Trans. Nonferrous Met. Soc. China 26(2016) 431-436

Segregation of niobium in laser cladding Inconel 718 superalloy

Yi-tong LONG, Pu-lin NIE, Zhu-guo LI, Jian HUANG, Xiang LI, Xin-mei XU

Shanghai Key Laboratory of Materials Laser Processing and Modification, Shanghai Jiao Tong University, Shanghai 200240, China

Received 22 March 2015; accepted 11 September 2015

Abstract: Inconel 718 superalloy is widely used in the aerospace and turbine industry. Segregation of niobium appears in the laser cladding Inconel 718 superalloy and consequently influences the phase transformation during the rapid solidification. In order to control the microstructure and improve the mechanical properties of the deposited coating, the the influence of solidification conditions on the segregation of niobium and the resultant formation of Nb-rich Laves phase was studied using the microstructure observation and EDS analysis. The results show that the cooling rate has considerable influence on the microstructure of the deposited coating. High cooling rate is beneficial for suppressing the segregation of Nb and reducing the formation of Laves phase, which is believed to be detrimental to the performance of the Inconel 718 alloy.

Key words: Inconel 718 superalloy; segregation of niobium; laser cladding; cooling rate

1 Introduction

Inconel 718 alloy is a Nb-bearing nickel-based superalloy with high yield, tensile and creep-rupture properties at medium temperature. The element of Nb has a significant influence on the formation of the phases in the superalloy, e.g., γ (Ni3Nb, DO22 structure), δ (Ni3Nb), carbide ((Ti/Nb)C), and Laves ((Ni, Fe, Cr)2(Nb, Mo and Ti)) phases [1-3]. Therefore, the redistribution of Nb during the solidification has a critical effect on the transformation of the solidified microstructure and the resultant performance of the alloy. Traditionally, Inconel 718 alloy components are fabricated by thermal processing, such as cast, wrought and welding. With the development of the modern technology, many new processes have been used in the fabrication of the components by Inconel 718 alloy. One of the most promising technologies is laser cladding [4-7], which is a process that uses a high-power laser source to melt the powder or wire feedstock materials to form a coating on the substrate with a low dilution. The microstructure of the laser cladding Inconel 718 is composed of Nb-rich Laves phase, which contains more than 20% Nb, and γ phase [8,9].

Similar to the welded Inconel 718 alloy, the segregation of Nb widely appears in the laser cladding Inconel 718 alloy and results in a precipitation of Nb-rich Laves phase, which is believed to be detrimental to the performance of the Inconel 718 alloy [10,11]. The reduction of the segregation of Nb is critical to the control of the precipitation of Laves phase for improving the performance of the Inconel 718 alloy. In the past decades, several works have been employed to study the suppression of the Laves phase. For example, ANTONSSON and FREDRIKSSON [12] used a self-designed levitation casting technique to obtain a super rapid cooling rate, which is up to 20000 °C/s for suppressing the segregation of Nb in the solidified Inconel 718 alloy. RADHARKRISHNA and RAO [13] reported that the degree of segregation of Nb in beam welding (EBW) Inconel 718 alloy is reduced considerably compared with that in the gas tungsten arc welding (GTAW) superalloy 718 due to a higher cooling rate obtained in the EBW process. All those previous works show that the segregation of Nb is strongly influenced by the cooling rate of the alloy during the solidification from liquidus to solidus states. Therefore, a full understanding of the segregation of Nb during solidification is highly appreciated.

The present work investigated the segregation of Nb and the resultant formation of Laves phase in laser cladding Inconel 718 alloy. The influence of the solidification conditions, i.e., cooling rate, on the solidified microstructure is discussed via the microstructure observation and EDS analysis. The variation of the morphology of microstructure with respect to the solidification condition is also discussed via the determination of the cooling rate in the deposited alloy during the solidification by secondary dendrite arm spacing. The work presented herein offers a comprehensive understanding of the microstructure development during the solidification of Nb-bearing nickel-based superalloy fabricated by laser cladding. It is firmly believed that this work is useful for research that aims to improve the performance of the Inconel 718 alloy by controlling Laves phase particles in the laser cladding and other thermal processing.

2 Experimental

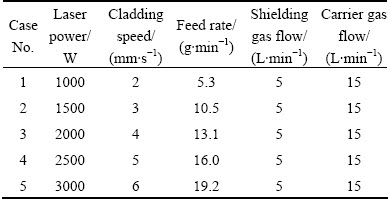

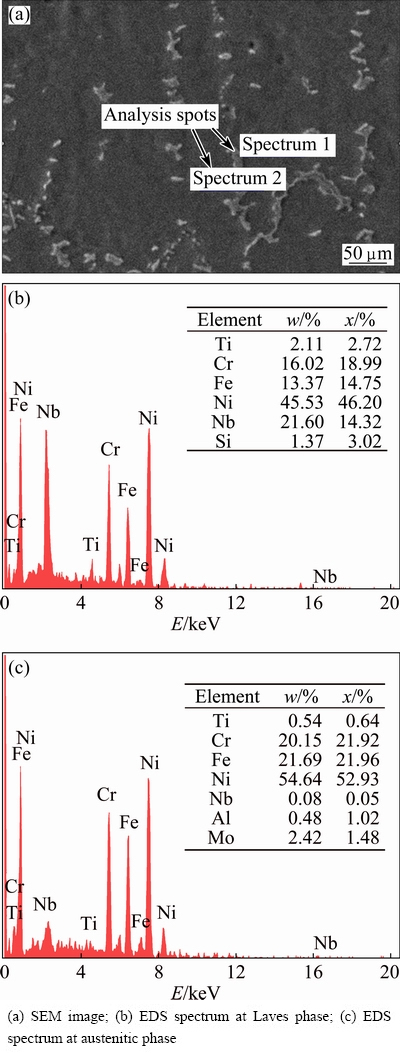

A 3.5 kW diode laser (Rofin DL-035Q) equipped with a coaxial powder feed nozzle was used in the laser cladding process. The processing parameters used in the present work are shown in Table 1. The linear energy, which is the ratio of laser power to cladding speed, is fixed to be 500 J/mm. The spherical Inconel 718 powder with a diameter of ~100 μm was used in the cladding process. Pure argon was used as the carrier and shielding gas. The substrate for deposition was also Inconel 718 alloy. The chemical compositions of the alloy powder, substrate and cladding are listed in Table 2.

Table 1 Processing parameters of laser cladding

Table 2 Chemical compositions of powder and substrate (mass fraction, %)

The deposited specimens of Inconel 718 alloy were etched by a Kalling’s reagent (50 mL HCl, 50 mL ethanol and 2.5 g CuCl2) and investigated micro- structurally with optical microscopy and field emission scanning electron microscope (FESEM). The phase identification and element distribution in the claddings were analyzed using energy-dispersive X-ray spectrometry (EDS). The influence of the solidification condition on the microstructure of the coating was discussed based on the observation of the microstructure.

3 Results and discussion

3.1 Microstructure of laser cladding Inconel 718 alloy

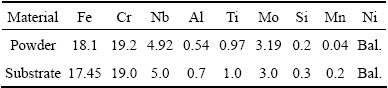

Due to the nature of rapid solidification, the deposited specimens show a typical dendritic microstructure in the cross section of the samples (Fig. 1). However, the morphology of the dendrite is influenced by the laser processing parameters. It can be seen that the equiaxed-dendrite appears in the low laser power and cladding speed case (Figs. 1(a) and (b)), while the columnar dendrite appears in the high laser power and cladding speed case (Figs. 1(i) and (j)). In the intermediate laser power and cladding speed case (Figs. 1(c) to (f)), the columnar dendrite appears in the lower zone of the cross section of the deposited coating, while the equiaxed dendrite in the upper zone. There is a transition zone of the dendritic structure from columnar to equiaxed morphology. In summary, the variation of the morphology in Fig. 1 reflects the change of the solidification condition with respect to the laser processing details in Cases 1 to 5 (Table 1).

Based on the solidification theory, the morphology of the dendrite is determined by the ratio of the temperature gradient (G) to the growth rate (R). Equiaxed growth of the dendrite occurs at a low G/R ratio, while columnar growth takes place at a high G/R ratio [14].  et al [15] formulated the columnar to equiaxed transition in the laser deposition of superalloys using a ratio of G3.4/V, where V is the solidification velocity of the columnar front. The study showed that the structure of the deposited alloy is dominated by columnar dendrite as G3.4/V>2.7×1024 (K3.4/(m4.4·s)). In contrast, the structure is dominated by equiaxed dendrite as G3.4/V<2.7×1024 (K3.4/(m4.4·s)). In addition, NIE et al [16] investigated the dependence of the growth mode of the dendrites in Inconel 718 alloy on the cooling rate by a simulation, which showed that the dendrite transforms from a columnar to equiaxed morphology with respect to an increase in the cooling rate at a fixed temperature gradient.

et al [15] formulated the columnar to equiaxed transition in the laser deposition of superalloys using a ratio of G3.4/V, where V is the solidification velocity of the columnar front. The study showed that the structure of the deposited alloy is dominated by columnar dendrite as G3.4/V>2.7×1024 (K3.4/(m4.4·s)). In contrast, the structure is dominated by equiaxed dendrite as G3.4/V<2.7×1024 (K3.4/(m4.4·s)). In addition, NIE et al [16] investigated the dependence of the growth mode of the dendrites in Inconel 718 alloy on the cooling rate by a simulation, which showed that the dendrite transforms from a columnar to equiaxed morphology with respect to an increase in the cooling rate at a fixed temperature gradient.

The growth of dendrite influences the evolution of the microstructure in the alloy, such as the segregation of the alloy elements and the formation of the phase during the solidification. NIE et al [16] found that the columnar dendrite is beneficial for the formation of a long chain morphology of the Laves phase in Inconel 718 alloy, while equiaxed dendrite is beneficial for the formation of a discrete morphology of the Laves phase. This is due to the dependence of the phase transition on the segregation of Nb, which is a critical element for the formation of eutectic phase (Laves phase) in Inconel 718 alloy, under different dendrite growth modes. All those previous works showed that the microstructure of the alloy is strongly influenced by the solidification conditions, and it is possible to control the microstructure by optimizing the solidification condition via the change of the processing details, such as laser power and cladding speed.

Fig. 1 Microstructures of laser cladding Inconel 718 alloy in Case 1 (a, b), Case 2 (c, d), Case 3 (e, f), Case 4 (g, h) and Case 5 (i, j)

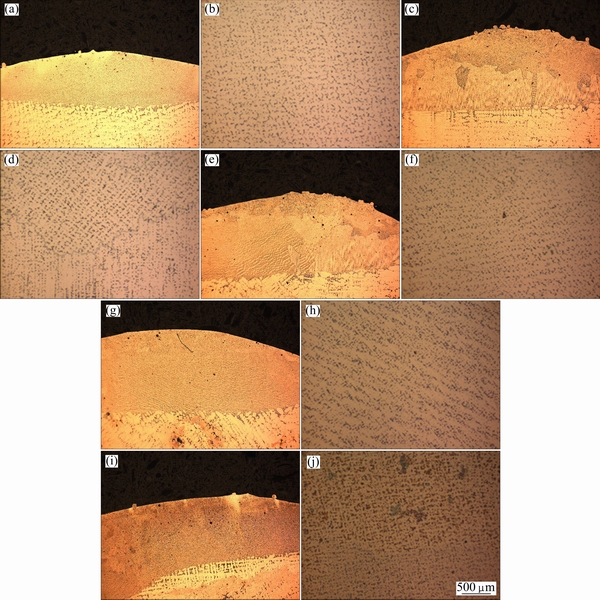

In this work, the phase in the alloy is determined by EDS analysis. The elements of Fe, Ni, Cr, Nb, Al, Ti, Mo and Si were determined in the EDS spectra (Fig. 2). In particular, the content of Nb in the interdendritic precipitate, which is determined as Laves phase, is as high as 21.6%; in contrast, the content of Nb in austenitic matrix, which is γ phase, is as low as 0.08%. The average content of Nb in the Inconel 718 superalloy is about 5.0% (Table 2). Therefore, the segregation of Nb appears in the solidified Inconel 718 alloy. DUPONT et al [17] investigated the solute redistribution and microstructural development in the fusion welds of Nb-bearing superalloy. The work revealed that the transformation of phase in Nb-bearing surperalloy during solidification is controlled by the segregation of Nb. NIE et al [16] further showed that a high concentration of Nb in the interdendritic location is beneficial for the formation of Nb-rich Laves phase. The solidification condition has great effect on the formation of those high concentration spots during the solidification, and consequently influences the formation of Laves phase at those spots. In the subsequent section, the solidification conditions under different laser processing details are determined.

Fig. 2 SEM image and EDS spectra of Inconel 78 alloy

3.2 Solidification conditions under different laser processing details

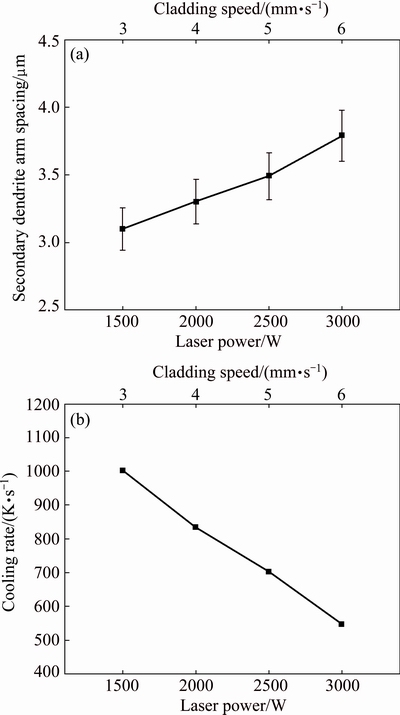

Based on the solidification theory, the cooling rate of the materials during the solidification can be determined by the secondary dendrite arm spacing by using the equation [18]: λ2=a(G×R)-n, where λ2 is secondary dendrite arm spacing, a and n are constants defined as 31 and 1/3, respectively [19]. Figure 3(a) and (b) respectively show the secondary dendrite arm spacing and calculated cooling rates of the laser cladding Inconel 718 alloy corresponding different processing cases. It can be seen that the cooling rate increases with respect to the decrease of the laser energy and cladding speed. The simulation work in Ref. [20] also shows a similar decreasing tendency of the cooling rate with respect to the increase of laser power and cladding speed under a fixed linear energy condition.

Fig. 3 Secondary dendrite arm spacing (a) and calculated cooling rates (b) under different laser processing cases

Small secondary dendrite arm spacing under low laser power and cladding speed is highly appreciated, because a fine size of the microstructure is beneficial for improving the mechanical properties of the coating according to the Hall-Petch theory. In addition, the small secondary dendrite arm spacing is also beneficial for suppressing the formation of the coarse long-chain Laves phase, which is prone to induce the hot cracking during the solidification of the alloy, by separating the remaining high Nb concentration liquid zone into several small isolated liquid spots at the end stage of solidification [16]. So, the optimization of the morphology of the microstructure is also very important for improving the performance of the solidified alloy, besides the control of the volume fraction of the Laves phase. Although the homogenization heat treatment can be applied to removing Laves phase [21,22], the hot cracking induced in the solidification cannot be eliminated by those postal heat treatments.

The above analysis shows that the solidification condition, such as cooling rate, is influenced by the laser processing details, i.e., the laser energy and cladding speed. The change of the solidification will consequently influence the evolution of the microstructure during the solidification, including the change of dendrite morphology (Section 3.1), segregation of Nb and the resultant formation of Nb-rich Laves phase.

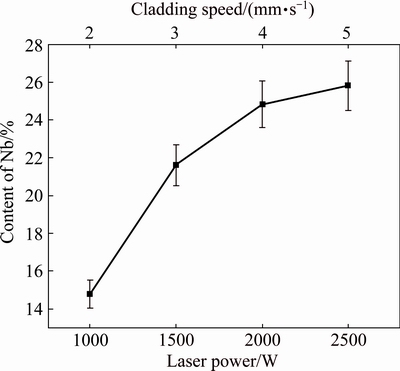

3.3 Segregation of Nb and resultant formation of Nb-rich Laves phase

The segregation of Nb widely exists in the laser cladding Inconel 718 alloy. The element Nb is rich in Laves phase but depleted in austenitic phase as shown in the EDS analysis (Fig. 2). However, the degree of segregation in the Inconel 718 alloy is visibly influenced by the solidification conditions under different laser cladding processes. Figure 4 shows that the content of Nb at Laves phase particle increases with respect to the increase of the laser power and cladding speed under a fixed linear energy. It can contribute to a decreasing tendency of cooling rate with respect to the laser power and cladding speed. Several previous researches have proven that a high cooling rate is beneficial for suppressing the segregation of Nb in Inconel 718 alloy. For example, Ref. [12] suppressed the degree of segregation of Nb to less than 10% in Inconel 718 alloy with increasing the cooling rate up to 20000 °C/s. So, the key to controlling the segregation of Nb is the cooling rate during the solidification. The magnitude of cooling rate can also be changed in a wider range by varying the laser cladding parameters, including the laser energy and cladding speed [20]. This offers a possible way to control the segregation of Nb in the laser cladding 718 alloy.

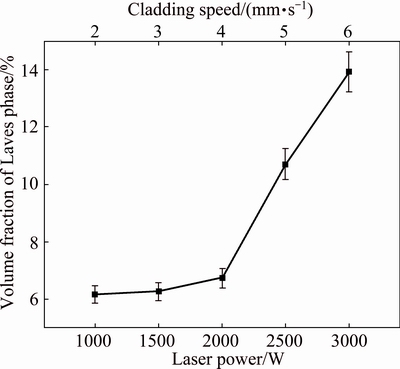

The segregation of Nb contributes to the formation of Nb-rich Laves phase during the eutectoid transformation at the end stage of solidification. Further, the volume fraction of Laves phase is influenced by the degree of segregation of Nb in the alloy. Figure 5 shows an increasing tendency of volume fraction of Laves phase with respect to an increase of laser power and cladding speed. The lower cooling rate appears in a higher laser power and cladding speed case (Fig. 3), which results in a higher concentration of Nb and consequent more precipitation of Nb-rich Laves phase (Fig. 4). The experimental result herein coincides with the previous simulation work in Ref. [20]. So, increasing the cooling rate with decreasing the laser power and cladding speed is beneficial for suppressing the formation of Laves phase, which is known to be detrimental to the mechanical properties of Inconel 718 alloy.

Fig. 4 Dependence of segregation of Nb on laser cladding parameters

Fig. 5 Dependence of volume fraction of Laves phase on laser cladding parameters

4 Conclusions

The microstructure, including the dendrite morphology, segregation of Nb and fraction of Laves phase, of the laser cladding Inconel 718 alloy was investigated by microstructure observation and EDS analysis. The effect of cooling rate of the cladding alloy during the solidification on the evolution of microstructure was studied by a comparison of the microstructure of alloy deposited by five different laser processing parameters with a fixed linear energy. The results show that the basic structural feature of the cladding Inconel 718 alloy includes primary Nb-deplete austenitic dendrites and Nb-rich interdendritic precipitates due to the segregation of Nb during the solidification. Rapid cooling rate is advantageous to suppress the segregation of Nb with low volume fraction of Nb-rich precipitates. Lower content of Nb in Laves phase precipitates is presented in the higher cooling rate case. In general, the low laser energy and cladding speed should be used in the cladding Inconel 718 alloy for obtaining high cooling rate and consequently suppressing the segregation of Nb and the resultant formation of Nb-rich Laves phase, which is detrimental to the mechanical properties of Inconel 718 alloy.

References

[1] MILLER M K, BABU S S, BURKE M G. Comparison of the phase compositions in alloy 718 measured by atom probe tomography and predicted by thermodynamic calculations [J]. Materials Science and Engineering A, 2002, 327: 84-88.

[2] KNOROVSKY G A, CIESLAK M J, HEADLEY T J, ROMIG A D, HAMMETTER W F. Inconel 718: A solidification diagram [J]. Metallurgical and Materials Transactions A, 1989, 20: 2149-2158.

[3] GAO Peng, ZHANG Kai-feng, ZHANG Bing-gang, JIANG Shao-song, ZHANG Bao-wei. Microstructures and high temperature mechanical properties of electron beam welded Inconel 718 thick plate [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S): s315-s322.

[4] WANG W F, WANG M C, ZHANG J, SUN F J, HUANG D W. Research on the microstructure and wear resistance of titanium alloy structural members repaired by laser cladding [J]. Optics and Lasers in Engineering, 2008, 46: 810-816.

[5] LIN X, CAO Y Q, WU X Y, YANG H O, CHEN J, HUANG W. Microstructure and mechanical properties of laser forming repaired 17-4PH stainless steel [J]. Materials Science and Engineering A, 2012, 553: 80-88.

[6] LEUNDA J, SORIANO C, SANZ C,  NAVAS V. Laser cladding of vanadium-carbide tool steels for die repair [J]. Physics Procedia, 2011, 12: 345-352.

NAVAS V. Laser cladding of vanadium-carbide tool steels for die repair [J]. Physics Procedia, 2011, 12: 345-352.

[7] GRAF B, GUMENYUK A, RETHMEIER M. Laser metal deposition as repair technology for stainless steel and titanium alloys [J]. Physics Procedia, 2012, 39: 376-381.

[8] LIU F C, LIN X, LENG H, CAO J, LIU Q, HUANG C P, HUANG W D. Microstructural changes in a laser solid forming Inconel 718 superalloy thin wall in the deposition direction [J]. Optics & Laser Technology, 2013, 45: 330-335.

[9] LAMBARRI J, LEUNDA J, NAVAS V G, SORIANO C, SANZ C. Microstructural and tensile characterization of Inconel 718 laser coatings for aeronautic components [J]. Optics and Lasers in Engineering, 2013, 51: 813-821.

[10] RADHAKRISHNA C H, RAO K P. The formation and control of laves phase in superalloy 718 welds [J]. Journal of Materials Science, 1997, 32: 1977-1984.

[11] SIVPRSAD K, GANESH SUNDARA RAMAN S. Influence of weld cooling rate on microstructure and mechanical properties of alloy 718 weldments [J]. Metallurgical and Materials Transactions A, 2008, 39: 2115-2127.

[12] ANTONSSON T, FREDRIKSSON H. The effect of cooling rate on the solidification of Inconel 718 [J]. Metallurgical and Materials Transactions B, 2005, 36: 85-96.

[13] RADHAKRISHNA C H, RAO K P. The formation and control of Laves phase in superalloy 718 welds [J]. Journal of Materials Science, 1997, 32: 1977-1984.

[14] GAO Z G, OJO O A. Modeling analysis of hybrid laser-arc welding of single-crystal nickel-base superalloys [J]. Acta Materialia, 2012, 60: 3153-3167.

[15]  M,

M,  C, CANALIS P, KURZ W. Single-crystal laser deposition of superalloys: Processing- microstructure maps [J]. Acta Materialia, 2001, 49: 1051-1062.

C, CANALIS P, KURZ W. Single-crystal laser deposition of superalloys: Processing- microstructure maps [J]. Acta Materialia, 2001, 49: 1051-1062.

[16] NIE P L, OJO O A, LI Z G. Numerical modeling of microstructure evolution during laser additive manufacturing of a nickel-based superalloy [J]. Acta Materialia, 2014, 77: 85-95.

[17] DUPONT J N, ROBINO C V, MARDER A R. Modeling solute redistribution and microstructural development in fusion welds of Nb-bearing superalloys [J]. Acta Materialia, 1998, 46: 4781-4790.

[18] NORMAN A F, DUCHARME R, MACKWOOD A, KAPADIA P, PRANGNELL P B. Application of thermal modelling to laser beam welding of aluminium alloys [J]. Science and Technology of Welding and Joining, 1998, 3: 260-266.

[19] PATEL A D, MURTY Y V. Effect of cooling rate on microstructural development in alloy 718 [C]//LORIA E A. Superalloys 718, 625, 706 and Various Derivatives, Warrendale: TMS, 2001: 123-132.

[20] NIE P L, OJO O A, LI Z G. Modeling analysis of laser cladding of a nickel-based superalloy [J]. Surface and Coatings Technology, 2014, DOI: 10.1016/j.surfcoat.2014.07.030.

[21] OI H, AZER M, RITTER A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured Inconel 718 [J]. Metallurgical and Materials Transaction A, 2009, 40: 2410-2422.

[22] HUANG X, CHATURVEDI M C, RICHARDS N L. Effect of homogenization heat treatment on the microstructure and heat- affected zone microfissuring in welded cast alloy 718 [J]. Metallurgical and Materials Transaction A, 1996, 27: 785-790.

激光熔覆Inconel 718合金铌偏聚

龙怡彤,聂璞林,李铸国,黄 坚,李 想,徐昕媚

上海交通大学 上海市激光制造与材料改性重点实验室,上海 200240

摘 要:Inconel 718高温合金被广泛地应用于航空航天和汽轮机领域。在激光熔覆Inconel 718合金中存在铌的偏聚现象,而铌偏聚会影响到合金在快速凝固过程中的相变。为了控制熔覆层的显微组织并提高其力学性能,采用组织观察和能谱分析研究凝固条件对铌偏聚及富铌Laves相形成的影响规律。结果表明冷却速度对熔覆组织具有显著影响。高的冷却速度有利于抑制铌的偏聚,减少对Inconel 718合金力学性能有害的Laves相的析出。

关键词:Inconel 718高温合金;铌偏聚;激光熔覆;冷却速率

(Edited by Yun-bin HE)

Foundation item: Project (51341004) supported by the National Natural Science Foundation of China; Project (S050ITP7005) supported by the Shanghai Jiao Tong University Undergraduate Innovative Practice Program, China

Corresponding author: Pu-lin NIE; Tel: +86-21-54748940-8022; E-mail: nplhxy@sjtu.edu.cn

DOI: 10.1016/S1003-6326(16)64131-6