文章编号:1004-0609(2015)02-0458-08

基于数值模拟的TP2铜管三联拉工艺优化

刘劲松1, 2,陈大勇1,张士宏2

(1. 沈阳理工大学 材料科学与工程学院,沈阳 110159;

2. 中国科学院 金属研究所,沈阳 110016)

摘 要:通过对某公司原有TP2铜管三联拉工艺进行延伸系数和变形量的计算,发现该工序变形量大、对管材质量的影响大,且尚有可优化空间。运用有限元分析软件MSC.Marc对此工艺进行数值模拟研究,得出温度和等效应力随变形率、拉拔道次和拉拔速度变化的规律。对原有拉拔工艺中的变形温度进行实验测量,将实验结果与有限元分析结果进行比较,验证有限元模型与真实工艺的符合程度,为联合拉拔工艺的合理改进提供理论依据,并以此为基础提出优化工艺方案。综合对比分析原有的拉拔工艺和优化的拉拔工艺,发现优化工艺增大了各道次的变形率,使得变形温度有所提高,但等效应力的变化幅度较小,优化工艺方案切实可行。

关键词:三联拉工艺;温度;等效应力;数值模拟;优化工艺

中图分类号:TG356.5;TG359 文献标志码:A

Optimization of triple TP2 copper tube drawing process based on numerical simulation

LIU Jin-song1, 2, CHEN Da-yong1, ZHANG Shi-hong2

(1. School of Materials Science and Engineering, Shenyang Ligong University, Shenyang 110159, China;

2. Institute of Metals Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The triple tube drawing process plays a significant role in large deformation and high-quality tube drawing program which can still be optimized when the elongation coefficient and deformation were computed depending on some company’s existing triple TP2 tube drawing process. The relationships among temperature, equivalent stress and deformation rate, drawing passes, drawing velocity were obtained by using the FEM software MSC.Marc. The optimized FEM model can stand for the real process, the deformation temperature of the original process was measured and contrasted with FEM result. The optimized process strategy was putted forward by the support of above mentioned analysis and corresponding theory. The optimized tube drawing process is proved to have a high pass-deformation rate which causes an apparent temperature rising, but exerts a little influence on the equivalent stress. Whatsmore, it is improved that the drawing process project is feasible.

Key words: triple drawing process; temperature; equivalent stress; numerical simulation; optimized process

三联拉工序是TP2管材连铸连轧拉拔工艺中的一道重要工序,该工序中管材的变形量、变形力较大。对某公司所有拉拔光管产品截面收缩率计算发现,经过三辊行星轧制的管坯,后续拉拔工序变形量的70%以上均在联合拉拔道次,这充分说明联拉工序变形量大、变形力大、影响作用大的特点。

国内外学者针对管材拉拔已经做了很多研究工作,BUI等[1]提出,为了减少拉拔道次,要使每一道次达到最大的截面收缩率。樊立奎[2]和黄成江等[3]研究发现,减少拉拔道次和增大单道次壁厚减薄量有利于降低残余应力,提高产品质量。PERNIS等[4]指出厚壁管材的拉拔条件,设定了稳定拉拔条件下的模具参数。

BIHAMTA等[5]研究发现,最终成品管材的最大和最小壁厚很大程度上取决于初始管材的壁厚和外径。PALENGAT等[6]研究发现,管材和外模以及芯头之间的摩擦产生的温度变化对管材的塑性变形产生很大的影响。TANG等[7]通过大量实验证实外模锥角和变形量是拉拔工艺最重要的工艺参数。李志余等[8]提出,随着拉拔道次的增加,铜管产生加工硬化,屈服强度增加,拉拔应力也相应增加。B LAND等[9]基于有限元优化了6063铝管拉拔模具。牟取晗等[10]通过数值模拟探索拉拔过程中的温度分布。陆晓峰等[11]对复合管材拉拔过程进行数值模拟,提出优化模型,模具寿命提高6倍。杨晓静等[12]依据模拟结果得到各个拉拔参数的合理值。

LAND等[9]基于有限元优化了6063铝管拉拔模具。牟取晗等[10]通过数值模拟探索拉拔过程中的温度分布。陆晓峰等[11]对复合管材拉拔过程进行数值模拟,提出优化模型,模具寿命提高6倍。杨晓静等[12]依据模拟结果得到各个拉拔参数的合理值。

联合拉拔可同时完成拉拔、矫直、无损探伤、切定尺和去毛刺等工序,其特点有自动化程度高、产量高、生产速度快。联合拉拔优点明显,但是多年来,有关联拉工序沿用原有工艺的研究也鲜见报道。本文作者针对某厂原有三联拉工艺,采用有限元模拟和实验测量,研究联合拉拔过程温度和应力的变化规律,提出工艺优化模型,通过合理增加联拉各道次的变形量,缩短后续盘拉工序的变形道次,提高效率,降低能源消耗。

1 TP2铜管材三联拉工艺特点

联合拉拔工艺采用两个或者3个联合拉拔机协同工作,对轧制管坯进行连续地二或三道次的拉拔,达到减径减壁的目的。其特点主要如下。

1) 道次变形率大,拉拔力较大,拉拔速度较高,最高速度达到100 m/min。各拉拔道次的拉拔速度匹配,协同工作,管材呈直条状通过拉伸机,长度不受限制,管材横截面不受弯曲应力的作用,壁厚偏差较小。延伸系数较高,最高可达1.8;减少制头次数,一次制头可完成两到三道次拉拔变形,几何损失小,成品率高。

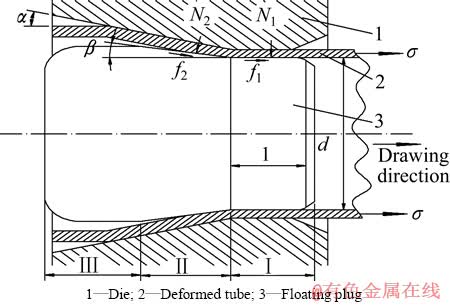

图1 游动芯头在变形区的受力情况

Fig. 1 Force condition of floating plug in deformation zone

2) 游动芯头拉拔过程芯头不固定,而是依靠自身的形状以及管材与芯头之间的接触力达到平衡。游动芯头的稳定性取决于其轴向作用力的平衡[13],即正压力的水平分力和摩擦力的水平分力达到动态平衡。游动芯头在变形区受力情况如图1所示。图1中N1为芯头定径段所受正压力;N2为芯头锥形段所受正压力;f1为芯头定径段所受摩擦力;f2为芯头锥形段所受摩擦力;l为芯头定径段长度;d为芯头定径段直径; 为管材的轴向拉拔应力;Ⅰ为芯头定径段;Ⅱ为芯头锥形段;Ⅲ为芯头后圆柱段。

为管材的轴向拉拔应力;Ⅰ为芯头定径段;Ⅱ为芯头锥形段;Ⅲ为芯头后圆柱段。

游动芯头拉拔管材的基本条件如下。

1) 游动芯头锥角 必须大于摩擦角

必须大于摩擦角 ,否则芯头将被带入到外模定径区,直至芯头锥面与外模具转折处管材被切断,或造成管材空拉。

,否则芯头将被带入到外模定径区,直至芯头锥面与外模具转折处管材被切断,或造成管材空拉。

2) 游动芯头锥角 必须小于或等于外模锥角

必须小于或等于外模锥角 ,如果芯头锥角大于外模锥角,锥形段管材被挤压造成断管,或者由于轴向力的变化,芯头往返运动在管坯内部挤出环状痕迹。

,如果芯头锥角大于外模锥角,锥形段管材被挤压造成断管,或者由于轴向力的变化,芯头往返运动在管坯内部挤出环状痕迹。

图中 为外模具锥形段与水平轴线之间的夹角;

为外模具锥形段与水平轴线之间的夹角; 为游动芯头锥形段与水平轴线之间的夹角;

为游动芯头锥形段与水平轴线之间的夹角; 为摩擦角。

为摩擦角。

2 有限元模型的建立

2.1 铜管坯和模具单元体模型的建立

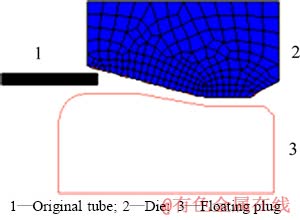

管坯初始尺寸为d 50 mm×2.5 mm,最终尺寸为d 28 mm×1.2 mm,长度为20 mm;由于拉拔变形沿轴向进行,为轴对称变形,可以将数值计算过程简化为二维轴对称模型;变形体网格划分为400×10=4000个四节点的单元;拉拔模具采用通用的硬质合金YG8,考虑到游动芯头与外模具接触定义,将外模具设置成变形体;忽略实际生产中的制头工序,并去掉外模入口端的圆角;芯头设置成刚体,不发生塑性变形;芯头由弹簧驱动,模拟其自适应功能,保证其在前后极限之间来回移动。管材的初始有限元模型如图2所示(图中1为变形管坯,2为外模具,3为芯头)。

2.2 模拟参数

2.2.1 变形体参数设置

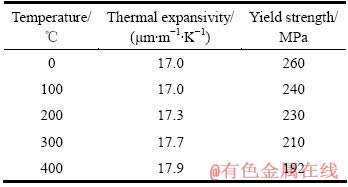

变形体材料:TP2铜,质量密度为8940 kg/m3;比热容为400 J/(kg·K);导热系数为400 W/(m·K);弹

性模量为1.15×105 MPa;泊松比为0.33;边界条件:3道次拉拔速度分别为40、60和90 m/min;摩擦因数为0.05[12];热膨胀系数和屈服强度随温度变化,具体数值如表1所列。

图2 管材的初始有限元模型

Fig. 2 Initial FEM model of tube

表1 TP2铜管材的热膨胀系数和屈服强度

Table 1 Thermal expansivity and yield strength of TP2 copper tube

2.2.2 模具体参数设置

质量密度:14.8 Mg/m3,弹性模量:700 GPa,泊松比:0.21;屈服应力:142 GPa,热膨胀系数:4.5 μm/(m·K)。

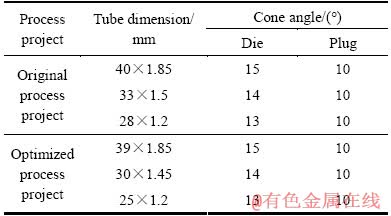

2.3 工艺优化方案

两种工艺下外模和芯头的锥角没有变化,但是各个道次的外模具和芯头定径段直径尺寸发生较大的变化。原三联拉和优化工艺方案具体参数如表2所列。

表2 管材的原有和优化工艺方案

Table 2 Original and optimized process project of tube

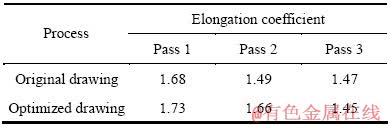

两种工艺下总的延伸系数分别为3.69和4.16,总变形率分别为72.92%和75.95%,说明优化工艺中三联拉工序承载了拉拔工艺(包括三联拉和盘拉)更多的塑性变形量,为减少后续盘拉工序拉拔道次奠定良好的基础。两种工艺下延伸系数如表3所列。

表3 不同拉拔工艺下管材延伸系数的分配

Table 3 Distribution of elongation coefficient of tube at different drawing processes

3 模拟结果与分析

3.1 温度场分析

3.1.1 工艺优化对变形温度的影响

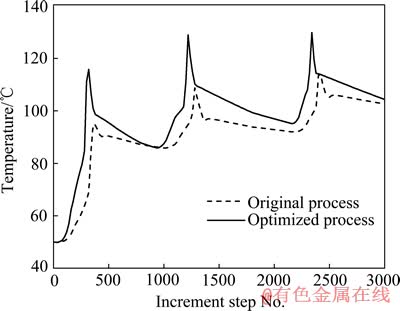

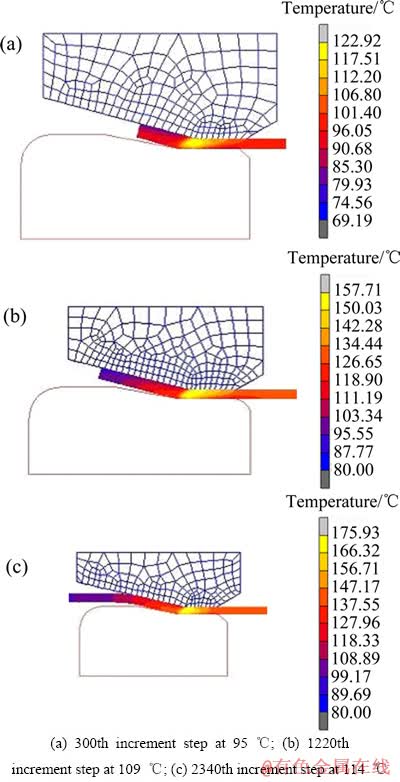

为模拟实际工艺连续变形条件下温度的变化情况,外模具和游动芯头的初始温度设置为80 ℃。模拟结果显示,原有联拉工艺各道次温度极值为95、109和114 ℃,优化后拉拔各道次的温度极值分别为116、129和132 ℃。优化工艺各道次塑性变形热增加,每道次的管材温度均有不同程度地升高。优化工艺相对于原有工艺各个道次温度差约为20 ℃,原因主要有以下两点:1) 模型经过简化后,管材较短,管材塑性热不会向管材前部和后部传递,而是以对空气的热传导形式向环境传递热量,而管材与空气之间的换热系数远远低于管材与管材的接触导热系数,其对温度降低作用有限,因此温度受变形量的影响较为明显;2) 原有工艺的变形率分别为41%、60%和73%,优化工艺的的变形率分别为42%、65%和76%,联拉第二、三道次变形量明显增大,道次变形量增大引起塑性变形热增加,变形热的累积导致温度的进一步升高,两种工艺条件下模具锥形角以及结构基本相同,产生的摩擦热基本相同,各道次变形量的增大产生更多的塑性变形热。两种工艺条件下,都存在随着道次数的增加温度上升的现象,这是由于拉拔速度的提高,单位时间内积累更多的塑性热和摩擦热,最高变形温度随着道次数的增加而提高,但是该提高趋势不明显。两种工艺条件下三道次拉拔管材的温度曲线如图3所示。

由图3可知,在三道次拉拔中,温度出现3次激增并达到极值。优化拉拔工艺模型中,温度极值出现在第300、1220、2340增量步,这3个增量步都位于各个道次外模具锥形段和定径段交接处,具体见联合拉拔一、二、三道次的温度场分布云图,分别如图4所示。由于锥形段管材外径急剧减小和壁厚迅速减薄,管坯内部积累大量的塑性变形热;同时,锥形段变形体与模具摩擦接触面积较大,摩擦产生大量的热量。当管材到达锥形段和定径圆柱段之间过渡圆角处,变形量最大,因此,温度出现陡增并达到极值。具体温度极值出现位置如图4所示。

图3 优化前、后管材温度的变化曲线

Fig. 3 Temperature change curves of original and optimized tube forming process

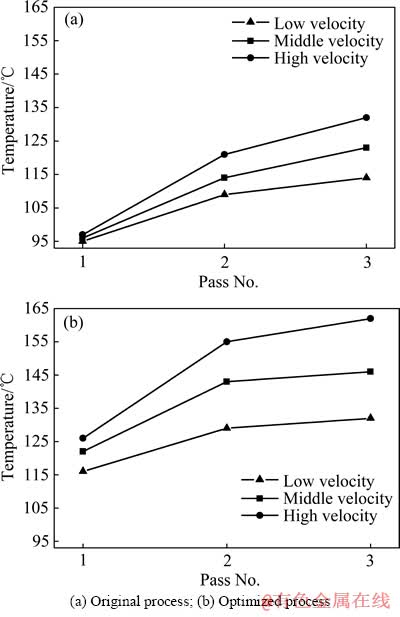

3.1.2 拉拔速度对变形温度的影响

对原有和优化三联拉工艺设置不同的拉拔速度,分别为低速、中速和高速。改变原有和优化三联拉模型的速度工艺参数,其具体数值如表4所列。

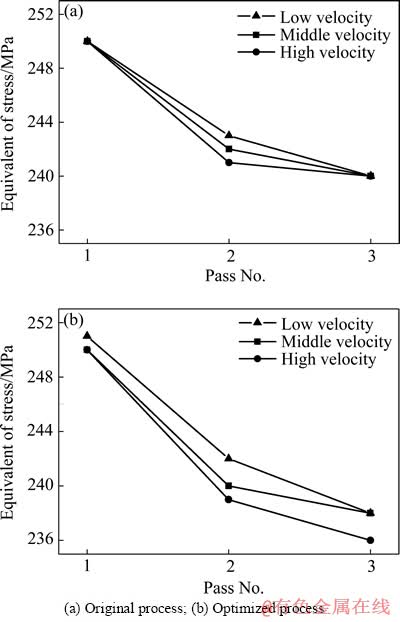

从模拟结果可以看出,拉拔速度对变形温度影响作用较为明显,在同一种工艺下随着拉拔速度的提高温度上升,上升幅度随着拉拔道次的增加而加大,第一道次到第二道次的温度升高速率明显大于第二道次到第三道次的速率;优化工艺每道次的温度(如图5(b)所示)均比原有工艺(如图5(a)所示)高,且在高速拉拔状态下,升温速率明显大于原工艺的。优化工艺各道次温度比原有工艺各道次温度数值高,说明随着变形量的增加变形热增加,进而造成温度升高。3种不同的拉拔速度配比方案对变形温度的影响作用如图5所示。

3.2 等效应力分析

3.2.1 工艺优化对等效应力的影响

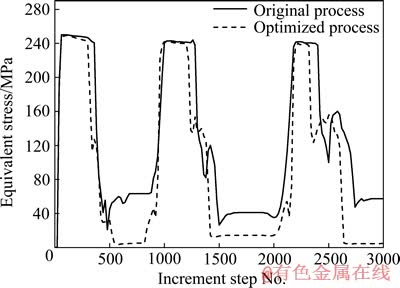

将优化模型和原工艺模型进行比较,在同一拉拔工艺中锥形段等效应力数值较为稳定,维持在235~250 MPa,并且随着道次增加等效应力数值变化非常小,定径段等效应力会发生较大幅度的波动。并且在定径区,优化工艺的平均等效应力略小于原有工艺。管材等效应力不仅受温度的影响,还与实际的应力状态有关,优化工艺相对于原有工艺,单道次变形量增大,模具作用在变形管材上的摩擦力和压力相应增大,这会降低温度升高对管材的软化作用。另外温度差值较小,两种工艺下力学性能曲线几乎重合,等效应力曲线比较接近。因此,等效应力数值变化较小。等效应力随着增量步增加的变化情况如图6所示。

图4 TP2铜管温度极值出现的位置

Fig. 4 Location of temperature extremum value of TP2 copper tube

表4 不同拉拔速度下管材的参数

Table 4 Drawing speeds of tube in different processes

3.2.2 拉拔速度对等效应力的影响

在原有拉拔工艺和优化拉拔工艺的三道次拉拔中,随着拉拔速度的增加,等效应力值基本不变。原有联拉工艺(如图7(a)所示),第二道次等效应力随着速度的提高略有下降;优化拉拔工艺中第二、三道次的等效应力相对于原工艺有小幅的下降;两种工艺条件下随着道次数的增加,等效应力下降。由于本模型着重考虑温度对变形体等效应力的影响作用,暂时未考虑冷变形量对材料硬化的影响,因此,温度对材料屈服强度的影响占主导作用。由表1可知,变形体材料屈服强度随着温度的升高而降低,当温度为100 ℃时,铜管材的屈服强度为240 MPa,模拟结果显示温度范围为95~162 ℃,等效应力范围为235~250 MPa,两者符合程度较好。而随着道次数的增加,拉拔速度提高,造成变形温度进一步提高,所以等效应力数值略有下降,但是下降幅度较小。综合考虑温度对屈服强度的降低作用和变形率的增加对屈服极限提高作用可以发现,温度对屈服强度数值地影响趋势小于变形率对其影响。拉拔速度对屈服极限的影响趋势如图7所示。

图5 不同工艺下拉拔速度对TP2铜管材温度场的影响

Fig. 5 Effect of drawing speed on temperature field at different processes

图6 TP2铜管材等效应力变化曲线

Fig. 6 Change curves of equivalent stress of TP2 copper tube

图7 拉拔速度对TP2铜管材等效应力的影响

Fig. 7 Effect of drawing velocity on equivalent stress of TP2 copper tube

4 实验分析

4.1 管材实际拉拔温度测量

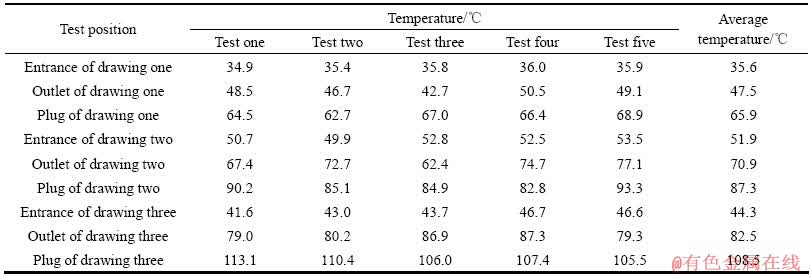

采用红外线测温仪,测量原三联拉变形温度,分别得到管坯在入口端、出口端温度和游动芯头温度。每个部位测试5组数据,入口端测试部位为外模润滑油喷出口部位,出口端测试位置是外模具定径段出口3厘米处,每道次拉拔结束立刻测量芯头温度。根据变形热生成机理和模具几何结构,可知芯头锥形段、定径段和外模的相应部位温度最高,在连续拉拔生产中,芯头的温度近似于变形区管材的温度,模具入口和出口端管材的温度,可以间接地反应变形区温度。由温度测量数据可知,3个道次芯头的平均温度分别为65.9、87.3和108.5 ℃,说明随着拉拔道次的增加,拉拔速度的提高,变形温度呈上升趋势。具体实验测量温度数值如表5所列。

4.2 模拟与实际测量温度比较

数值模拟给出的三道次变形区温度分别为95、109、114 ℃,各道次的温度均高于实验测得数据,原因是实验在冬天进行,环境温度较低,约为10 ℃;实验测量时,芯头掉出瞬间对周围环境放热,造成温度迅速降低,而模拟无此误差;芯头表面粘有润滑油,对芯头内部热量有一定的隔离作用,测量数据会稍低于实际温度数值。综合考虑以上几种因素,数值模拟温度值和实际温度值符合度较好,因此,热力耦合数值模拟模型对实际生产工艺的优化结果有效、可信。

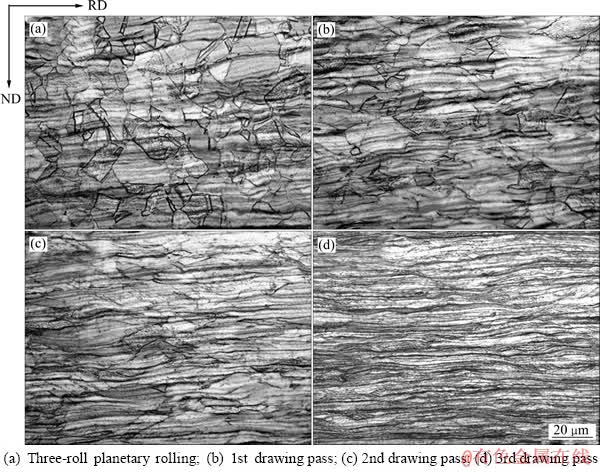

4.3 金相组织分析

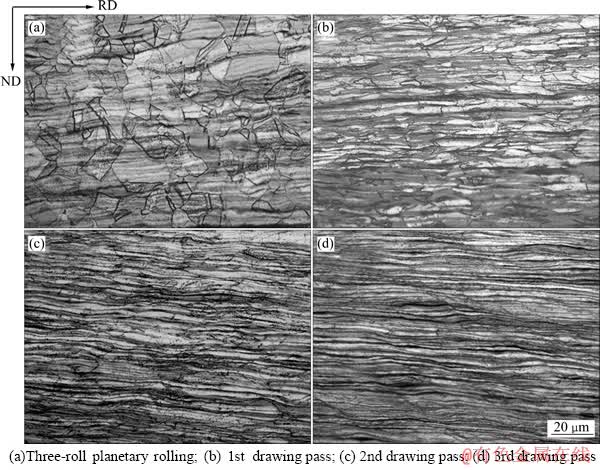

为了探究原有和优化拉拔工艺对管材组织的影响,对两种工艺下各个道次管坯进行取样,并经过磨、抛和腐蚀,最终获得的三辊行星轧制以及三道次联合拉拔管材的沿轴向金相组织,分别如图8和9所示。

表5 实际温度测试

Table 5 Experimental temperature

图8 原有工艺下TP2铜管材纵向截面的显微组织

Fig. 8 Microstructures of longitudinal section of TP2 copper tube by original process

图9 优化工艺下TP2铜管材纵截面的显微组织

Fig. 9 Microstructures of longitudinal section of TP2 copper tube by optimized process

对于原有拉拔工艺,由图8可发现,随着工序从轧制(见图8(a))到三道次联合拉拔(见图8(b)、(c)和(d)),晶粒大小呈现依次递减趋势,平均晶粒尺寸分别为30、25、15和10 μm,沿着拉拔方向出现明显的流线组织,随着拉拔道次的增加,流线数目明显增加,且流线层逐渐减薄。晶粒由最初的较为均匀的等轴晶逐渐被轴向拉长为条状晶粒,再被拉拔成线状晶粒,当拉拔变形量达到80%时,组织呈波浪状,晶界和枝晶难以辨认,如图8(d)所示。这与梅俊等[14]的研究结果一致。

优化拉拔工艺下三辊行星轧制管材的三道次联合拉拔工序变形体微观组织如图9所示。由图9可看出,三辊行星轧制管材的显微组织随拉拔道次的变化规律与原有工艺相同,但是平均晶粒尺寸有一定的变化,三辊行星轧制道次和优化后的三联拉道次的平均晶粒尺寸分别为30、15、10和8 μm。这是由于优化拉拔工艺较原有工艺单道次的加工率增大,冷变形将再结晶晶粒破碎,晶粒尺寸减小,材料力学性能提高[15],由于变形量较大,晶粒被严重拉长,等轴晶完全消失[16],晶粒进一步细化。变形量增大、晶粒的细化客观上会增大拉拔力,但是拉拔力的增大在拉拔机允许范围内。结果表明:优化拉拔工艺可以细化晶粒,提高产品质量,该优化工艺切实可行。图8、9中RD表示管材拉拔方向,ND表示管材径向。

5 结论

1) 在TP2管材游动芯头拉拔成形过程中,随着道次变形量与道次数的增加,管材温度呈升高趋势。由于优化工艺变形量相对于原有工艺有较为明显的增加,加之有限元模型经过简化,使得温度升高值比预想稍大,但是仍在合理范围内。

2) 联合拉拔工艺经过优化后,变形量有较大程度的提高,稳定拉拔时锥形段等效应力略有下降,维持在235~250 MPa。优化后的拉拔工艺对各道次的等效应力影响较小,有助于减少后续盘拉工艺拉拔道次,提高生产效率和降低能耗。

3) 三联拉工序使得管材组织由等轴晶粒变为条状晶粒,最终拉长成为线状晶粒,再结晶晶粒破碎,晶粒尺寸减小。优化工艺每道次的变形量大于原有工艺的,优化工艺可以对管材晶粒起到细化作用,提高产品质量。

REFERENCES

[1] BUI Q H, BIHAMTA R, GUILLOT M, D’AMOURS G, RAHEM A, FAFARD M. A new method for determination of formability limit in the tube drawing process[EB/OL]. [2011-05-02]. http://nparc.cisti-icist.nrc-nrc.gc.ca/npsi/ctrl? action=rtdoc&an=16919807&lang=en.

[2] 樊立奎. 不锈钢薄壁小直径管材拉伸加工的研究与应用[J]. 试验与研究, 2000, 29(4): 11-13.

FAN Li-kui. The research and application of thin wall and minor diameter drawing tube processing[J]. Experiments and Research, 2000, 29(4): 11-13.

[3] 黄成江, 李殿中, 戎利建, 李依依. 多道次拉拔管的三维弹塑性有限元分析[J]. 钢铁研究学报, 2000, 12(3): 27-30.

HUANG Cheng-jiang, LI Dian-zhong, RONG Li-jian, LI Yi-yi. 3D elasto-plastic FEM analysis of multi tube drawing[J]. Journal of Iron and Steel Research, 2000, 12(3): 27-30.

[4] PERNIS R, KASALA J. The influence of the die and floating plug geometry on the drawing process of tubing[J]. Int J Adv Manuf Technol, 2013, 65(5/8): 1081-1089.

[5] BIHAMTA R, BUI Q H, GUILLOT M, D’AMOURS G, RAHEM A, FAFARD M. A new method for production of variable thickness aluminium tubes: Numerical and experimental studies[J]. Journal of Materials Processing Technology, 2011, 211(4): 578-589.

[6] PALENGAT M, CHAGNON G, FAVIER D, LOUCHE H, LINARDON C, PLAIDEAU C. Cold drawing of 316L stainless steel thin-walled tubes: Experiments and finite element analysis[J]. International Journal of Mechanical Sciences, 2013, 70: 69-78.

[7] TANG Yong, OU Dong-sheng, WAN Zhen-ping, LU Long-sheng, LIAN Bin. Influence of drawing process parameters on forming of micro copper tube with straight grooves[J]. Transaction of Nonferrous Metals Society of China, 2011, 21(10): 2264-2269.

[8] 李志余, 张明明, 王 达, 彭丽红, 袁 静. 三连拉和盘拉工序的数值模拟[J]. 上海有色金属, 2011, 32(2): 66-68.

LI Zhi-yu, ZHANG Ming-ming, WANG Da, PENG Li-hong, YUAN Jing. Numerical simulation of triple drawing and jiggering process[J]. Shanghai Non-ferrous Metals, 2011, 32(2): 66-68.

[9] B LAND J F, FAFARD M, RAHEM A, D’AMOURS G, C

LAND J F, FAFARD M, RAHEM A, D’AMOURS G, C T

T T. Optimization on the cold drawing process of 6063 aluminium tubes[J]. Applied Mathematical Modelling, 2011, 35(11): 5302-5313.

T. Optimization on the cold drawing process of 6063 aluminium tubes[J]. Applied Mathematical Modelling, 2011, 35(11): 5302-5313.

[10] 牟取晗, 黄东男. 游动芯头拉拔模具受力和温度分布的数值模拟[J]. 内蒙古石油化工, 2007(2): 26-28.

MU Qu-han, HUANG Dong-nan. Numerical simulation of drawing die and temperature distribution during floating plug drawing process[J]. Inner Mongolia Petrochemical Industry, 2007(2): 26-28.

[11] 陆晓峰, 郑 新. 基于有限元模拟的20/316L双金属复合管拉拔参数的优化[J]. 中国有色金属学报, 2011, 21(1): 205-213.

LU Xiao-feng, ZHENG Xin. Optimization of drawing parameter with 20/316L double metal composited tube based on numerical simulation[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 205-213.

[12] 杨晓静, 孙方宏, 张志明, 沈荷生, 郭松寿. 基于有限元模拟的空拔铜管拉拔参数的优化[J]. 中国有色金属学报, 2008, 18(12): 2245-2252.

YANG Xiao-jing, SUN Fang-hong, ZHANG Zhi-ming, SHEN He-sheng, GUO Song-shou. Optimization of drawing parameter with copper tube hollow drawing based on numerical simulation[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2245-2252.

[13] 唐伟东, 张士宏, 林 涛, 刘劲松, 程大勇. 游动芯头拉拔模具失效分析[J]. 材料科学与工艺, 2012, 20(3): 109-116.

TANG Wei-dong, ZHANG Shi-hong, LIN Tao, LIU Jin-song, CHENG Da-yong. Die failure analysis of tube drawing with floating plugs[J]. Materials Science and Technology, 2012, 20(3): 109-116.

[14] 梅 俊, 刘新华, 姜雁斌, 谢建新. 轴向取向组织BFe10-1-1管材冷轧加工过程中组织、织构与力学性能的变化[J]. 中国有色金属学报, 2012, 22(9): 2529-2538.

MEI Jun, LIU Xin-hua, JIANG Yan-bin, XIE Jian-xin. Evolution of microstructure, texture and mechanical properties of BFe 10-1-1 tube with microstructure along axial orientation during cold-rolling[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2529-2538.

[15] 臧 冰, 易丹青, 孙顺平, 王 斌, 刘 欢, 柳公器. 冷拉拔对Al-Zr-(RE)合金硬度的影响及人工神经网络预测[J]. 中国有色金属学报, 2012, 22(8): 2187-2195.

ZANG Bing, YI Dan-qing, SUN Shun-ping, WANG Bin, LIU Huan, LIU Gong-qi. Effect of cold drawing on Vickers hardness of Al-Zr-(RE) alloys and artificial neural network prediction[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2187-2195.

[16] 王 成, 李 萍, 薛克敏, 李 晓, 章 凯. 纯铜挤扭工艺数值模拟与实验研究[J]. 中国有色金属学报, 2011, 21(12): 3071-3075.

WANG Cheng, LI Ping, XUE Ke-min, LI Xiao, ZHANG Kai. Numerical simulation and experimental research on pure copper by twist extrusion[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(12): 3071-3075.

(编辑 李艳红)

基金项目:中国科学院战略性新兴产业科技行动计划专项项目(46300378-5)

收稿日期:2014-05-25;修订日期:2014-09-15

通信作者:刘劲松,副教授,博士;电话:13514216091;Email: jsliu@imr.ac.cn