文章编号: 1004- 0609(2005)04- 0572- 06

Al-Zr-O-B体系原位合成颗粒增强铝基复合材料及其性能

李桂荣, 戴起勋, 赵玉涛, 王宏明, 朱延山

(江苏大学 材料科学与工程学院, 镇江 212013)

摘 要: 研究了采用Al-Zr(CO3)2-KBF4组元通过熔体反应法原位合成颗粒增强铝基复合材料。 X射线衍射(XRD)和扫描电镜(SEM)分析表明: 内生增强相颗粒为ZrAl3、 ZrB2和Al2O3, 粒度为3~4μm, 且在基体中弥散分布。 复合材料的力学性能和干滑动磨损特性研究表明: 在反应物加入量为0~20%(质量百分数)范围内时, 复合材料的抗拉强度和屈服强度较纯铝基体明显提高, 当反应物加入量为20%时, 抗拉强度为150.3MPa, 屈服强度为113.7MPa。 当反应物加入量为5%时延伸率最佳为33%, 属塑性断裂。 复合材料的耐磨性较铝基体显著提高, 当反应物加入量为10%时耐磨性最好。 铝基体的磨损机制是粘着磨损, 而(ZrAl3+ZrB2+Al2O3)p/Al 复合材料的磨损机制是磨粒磨损。

关键词: Al-Zr-O-B体系; 复合材料; 原位合成; 抗拉强度; 磨粒磨损 中图分类号: TB331; TG146.21

文献标识码: A

Fabrication and properties of particles reinforced aluminum

matrix composites in-situ synthesized in Al-Zr-O-B system

LI Gui-rong, DAI Qi-xun, ZHAO Yu-tao, WANG Hong-ming, ZHU Yan-shan

(School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China)

Abstract: The Al-Zr(CO3)2-KBF4 components were used to fabricate the particle reinforced aluminum-based composites by the direct melt reaction method. The results of X-ray diffractometry(XRD) and scanning electron microscopy(SEM) show that the in-situ endogenetic particles are ZrAl3, ZrB2 and Al2O3, which are well distributed in the aluminum matrix. The sizes of particles are 3- 4μm. The results of mechanical and wearing properties of the composites show that the tensile strength and yield strength are improved with the increase of adding amounts of reactants in the range of 0- 20%(mass fraction), which are much superior to those of aluminum matrix. The best elongation is 33% when the adding amount is 5%. The wear-resistance of the composites are much higher than that of aluminum matrix. The wearing mechanism of the aluminum matrix is adhesive wear while the wearing mechanism of (ZrAl3+ ZrB2+Al2O3)p/Al composites is abrasive wear.

Key words: Al-Zr-O-B system; composite; in-situ fabrication; tensile strength; abrasive wear

颗粒增强铝基复合材料因具有高的比强度和比刚度、 低的热膨胀系数、 耐磨性好、 成本低等特点, 近年来正在快速发展, 并已开始实现实用化和商业化。 其中原位合成内生颗粒增强的铝基复合材料有着界面清洁、 合成工艺简单、 易操作、 复合材料力学性能高等优点。 近年来合成的内生硬质陶瓷增强颗粒相主要有: Al2O3、 TiB2、 TiC、 TiAl3、 ZrAl3、 AlN等[1- 9]。

本文作者在前期Al-Zr-O体系反应生成ZrAl3和Al2O3颗粒增强复合材料的基础上, 开发了Al-Zr-O-B原位合成新体系, 研究了Al-Zr(CO3)2-KBF4组元通过熔体反应法原位合成的颗粒增强铝基复合材料, 并对其微观组织、 反应热力学、 力学性能和磨损性能等进行了探讨。

1 实验方法

实验用原材料为工业纯铝(纯度为99.95%)、 碳酸锆(Zr(CO3)2)粉剂(纯度为99%)和KBF4粉剂(纯度为99.5%)。 首先将各反应物粉剂在300℃下烘烤3h, 充分去除结晶水, 然后冷却、 研磨, 经过70目标准筛筛分, 得到粒度≤0.21mm的粉末添加料。 将工业纯铝锭在电阻炉中熔化, 随后过热至不同反应温度, 精炼, 向熔体中分批加入适量经脱水处理的反应物粉剂, 用钟罩压入熔体中并用石墨棒搅拌, 使之与铝液充分接触反应。 用便携式温度测试仪连续测定反应过程中熔体温度的变化, 反应结束后用熔剂除气、 除渣, 并静置10min, 于720℃浇入金属型中, 制得铸态内生颗粒增强铝基复合材料试样和试棒。

为了获得最佳的复合材料合成条件, 用L9(34)正交表设计三因子三水平正交实验, 其主要参数和水平为: 起始反应温度800、 850、 900℃; 反应物混合剂(Zr(CO3)2+KBF4)加入量5%、 10%、 20%(为铝液的质量分数); 反应时间15、 25、 35min。

拉伸性能测试在WD10电子拉伸机上进行, 干磨损实验在MM-200型销盘式试验机上进行。 磨损试样采用线切割成尺寸19.5mm×10mm×8mm, 对磨面为19.5mm×8mm, 其磨面用金相砂纸磨至1200号。 对磨件为40Cr钢(HRC40), 尺寸为d40mm×10mm, 磨损量以试样磨损前后的质量差来衡量, 称量采用MA110电子分析天平, 精度为0.0001g, 在JEOL- JXA- 840A型扫描电镜上观察颗粒增强相的形貌、 大小、 分布和拉伸断口形貌以及磨损表面形貌。

2 结果与讨论

2.1 复合材料的微观组织和热力学分析

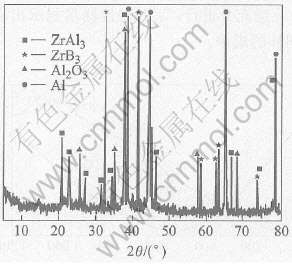

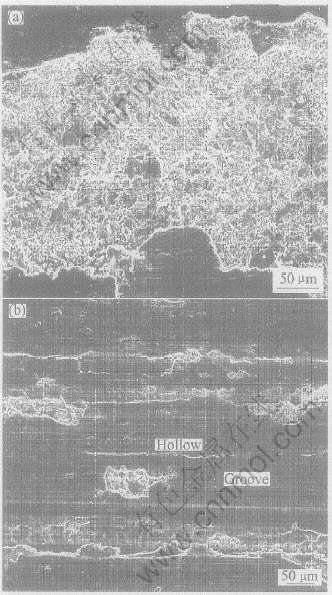

图1所示为Al-Zr-O-B体系熔体反应法合成复合材料的XRD图。 由图1可见合成的铝基复合材料中存在ZrAl3、 ZrB2和Al2O3物质, 这3种物质在1090℃时对应的弹性模量分别为308、 503和379GPa, 都属于硬质的陶瓷颗粒。 图2所示为Al-Zr-O-B体系合成复合材料的微观组织。 由图2可见, 生成的颗粒在基体中粒度大小均匀, 尺寸范围在3~4μm, 而且颗粒在铝基体中均匀弥散分布。

图1 Al-Zr-O-B体系合成复合材料的XRD谱

Fig.1 XRD pattern of composites synthesized in Al-Zr-O-B system

图2 Al-Zr-O-B体系合成复合材料的SEM图

Fig.2 SEM photograph of composites synthesized in Al-Zr-O-B system

以复合材料试样SEM照片中颗粒的粒度和分布为标准来比较正交实验结果, 由此确定Al-Zr(CO3)2-KBF4合成复合材料的最佳条件。 实验表明Al-Zr(CO3)2-KBF4反应体系的最佳合成条件为: 反应物加入量20%, 起始反应温度870℃, 反应时间25min。

图3所示为Al-Zr(CO3)2-KBF4组元的DSC分析曲线, 升温速率为10℃/min。 由图3可见, 在整个升温过程中, 647.3℃时对应铝的熔化吸热, Al-Zr(CO3)2-KBF4反应体系在870℃时的热效应明显增加, 继之发生放热反应, 此时在熔体中生成了新相, 最高温度达到1006.7℃。 由此可见Al-Zr-O-B体系通过原位反应合成颗粒增强铝基复合材料时的一个明显特征, 即在体系达到某一起始温度后, 放热效应明显增加, 熔体温度存在一个最高点, 在实验过程中可以观察到此时熔体内液面剧烈波动, 反应充分进行, 实时温度测量显示出和差热分析同样的规律。

图3 Al-Zr(CO3)2-KBF4组元差热分析结果

Fig.3 TG-DSC curves of Al-Zr(CO3)2-KBF4 components

进一步分析Al-Zr(CO3)2-KBF4反应组元原位合成过程中的化学反应, 可知在铝熔体中会发生如下反应。

1) 第一步

由图3可知, 550℃时有吸热反应发生, 同时热重分析曲线表明试样质量减轻, 该点对应的是Zr(CO3)2的分解温度, 产物为ZrO2和CO2。

2) 第二步

在尚未达到预定合成时间的过程中提取中间产物试样, 经X射线衍射分析发现试样中有大量的AlB2中间产物, 验证反应(2)可以发生。

3) 第三步

根据文献[10- 12]提供的数据, 计算可得到:

所以反应式(3)的吉布斯自由能值为

该反应达到平衡时的温度为1322.8K(1049.7℃), 当体系温度低于1049.7℃时, ΔG3〈0, 反应自发进行。 因为Al-Zr(CO3)2-KBF4反应体系在合成过程中的熔体温度波动范围在870~1006.7℃, 所以在整个合成过程中, 反应(3)可自发进行。

4) 第四步

反式(4)的吉布斯自由能变化值为

该反应达到平衡时的温度为1030.4K(757.3℃), 当体系温度低于757.3℃时, ΔG4〈0, 反应自发进行在合成过程中能够满足反应(4)发生的温度范围有限, 所以反应(4)进行的程度不够充分。 这解释了在X射线衍射谱中ZrB2含量较少的实验结果。

将反应式(1)+ (2)+ (3)+ (4), 得到总的反应方程:

2.2 (ZrAl3+ZrB2+Al2O3)p/Al复合材料的力学性能和断口形貌

图4所示为Al-Zr-O-B体系反应合成(ZrAl3+ZrB2+Al2O3)p/Al复合材料的室温拉伸性能。 由图4可知, 复合材料的屈服强度和抗拉强度均随反应物加入量的增加而提高。 当反应物加入量为20%时, 复合材料的抗拉强度达150.3MPa, 较纯铝基体的78.0 MPa提高了92.7%。 另外复合材料的屈服强度达113.7MPa, 较铝基体的42.0MPa提高了170.7%。 上述结果表明, 复合材料的抗拉强度和屈服强度与纯铝基体相比有了显著提高。 其原因在于原位生成的细小弥散的增强相颗粒强化了铝基体, 其强化机理分析如下。

1) 位错强化。 金属晶体缺陷理论提出, 位错缺陷密度增加能够有效地提高强度。 在(ZrAl3+ZrB2+Al2O3)p/Al颗粒增强复合材料中, 增强体ZrAl3、 ZrB2和Al2O3与铝基体间存在较大的热膨胀系数差异, 800℃时, Al、 ZrAl3、 ZrB2和Al2O3的线膨胀系数分别为23.6×10-4/℃、 12.1×10-4/℃、 8.28×10-4/℃和7.92×10-4/℃, 这导致材料内部产生较大的热应力, 继而引发材料塑性变形, 位错密度显著增加, 从而提高了复合材料的抗拉强度和屈服强度。

图4 (ZrAl3+ZrB2+Al2O3)p/Al复合材料的拉伸性能

Fig.4 Tensile properties of (ZrAl3+ZrB2+Al2O3)p/Al composites

2) 细晶强化。 基体的晶粒结构是影响金属基复合材料力学性能的主要因素之一, 当增强体和基体存在一定的晶体学位向关系时, 增强体的表面就成为非均质形核的基底, 在加大形核率的同时细化晶粒。 据文献报道[13- 15], (ZrAl3 +Al2O3)p/Al复合材料中, 增强相ZrAl3与Al存在一定的晶体学位向关系: [100] ZrAl3∥[100]Al, (001)ZrAl3∥(001)Al, 其错配度为0.95%, 满足共格对应条件。 这表明ZrAl3可作为铝基体的非均质形核基底, 起到细化晶粒、 增加强度的作用。

图5所示为(ZrAl3+ZrB2+Al2O3)p/Al复合材料室温拉伸断口的SEM形貌。 从图5(a)可见, 断口上存在着许多韧窝和撕裂棱, 韧窝中分布着细小的颗粒, 撕裂棱细密弯曲, 且相互缠结, 属塑性断裂。 当反应物加入量由5%增加到20%时, 断口上的韧窝和撕裂棱大大减少, 同时韧窝也变大, 其对应的延伸率也明显降低(图4)。 当反应物加入量为5%时复合材料的延伸率为33%, 较铝基体延伸率的30%提高10%, 加入量为20%时延伸率下降到8.5%, 但其断口仍为塑性断裂。 这表明, 断口形貌分析的结果与图4中的力学性能数据吻合。

图5 (ZrAl3+ZrB2+Al2O3)p/Al复合材料室温拉伸断口形貌

Fig.5 SEM morphologies of tensile fracture surface of (ZrAl3+ZrB2+Al2O3)p/Al composites at room temperature

2.3 (ZrAl3+ZrB2+Al2O3)p/Al 复合材料的干滑动磨损特性

将纯铝基体和(ZrAl3+ZrB2+Al2O3)p/Al复合材料的硬度和磨损性能进行对比分析。 施加载荷为90N, 磨损时间为90min, 结果如图6所示。 由图6可见: (ZrAl3+ZrB2+Al2O3)p/Al复合材料的硬度和耐磨性都较铝基体有很大改善; 随着反应物加入量从5%增加到20%, 磨损量呈现抛物线形状变化, 当加入量为10%时, 磨损量最低为58.2mg, 不到铝基体120mg磨损量的一半, 复合材料的耐磨性能明显提高。 同时可见: 反应物加入量并非越多耐磨性越好, 而是存在一个最佳值, 这与磨损机制有关; 材料硬度越高, 磨损量越小, 耐磨性越好, 大体上存在着对应关系。

图7所示是磨损表面的SEM形貌。 由图7(a)可见, 纯铝基体的磨损表面剥落严重, 受变形和挤[CM(22]压而产生的变形迁移层明显。 分析其原因在于基体与40Cr钢对磨件在载荷作用下产生表面接触, 由于铝基体硬度低, 只有HB25, 在摩擦过程中产生热量使纯铝基体表面层温度升高而软化变形, 接着在磨擦表面形成凸起的具有犁削作用的粘着点, 随着摩擦磨损过程的不断进行, 粘着点逐渐增大, 在剪切力的作用下, 致使铝基体的剥落加剧, 表面因磨削而被大片撕脱转移, 由此产生大面积的凹坑, 磨损机制为粘着磨损。

图6 反应物加入量和硬度、 磨损量的关系

Fig.6 Relationship between amount of reactants and hardness, wearing loss

图7(b)所示为反应物加入量为20%, 起始反应温度870℃, 反应时间25min条件下制备的(ZrAl3+ZrB2+Al2O3)p/Al 复合材料, 其摩擦磨损表面沿滑动方向的SEM照片。 可见表面较平整光滑, 有几处小凹坑, 明显地比图7(a)的撕裂坑面积小而浅。 分析其原因是由于内生增强颗粒凸出于磨损表面, 起到了抵抗对磨材料对复合材料表面的微切削破坏作用, 可以限制铝基体的变形, 从而提高了基体抗剪切应变的能力, 有利于在摩擦表面形成摩擦转移膜, 减少了铝基体与对磨材料直接接触, 也减少了摩擦表面上合金基体可能被粘着的区域面积, 因此磨损表面粘着撕脱的面积和数量均降低。 从图7(b)上还可以看到复合材料磨损表面的犁沟形貌, 痕迹明显且轮廓清晰, 这是由于复合材料磨损表面脱落的较硬颗粒在摩擦过程中起到了磨粒的作用, 在较大载荷的作用下压入了复合材料摩擦表面, 并沿摩擦方向发生了滑移, 从而在磨损表面形成了犁沟。 综合来看, (ZrAl3+ZrB2+Al2O3)p/Al 复合材料的磨损机制为磨粒磨损。 在合成过程中当反应物加入量较小时, 内生颗粒数量少, 不能起到很好的支撑减磨的作用; 而当加入量较大时, 内生颗粒数量多, 颗粒分布相对比较密集, 硬质颗粒对表面的犁削作用加重, 同时颗粒脱落生成的凹坑增加, 会加速磨损。 硬质陶瓷颗粒在铝基复合材料耐磨性的研究中存在两面性, 所以合成过程中反应物的加入量对应一最佳值, 用Al-Zr(CO3)2-KBF4组元合成(ZrAl3+ZrB2+Al2O3)p/Al 颗粒增强铝基复合材料时, 对应的最佳反应物加入量为铝基体的10%。

图7 铝基体和复合材料的磨损表面SEM照片

Fig.7 SEM photographs of wear surface of Al(a) and (ZrAl3+ZrB2+Al2O3)p/Al composites(b)

3 结论

1) 以Al-Zr(CO3)2-KBF4作为反应组元, 通过熔体反应法原位合成了(ZrAl3+ZrB2+Al2O3)p/Al复合材料, 增强相颗粒粒度3~4μm, 在基体中均匀弥散分布。

2) (ZrAl3+ZrB2+Al2O3)p/Al复合材料的抗拉强度和屈服强度随反应物加入量的增加而增大, 都较铝基体有了较大改善, 但延伸率随反应物加入量的增加呈现抛物线形状, 加入量为5%时延伸率对应最佳值33%, 从拉伸断口看, 其断裂属塑性断裂。

3) 复合材料的硬度和耐磨性都较铝基体好, 当反应物加入量为10%时, 耐磨性能最好。 磨损表面形貌分析结果表明, 铝基体磨损机制是粘着磨损, 而(ZrAl3+ZrB2+Al2O3)p/Al复合材料的磨损机制是磨粒磨损。

REFERENCES

[1] Lioyd D J. Particle reinforced aluminum magnesium matrix composites[J]. International Materials Review, 1994, 39(1): 1- 22.

[2] Feest E A, Kyoung R M. Who can profit from the use of metal matrix composites[J]. Metallurgist, 1996(3): 113- 119.

[3] HUANG Zan-jun. Study of in-situ Al2O3 particulate reinforcement aluminum-based composites[J]. Acta Metallurgica Sinica, 2002, 6: 568- 574.

[4] 陈子勇, 陈玉勇, 舒 群, 等. 熔体反应法制备Al-4.5Cu/TiB2复合材料的热力学[J]. 材料研究学报, 2000, 14(1): 68- 74.

CHEN Zi-yong, CHEN Yu-yong, SHU Qun, et al. Thermodynamic of Al-4.5Cu/TiB2 composites fabricated by direct melt method[J]. Journal of Materials Research, 2000, 14(1): 68- 74.

[5] 赵玉涛, 孙国雄. Al-ZrOCl2反应体系制备ZrAl3(p)+Al2O3(p)/Al复合材料[J]. 中国有色金属学报, 2001, 11(1): 41- 46.

ZHAO Yu-tao, SUN Guo-xiong. ZrAl3(p)+Al2O3(p)/Al composites fabricated by reaction in system Al-ZrOCl2[J].The Chinese Journal of Nonferrous Metals, 2001, 11(1): 41- 46.

[6] ZHANG E-lin, ZENG Xiao-chun, ZENG Song-yan. Microstructure and property of Al/TiC composites prepared by reaction systhesis[J]. Trans Nonferrous Met Soc China, 1996, 6(1): 114- 119.

[7] ZHAO Yu-tao, LI Zhong-hua, CHENG Xiao-nong, et al.In-situ synthesized ZrAl3(p)+Al2O3(p)/A356 composites by direct melt reaction in Al-Zr-O system[J]. Trans Nonferrous Met Soc China, 2003, 13(4): 769- 773.

[8] Kuruvilla A K, Prasad K S, Bhanuprasad V V, et al. Microstructure-property correlation in Al/TiB2/(XD) composites[J]. Scripta Metall, 1990, 24: 873- 880.

[9] 赵玉涛, 孙国雄. ZrOCl2-Al体系熔体反应生成Al3Zr(p), Al2O3(p)/Al复合材料的反应机制[J]. 中国有色金属学报, 2001, 11(3): 372- 376.

ZHAO Yu-tao, SUN Guo-xiong. Reactive mechanism of Al3Zr(p), Al2O3(p)/Al composites formed by reaction between ZrOCl2 and liquid aluminum[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 372- 376.

[10] 刘光启. 化学化工物性数据手册[M]. 北京: 化学工业出版社, 2002.

LIU Guang-qi. Physical Data Manual of Chemistry and Chemical Engineering[M]. Beijing: Chemical Industry Press, 2002.

[11] 姚永斌. 物理化学手册[M]. 上海: 上海科学技术出版社, 1985.

YAO Yong-bin. Manual of Physical Chemistry[M]. Shanghai: Shanghai Science and Technology Press, 1985.

[12] 曾志明. 机械工程材料手册[M]. 北京: 机械工业出版社, 2003.

ZENG Zhi-ming. Manual of Mechanical Engineering Materials[M]. Beijing: China Machine Press, 2003.

[13] 王 俊, 杨汉国, 赵华庭, 等. Al2O3p/ZA22复合材料拉伸时的原位观察[J]. 实验力学, 1998, 13(1): 47- 51.

WANG Jun, YANG Han-guo, ZHAO Hua-ting, et al. The in-situ observation of tension deformation for Al2O3p/ZA22 composite[J]. Journal of Experimental Mechanics, 1998, 13(1): 47- 51.

[14] 秦蜀懿, 刘世楷, 张国定. δ-Al2O3/Al-12Si-Cu复合材料断裂过程原位观察[J]. 机械工程材料, 1998, 22(4): 1- 3.

QIN Shu-yi, LIU Shi-kai, ZHANG Guo-ding. In situ observation of fracture of δ-Al2O3/Al-12Si-Cu composite[J]. Materials for Mechanical Engineering, 1998, 22(4): 1- 3.

[15] 孙建祥, 赵玉涛, 戴起勋, 等. Al-Zr(CO3)2 体系合成复合材料的力学性能与断裂行为[J]. 中国有色金属学报, 2004, 14(7): 1228- 1233.

SUN Jian-xiang, ZHAO Yu-tao, DAI Qi-xun, et al. Mechanical properties and crack behavior of in-situ composite synthesized in Al-Zr(CO3)2 reaction system[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1228- 1233.

基金项目: 国家自然科学基金资助项目(50471050); 教育部重点基金资助项目(2000156); 江苏省“十五”科技攻关项目(BE2002040); 江苏省高等学校高新技术产业化发展项目(JH02-039); 江苏省铝基复合材料工程中心研发项目(BM2003014); 江苏大学高级人才基金项目

收稿日期: 2004- 10- 08; 修订日期: 2004- 12- 13

作者简介: 李桂荣(1976- ), 女, 讲师, 博士研究生.

通讯作者: 李桂荣; 电话: 0511-8791844; E-mail: whmlgr@ujs.edu.cn

(编辑 袁赛前)