Effect of crystallization temperature on microstructure and ferroelectric property of Bi3.25Eu0.75Ti3O12 thin films prepared by MOD method

HE Lin(何 林)1,2, ZHANG Tong(张 彤)3, TANG Ming-hua(唐明华)1,2, DENG Shui-feng(邓水凤)1, 2

1. Faculty of Material and Photoelectronic Physics, Xiangtan University, Xiangtan 411105, China;

2. Key Laboratory for Advanced Materials and Rheological Properties, Ministry of Education,

Xiangtan University, Xiangtan 411105, China;

3. College of Electronic Science and Engineering, Jilin University, Changchun 130012, China

Received 25 March 2006; accepted 31 May 2006

Abstract: Europium-substituted bismuth titanate (Bi3.25Eu0.75Ti3O12) thin films were deposited on the Pt/Ti/SiO2/Si(111) substrates by metal-organic decomposition (MOD) method using a repeated coating/drying cycle. Effect of crystallization temperature on microstructure of Bi3.25Eu0.75Ti3O12 (BET) thin films was investigated by X-ray diffractometry(XRD), scanning electron microscopy (SEM) and Raman spectroscopy, and ferroelectric property was studied by Precision Workstation Ferroelectric Tester. The crystallinity of BET thin films is improved and the average grain size increases with the crystallization temperature from 600 to 750℃. Under 9 V applied voltage, the remnant polarization (2Pr) of BET thin films annealed at 700 ℃ is 50.7 μm/cm2, which is higher than that of the films annealed at 600, 650 and 750℃.

Key words: BET thin film; ferroelectric property; metal-organic decomposition; Bi-layered perovskite

1 Introduction

Many researches have been done on candidates in ferroelectric material for non-volatile random access memories applications. Among them, lead zirconate titanate(PZT) thin films have been widely studied because they have many advantages such as large 2Pr and low processing temperature, and their mechanical and electrical properties are investigated deeply[1-3]. However, there are some serious drawbacks such as lead toxicity, lead pollution, fatigue, and leakage current for use. Bismuth titanate-based thin films are considered to be candidates for the nonvolatile memory applications. Recent studies reveal that Bi3+ in Bi4Ti3O12 structure can be substituted by trivalent lanthanoid ions to improve ferroelectric properties[4-6]. Lanthanum-substituted bismuth titanate thin films have large 2Pr and high fatigue resistance on Pt electrode, which makes them applicable to direct commercialization. For instance, (Bi4-xLax)Ti3O12[7], (Bi4-xSmx)Ti3O12[8], and (Bi4-xNdx)- Ti3O12[9-13] thin films are attractive lead-free materials for memory applications. Bi3.25La0.75Ti3O12(BLT) thin film deposited on Pt/Ti/SiO2/Si substrate by pulsed laser deposition(PLD) method was reported to have a high 2Pr value and good fatigue endurance[7]. Bi3.15Sm0.85Ti3O12 (BST) thin films having fatigue-free characteristic were deposited on Pt/TiO2/SiO2/Si(100) substrate deposited by MOD. The 2Pr value of BST thin film capacitor with Pt electrodes was 49 μm/cm2 at applied voltage of 10 V[8]. The 2Pr of Bi3.54Nd0.46Ti3O12(BNT) thin film deposited on Pt/TiO2/SiO2/Si(100) substrate by spin coating was 50 μC/cm2[9].

Recently, BET thin films have emerged as new ferroelectric materials due to good fatigue endurance and large polarization[14, 15]. KIM and LIM reported that 2Pr of Bi3.25Eu0.75Ti3O12(BET) thin film deposited on Pt/TiO2/SiO2/Si(100) substrates by MOD is 60.99 μC/ cm2 annealed at 800 ℃[15]. However, the annealing temperature was too high to be adapted in ferroelectric memory fabrication process. It is well known that the annealing temperature has grate effect on the microstructure and ferroelectric property of ferroelectric thin films deposited by MOD and the lower processing temperature is very important in ferroelectric memory applications. Few studies have involved in the structural stability and ferroelectric property of the Bi3.25Eu0.75- Ti3O12 thin films annealed at low temperature, so it is imperative for us to characterize microstructure and ferroelectric properties of BET thin films annealed under a moderate annealing temperature.

In this article, the BET thin films, deposited on Pt/Ti/SiO2/Si(111) substrates by MOD method in oxygen atmosphere, were annealed under a moderate temperature from 600 ℃ to 750 ℃ at an interval of 50℃. Effect of crystallization temperature on micro- structure of BET thin films was studied by XRD, SEM and Raman spectroscopy, and ferroelectric property was studied by Precision Workstation Ferroelectric Tester.

2 Experimental

BET thin films were prepared by MOD method, and spin-coated on Pt(200 nm)/Ti(30 nm)/SiO2/Si(111) substrate. The precursor materials were bismuth(Ⅲ) acetate {Bi[CH3CO2]3}, europium(Ⅲ) acetate hydrate {Eu[CH3CO2]3} and tetrabutyl titanium {Ti[OC4H9]4}. The solvents were acetic acid {CH3CO2H} and acetylacetone {CH3COCH2COCH3}. A 10% excess amount of bismuth acetate was used to compensate Bi-loss during annealing.

Firstly, the solid-state bismuth acetate and europium acetate were dissolved in the acetic acid, and the solutions were mixed to obtain a (Bi, Eu) stock solution followed by stirring for 12h. Secondly, the acetylacetone was dropped, and the tetrabutyl titanium was dissolved and magnetically stirred in the air atmosphere for 1h. Finally, the flaxen, transparent and stable BET precursor solution was prepared.

The precursor solution with the mole ratio x(Bi)? x(Eu)?x(Ti) of 3.575?0.75?3 was spun on the Pt/Ti/SiO2/ Si(111) substrate at 4000 r/min for 30 s. After the spin-coating procedure, the thin films were rapidly annealed at 400 ℃ for 180 s to remove the organic ingredients. The coating/drying circles were repeated 7 times to achieve desired film thickness. The prebaked films were annealed at 600, 650, 700 and 750 ℃ in oxygen atmosphere to promote crystallization. Au top electrodes were deposited using a shadow mask by DC magnetron sputter to measure electrical property.

Phase identification, crystalline orientation, and degree of crystallinity of BET thin films were inves- tigated by XRD (Rigaku D/Max 2500) using normal scanning method, and they were scanned at 4 (?)/min with degree increment of 0.02? with Cu Kα radiation (40 kV, 300 mA). Surface morphology of BET thin films was identified by SEM (LEO-1530) with magnification of 50 000, and the thickness of BET thin film annealed at 750 ℃ was obtained by a cross-sectional micrograph of SEM with magnification of 30 000. The Raman spectro- scopy was conducted with a micro-Raman system (Reinishaw model 3000) in the backscattering configura- tion. Argon ion laser beam of 514.5 nm wavelength with a power of 0.5 mW was focused on a 1 mm spot on the middle of BET thin films. The ferroelectric property was measured by Precision Workstation Ferroelectric Tester with 9 V applied voltage. Measurements were made at room temperature.

2 Results and discussion

The X-ray diffraction patterns of BET thin films annealed at 600, 650, 700 and 750 ℃ are shown in Fig.1. It is obvious that the XRD peak corresponding to (117) reflection appears above 600 ℃. This indicates that the beginning of crystallization to a Bi-layered perovskite is below 600 ℃. From 600 ℃ to 750 ℃, BET thin films show typical XRD patterns of the Bi-layered perovskite polycrystalline structure. No pyrochlore phase (cubic Bi2O3) and no preferred orientation are found. The possible reason is that the Eu3+ in BET thin films does not form pyrochlore phase but can be dissolved into the pseudoperovskite structure, so that Eu3+ can easily substitute for the Bi3+ in pseudoperovskite structure[14]. The partial substitution of Eu3+ for the Bi3+ in bismuth titanate thin films affects on the structural properties of Bi layer. With increasing annealing temperature, the XRD diffraction peaks become sharper and stronger, while the full width at a half maximum (FWHM) decreases. The results indicate that the grain size increases with annealing temperature.

Fig.1 X-ray diffraction patterns of BET thin films on Pt/Ti/ SiO2/Si substrates annealed at 600 ℃(a), 650℃(b), 700 ℃(c), and 750 ℃(d)

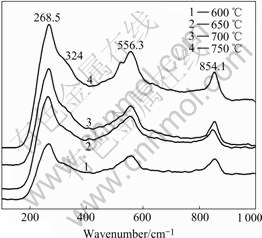

Fig.2 shows Raman spectroscopy of BET thin films. BET thin films with the mole ratio x(Bi)?x(Eu)?x(Ti) of 3.25?0.75?3 are in an orthorhombic symmetry(B2cb), so the observed Raman peaks centered at 268.5, 556.3, and 854.1 cm-1 correspond to A1(TO1), A1(TO2) and A1(LO3) mode, which are consistent with the results of CHU et al[16] and IDINK et al[17]. The peak centered at 268.5 cm-1 corresponds to the TiO6 octahedron torsional bending mode, which is the representative of the pseudo- perovskite structure in BET thin films. Peaks centered at 556.3 cm-1 and 854.1 cm-1 are related to the TiO6 stretching mode. The intensity and sharpness of these three peaks increase with annealing temperature (up to 750 ℃), indicating the improvement in crystalline quality of the perovskite structure, which is consistent with the XRD results. Apart from these three main modes, the 324 cm-1 mode (seen as a peak on the right of the 268.5 cm-1 mode), which corresponds to the combination of stretching and bending of the TiO6 octahedron, becomes sharper and more distinct with increasing annealing temperature. This change in the TiO6 modes is most probably due to exaggerations of orthorhombic distortion and octahedral tilting at higher annealing temperature.

Fig.2 Raman spectroscopy of BET thin films at 600, 650, 700 and 750 ℃ measured in parallel polarization configuration

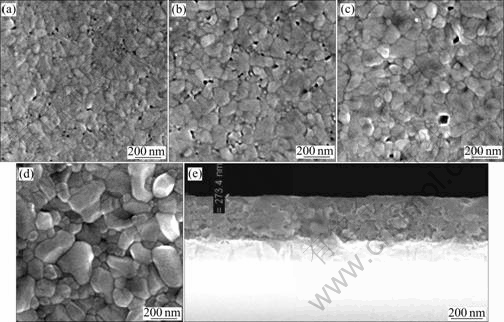

The SEM surface micrographs of BET thin films annealed at 600, 650, 700 and 750 ℃ and a cross- sectional micrograph of BET film annealed at 750 ℃ are shown in Fig.3. It is found that the surface morphology of BET thin films is influenced by the annealing temperature. The surface of BET thin film is uniform, compact, smooth and crack-free. The crack-free surface seems to be important to ferroelectric thin film because the surface cracks will affect its microstructure and ferroelectric properties[18]. As shown in Figs.3(a)- (d), the grain size of BET thin films increases with annealing temperature, which is fitted with the XRD and Raman results. From Fig.3(e), the thickness of BET thin film annealed at 750 ℃ is about 273 nm.

Fig.3 Surface morphologies of BET thin films annealed at different temperatures: (a) 600 ℃; (b) 650 ℃; (c) 700 ℃; (d) 750 ℃; (e) Cross-sectional micrograph for thin film annealed at 750 ℃

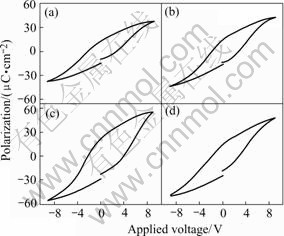

ig.4 shows the P—V loops of BET thin films annealed at different temperatures. In Fig.4(a), the P—V loop of BET thin film annealed at 600 ℃ is not saturated well, while BET thin films annealed at temperatures above 650 ℃ (Figs.4(b)-(d)) show saturated P—V loops.

Fig.4 P—V loops of BET thin films annealed at 600 ℃(a), 650 ℃(b), 700 ℃(c) and 750 ℃(d)

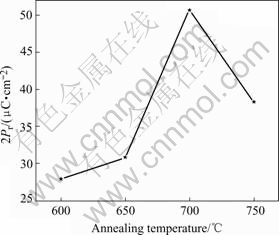

2Pr of the BET thin films as function of annealing temperatures is shown in Fig.5. Under applied voltage of 9 V, the 2Pr values of BET thin films annealed at 600, 650, 700 and 750°C are 27.9, 30.8, 50.7 and 38.2 μC/cm2, respectively. It can be seen that the 2Pr values increase with annealing temperature up to 700 ℃, but the values of 2Pr begin to decrease when the annealing temperature is above 700 ℃. The ferroelectric properties are related to grain size and the element stoichiometry of BET thin films. One reason for 2Pr values of BET thin films increasing with annealing temperature from 600 ℃ to 700 ℃ is that the grain size increases with annealing temperature. The number of domain switching variants will increase with increasing grain size, because the reduction of volume fraction of the grain boundaries and the domain wall will make the reorientation of the domains easier[7]. The other reason is that 10% excess amount of bismuth acetate can compensate Bi-loss during annealing, and it can keep BET thin films in accurate element stoichiometry when the annealing temperature is below 700℃. The 2Pr decreases when the annealing temperature is above 700 ℃, due to the insufficient Bi supply, which results in nonstoichiometric structural defects in the BET thin films.

Fig.5 2Pr of BET thin films as function of annealing tempera- tures

4 Conclusions

1) BET thin films were prepared by MOD method using a spin coating technique under a moderate temperature annealing in an oxygen atmosphere. BET thin films show the Bi-layered perovskite polycrystalline structure without secondary phase and preferred orientation. Raman spectroscopy indicates that the increasing annealing temperature (up to 750 ℃) improves the crystalline quality of perovskite structure.

2) The SEM micrographs show that surface of BET thin film is uniform, compact, smooth and crack-free. The 2Pr values of the samples increase rather steeply with the annealing temperature, when the annealing temperature is below 700 ℃; but 2Pr values decrease when the annealing temperature is above 700 ℃. The 2Pr values of the BET thin film annealed at 700℃ is 50.7 μC/cm2, which is comparable with that of PZT thin film.

References

[1] ZHENG X J, ZHOU Y C, ZHONG H. Dependence of fracture toughness on annealing temperature in PZT thin films produced by metal organic decomposition [J]. Journal of Materials Research, 2003, 18(3): 578-584.

[2] ZHENG X J, LI J Y, ZHOU Y C. X-ray diffraction measurement of residual stress in PZT thin films prepared by pulsed laser deposition [J]. Acta Mater, 2004, 52(11): 3313-3332.

[3] ZHENG X J, ZHOU Y C, LI J Y. Nano-indentation fracture test of Pb(Zr0.52Ti0.48)O3 ferroelectric thin films [J]. Acta Mater, 2003, 51: 3985-3997.

[4] LEE H N, HESSE D, ZAKHAROV N, GOSELE U. Ferroelectric Bi3.25La0.75Ti3O12 films of uniform a-axis orientation on silicon substrates [J]. Science, 2002, 296: 2006-2009.

[5] CHON U, YI G C, JANG H M. Fatigue-free behavior of highly oriented Bi3.25La0.75Ti3O12 thin films grown on Pt/T/SiO2/Si(100) by metalorganic solution decomposition [J]. Phys Rev Lett, 2001, 78: 658-660.

[6] CHON U, SHIM J S, JANG H M. Ferroelectric properties and crystal structure of praseodymium-modified bismuth titanate [J]. J Appl Phys, 2003, 93: 4769-4775.

[7] KIM K T, KIM C I. Characterization of ferroelectric Bi3.25La0.75Ti3O12 thin films prepared by metal organic decomposition method [J]. Thin Solid Films, 2005, 478: 6-12.

[8] CHON U, KIM K B, JANG H M, YI G C. Fatigue-free samarium-modified bismuth titanate Bi4-xSmxTi3O12 film capacitors having large spontaneous polarizations [J]. Appl Phys Lett, 2001, 79: 3137-3139.

[9] MELGAREJO R E, TOMAR M S, BHASKAR S, DOBAL P S, KATIYAR R S. Large ferroelectric response in Bi4-xNdxTi3O12 films prepared by sol–gel process [J]. Appl Phys Lett, 2002, 81: 2611-2613.

[10] GARG A, BARBER Z H, DAWBER M, SCOTT J F, SNEDDEN A, LIGHTFOOT P. Orientation dependence of ferroelectric properties of pulsed-laser-ablated Bi4-xNdxTi3O12 films [J]. Appl Phys Lett, 2003, 83: 2414-2416.

[11] WANG ZH, YANG CH H, YU X Y, YU T. Synthesis and characteristics of Na-doped Bi4Ti3O12 thin films on Si substrate [J]. Journal of Crystal Growth, 2005, 280: 557-561.

[12] ZHONG X L, WANG J B, ZHENG X J, AND ZHOU Y C, YANG G W. Structure evolution and ferroelectric and dielectric properties of Bi3.5Nd0.5Ti3O12 thin films under a moderate temperature annealing [J]. Appl Phys Lett, 2004, 85: 5661-5663.

[13] LEE S Y, PARK B O. Microstructure and ferroelectric properties of Nb-doped Bi4Ti3O12 thin films prepared by sol–gel method [J]. Journal of Crystal Growth, 2005, 283: 81-86.

[14] KIMA W J, KIMA S. Ferroelectric Bi3.4Eu0.6Ti3O12 thin films deposited on Si(100)and Pt/Ti/SiO2/Si(100) substrates by a sol–gel process [J]. Journal of Crystal Growth, 2004, 262: 327-333.

[15] LIM K T, KIM K T. Electrical properties of Bi4-xEuxTi3O12(BET) thin films after etching in inductively coupled CF4/Ar plasma [J]. Thin Solid Films, 2004, 447-448: 337-342.

[16] CHU M W, GANNE M, CALDES M T. X-ray photoelectron spectroscopy and high resolution electron microscopy studies of Aurivillius compounds: Bi4-xLaxTi3O12(x=0, 0.5, 0.75, 1.0, 1.5 and 2.0) [J]. J Appl Phys, 2002, 91: 3178-3187.

[17] IDINK H, SRIKANTH V, WHITE W B, SUBBARAO E C. Raman study of low temperature phase transitions in bismuth titanate, Bi4Ti3O12 [J]. J Appl Phys, 1994, 76: 1819-1823.

[18] KNAUSS L A, POND J M, HORWITZ J S, CHRISEY D B, MUELLER C, TREECE H. The effect of annealing on the structure and dielectric properties of BaxSr1- xTiO3 ferroelectric thin films [J]. Appl Phys Lett, 1996, 69: 25-27.

Foundation item: Project(10472099) supported by the National Natural Science Foundation of China; Project(05JJ30208) supported by the Natural Science Foundation of Hunan Province, China; Project(05FJ2005) supported by Key Project of Scientific and Technological Department of Hunan Province, China

Corresponding author: DENG Shui-feng; Tel: +86-732-8293648; Fax: +86-732-8292468; E-mail: sfdeng@xtu.edu.cn

(Edited by YANG Bing)