非均相沉淀-热还原法制备金属镍包裹氧化铝球形微粉

李旺兴1, 2, 刘业翔1

(1. 中南大学 冶金科学与工程学院, 长沙 410083;

2. 中国铝业股份有限公司 郑州研究院, 郑州 450041)

摘 要: 利用非均相沉淀包裹技术, 在室温下的水溶液中, 以球形碱式碳酸铝铵(AACH)、 硫酸镍和碳酸氢铵为原料, 制备了金属镍包裹氧化铝球形微粉前驱体, 即碱式碳酸镍(NCH)包裹碱式碳酸铝铵微粉。 然后, 将前驱体在500℃下用氢气还原, 成功制备了表面光滑、 致密的金属镍包裹氧化铝球形微粉。 研究了在非均相沉淀过程中, 被包裹碱式碳酸铝铵微粉粉体浓度、 硫酸镍和碳酸氢铵加料速度、 反应时间、 表面活性剂等因素对复合粉体前驱体制备的影响, 利用SEM、 EDS、 XRD等手段表征了复合粉体前驱体及还原产物的表面及切面形貌、 成分和结构。

关键词: 非均相沉淀; 包裹氧化铝; 复合材料; 金属镍 中图分类号: TB333

文献标识码: A

Preparation of nickel-coated Al2O3 spherical micro-powders by heterogeneous precipitation-thermal reduction process

LI Wang-xing1, 2, LIU Ye-xiang1

(1. School of Metallurgical Science and Engineering, Central South University,Changsha 410083, China;

2. Zhengzhou Research Institute of Chalco, Zhengzhou 450041, China)

Abstract: Nickel carbonate hydroxide(NCH)-coated spherical ammonium aluminum carbonate hydroxide(AACH) powders as the precursor of nickel-coated alumina spherical micrometer powders were prepared at room temperature by the aqueous heterogeneous precipitation method using nickel sulfate, ammonium bicarbonate solutions and spherical AACH powders as the major starting materials. The effects of the concentration of spherical AACH powders, rate of pumping nickel sulfate and ammonium bicarbonate solutions, reaction time, surface active reagent etc on coating of NCH on AACH were examined respectively. Uniform nickel-coated alumina micro-powders were successfully produced by reducing the as-prepared NCH-coated AACH precursors in H2 atmosphere at 500℃ for 2h and the coating thickness of NCH or the resultant Ni thickness can be tailored by controlling the precipitating factors. The powders obtained were characterized by scanning electron microscopy(SEM), energy dispersive spectroscopy(EDS) and X-ray diffraction(XRD).

Key words: heterogeneous precipitation; Ni-coated Al2O3; composite materials; Ni

氧化铝陶瓷在耐磨、 耐腐蚀、 耐高温、 抗氧化等方面表现出优良的性能, 因而获得了广泛的应用, 但氧化铝陶瓷所固有的脆性在很大程度上限制了其在工程领域的应用范围。 陶瓷/金属结构复合增韧是近年来研究较多的一种氧化铝陶瓷增韧方式。 目前常用的氧化铝陶瓷/金属复合方法是粉末冶金法[1-4]、 原位合成法[5]和熔融浸渍法[6]等。 这些方法虽然制备工艺简单, 容易实现规模化, 但制备的复合材料只发生部分陶瓷相和金属相之间的接触, 不能获得均匀的显微结构, 烧结后, 仍有相当数量的陶瓷粉体直接接触并保持原有的硬性结合状态, 金属相仅能承担有限的外加载荷。

球形包裹结构粉体具有流动性好、 易分散、 烧结过程中各向反应特性相同, 晶粒生长一致, 可以大大提高显微结构的均匀性, 使氧化铝陶瓷粉体能在最大程度上均匀分布在金属三维结构中[7], 拓宽材料的基体组织结构和与之相关的其他性能[8, 9]。 化学镀[10, 11]和溶胶-凝胶法[8]是目前使用较成功的制备包裹粉体的方法, 但分别存在制备工艺流程复杂、 难控制、 成本高等缺点。 有些学者则利用非均相沉淀包裹技术来制备金属包裹氧化铝结构复合粉体, 如Voytovych[12], 李国军[13], Oh[14]等分别利用该法制备了Y/Al2O3、 Ni/Al2O3、 FeNi/Al2O3包裹结构粉体。 这种方法不仅克服了上述两种方法的缺点, 并已初步证明是制备包裹材料的有效方法。 但由于他们均采用形貌不规则的氧化铝作为包裹核心, 未能对包裹颗粒形貌进行控制, 因而包裹的均匀性和完整性并不理想。 本文作者采用球形碱式碳酸铝铵(AACH)微粉作为包裹核心, 外面包裹一层碱式碳酸镍(NCH), 制备了NCH包裹AACH复合粉体, 经过氢气还原获得了球形Ni/Al2O3包裹结构复合微粉。

1 实验

1.1 主要原料

硫酸镍(NiSO4·6H2O, AR), 碳酸氢铵(NH4HCO3 AR), 聚乙二醇(PEG400); 球形碱式碳酸铝铵(NH4AlO(OH)HCO3, 由中国铝业股份有限公司提供), 粒径分布在5~15μm。

1.2 实验过程

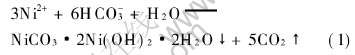

包裹粉体的制备流程如图1所示。 首先以去离子水配制0.5mol/L的硫酸镍溶液A和1.0mol/L的碳酸氢铵溶液B。 向pH=8的碳酸氢铵溶液C(作为母液, 体积5L)中加入一定量的AACH粉体(10g/L或15g/L), 在连续搅拌下将A和B通过计量泵连续缓慢滴加到母液C中, 在悬浮液中发生如下反应[15]:

为了尽量减少镍盐的流失, 控制溶液pH值为8, 在室温下反应一定时间, 可以观察到反应体系中白色AACH微粉随着绿色NCH包裹层厚度的增加由白色逐渐变绿直至深绿色。 将沉淀物过滤、 多次洗涤, 在空气中60~80℃下干燥10~12h, 即得到NCH包裹AACH复合微粉。 利用程控管式炉(SX-77-16, 上海才兴高温元件电炉厂生产)将AACH/NCH复合粉体在N2/H2(体积比10∶1, H2流速80mL/min)混合气体中于500℃还原2h即得到Ni包裹Al2O3复合微粉。

图1 Ni包裹Al2O3复合微粉制备流程图

Fig.1 Flow chart for preparation of nickel-coated alumina microspheres

1.3 测试与表征

采用日本Jeol公司JSM-5600LV扫描电子显微镜(SEM)和能量发散能谱(EDS)表征Al2O3/Ni包裹结构复合材料及前驱体的表面形貌和成分; 利用日本理学 D/max-rA X射线衍射仪(CuKα)分析前驱体及还原产物的物相组成。

2 结果与讨论

2.1 NCH包裹AACH复合微粉的制备

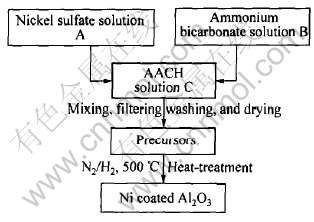

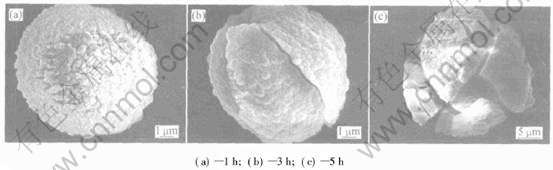

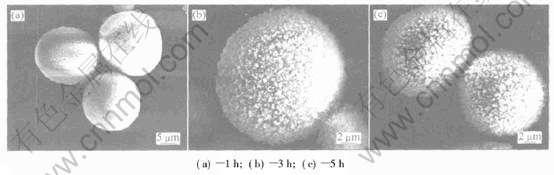

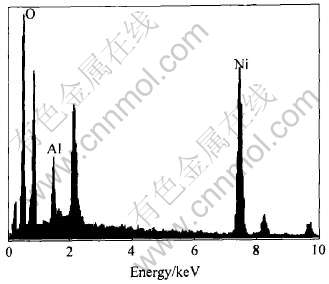

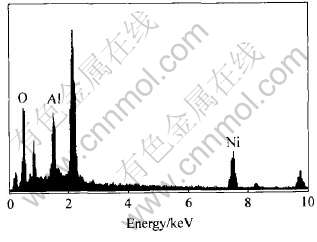

图2所示为在AACH颗粒浓度10g/L、 反应物(硫酸镍及碳酸氢铵)加料速度5mL/min、 未加表面活性剂(聚乙二醇PEG)的情况下不同反应时间的包裹粉体形貌。 由图2可见, 粉体颗粒的包裹层较致密, 表面晶粒粗大, 且反应5h后包裹层厚度已达4~5μm, 但产生严重开裂。 图3(a)和(b)所示分别为图2(c)所示颗粒核心和表面的能谱图。 由图3可以看出, 颗粒核心几乎不含镍成分, 而表面层几乎由镍盐(NCH)组成, 说明这是一种典型的包裹结构(Al、 O、 Ni峰以外的峰均为电镜样品台产生的杂峰, 下同)。 包裹层的开裂将引起包裹层的脱落, 从而无法形成均匀完整的NCH/AACH包裹微粉。 针对颗粒表面晶粒粗大、 包裹层开裂的问题, 本文作者对颗粒浓度(被包裹粉体 AACH浓度)、 加料速度、 反应时间及添加表面活性剂等因素进行了研究。

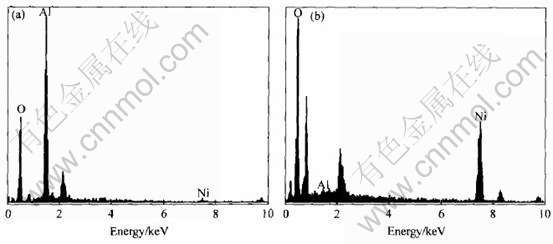

图4所示为在AACH颗粒浓度15g/L、 硫酸镍及碳酸氢铵加料速度2.5mL/min、 加表面活性剂(PEG)5mL/L情况下不同反应时间的包裹粉体的形貌。 图5所示为反应时间为1h时的表面能谱。 由图可见, 包裹反应1h后, 粉体颗粒表面较光滑致密, 表面晶粒细小, 同时由图5 Ni/Al峰强比可以确定母粒子AACH表面已被NCH包裹, 只是由于包裹厚度较小, EDS能谱中仍能看到Al峰; 随着反应时间的延长, 颗粒表面变得较为疏松, 未发现包裹层开裂。

图2 不同反应时间下包裹粉体的形貌

Fig.2 Morphologies of coated microspheres with different reaction time

图3 包裹粉体核心和表面能谱图

Fig.3 EDS data for core(a) and shell(b) of coated microspheres

图4 改善条件后不同反应时间下包裹粉体的形貌

Fig.4 Morphologies of coated microspheres with different reaction time under optimized preparative conditions

图5 反应1h后包裹粉体的表面能谱

Fig.5 EDS data for coated microspheres after 1h under optimized preparative conditions

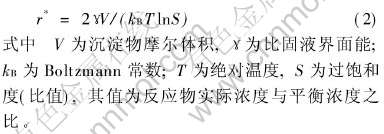

上述NCH包裹AACH过程实际上包括反应结晶与非均相沉淀两个反应过程, 具体包括溶液混合→反应结晶→异相成核→聚集长大等步骤。 根据反应沉淀结晶理论[16], 在反应成核过程中存在着临界晶核, 只有半径r 大于临界晶核半径r*的晶胚, 才能继续生长, 以降低自由能, 并最终形成稳定晶核; 而r〈r*的晶胚则将溶解。 r*的表达式为

可见, 在常温下, 临界晶核的大小主要由过饱和度S 和固液界面能γ控制。 因此, 提高过饱和度和降低固液界面能均能使r* 减小, 有利于提高形核速度和细化晶粒。 NCH晶粒的细化有利于获得细晶金属镍包裹的氧化铝复合粉体, 晶界的大量增加可能降低NCH包裹层与基体AACH之间以及NCH晶粒之间的界面张力, 从而减少包裹层产生裂纹的可能性。

然而, 根据非均相沉淀理论[17], 在悬浮体系中, 表面异相成核制备复合粒子需要控制过程中许多种影响因素。 首先, 由于范德华力的影响, AACH容易与新生的NCH晶核形成牢固的团聚体而很难再分散, 故可通过添加表面活性剂(PEG)使被包覆的粒子AACH在液相中始终保持稳定的分散性, 自身不产生团聚。 其次, 根据Jonghe等[18]关于异相成核的观点, 只有沉淀反应物(溶质)的过饱和浓度小于均相成核所需的临界值Chomo并大于临界晶核溶解所需的临界值Cs, 才能保证溶质离子在固相表面发生异相形核, 否则将产生游离沉淀物或沉淀溶解。 因此在NCH/AACH包裹反应过程中, 有必要控制反应物的过饱和浓度, 使之处于NCH非均相成核区域内。 在NCH包裹AACH微粉制备过程中, 将两种反应物通过计量泵同时缓慢地滴加到反应器中, 通过对溶液pH及Ni离子浓度的控制来实现对反应物过饱和浓度的控制, 并在机械搅拌作用下利用湍流扩散和颗粒表面磨擦使新形成的NCH晶粒细小、 均匀。 第三, 在悬浮液中, 新生成的晶粒在降低表面能的热力学驱动力作用下, 容易与其它已有粒子发生聚集生长, 而且新生晶粒在粗糙界面上的生长速率远大于光滑界面。 本实验首先在溶液中加入了微观表面粗糙的AACH球形微粉, 为NCH提供了容易降低新相表面自由能的结晶场所, 有利于NCH晶粒在AACH上的沉淀和聚集生长。 因此通过控制适当的AACH浓度, 可保证反应在足够的异相成核区域中进行, 实现均匀完整的包裹。 在其他条件一定的情况下, NCH包裹层的厚度随反应时间的延长而增加, NCH包裹层或金属镍包裹层的厚度可以通过调节反应时间来控制。 但随着NCH厚度的增加, 包裹粒子有产生裂纹的趋势, 这可能是因为NCH与AACH存在晶体结构或热膨胀系数差异, 在加热干燥时使包裹层内外受到不同的热应力而产生开裂。

在NCH包裹AACH颗粒过程中, 表面活性剂(PEG)也起了重要作用[19]。 通常情况下, 固态微细粉体在水溶液中存在时, 颗粒之间受范德华力、 库仑静电引力、 磁场力以及表面大量吸附水、 配位水的毛细作用, 使粒子在溶液中容易产生团聚, 因此需要加入一些高分子表面活性剂来减小这一作用。 PEG分子只含有醚基和羟基两种亲水基团, 而无疏水基, 其分子链在水溶液中呈蛇形。 大分子链上大量醚键(—O—)与AACH表面的—OH基形成氢键包覆于粒子表面, 在颗粒表面形成一层大分子亲水保护膜, 使颗粒表面的水化斥力作用范围大大增加, 起到空间位阻效应, 抑制同类粒子之间的团聚。 此外, 吸附在AACH表面的PEG分子有可能会降低AACH的表面自由能, 使新生NCH晶核更容易沉积在AACH表面, 促进了包裹。 但由于在新生成的部分NCH晶核表面也同样会被PEG包覆, 且随着包裹厚度的增加, 新相粒子受母粒子AACH的影响逐渐减小, 所以新形成的NCH粒子之间开始变得疏松, 如图4(b)和(c)所示, 从而缓解了颗粒包裹层的表面张力, 避免产生裂纹。

2.2 Ni包裹Al2O3复合微粉的制备

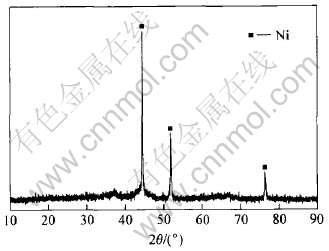

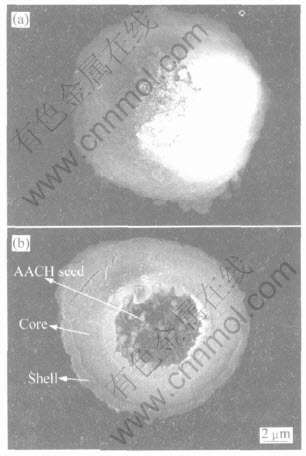

图6所示为在优化条件(AACH浓度15g/L, 加料速度2.5mL/L, 反应时间1h, 表面活性剂5mL/L)下获得的NCH包裹AACH前驱体经500℃氢气还原2h后产物的XRD谱。 由图可以看出, 前驱体粉体经500℃氢气还原2h后, NCH已完全转变为金属镍相, 而由于热处理温度较低, AACH只转变为无定形氧化铝。 图7所示为Al2O3/Ni包裹结构复合粉体的表面能谱图。 图8所示为其表面及切面形貌(其中最内层核心为制备AACH时所使用的AACH晶种)。 由图可见, 氢气还原后的复合粉体的表面仍存在连续、 致密的包裹层, 厚度达500nm左右, EDS能谱图中Al峰的出现仍然是由于镍包裹层较薄所致。 因此, NCH包裹AACH前驱体通过氢气还原, 能够成功制备金属镍包裹氧化铝结构复合微粉。 这种复合微粉可应用于制备氧化铝/金属镍复合材料, 对改善金属镍在氧化铝陶瓷相间三维结构的均匀分布, 从而提高氧化铝陶瓷的韧性具有重要意义。 同时本研究所开发出的金属镍包裹氧化铝陶瓷微球复合微粉制备技术对其他类似体系的制备也有借鉴作用。

图6 AACH/NCH还原产物的XRD曲线

Fig.6 XRD pattern for reduced product from AACH/NCH

图7 Ni包裹Al2O3复合微粉的表面能谱

Fig.7 EDS spectrum of nickel-coated alumina microspheres

图8 Ni包裹Al2O3复合微粉的表面及切面图

Fig.8 Morphologies for surface(a) and intersection(b) of Ni-coated alumina microspheres

3 结论

以硫酸镍、 碳酸氢铵、 球形碱式碳酸铝铵微粉为原料, 在水溶液中于室温下采用非均相沉淀包裹技术制备了金属镍包裹氧化铝球形微粉前驱体, 即NCH包裹AACH微粉。 通过控制颗粒浓度、 加料速度、 反应时间以及添加表面活性剂等工艺参数, 在优化条件(AACH浓度15g/L, 加料速度2.5mL/min, 反应时间1h, 表面活性剂5mL/L)下获得了较为理想的包裹结构复合粉体前驱体。 将此前驱体在氢气气氛下, 于500℃还原2h, 成功制备了球形Ni/Al2O3包裹结构复合微粉。 这种包裹结构复合材料将有利于改善氧化铝/金属镍复合结构陶瓷的力学性能。

REFERENCES

[1]Rhee O W, Lee H Y, Lkang S J. Diffusion induced grain-boundary migration and mechanical property improvement in Fe-doped alumina[J]. J Eur Ceram Soc, 2003, 23(10): 1667-1674.

[2]晏泓, 许并社. 纳米α-Al2O3/W复合粉体的制备[J]. 无机材料学报, 2003, 18(5): 1127-1130.

YAN Hong, XU Bing-she. Preparation of α- Al2O3/W nanocomposite powders[J]. J Inorganic Materials, 2003, 18(5): 1127-1130.

[3]王永庆, 周科之. 金属铜颗粒对氧化铝陶瓷抗热震行为的影响[J]. 佛山陶瓷, 2000, 10(6): 5-7.

WANG Yong-qing, ZHOU Ke-zhi. The effects of copper powders on thermal shock behavior of alumina ceramics[J]. Foshan Ceramics, 2000, 10(6): 5-7.

[4]Dyaz L A, Valdes A F, Dyaz C, et al. Alumina/molybdenum nanocom posites obtained in organic media[J]. J Euro Cera Soc, 2003, 23(15): 2829 -2834.

[5]Osso D, Tillement O, Lecaer G, et al. Alumina-alloy nanocomposite powders by mechanosynthesis[J]. J Mater Sci, 1998, 33(12): 3109-3119.

[6]刘政, 刘小梅, 朱应禄, 等. 低浸渗压力制备氧化铝/锌合金复合材料[J]. 矿冶, 1998, 7(2): 49-67.

LIU Zheng, LIU Xiao-mei, ZHU Ying -lu, et al. Fabrication of alumina/zinc alloy composites at low infiltration pressure[J]. Ming and Metallurgy, 1998, 7(2): 49-67.

[7]Kishimoto S, Shinya N. Development of metallic closed cellular materials containing polymers[J]. Mater Des, 2000, 21(6): 575-578.

[8]Bhattacharya P, Chattopadhyay K. Nano Al2O3-Pb and SiO2-Pb cermets by sol-gel technique and the phase transformation study of the embedded Pb particles[J]. Nano Structured Materials, 1999, 12(5-8): 1077-1080.

[9]卢金山, 高濂, 归林华, 等. Al2O3/Ni包裹粉体的制备、 烧结行为及其显微结构研究[J]. 无机材料学报, 2001, 16(2): 277-282.

LU Jin-shan, GAO Lian, GUI Lin -hua, et al. Preparation, sintering behavior and microstructure of Al2O3-coated Ni powders[J]. J Inorganic Materials, 2001, 16(2): 277-282.

[10]Kima S S, Kim S T, Ahn J M, et al. Magnetic and microwave absorbing properties of Co-Fe thin films plated on hollow ceramic microspheres of low density[J]. J Magn Magn Mater, 2004, 271(1): 39-45.

[11]王宇, 张骁勇, 毛丽, 等. 空心玻璃微珠化学镀银的研究[J]. 材料科学与工程学报, 2004, 22(5): 753-756.

WANG Yu, ZHANG Xiao-yong, MAO Li, et al. Studies of electroless silver plating on cenospheres[J]. J Mater Sci Eng, 2004, 22(5): 753-756.

[12]Voytovych R, Maclaren I, Gulgun M A, et al. The effect of yttrium on densification and grain growth in α-alumina[J]. Acta Materialia, 2002, 50(13): 3453-3463.

[13]李国军, 赵世柯, 黄校先, 等. Ni包裹Al2O3复合粉体的制备[J]. 无机材料学报, 2002, 17(2): 235-240.

LI Guo-jun, ZHAO Shi-ke, HUANG Xiao-xian, et al. Preparation of nano-Ni-coated-Al2O3 composite powder[J]. J Inorganic Materials, 2002, 17(2): 235-240.

[14]Oh S T, Seok N K, Lee J S. Synthesis and magnetic properties of a Fe-Ni alloy dispersed Al2O3 nanocomposite powder prepared by a chemical method[J]. J Mater Sci Lett, 2002, 21(4): 275- 277.

[15]李亚栋, 李成韦, 段镶锋, 等. 混合溶剂中纳米级NiO的制备及表征[J]. 中国科技大学学报, 1997, 27(3): 346-349.

LI Ya-dong, LI Cheng-wei, DUAN Xiang-feng, et al. Preparation of nanocrystalline NiO in mixed solvent[J]. J China University of Science and Technology, 1997, 27(3): 346-349.

[16]彭美勋. 球形氢氧化镍的微结构形成机理与电化学性能.博士学位论文[D]. 长沙: 中南大学, 2004. 54-61.

PENG Mei-xun. Formation Mechanism of the Microstructures and the Electrochemical Performance for Spherical Nickel Hydroxide[D]. Changsha: Central South University, 2004. 54-61.

[17]安胜利, 宋希文, 赵文广. 湿化学法制备氧化物超微粉体的基本原理[J]. 包头钢铁学院学报, 2000, 19(2): 107-110.

AN Sheng-li, SONG Xi-wen, ZHAO Wen-guang. Chemical principles on preparation of ultra fine oxide powders[J]. J Baotou University of Iron and Steel Technology, 2000, 19(2): 107-110.

[18]Jonghe D, Kapolnek, De L C. Particulate composites from coated powders[J]. J Euro Ceram Soc, 1992, 7(4): 345-351.

[19]贾晓林, 钟香崇. 聚乙二醇在MgAl2O4前驱体表面的吸附及改性作用[J]. 中国粉体技术, 2004, 10(5): 12-15.

JIA Xiao-lin, ZHONG Xiang-chong. Effect of PEG on absorption state and surface mordification of MgAl2O4 precursor[J]. China Powder Science and Technology, 2004, 10(5): 12-15.

(编辑何学锋)

收稿日期: 2005-04-15; 修订日期: 2005-08-15

作者简介: 李旺兴(1962-), 男, 教授级高级工程师, 博士

通讯作者: 李旺兴, 教授级高级工程师; 电话: 0371-68918280; E-mail: wx_li@chalco.com.cn