quality factor Qm and dielectric loss tan δ increase.

3) Taking into consideration of kp, Qm, εr, tan δ, TC and sintering temperature, it is concluded that the ceramics (x=0.07) sintered at 1 250 ℃ is a promising material for piezoelectric transformer (εr=674.8, tan δ=0.005 25, kp=0.658, Qm=1 520, d33=230 pC/N, TC=275 ℃).

References

[1] YOO J, YOON K, HWANG S, SUH S, KIM J, YOO C. Electrical characteristics of high power piezoelectric transformer for 28 W fluorescent lamp[J]. Sens Actuators A, 2001, 90: 132-137.

[2] HU J H, LI H L, CHAN H L W, CHOY C L. A ring-shaped piezoelectric transformer operating in the third symmetric extensional vibration mode [J]. Sens Actuators A, 2001, 88: 79-86.

[3] HWANG L, YOO J, JANG E, OH D, JEONG Y, AHN I, CHO M. Fabrication and characteristics of PDA LCD backlight driving circuits using piezoelectric transformer[J]. Sens Actuators A, 2005, 115: 73-78.

[4] VASIC D, SARRAUTE E, COSTA F, SANGOUARD P, CATTAN E. Piezoelectric micro-transformer based on SOI structure [J]. Sens Actuators A, 2005, 117: 317-324.

[5] LI L T, YAO Y J, MU Z H. Piezoelectric ceramics transformer [J]. Ferroelectrics, 1980, 28: 403-406.

[6] HOU Y D, ZHU M K, WANG H, WANG B, YAN H, TIAN C S. Piezoelectric properties of new MnO2-added 0.2 PZN-0.8 PZT ceramics [J]. Materials Letters, 2004, 58: 1508-1512.

[7] YOO J, LEE Y, YOON K, HWANG S, SUH S, KIM J, YOO C. Microstructural, electrical properties and temperature stability of resonant frequency in Pb(Ni1/2W1/2)O3-Pb(Mn1/3Nb2/3)O3-Pb(Zr, Ti)O3 ceramics for high-power piezoelectric transformer [J]. Jpn J Appl Phys, 2001, 40: 3256-3259.

[8] GAO Y K, CHEN Y H, RYU J, UCHINO K, VIEHLAND D. Eu and Yb substituent effects on the properties of Pb(Zr0.52Ti0.48)O3- Pb(Mn1/3Sb2/3)O3 ceramics: development of a new high-power piezoelectric with enhanced vibrational velocity [J]. Jpn J Appl Phys, 2001, 40: 687-693.

[9] ZHU Z G, LI B S, LI G R, ZHANG W Z, YIN Q R. Microstructure and piezoelectric properties of PMS–PZT ceramics [J]. Mater Sci Eng B, 2005, B117: 216-220.

[10] LONG J W, CHEN H Y, MENG Z Y. Effects of compositions and Nb-doping on microstructure and piezoelectric properties of PMS-PZ-/PT system [J]. Mater Sci Eng B, 2003, B99: 445-448.

[11] CHEN C Y, LIN H L. Piezoelectric properties of Pb(Mn1/3Nb2/3)O3- PbZrO3-PbTiO3 ceramics with sintering aid of 2CaO-Fe2O3 compound[J]. Ceramics International, 2004, 30: 2075-2079.

[12] HOU Y D, ZHU M K, WANG H, WANG B, TIAN C S, YAN H. Effects of atmospheric powder on microstructure and piezoelectric properties of PMZN-PZT quaternary ceramics[J]. Journal of the European Ceramic Society, 2004, 24: 3731-3737.

[13] DU H L, QU S B, CHE J, LIU Z Y, WEI X Y, PEI Z B. The effect of composition on microstructure and properties of PNW–PMS–PZT ceramics for high-power piezoelectric transformer [J]. Mater Sci Eng A, 2005, A393: 36-41.

(Edited by YUAN Sai-qian)

Foundation item: Project (10474077) supported by the National Natural Science Foundation of China

Corresponding author: DU Hong-liang; Tel: +86-29-88488007; Fax: +86-29-88494547; E-mail: duhongliang@126.com