球磨工艺对Ti/HA复合材料原始粉料细化的影响

来源期刊:中南大学学报(自然科学版)2003年第6期

论文作者:刘芳 周科朝 刘咏

文章页码:593 - 597

关键词:复合材料;高能球磨;球磨工艺;弥散

Key words:composites; high-energy ball milling; milling technology; dispersion

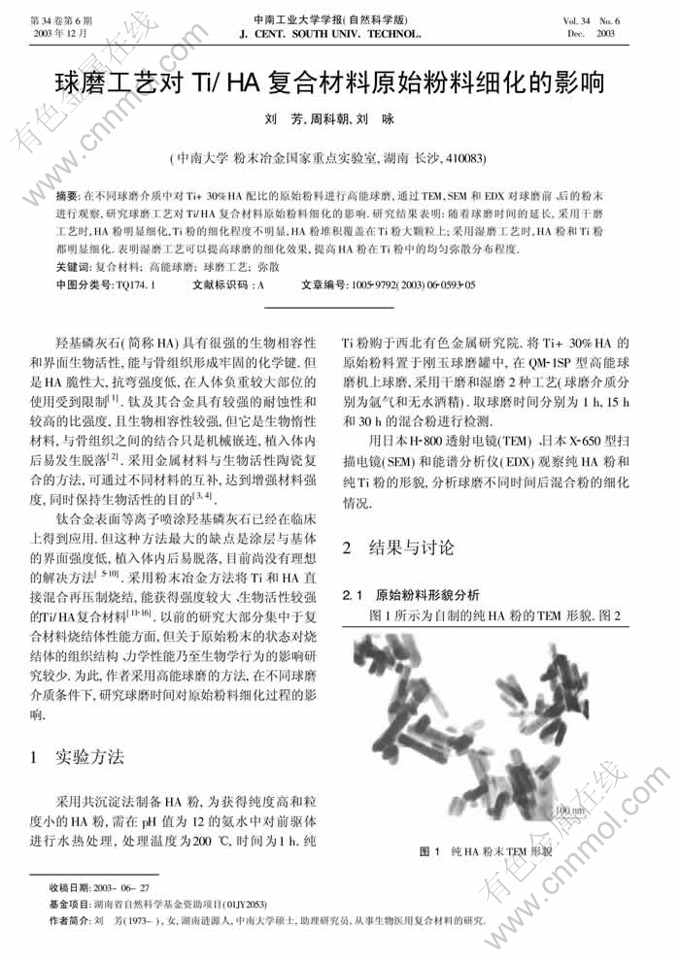

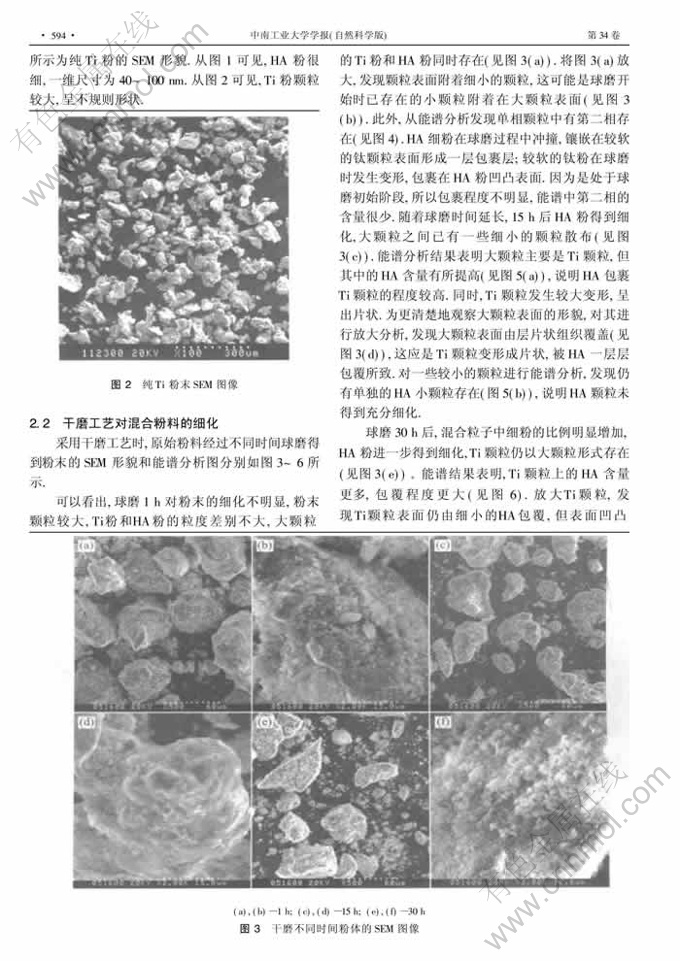

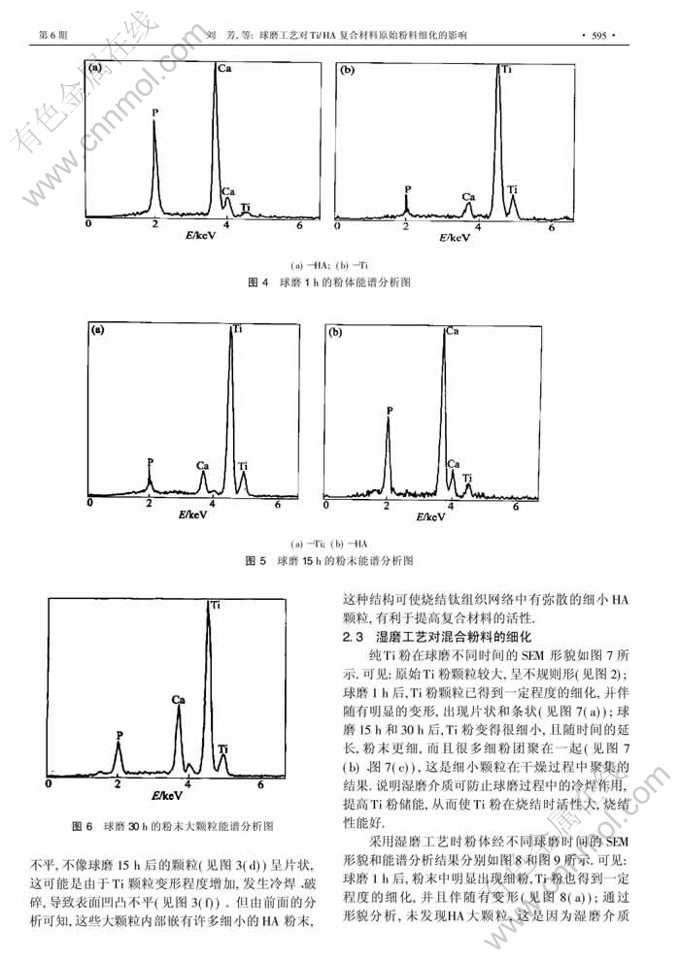

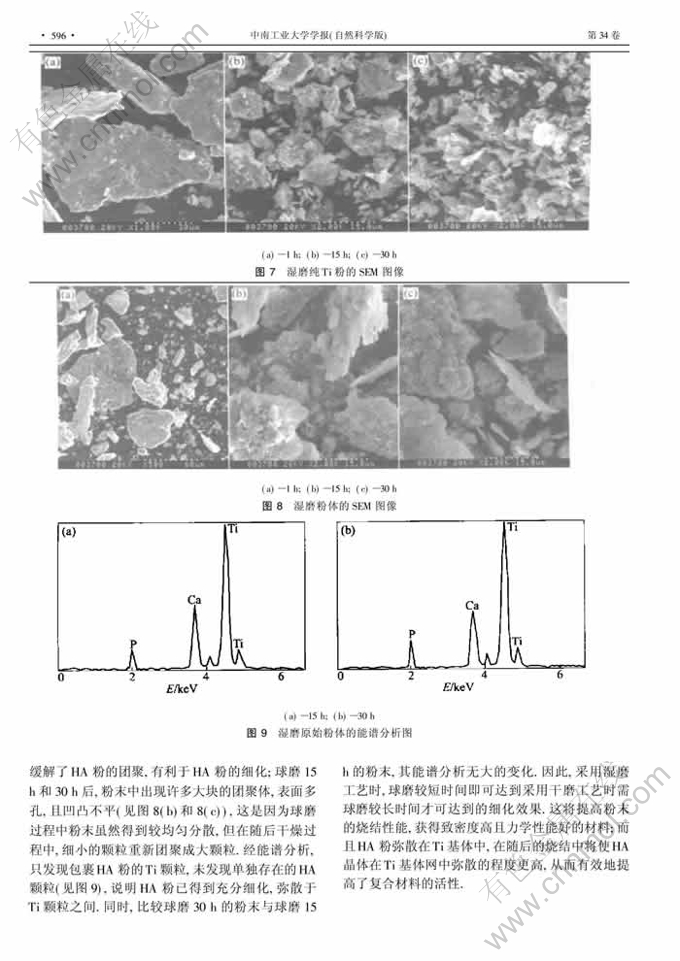

摘 要:在不同球磨介质中对Ti+30%HA配比的原始粉料进行高能球磨,通过TEM,SEM和EDX对球磨前、后的粉末进行观察,研究球磨工艺对Ti/HA复合材料原始粉料细化的影响.研究结果表明:随着球磨时间的延长,采用干磨工艺时,HA粉明显细化,Ti粉的细化程度不明显,HA粉堆积覆盖在Ti粉大颗粒上;采用湿磨工艺时,HA粉和Ti粉都明显细化.表明湿磨工艺可以提高球磨的细化效果,提高HA粉在Ti粉中的均匀弥散分布程度.

Abstract: Ti+30%HA powder was high-energy ball milled in different milling media. The effects of milling technology on powder of Ti/HA composites were studied. The results show that: during dry-milling, increasing milling time can greatly refine HA powder, but has almost no influence on refinement ofTi powder. Under this condition, large Ti powders are packed and wrapped by fine HA powders. During wet milling, both Ti powder and HA powder can be obviously refined by increasing milling time, but the kinds of powder are together. Therefore, the existence of wet-milling medium can improve the effect of milling and dispersity of HA in Ti powder.