AlSiC电子封装基片的制备与性能

熊德赣, 刘希从, 鲍小恒, 白书欣, 杨盛良, 赵 恂

(国防科技大学 航天与材料工程学院, 长沙 410073)

摘 要: 采用模压成形制备SiC预制件和真空压力浸渗相结合的技术, 成功制备出AlSiC电子封装基片。 研究磷酸铝含量和成形压力对SiC预制件抗弯强度和孔隙率的影响规律, 并对所制备的AlSiC电子封装基片的性能进行评价。 结果表明, 在磷酸铝含量为0.8%, 成形压力为200MPa时, 经600℃恒温2h处理的SiC预制件抗弯强度为8.46MPa, 孔隙率为37%。 当温度为100~500℃时, AlSiC电子封装基片的热膨胀系数介于6.88×10-6和8.14×10-6℃-1之间, 热导率为170W/(m·K), 抗弯强度为398MPa, 气密性小于1×10-8 Pa·m3/s。 用钯盐活化进行化学镀镍, 得到光亮、 完整的镀层。 镀层于450℃恒温120s后, 镀层不变色, 未见起皮和鼓泡。

关键词: AlSiC电子封装基片; 气密性; 真空压力浸渗; 化学镀镍 中图分类号: TG146

文献标识码: A

Fabrication and property of aluminum silicon carbide electronic packaging baseplates

XIONG De-gan, LIU Xi-cong, BAO Xiao-heng, BAI Shu-xin, YANG Sheng-liang, ZHAO Xun

(College of Astronautics and Material Engineering, National University of Defence Technology,Changsha 410073, China)

Abstract: The aluminum silicon carbide electronic packaging baseplates were produced successfully by combination of compression molding for SiC preform and vacuum pressure infiltration. The effects of amount of aluminum phosphate and molding pressure on porosity and strength of SiC preform were investigated, and the properties of AlSiC electronic packaging baseplates were also evaluated. The results show that the bending strength and porosity of SiC perform dried at 600℃ for 2h are 8.46MPa and 37%, respectively, when the content of aluminum phosphate is 0.8% and the molding pressure is 200MPa. The coefficient of thermal expansion of AlSiC electronic packaging baseplates ranges from 6.88×10-6to 8.14×10-6℃-1 at the temperatures of 100-500℃, the thermal conductivity is 170 W/(m·K), the bending strength is 398MPa and the hermeticity is less than 1×10-8 Pa·m3/s. The electroless nickel was processed by utilizing palladium chloride as activator. The plating layer with bright, smooth and continuous surface has good adhesion when it is exposed at 450℃ for 120s.

Key words: aluminum silicon carbide electronic packaging baseplate; hermeticity; vacuum pressure infiltration; electroless nickel plating

AlSiC电子封装构件由于原材料价格便宜, 能近净成形复杂形状, 且具有热导率高、 膨胀系数可调、 比刚度大、 密度小, 使封装结构具有功率密度高、 芯片寿命长、 可靠性高和质量轻等特点, 在电子封装领域的应用日益广泛[1-2]。

AlSiC电子封装构件的制备方法由SiC预制件制备和融熔铝合金液浸渗两步组成。 目前, 预制件的制备方法主要有模压成形[3]、 美国AFT公司的粉末注射成形和美国CPS公司的QuicksetTM注射成形技术[4]。 模压成形适用于一些结构简单的构件, 成型模具制造简单、 操作方便、 周期短、 效率高, 便于实现自动化生产, 但成型尺寸精度较差, 较适用于产品的前期研制。 融熔铝合金液浸渗方法主要有挤压铸造[5]、 真空压力浸渗[6-7]、 真空辅助压力铸造[8-9]和无压浸渗[10-11]4种。 挤压铸造、 真空压力浸渗和真空辅助压力铸造需要高压设备, 可采用各种铝合金作基体, 构件孔隙率小, 后两者还可同步集成引线、 密封环和基片。 无压浸渗不需要高压设备, 也不需要真空条件, 浸渗模具材料选择范围广, 能够用于制造大尺寸及形状复杂构件, 生产成本较低, 但对基体合金的成分有较严格的要求, 浸渗需在流动的氮气气氛中进行, 构件孔隙率较大和浸渗时间较长, 无法实现同步集成等。 本文作者采用模压成形和真空压力浸渗相结合的工艺, 实现了高致密度及体积分数为63%的AlSiC电子封装基片批量制备, 并对基片的性能进行了测试与分析。

1 实验

1.1 原料

基体采用商用6063合金, 其成分(质量分数, %)为: Mg为0.45~0.9, Si为0.2~0.6, Fe小于0.35, Mn小于0.1, Cu小于0.1, Al为余量。

碳化硅粉末为市售α-SiC, 粉末平均粒径分别为45, 20和10μm, 其成分为(质量分数): w(SiC)≥98.5%, 自由碳不大于0.3%, w(Fe2O3)≤0.05%, w(SiO2)≤0.7%。

自制的磷酸铝溶液中磷铝摩尔比为10∶1, 密度为1.2g/cm3。 糊精和聚乙二醇6000(化学纯)为市售。

1.2 材料制备

按一定比例称取多种粒径的碳化硅粉末, 先用三维混合机混合均匀, 然后加入粘接剂搅拌均匀, 经造粒后模压成形得湿坯, 湿坯经600℃恒温2h处理后随炉冷却即得基片预制件, 按同样的工艺制备了抗弯强度预制件样品。 将基片预制件装入钢模具中, 置于ZYQ250/400-1000型真空压力浸渗炉进行浸渗, 具体工艺参数为: 上室(预制件)温度为650~670℃, 下室(6063铝熔体)的温度为700℃, 浸渗压力12MPa, 保压15min后随炉冷却。

浸渗完成后, 从钢模具中取出复合材料, 机械加工后制得AlSiC基片。 在基片表面进行化学镀镍处理和镀金处理。

1.3 测试

复合材料性能测试前, 将试样于450℃保温2h, 炉冷退火处理。 预制件表观密度及孔隙率和复合材料的密度采用阿基米德法测量。 材料的热膨胀系数采用日产理学TAS-100型膨胀仪, 在20~500℃的温度范围内测试, 试样尺寸为20mm×3mm×4mm, 加热速率为5℃/min。 为保证测试时温度均匀和防止试样氧化, 采用氮气保护, 流量为20mL/min。 热扩散系数采用JR-2型激光导热仪测定, 试样尺寸为d10mm×3mm, 导热系数则根据测得的热扩散系数和质量热容计算得出。 用WDW-100KN型电子万能试验机测定预制件和复合材料的三点抗弯强度, 压头移动速率为0.5mm/min, 试样尺寸为4mm×3mm×40mm, 跨距为30mm。 用扫描电镜观察预制件断口和基片表面镀层形貌, 镀层结合力按GJB1420A进行考核。 基片的气密性采用氦质谱仪测定, 随机抽取30件基片研磨后置于密闭的容器中通入0.5MPa氦气2h, 取出后放入氦质谱仪中检测高真空下的放气率。

2 结果与分析

2.1 AlSiC电子封装基片的制备

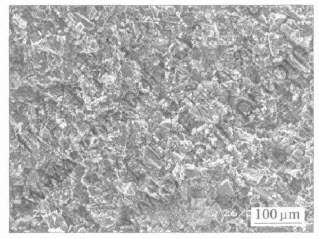

预制件成形是获得高质量复合材料及近净成形构件的关键, 在文献中均未作详细报道。 制备构件预制件时, 既要控制形状和尺寸精度, 又要控制粗细粉末的分布均匀性, 还需较高的强度以满足浸渗铸造的技术要求。 影响模压成形预制件的主要因素有: 粉末粒径级配、 无机粘接剂种类及含量和成形压力[6]。 用糊精作有机粘接剂, 聚乙二醇作塑化剂和润滑剂, 磷酸铝含量和成形压力对预制件性能的影响如表1所示。 在磷酸铝含量相同的条件下, 随成形压力增加, 粗细粉末被压制得更紧密, 孔隙率降低, 导致预制件密度逐渐增加, 有效承载面积增加, 因此预制件抗弯强度也增大。 由于碳化硅硬度高, 外形呈多角状, 成形压力愈大, 成形模具的磨损愈严重, 模具的寿命愈短, 因此粒径级配确定后, 成形压力愈小愈好。 成形压力相同时, 随磷酸铝含量的增加, 预制件抗弯强度也提高。 Lee等[5]的研究表明, 当SiO2含量从0.5%增加到3%时, 预制件抗压强度从50MPa提高到121MPa。 由于磷酸铝作为杂质相存在会影响复合材料的热导率, 因此在满足真空浸渗的条件下, 磷酸铝的含量愈少愈好。 成形压力为200MPa, 磷酸铝含量为0.8%预制件的断口形貌如图1 所示。 从图1中可以看出, 细粉末填充到粗粉末间隙中, 粗细粉末分布均匀。

表1 不同工艺条件下预制件的性能

Table 1 Properties of preforms fabricated by different processes

图1 碳化硅预制件断口的SEM像

Fig.1 SEM image of fracture surface of SiC preform

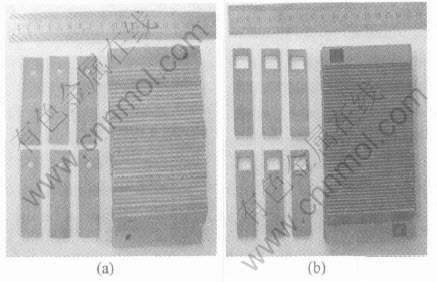

基片的厚度为2.5mm, 因此可采用以下两种方法: 一是间接法, 即先制成厚件, 然后再机械加工分割成多件; 另一种方法是直接法, 即预制件厚度与制品厚度接近。 间接法制备厚预制件, 模压时常常使预制件密度沿厚度方向不均匀; 浸铝制成复合材料后, 若采用金刚石切割片切割, 铝合金经常粘附在金刚石磨料表面, 导致切割片使用寿命低; 若采用电火花线切割加工, 则加工效率低, 表面光洁度很难达到要求。 综合考虑, 本研究采用直接法制备了如图2所示预制件及AlSiC电子封装基片实物照片。

2.2 AlSiC电子封装基片的性能

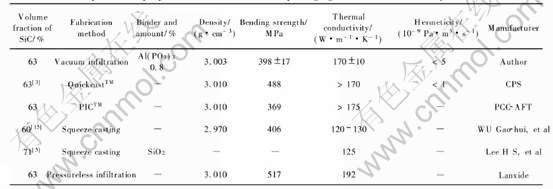

图3所示为所制备的AlSiC封装基片的热膨胀系数随温度变化的曲线。 由图3可看出, AlSiC封装基片的膨胀系数在6.88×10-6~8.14×10-6℃-1间变化, 这可以与陶瓷基片保持良好的热匹配。 随着温度升高, AlSiC封装基片的热膨胀系数呈现先增加后减小的趋势。 这与张建云等[12]、 张强等[13]和于家康等[14]的研究结果类似, 他们均采用无压浸渗技术, 因此基体合金中含有较高的Si元素。 张强等[13]认为在高温阶段, 基体中的Si在α(Al)固溶体中的固溶度急剧增加, 由于硅的膨胀系数小, 使基体合金的膨胀系数降低, 从而导致复合材料的热膨胀系数在高温时减小。 而本研究所用的6063Al中含Si量仅为0.2%~0.6%, 造成高温时热膨胀系数减小可能与预制件中含有较多磷酸铝, 而磷酸铝形成了网络结构有关, 但具体机制还有待进一步研究。 表2所列为本研究所制备的AlSiC封装基片的其他性能测试结果, 同时也比较了其他方法制备的AlSiC电子封装材料的性能。 可看出采用真空压力浸渗方法制备的AlSiC电子封装基片的气密性基本满足封装构件的要求, 但与美国CPS公司的产品相比, 差别较明显, 其原因是由于真空压力浸渗炉的最大压力只有12MPa, 而QuicksetTM工艺的浸渗压力大于50MPa。 研制的AlSiC基片的热导率接近美国CPS公司、 PCC-AFT公司和

图2 基片预制件(a)和AlSiC电子封装基片(b)的照片

Fig.2 Photos of substrates preform(a) and AlSiC electronic packaging substrates(b)

LANXIDE公司产品的, 其原因是由于研制基片的基体为6063Al, 而CPS公司产品的基体为A356合金, 6063Al和A356Al的热导率分别为213和150W/(m·K)。 研制基片的抗弯强度大于PCC-AFT公司产品的抗弯强度, 而小于CPS公司和LANXIDE公司产品的抗弯强度, 其原因可能有3点: 首先是本研究所用的碳化硅颗粒尖角明显, 因铝合金与碳化硅膨胀系数相差大, 制备过程中很容易在碳化硅颗粒尖角处产生较大的应力集中, 使抗弯强度降低; 其次是CPS公司采用浸渗的压力较大, 气密性比本研究的高, 组织更致密, 孔隙率更小; 最后是本研究采用的真空压力浸渗工艺, 液相浸渗后冷却速率慢, 从而导致基体铝合金晶粒较粗。

图3 AlSiC封装基片的热膨胀曲线

Fig.3 Coefficient of thermal expansion of AlSiC electronic packaging substrates

2.3 AlSiC电子封装基片的表面镀涂

AlSiC封装基片在使用时常与低温共烧陶瓷基板和膨胀合金围框进行钎焊连接。 为了提高构件耐腐蚀性能, 改善焊接性能, 增加焊料对基材的润湿, 降低对保护气体纯度的要求, 需要在AlSiC构件表面涂覆一层金属。 化学镀镍是最常用的一种方法。 AlSiC封装基片表面是经机械加工所得, 使SiC粉末裸露于表面, 铝合金化学镀镍方法不能在SiC粉末表面获得结合力良好的镀层[16], 因此采用钯盐活化方法进行化学镀镍, 镀层色泽均匀、 无麻点、 霉点和表面沾污现象。 图4所示为AlSiC封装基片化学镀镍层的SEM像。 由图4可看出, 镀层光亮、 连续、 均匀。 化学镀镍后再镀金, 镀层结合力按GJB1420—1992规定, 在电阻炉中于空气气氛、 450℃恒温120s后, 镀层不变色, 未见起皮和鼓泡, 表明镀层结合力良好。

图4 化学镀镍层表面SEM像

Fig.4 SEM image of electroless nickel plating

表2 不同方法制备的AlSiC电子封装材料性能的比较

Table 2 Comparison of properties of AlSiC electronic packaging materials fabricated by different methods

4 结论

1) 采用单件模压成形制备SiC预制件和真空压力浸渗工艺可以较低成本、 批量制备AlSiC电子封装基片。 所制备含63%SiC(体积分数)的AlSiC电子封装基片的热膨胀系数为6.88×10-6~8.14×10-6℃-1, 热导率为170 W/(m·K), 抗弯强度为398MPa, 气密性满足封装构件的要求。

2) 磷酸铝含量和成形压力影响SiC预制件的抗弯强度和孔隙率。 当成形压力为200MPa、 磷酸铝含量为0.8%时, 预制件的抗弯强度和孔隙率分别为8.46MPa和37%。

3) 采用钯盐活化方法可以在AlSiC电子封装基片进行化学镀镍, 镀层光亮、 连续、 均匀, 镀层结合强度通过GJB1420—1992指标。

REFERENCES

[1]Zweben C. Advances in composite materials for thermal management in electronic packaging[J]. JOM, 1998, 50(6): 47-51.

[2]Bugeau J, Conghlin W Ⅲ, Priolo M, et al. Advanced MMIC T/R module for 6 to 18GHz multifunction arrays[A]. 1992 IEEE MTT-S Digest[C]. 1992: 81-84.

[3]Soon H H, Hyo S L, Kyung Y J. Process for preparing a preform with high volume fraction SiC[P]. US6190604. 2001-02-20.

[4]Occhionero M A, Hay R A, Adams R W, et al. Aluminum silicon carbide (AlSiC) thermal management packaging for high density packaging applications[A]. Proceedings of SPIE - The International Society for Optical Engineering[C]. 1999: 34-39.

[5]Lee H S, Jeon K Y, Kim H Y, et al. Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications[J]. J Mater Sci, 2000, 35: 6231-6236.

[6]Lai S W, Chung D D L. Fabrication of particulate alumininum-matrix composites by liquid metal infiltration[J]. J Mater Sci, 1994, 29: 3128-3150.

[7]喻学斌, 张国定, 吴人杰. 真空压浸铸造铝基电子封装复合材料研究[J]. 材料工程, 1994(6): 9-12.

YU Xue-bin, ZHANG Guo-ding, WU Ren-jie. An investigation of aluminum matrix composites for electronic packaging fabricated by vacuum pressure infiltration casting[J]. Material Engineering, 1994(6): 9-12.

[8]Premkumar M K, Yun D I, Sawtell R R. Advanced aluminum composites for high-performance applications in electronic packaging[A]. Proc of 1993 International Symposium on Microelectronics[C]. Wheaton, IL: Int Soc for Hybrid Microelectronics, 1993: 399-402.

[9]Yun D I, Sawtell R R, Hunt W H, et al. Fabrication of Metal Matrix Composites by Vacuum Die Casting[P]. USA 5259436, 1993.

[10]Pech M I, Katz R N, Makhlouf M M. Optimum parameters for wetting silicon carbide by aluminum alloys[J]. Metall Mater Trans A, 2000, 31A: 565-573.

[11]Johnson W B, Sonuparlak B. Diamond/Al metal matrix composites formed by the pressureless metal infiltration process[J]. J Mater Res, 1993, 8(3): 1169-1173.

[12]张建云, 孙良新, 王磊, 等. 电子封装SiCp/356Al复合材料制备及热膨胀性能[J]. 功能材料, 2004, 35(4): 507-512.

ZHANG Jian-yun, SUN Liang-xin, WANG Lei, et al. Preparation of SiC particulate reinforced 356Al matrix composite for electronic packaging and its thermal expansion performance[J]. Journal of Functional Materials, 2004, 35(4): 507-512.

[13]张强, 修子杨, 宋美惠, 等. 电子封装用SiCp/Al复合材料的组织与性能[J]. 功能材料, 2004, 35(增刊): 1073-1076.

ZHANG Qiang, XIU Zi-yang, SONG Mei-hui, et al. Microstructure and properties of SiCp/Al composites used for electronic packaging applications[J]. Journal of Functional Materials, 2004, 35(suppl): 1073-1076.

[14]于家康, 梁建芳, 王涛, 等. 高导热金属基复合材料的热物理性能[J]. 功能材料, 2004, 35(增刊): 1668-1670.

YU Jia-kang, LIANG Jian-fang, WANG Tao, et al. Thermophysical properties of metal matrix composites with high thermal conductivity[J]. Journal of Functional Materials, 2004, 35(suppl): 1668-1670.

[15]武高辉, 张强, 姜龙涛, 等. SiCp/Al复合材料在电子封装应用中的基础研究[J]. 电子元件与材料, 2003, 22(6): 27-29.

WU Gao-hui, ZHANG Qiang, JIANG Long-tao, et al. Fundamental study of SiCp/Al composites in electronic packaging applications[J]. Electronic Componets and Materials, 2003, 22(6): 27-29.

[16]Cook A J. Plating for Metal Matrix Composites[P]. USA 5455118, 1995-10-03.

(编辑李艳红)

收稿日期: 2006-02-13; 修订日期: 2006-09-04

通讯作者: 熊德赣; 电话: 0731-4574772; E-mail: xiongdeganmmc@netease.com